Rating of the best rope slings for 2022

Transportation of oversized cargo always requires considerable effort and the use of special equipment. You have to lift such objects with the help of rope slings, they are also “caps”. They are made from high-strength steel or from strong synthetics, or reliable plant materials. Among other types of slings, rope slings remain the undoubted leader, because they can withstand even the heaviest loads.

Content

General information

Rope slings are considered an easy-to-maintain device for lifting loads, they are widely used in various areas of construction, production and economic activity. They look like ordinary ropes made from synthetic or steel fibers, and at their ends there are loops / hooks for attaching to the load.

In the production of the type of sling in question, several ropes are used at once, having a mandatory core, on which the wire thread is wound. The ends of the steel cable are twisted, forming loops, for which the method of manual weaving or pressing is used. In the subspecies of ring rope slings, the production technology is slightly different: they have a completely closed loop design, where both ends are fixed to each other. At the same time, it is allowed to place a thimble in the upper part, and the lower one can be equipped with:

- shackle;

- Hook;

- Lanyard.

In order to effectively use the devices in question, it is necessary to strictly observe the norms of state standards in the process of their manufacture.As a result, the final product is always equipped with an information tag, which indicates its maximum load capacity and the date of the last test, as well as the name of the manufacturer.

Scope of use

Rope equipment is used where constant movement of heavy objects is required. Due to its special resistance to various extreme conditions, such slings are often used in:

- Organization of cargo transportation;

- Warehouse and transport facilities;

- Forest industry;

- Construction business;

- Oil industry complex;

- Metallurgy.

The main advantages of rope slings

These certainly include the following points:

- Wear resistance - the product is able to perform tasks at ambient temperatures from -45 to +40 degrees Celsius. At the same time, it easily tolerates permanent increased loads, even if the movement is jerky.

- Long-term operation - wear of the product does not occur at once, but can last for a long time, which is quite enough to notice the defect during tension and eliminate it in time.

- Comfort of use - the flexible base of the device makes it possible to work even with irregularly shaped loads, while simultaneously ensuring their complete fixation during movement. In addition, based on several lines, you can create your own binding combinations by combining several items with each other.

The disadvantages of the equipment under consideration are few: they include only a rather impressive weight and some restrictions when working in extremely chemically aggressive environments. Also, do not turn over extremely fragile objects that are not provided with external protection.

Production standards

The technology for the production of rope slings is established by the State Standard No. 25573 and Guiding Documents No. 10-33 of 1993. The quality of manufacturing materials is enshrined in the State Standard No. 1050 and involves their manufacture from steel grade "60", but not lower. The rope must be braided in the way of twisting wire threads, and there must be a core inside. The twining can be carried out according to the double or cruciform method. The wire threads used must have a layer of special lubricant. Inside the wire weave is a core made on the basis of ordinary hemp. It is convenient in that it easily absorbs excess lubricant from the wire and thereby gives the final product the necessary flexibility properties. As a result, the pressure exerted on the sling does not allow the wire threads to quickly wear out and fray. Sometimes the core can be made of asbestos or steel.

Optional retrofit

This category of accessories will help to significantly expand the capabilities of the sling. For example, special hooks or carabiners can be installed on it, which will provide better attachment of the rope to the object being transported. Also, retrofitting is possible by means of a high-strength steel traverse or the use of special cargo grips - these devices will be very useful in the auto industry. If the rope sling has an open type, then it is equipped with a thimble - this is a special teardrop-shaped or oval-shaped mandrel made of steel. Using the thimble, you can reduce the pressure exerted on the loop, making its bends smoother, which in turn will reduce the degree of abrasion of the working base. To move bulky goods with an unusual shape, links can be used.

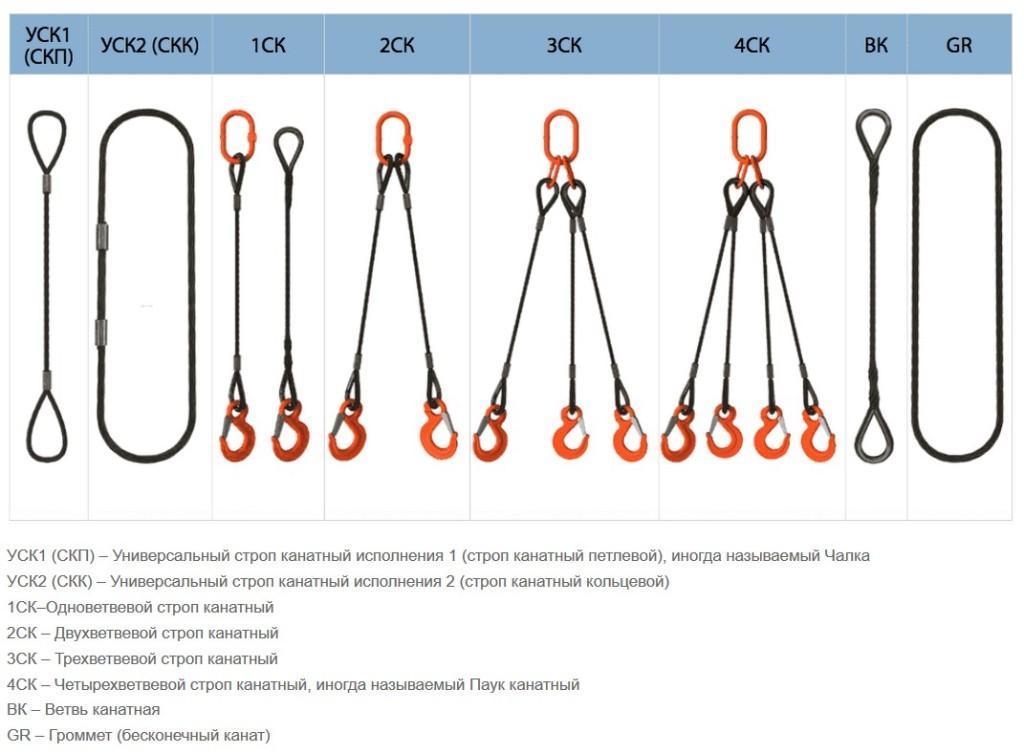

Modern types of rope slings and their marking

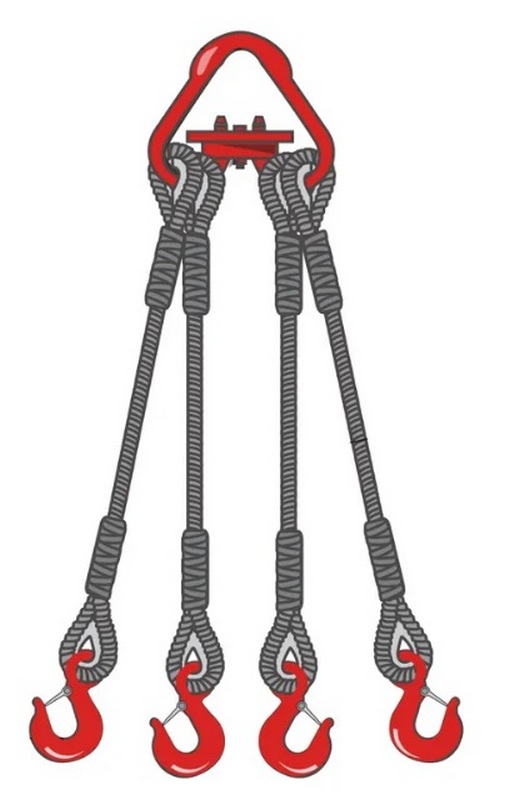

On today's market, there are two types of the device in question - these are loop and branch slings. The latter are several ropes linked between each other, with hooks installed at the end. The first have loops at the ends, so they are not attached to the load, but only wrap it around.

Depending on the number of branches available, the product marking will also differ:

- Single-branched - "1-SK", may or may not have a thimble. In the first case, the model is intended to be used as a repair kit with a possible replacement of a branch;

- Two-branch - "2-SK", a standard model that is widely used in warehousing and industrial facilities;

- Four-branch - "4-SK", oriented to work with oversized objects;

- Universal straight lines - "USK-1", have two loops and are intended for coupling with a load by means of hooks;

- Universal ring - "USK-2", they are closed and are used for attaching hooks to loads, but their carrying capacity is somewhat less.

All of the above data must be reflected in the information tag of the product. In addition, the following information must be included:

- Full name of the manufacturer;

- Product identification number;

- Maximum load capacity;

- Total length;

- Date of last production test.

IMPORTANT! State Standard No. 3377 also provides for the addition of additional data to the tag that may be of technical importance, for example, the estimated service life of the product.

Inspection and rejection procedures

In fact, these are measures for the regular inspection of the product for the absence / presence of defects.They are carried out in order to ensure the safety of working people and the integrity of transported objects. It is for rope slings that the following inspection procedure is provided:

- Checking the fact of the presence of a product passport or information tag;

- Testing the device for the degree of wear, possible breaks of individual wire strands or a group of strands, their corrosion damage, change in the position of the core, as well as general irreversible deformations of the entire structure;

- Inspection of the components of the sling (thimble and sleeves, links and hooks) to detect breaks, cracks, chips, excessive curvatures;

- Determination of compliance with the established standards of individual elements by means of measuring instruments.

The entire process must be carried out by an authorized specialist with appropriate approvals. Based on the results of the inspection, he makes a decision on the rejection of the sling or its further operation.

- If the following defects are found, the rope sling is considered defective and cannot be used:

- There are cracks or tears in the wire thread;

- The wear of the connecting end at the point of convergence with the hook was found to be 10% or more of the original diameter;

- Found excessive bends and twists in the connecting elements;

- The product does not have a passport or information tag.

The following flaws may indicate the critical wear of a rope sling:

- Heterogeneously protruding parts of the wire thread or knots;

- The presence of pronounced twists and kinks;

- The wire strands have worn out more than 10% of their original diameter;

- The presence of temperature melting at the joints (due to working friction).

Storage and service life issues

The storage process of rope slings also has strict regulations:

- Storage conditions must be provided in accordance with standard No. 5 (OZH4) in accordance with GOST No. 15150;

- Storage is carried out only in closed, but ventilated rooms;

- Slings should be located in a suspended state, i.e. vertically. Horizontal laying is only allowed in certain cases;

- All devices should be grouped according to their design type and technical features;

- Each storage position must have its own marking;

- If the period of complete non-use is exceeded for more than six months, each device must be subjected to production tests.

Thus, any copy should be safe and be ready for work at any time.

Regarding the minimum service life of the type of equipment in question, then, according to regulatory and technical documents, it is:

- At least three calendar months from the date of first use (the main condition is to work only in one shift);

- At least six months from the date of manufacture.

Difficulties of choice

Before buying rope slings, you should decide in advance what weight and what dimensions of cargo will have to be handled. This will affect the selection of the size of the rope section, its type of weaving, as well as the overall length and the need for additional equipment. You should always check the product for its full compliance with the state standards in force in the Russian Federation, which will be directly recorded in the accompanying documents. As a result, the following questions should be considered:

- Weight, dimensions and configuration features of transported objects;

- Possible ways and methods of object slinging;

- Operating conditions - humidity and temperature, the presence of a chemically aggressive environment, etc.

Slings must correspond to the mass of the object being transported, although its (mass) excess is allowed within 25% of the possible, which should be implied by the design of the sling itself. The gripping devices (hooks and loops) present on the product must properly ensure the security of fastening. At the same time, it is not recommended to choose rope slings with a large diameter if it is intended to work only with light weight loads, or when it will only be necessary to perform the tying function.

Selection questions regarding the characteristics of the carrying capacity should relate to such nuances as:

- Compliance of the weight of the object with the maximum carrying capacity of the goods (preferably without permissible excesses);

- The length of the product prevents the possibility of excessive torsion and rocking of the object on weight;

- Avoid going beyond the 60-90 degree anchor angle for multi-branch slings.

Regarding the information and technical support of the goods, it is necessary to make sure of the following qualities:

- Equipment must comply with current standards and regulations;

- The possibility of reliable retention of the cargo must be confirmed by the documentary results of testing the goods;

- The safety of people when working with equipment must be ensured by the presence of a visual instruction manual;

- Accompanying documents must have complete data on the shelf life and operation of the product.

Rating of the best rope slings for 2022

Budget segment

3rd place: "SKK USK2 GROSCO 0.63t / 1000 mm (1m)"

The model is a closed ring, manufactured using serial technology. It is one of the main components for rigging. Convenient for slinging loads with almost any configuration.When combined, it is convenient to work with steel pipes, other types of rolled metal items, as well as with objects made of reinforced concrete and most of the overall timber. The recommended cost for retail chains is 620 rubles.

- Durable material;

- Load capacity - 630 kilograms;

- Applied versatility.

- Not detected.

2nd place: "VK GROSCO 0.63t / 1000 mm (1m)"

This rope branch is intended for the equipment of the rigging route. In view of the focus on intensive operation, the manufacturer has provided for the possibility of easy replacement of worn parts. The model fully complies with current state standards (No. 25573 of 1982) and guidelines No. 10-33 of 1993 and No. 10-231 of 1998. The recommended cost for retail chains is 650 rubles.

- Ability to withstand loads up to 20 tons;

- Unlimited storage period (subject to the conditions thereof);

- Possibility of retrofitting.

- It is not recommended to work with fragile goods.

1st place: "Goodwork (GVK) loop USK1/SKP 1.0/1000"

The model fully complies with the requirements of the state standard No. 25573 of 1982. Produced by braiding and crimping on an aluminum core. This model has found its wide application in various fields: industrial production, construction, in the field of various unloading and loading operations, installation work and for the banal transportation of goods.It is characterized by an increased margin of safety, resistance to wear, as well as to permanent strong mechanical loads. Very easy to use. The recommended cost for retail chains is 760 rubles.

- Long length;

- Easily withstands a ton of cargo;

- Production technology prevents excessive wear;

- Ease of operations.

- Not detected.

Middle price segment

3rd place: "Rope sling 2SK GROSCO 0.5t / 1000 mm (1m)"

This device can easily distribute the load on pairs of branches. Loops at the ends of the cable will be able to withstand a lot of weight. The applied braiding technology guarantees the reliability of the quality of work. The existing aluminum core, coupled with the production method of pressing, is an excellent result. The recommended cost for retail chains is 1950 rubles.

- Special technology for fixing the ends of the cable, produced by braiding;

- The operating temperature limits are from -40 to +50 degrees Celsius;

- The manufacturer provides a three-month warranty.

- Not detected.

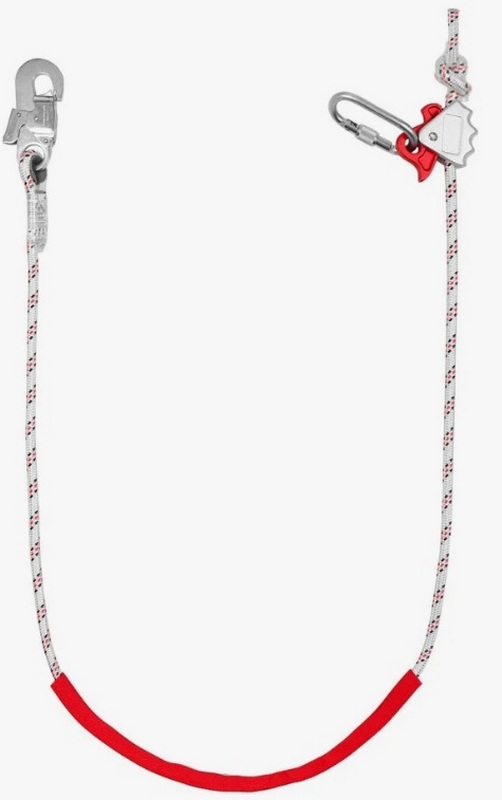

2nd place: “Single rope sling with slide type V11u length regulator”

This product must be used with a harness for positioning and securing harnesses. At the same time, it is easy to use as a base for safety systems. At the same time, it is possible to vary the speed of changing the length of the sling, which will have a beneficial effect on positioning. As a result: the knots of the sling received a heat-shrink film, through which external deformations are easily visually detected.The model is designed to lift an object weighing up to 150 kilograms. The recommended cost for retail chains is 3119 rubles.

- Sufficient load capacity;

- Strong threads;

- Proper heat resistance.

- Not detected.

1st place: "Rope loop sling KantaPlus braid ZSKP-3.0/3.0m"

A simple and versatile model that can withstand 3 tons. The special rope diameter of 18 millimeters ensures a proper grip. The total weight of the fixture is seven and a half kilograms (7.5 kg). The product is made according to the state standard No. 58752 of 2019. The recommended cost for retail chains is 5600 rubles.

- Strong weaving;

- Sufficient elasticity;

- Light weight.

- Not detected.

Premium class

3rd place: "Tambovtekhsnab" four-branch rope sling 5t 4m (spider) braid"

This model can be made in two variations: either by the braiding method, or by the crimping method with the inclusion of an aluminum sleeve. The branches are securely fastened to a triangular link of the “Pt” type. The production material is high-strength steel, the maximum total operating load is 30 tons, the length of the rope is 4 meters. The recommended cost for retail chains is 12,300 rubles.

- Extended load capacity;

- High-strength manufacturing material;

- Reliable fastener technology.

- Not detected.

2nd place: "3SK GROSCO 2.5t / 15000 mm (15m)"

This durable steel sling is made in the 3SK design, is particularly reliable in operation, is characterized by long-term operation, good wear resistance and an adequate price. Nevertheless, it has a fairly large dead weight, but this is more than covered by the carrying capacity of the product, as well as its strength. The surface of the sample and all its working parts are made in such a way that any, even the most insignificant damage to it, becomes immediately visually noticeable, which means that it is possible to prevent an emergency in time, take the product out of service, replacing it with a new one. The recommended cost for retail chains is 19,600 rubles.

- The margin of safety calculated for the product is 5 to 1;

- The maximum possible hanging load is 25 tons;

- Improved deformation detection capabilities.

- Somewhat overpriced.

1st place: "4SK GROSCO 2t / 20000 mm (20m)"

This powerful model of rigging equipment is widely used in factories and plants, ports and construction sites, as well as warehousing. Its design of four branches provides reliable fastening of any oversized object, which is very important when lifting various building materials, ship parts, bulky internal building structures for buildings to a height. When working with special types of cargo, the latter will require the presence of special lugs in order to secure the work hooks as firmly as possible. The recommended cost for retail chains is 21,000 rubles.

- Unlimited storage period;

- Compatible with any lifting equipment;

- The highest level of possible load is 35 tons.

- Somewhat overpriced.

Conclusion

A competent choice of rope slings will ensure not only their effective use, but the safety of employees working with them. Separately, it is worth paying attention to the compliance of work tasks with the technical characteristics of the slings used, namely: total length, maximum load capacity, dead weight, specific strength and service life.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131649 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127687 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124516 -

The best men's sneakers in 2022

Views: 124030 -

The Best Complex Vitamins in 2022

Views: 121937 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114978 -

The best paint for gray hair - top rating 2022

Views: 113393 -

Ranking of the best wood paints for interior work in 2022

Views: 110317 -

Rating of the best spinning reels in 2022

Views: 105326 -

Ranking of the best sex dolls for men for 2022

Views: 104362 -

Ranking of the best action cameras from China in 2022

Views: 102214 -

The most effective calcium preparations for adults and children in 2022

Views: 102010