Rating of the best trowels and trowels for 2022

Construction trowel (mason's trowel may be called differently) and today is the tool that is actively used in the construction of buildings, despite the fact that most of similar work can already be done with automated tools.

A trowel or trowel is a hand-held device made in the form of a blade polished on both sides, which has a curved handle made of plastic or wood.

Basically, this toolkit is intended for laying building blocks or bricks, for jointing construction joints, laying tiles for exterior / interior decoration. At the same time, this device can apply and level plaster, cement or tile adhesive. For each type of construction operations and finishing works, a different type of trowel / trowel is used.As a result, they, having a simple design, can greatly facilitate the work of a finisher / builder, and the work itself will be more efficient and faster.

Content

Trowels and trowels - general information

These attachments are used for the construction of various building surfaces (for example, walls) in which heavy mortars are used. The trowel-trowel has the qualities of a simple and obedient device that can make work comfortable and versatile, and is designed to repeat all the movements of the builder's hand in the process of work. In principle, if necessary, a trowel-trowel is quite easy to do on your own. Nevertheless, if such a question is not very acute, then it is better to use factory samples in activities.

Structural elements

The device in question consists of four main parts:

- A working element made in the form of a small blade (flat);

- Neck, through which the connection with the handle is made;

- The handle itself;

- Butt.

Thus, outwardly, the trowel is a small blade of a triangular, rectangular or rounded shape. Its main characteristics are determined on the basis of the tasks performed. The working element is made of high-strength steel (sheet) and has a galvanized or stainless steel coating. The fastening in the form of a neck plays not only a fixing role, but also ensures the dilution of the blade and handle along different planes. With this feature, the trowel and trowel differ from the spatula, which has similar tasks.

The neck of the trowel, in addition to fixing the bending angle, is designed to play an additional role. It should determine what the grip of the hand will be in the process of work. As a rule, the handle, fixed by the neck, is made from materials that have an uneven (rough) surface. Such material can be:

- Rubber;

- Plastic;

- Wood;

- Or their combinations.

NOTE. Handles can also be made of hard materials - lead or steel, but they are rare and their main advantage is only impact resistance.

The butt is structurally located at the end of the handle and is made of hardened materials. This part is tapped on the masonry material in order to ensure its proper installation. The butt must be fastened firmly in place, and its incorrect backlash during construction can lead to cracking of the handle.

The areas of application for trowels are rather small.They belong to a group of specialized devices designed for masonry operations with building substances (for example, with concrete mortars). In addition, by means of a smooth and even platform blade, it is very convenient to distribute the plaster or tile adhesive over the surface to be treated. By tapping the working element, it is possible to create unique decorative chips on the surface of ceramics or stone. In extreme cases, it is not forbidden to use a trowel as a regular scraper.

IMPORTANT! Due to the fact that trowels and trowels are professional tools, their manufacture takes place in accordance with the current GOST standards. These indicators should be taken into account by the master during the selection of fixtures for a particular type of construction operations.

Production material

The blade-platform is usually made of high carbon steel. Stainless steel is used in samples used in plaster work. The material for the tool must be carefully ground to prevent adhesion of the mortar to the platform and to facilitate its transfer evenly. Plasterers and masons use steel versions as a standard, as they perform their functions more reliably when handling heavy substances. However, the trowel can also be made of plastic, for example, a model for applying tile or wallpaper glue, which has special teeth. Accordingly, such a trowel will weigh less, which means that the worker's hand will be less tired.

The handle of the trowel in most cases is made of wood, the slightly rough surface of which does not allow the hand to slip, while in cold weather such a handle will retain heat.A plastic handle can be handy too, but most pros don't consider it durable. Metal handles are the last century and are rare, because they add weight. In addition, they will need to be rubberized, otherwise the trowel is difficult to hold in hand.

Existing varieties of trowels and trowels

They can differ significantly in their purpose. Some, for example, are specifically used for brickwork, while others are designed for floor laying. In addition, depending on which planes need to be connected, rounded or pointed platforms can be used. Also, a special role is played by the type of work performed - external or internal decoration.

Concrete trowel - the most common type of trowel, in which the working platform has a triangular shape. This design allows you to quickly and comfortably apply and measure the cement mixture when laying bricks.

Trowel for plasterer-mason - this type of device under consideration has a slightly different shape of the platform - we are talking about a somewhat rounded body. This form will allow you to conveniently mix and measure various building mixtures using a tool. However, for these works, standard sizes of fixtures are established - 120-180 millimeters.

Trowel for tiler - for them, a drop-shaped form of a trowel was specially invented in order to provide additional comfort during work. This form helps to accurately apply, distribute and measure the mixture for operations on a thin base.

Narrow bricklayer's trowel - it is intended for the production of jointing, produced using a solution.Such an operation helps to observe the accurate execution of the seam at the point of convergence of the cinder block and brick. It is for such work that this trowel should be used. Visually, it has the following appearance - one side is made in the form of a narrowed blade, through which movements are carried out along a horizontal seam. The second side has a special bend, through which seams are created vertically with the correct shape. At the same time, there is also a pointed trowel (size from 75 to 100 millimeters) used to create an inter-brick joint.

Trowel - a unique type of device in question, with the help of which an attractive and neat appearance is given to the treated surfaces after drying and hardening. To the same variety can be attributed the trowel type, which is used when working with building glue for laying it out in a uniform layer. Usually, these trowels have sizes ranging from 4 to 10 centimeters.

Purpose Features

In practice, all work performed by trowels is divided into facing and roughing. The latter include the backfilling of the outer verst and the erection of internal walls, and the feather one - the processing of the front of the building.

Trowels for rough work

The main walls themselves are massive and a lot of building mix will be required for their construction. At the same time, it should be mentioned that they are folded in a short time and without worrying about accuracy, because in the future they will require cladding and will be plastered.

Such features left a certain imprint on the design of the trowel for rough work:

- It has a large working element to capture more of the mixture;

- It has a sufficient thickness of the metal, which increases its overall strength;

- It is carried out by a weighty body for the purpose of proper knocking out of blocks and bricks.

This trowel must be reliable, because the daily load on such a device is quite impressive. Any flaws in the design of the tool instantly make it unsuitable for work.

Its weakest part is the attachment of the blade to the handle. In cases where the seam is welded with insufficient quality, the masonry tool will easily fall apart during operation. Thus, only a welding machine will help to correct this situation, and it is not always at hand.

In structures with a wooden handle, weak points are also observed. As time passes, the place where the curved metal neck is attached weakens and the handle begins to scroll. It becomes completely uncomfortable to work with such a master. And it’s far from the load that falls on the trowel - the high humidity is to blame, due to which the wooden base of the handle is destroyed.

It is possible to repair all the described damage by enlarging the metal handle itself, wrapping it with a nylon cord, and then treating it with glue. Another option would be to carefully drive a couple of short nails into the base. Speaking of plastic trowels, they are devoid of the listed disadvantages, so they are quite popular with some professionals.

Trowel for fine cladding

Visually, it may seem somewhat "toy", since it solves completely different construction tasks.When laying out the outside of the building, the main emphasis is on attractiveness, cleanliness and accuracy, so a rough tool for such work is unacceptable.

Most often, trapezoidal platforms are used for such operations, the advantage of which lies in the blunt end of the blade. With its help, it is convenient to apply the mixture to the end of the brick and, as a result, the vertical joints with the mortar will be properly filled.

Somewhat less often, for these works, a petal-shaped trowel is used, i.e. its appearance resembles a "heart" and it is characterized by a more elongated platform. It also has a slightly rounded end, which distinguishes it from a trapezoid with a blunt end. However, it is more difficult for her to spread the mixture on the brick end, as she will have to make an additional movement to level the mixture on the surface. In addition, a small drawback can be called the fact that with the help of a “heart” trowel it is rather difficult to free the container from the remnants of the solution.

Tips for facing trowel

When selecting, it is necessary to pay careful attention to the handle, especially to its back. It is highly desirable that a metal cap be installed on it as a means of additional protection. Such protection is needed so that the outer cladding can be padded properly and accurately. Of course, such an operation can be performed not only with the end of the handle, but also with the edge, however, it is believed that the handle is more reliable. At the same time, unprotected handles made of wood or plastic will wear out much faster than with a metal cap, which can more or less withstand mechanical shocks. It is worth mentioning that not all samples are equipped with the mentioned tips. There are two ways to fix the situation:

- A large bolt / nail is inserted into the plastic handle heated on fire, with the cap out;

- You can screw a self-tapping screw with a wide hat into a wooden one.

Tips and features for using trowels and trowels

Plasterers and masons consider the following postulates as the key to their productive work:

- Wood is the most convenient material from which the handle should be made. The hand during contact with a wooden surface does not sweat much (in comparison with the same plastic). In addition, the tree does not heat up in the sun and may not cool to an uncomfortable state for a long time.

- It should be comfortable to work with a trowel so that you do not have to twist your arms to unnatural positions.

- The comfort of work should be provided not only to the master himself, but also to those around him.

- From time to time it is necessary to change the working platform if it is removable.

- You should not scoop up too much building mixture - when it hardens, it can leave roughness on the shoulder blade.

- The ideal option for purchasing is a sample from the middle price segment from a not widely known brand. Such a sample will functionally differ little from super-expensive models, and financial savings will be “obvious”. At the same time, too cheap models will quickly become worthless.

- You should not purchase too small or too large trowels - when choosing, you must rely on the future front of tasks that the trowel is supposed to perform. In principle, the same trowel may be suitable for several types of work.

- Retail purchases will always be more expensive than wholesale purchases. With wholesale deliveries, you can simultaneously order related materials.

- It is better to purchase in specialized stores in order to be completely sure of the reliability of the product.

Rating of the best trowels and trowels for 2022

Budget options

3rd place: "BIBER 180mm /50/ tov-191425"

A good finishing tool from a quality European brand. It has a teardrop shape, suitable for most finishing works. The handle is made of corrugated plastic and securely attached to the platform. The weight is light and the sample is held well in the hand.

| Name | Index |

|---|---|

| Manufacturer country | Germany |

| platform material | Stainless steel |

| Handle material | Plastic |

| Web form | drop-shaped |

| Dimensions, mm | 309х92х91 |

| Weight, kg | 0.21 |

| Price, rubles | 135 |

- Well-known European brand;

- Multifunctionality;

- Reliable fastening.

- Not detected.

2nd place: "Russia 86222"

This trowel is positioned by the manufacturer as a stove-maker's tool. Perfectly adapted for interaction with sand-cement mortar. The sample is able to provide ease of throwing and leveling the mixture. The handle has a metal butt pad for tapping, the wood is varnished to prevent drying out.

| Name | Index |

|---|---|

| Manufacturer country | Russia |

| platform material | Steel |

| Handle material | Wood |

| Web form | drop-shaped |

| Dimensions, mm | 320x110x95 |

| Weight, kg | 0.25 |

| Price, rubles | 175 |

- Special treatment of the handle against drying out;

- The presence of a metal butt plate;

- Comfortable grip.

- Not detected.

1st place: STAYER EURO 0830-12

The working element of this trowel has the shape of a trapezoid, it can be used when mixing mixtures, laying bricks, applying plaster to the surface in the production of finishing works. The platform is made of stainless steel.

| Name | Index |

|---|---|

| Manufacturer country | Germany |

| platform material | Stainless steel |

| Handle material | Wood |

| Web form | Trapezoidal |

| Dimensions, mm | 235x90x78 |

| Weight, kg | 0.13 |

| Price, rubles | 195 |

- Light weight;

- Comfortable handle design

- Reliable manufacturing material.

- The center of gravity is somewhat shifted at the handle.

Middle price segment

3rd place: "MATRIX MASTER 86318"

All steel trowel equipped with a reinforced wooden handle with a metal butt plate. Perfectly will be suitable both for construction and for plastering and finishing works. Perfectly copes with uniform laying, throwing and leveling of sand-cement mixtures. It is characterized by durability and reliability.

| Name | Index |

|---|---|

| Manufacturer country | Germany |

| platform material | Stainless steel |

| Handle material | Wood |

| Web form | Trapezoidal |

| Dimensions, mm | 275x80x65 |

| Weight, kg | 0.18 |

| Price, rubles | 255 |

- Reinforced housing;

- The presence of a metal butt plate;

- Suitable for tile adhesive.

- Not detected.

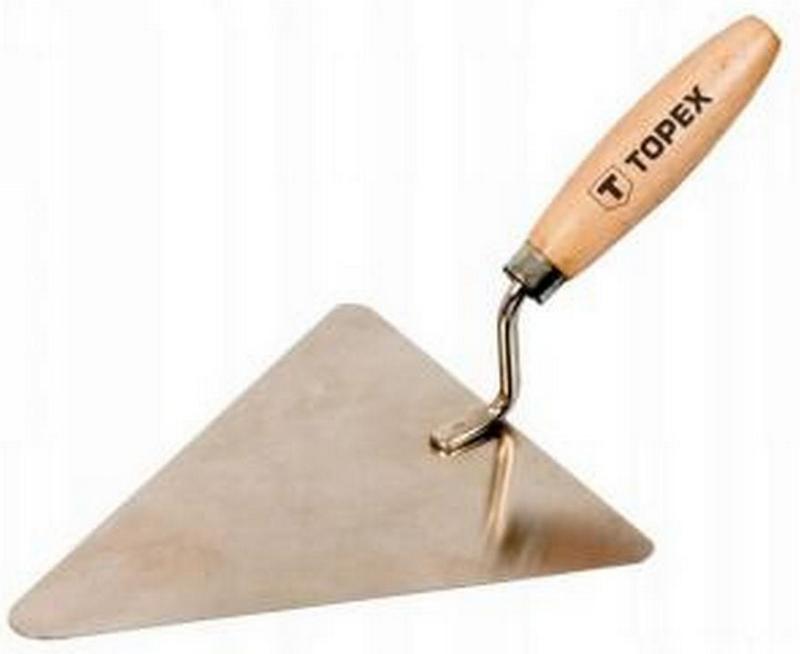

2nd place: "TOPEX 200×140 mm 13A119"

The sample is made from high quality materials and specializes in the application and leveling of adhesives and other building mixtures. It can also be used to work with masonry mortars, the manufacturer positions this tool as a model with an extended service life.The wooden handle fits perfectly in the hand, making it comfortable to use.

| Name | Index |

|---|---|

| Manufacturer country | Poland |

| platform material | Stainless steel |

| Handle material | Wood |

| Web form | Trapezoidal |

| Dimensions, mm | 240x140x65 |

| Weight, kg | 0.3 |

| Price, rubles | 260 |

- Versatility;

- Comfortable grip;

- Increased service life.

- Slightly uneven edges of the platform (a single factory defect is possible).

1st place: "TOPEX 200×185 mm 13A103"

Convenient trowel for working with cement mortars, which is particularly durable. It has a rigid platform, which, if desired, can also split a brick. The welded seam of accession to the handle is made reliably and of high quality.

| Name | Index |

|---|---|

| Manufacturer country | Poland |

| platform material | Stainless steel |

| Handle material | Wood |

| Web form | Triangle |

| Dimensions, mm | 330x180x70 |

| Weight, kg | 0.29 |

| Price, rubles | 280 |

- Good weld fastening;

- Rigid platform;

- Increased blade area (suitable for rough work).

- Not detected.

Premium Samples

3rd place: "Profi 180mm FIT HQ 05077"

A trowel specially designed for the concrete worker. Recommended for work with cement-sand mortars at various stages of repair. The working platform is made in the form of a stainless steel trapezoid, adapted to the effects of various aggressive substances. The handle is rubberized, does not slip in the hand, which means a significant reduction in the load during prolonged use.

| Name | Index |

|---|---|

| Manufacturer country | Canada |

| platform material | Stainless steel |

| Handle material | Plastic (rubberized) |

| Web form | Trapezoidal |

| Dimensions, mm | 290x105x80 |

| Weight, kg | 0.27 |

| Price, rubles | 480 |

- Ergonomics;

- Strength;

- Long service life.

- The angle of the handle is somewhat overestimated.

2nd place: "Profi 190mm FIT HQ 05075"

The plaster trowel consists of a steel sheet, for convenience it has a rubberized handle. The handle is additionally equipped with a finger protector, which provides a secure and comfortable grip. Can be used for applying and mixing various types of mixtures.

| Name | Index |

|---|---|

| Manufacturer country | Canada |

| platform material | Stainless steel |

| Handle material | Plastic (rubberized) |

| Web form | "Heart" |

| Dimensions, mm | 320x150x90 |

| Weight, kg | 0.29 |

| Price, rubles | 520 |

- The presence of a protector for the fingers;

- High-quality and durable material of manufacture;

- Wear resistance.

- Overcharge.

1st place: "CORTE 80mm 0953C"

This trowel is positioned by the manufacturer as a professional tool. With its help, it is easy to mix and apply various building materials to the surface or spatula. The blade, made of stainless steel, has undergone two-stage heat treatment, which indicates a long service life. The handle is made of two components and does not slip in the hand, which increases the comfort of the workflow.

| Name | Index |

|---|---|

| Manufacturer country | Russia |

| platform material | Hardened stainless steel |

| Handle material | Two-component |

| Web form | Trapezoidal |

| Dimensions, mm | 233x80x98 |

| Weight, kg | 0.14 |

| Price, rubles | 560 |

- Platform made of special hardened steel;

- Two-component handle;

- Extended service life.

- Slightly rough working part (a single factory defect is possible).

Instead of an epilogue

The analysis of the domestic market found that today it is not difficult to find a trowel / trowel for a certain type of work. There is a wide range of different types on the market and at quite affordable prices. However, it is worth noting that models from the middle price segment and produced by not so well-known brands are more popular.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131653 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127693 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124520 -

The best men's sneakers in 2022

Views: 124035 -

The Best Complex Vitamins in 2022

Views: 121941 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114981 -

The best paint for gray hair - top rating 2022

Views: 113397 -

Ranking of the best wood paints for interior work in 2022

Views: 110320 -

Rating of the best spinning reels in 2022

Views: 105331 -

Ranking of the best sex dolls for men for 2022

Views: 104369 -

Ranking of the best action cameras from China in 2022

Views: 102217 -

The most effective calcium preparations for adults and children in 2022

Views: 102012