Rating of the best twisted pair tools for 2025

For any electrical connection, the key to quality is the area on which the contacts touch - the smaller it is, the more unreliable the contact will be. Naturally, this parameter should be related to the cross section of the wires to be connected. Previously, connections of this type were ordinary “twists” crimped with pliers, but now, using a special tool, it is possible to obtain even wires, the cores of which are securely fastened inside with a special crimped sleeve. The disadvantage of this connection method is that its production is possible only with a special crimping tool, and also that various consumables (lugs and bushings) will have to be used. However, these shortcomings are more than offset by an increase in the speed of work, coupled with an increase in quality.

Content [Hide]

Scope of twisted pair crimping tool

Regardless of the size of the clamps, they can only be used in two ways - preparing wires for conducting current and fixing them in socket terminals, switches and other electrical elements, as well as connecting several wires to each other.

For the first cases, crimping will be justified if wires with many cores are processed. If they are clamped into contact terminals without preparation, then over time and due to the action of an electric current that creates microvibrations, free cavities form between them and the entire contact system weakens. This is just one of the reasons why single-core wiring is used for laying power wires, however, with the spread of crimping devices for wire lugs, this reason has lost its relevance.

At the same time, crimping can be used for cables with a large cross section - it was used long before the spread of household computer networks. However, a proper connection can only be obtained using a special crimping press for cable lugs, which even now may not be too small in size. To create the necessary force, these tools use the principle of the jack (or a special hydraulic drive). This approach is due to the fact that the standard and even excessive muscular efforts applied according to the principle of a lever in order to properly crimp a thick wire are not enough.

The crimping process can also come in handy when there is a need to join two or more cables. In this case, they are simply assembled together, a sleeve is installed on them and crimped. In this case, the wires can be inserted from both sides into the sleeve. If the insertion occurs only on one side, then a kind of “twisting” is obtained, and if from two, a semblance of a “coupling” is obtained.

The main advantage of this method is that at the end of the crimping inside the sleeve, air is blocked, which makes the connection itself airtight. In this way, both aluminum and copper wires can be connected, the contact between which is subject to oxidation over time.

Modern varieties of twisted pair tools

Structurally, pliers for working with twisted pair are divided into two types - diaphragm and working on the principle of pliers. The latter type is the most common, since they squeeze only from two sides, however, they differ from ordinary pliers in that their lips have cutouts of a special shape that perform the work of guides.Thus, it is possible to obtain a high-quality “P”-shaped form of the connection. The diaphragm tool is capable of crimping the wire from four or six sides at once, while replacing the crimping die is not required.

Press tongs

Their main purpose is to perform crimping of lugs and sleeves for wires. Their type and applied section can be extremely diverse. There are special samples of ticks, additionally equipped with an amplifier. Both a hydraulic mechanism and a lever with an increased leverage can act as an amplifier. From this it is clear that when using an amplifier, the operator must expend much less muscular effort when performing work, and the quality of crimping will increase markedly.

As a rule, any model of pressing tongs is equipped with a quality control mechanism for the work performed, which makes it possible to forcibly prohibit the unclenching of the handles until the end of the working stage. Naturally, it is extremely important to use high-quality tools for work. Professional samples, as a rule, have in their design a ratchet mechanism that blocks the reverse motion until the pressing cycle is terminated. Therefore, the incompleteness of the pressing process is simply excluded, even if the operator himself wishes it. It is worth noting that the level of crimping is directly dependent on how strong the pliers are used, and whether the electrical contact will be of high quality.

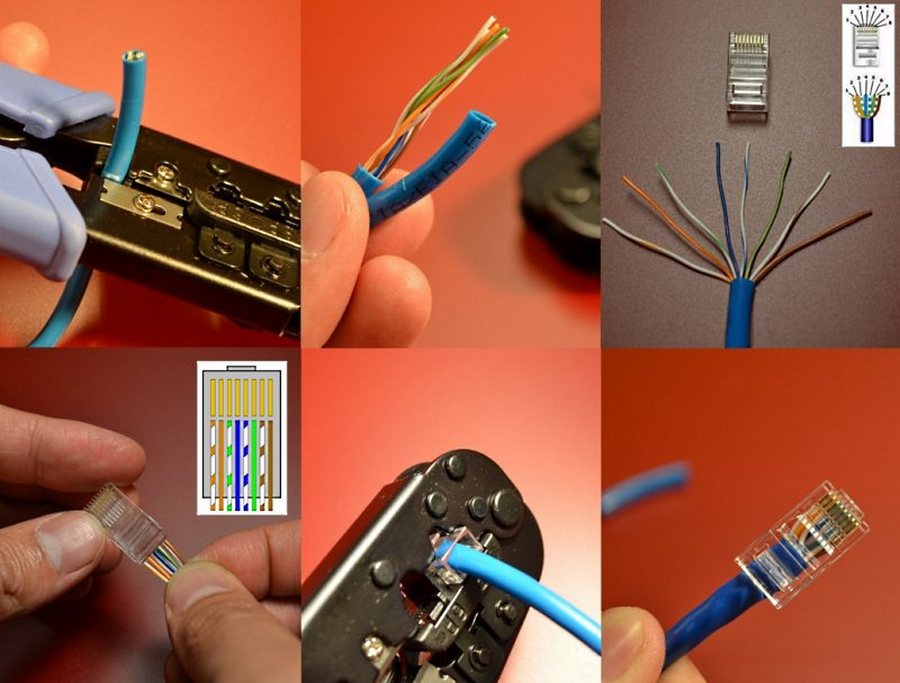

crimpers

This type of toolkit has two varieties - manual and automatic. In any case, the crimper is also used to work with twisted pair, as well as for other electrical work.Its task is to connect the wires to each other or to the contacts and connectors necessary for the high-quality transmission of electrical impulses. The use of such a device will completely avoid any soldering or welding.

There are situations in which twisted pair operation does not necessarily require wire crimping. In this case, it is preferable to choose a tool that combines the functions of both wire cutters and calibrated grooves. Moreover, some samples of crimpers have special elements in the kit, with the help of which the wire is stripped.

If you need to purchase a device not only for working with a certain type of twisted pair, then you need to choose a model with configuration options. With such a device, the blades are automatically adjusted to a certain diameter by means of a cam or screw responsible for this action. Thus, it is possible to qualitatively facilitate the stripping process and the operator does not need to control the entry of the wire into the groove.

The difference between automatic and manual crimpers lies in the fact that the former have the highest performance. Through them, it is possible to prepare the cable without any special difficulties, install the connector, and crimp it in semi-automatic or automatic mode. The automatic device has in its design an electric press and an applicator. Moreover, applicators will be needed for different types of connector tips.

Manual models are specially focused on a specific type of connectors and contacts (for different tips). In addition, they work solely due to the application of the muscular efforts of the operator. Accordingly, there is no question of any speed and high productivity in the performance of work.

Other working tools for twisted pair

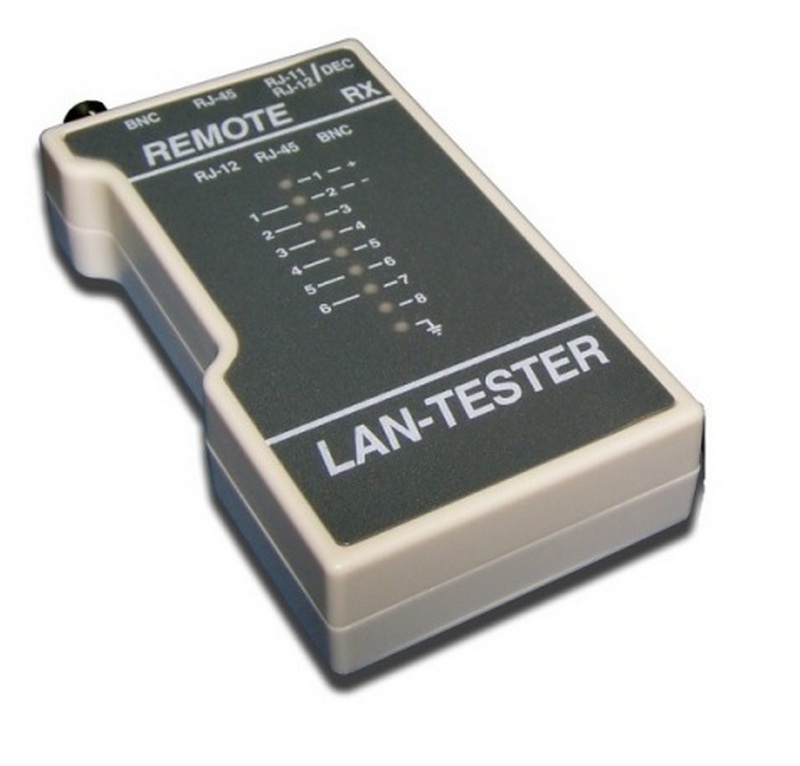

cable tester

It can also be referred to as a “network tester” or “twisted pair tester” - this device is designed to diagnose the wire in order to check the health of the cable line. It can detect breaks in the central cable, detect damage to the shielding or insulation, crossovers of conductors, short circuit phenomena. More professional models are able to set the bandwidth of the cable section by measuring the level and attenuation rate of the signal. With this tool, it is possible to avoid many errors and difficulties that may arise in the process of crimping, laying, and diagnosing cable networks.

The classic standard tester has two elements: main and remote. One of the ends of the tested wire is attached to each element. The elements are equipped with color indicators, there can be from one to eight pieces, which will correspond to the number of conductors "plus ground", marked with the letter "G" (ground). If the conductor is not damaged, i.e. its structure is intact, the corresponding indicators light up green. If a wire break is detected, there will be no signal. In the event that all wires are short-circuited or tangled, some models may give out an audible signal.

The main tasks performed by the tester:

- Accelerated diagnostics of network wires, checking their individual segments, searching for breaks, crossings and short circuits in the cable;

- Establishment of the technical condition, length and wiring diagram of cables of copper types twisted pair, STP and UTP;

- Establishing the facts of hidden laying of cables of type 5E and 6E, coaxial cables, USB cables and telephone lines;

- Checking coaxial cable (BNC) and twisted pair (RJ-45);

- Checking telephone twisted pair (RJ-12) and twisted pair (RJ-45);

- Checking patch cords and wires in local networks;

- Control of the laying of telephone and computer networks, wires for signaling (a special model of the tester is called a "route finder");

- Implementation of service tasks in the field of network technologies, maintenance of cable networks and telecommunications outside buildings.

The minimum functionality of a twisted pair tester should be able to check for short circuits, breaks, and wire lashings. Given that the length of the segment to be checked cannot be less than 300 meters. The device must be designed to work with twisted pairs of the "fifth" and "sixth" types, which are the most common. And for testing already laid networks, a tone generator with a length determinant will be needed.

Combined appliances

They are small-sized hand tools that can perform multiple tasks. These may include:

- Execution of cable tester functions;

- Installation of modular connectors;

- Crimp wiring.

Such a combination of functionality will allow the network installer not only to carry out the installation process, but also to immediately check the operability of the laid wiring and the quality of the installation of the modular connector. Checking the quality of signal transmission is possible only by pressing one key "TEST" - the whole procedure will occur automatically. The combination of several functions in one device makes such an instrument innovative for the modern period, especially since it has small dimensions.

Features of working with clamps over twisted pair

The process of installing the connector is intuitively clear - the tip is put on the cable, a matrix of tongs is connected to it, the handles of the tool are folded and the module contacts are connected to the wire contacts. However, in the absence of the necessary experience, the whole process may not go according to plan, and even after receiving the initial contact, in the future it may weaken or be completely broken.

Terminal Shape Keeping Problem

As a rule, the adjustment of the compression force of the matrix parts is to blame for this problem, which can vary both for individual types of cables and for the connectors themselves. Therefore, professionals recommend having at least two different devices so that there are no questions about reconfiguring the spring to work with other cables or connectors.

Also, the quality of the work will be affected by the material from which the connector is made and its thickness. Tighter terminals can be crimped much more easily and are better able to hold their shape than those made of softer material.

The main thing is to correctly orient the tip with the section. This requirement, although it seems self-evident, is often ignored. But for the quality of the network, not in all cases, the allowable error factor is acceptable.

The problem of choosing the right label

Different sizes of sleeves and modules are marked by the manufacturer in different colors, as well as the pliers of the crimping tool. At the moment, a single color scheme for all connectors and wires has not yet been developed (and even more so not legalized), therefore, before starting work, it is better to refer to the manufacturer's recommendations set out in the instructions for the tool. You should not rely only on the coincidence of colors, because they may differ for each manufacturer.

Rating of the best twisted pair tools for 2025

crimpers

3rd place: "REXANT 12-3451"

votes 0

This computer crimper has a rather narrow specialization and is designed for crimping cables and modules of the same type. The design is equipped with a return mechanism, which makes the implementation of numerous repeated operations extremely simple. With the nozzle installed, it is easy to remove the insulation or cut the cable. The handle is covered with non-slip material. The homeland of the brand is China, the established cost for retail chains is 520 rubles.

- budget cost;

- Quality performance;

- Comfortable handles.

- Narrow specialization.

2nd place: STAYER 22652

votes 1

This crimper is a universal model suitable for working with three different types of network cables. It can also be used for other electrical work. At the same time, it is able to perform the function of a stripper and can strip the insulation on round and flat cables. Processing can take place both on insulated and non-insulated tips. The working parts are made of high-quality tool steel, and the handles have an anti-slip coating - all this gives the structure special strength and reliability. The country of origin is Germany, the recommended cost for store chains is 690 rubles.

- Increased operational resource;

- Ergonomic design;

- Versatility.

- There is a backlash with prolonged and intensive use.

1st place: "REXANT 12-3441"

votes 1

Another option for a semi-professional crimper that can work with a wide range of network wires.The tool is made of hardened tool steel, burnished in its composition. The device is supplied with a tool for stripping (stripping) the cable. Handles are dressed in the plastic case and have an antiskid covering. The country of origin is China, the recommended cost for stores is 790 rubles.

- Adequate price;

- Cleaning tools included;

- Uniform crimping of all contacts on the connector module.

- Over time, the handle covers can slip.

Twisted Pair Testers

3rd place: "Cablexpert 100/1000 Base-TX NCT-2"

votes 0

This tester is capable of working on many types of cables in order to detect faults in networks. Testing is carried out for breaking, for short circuit, for checking the integrity of the shielding, as well as for correct wiring. The device has two modes of operation - "TEST" (manual) and "AUTO" (automatic), which simplifies the use of the device. Differs in small weight, small dimensions and special portability. Country - manufacturer - China. The established cost for retail chains is 950 rubles.

- Availability of adapters for several types of wires;

- Convenient case for transportation;

- LED indication of work.

- At first, the body smells strongly of plastic.

2nd place: "TWT TST-200"

votes 0

Two-piece test portable device for telephone and coaxial wires. The design includes a receiver unit and a transmitter unit. By connecting blocks to different ends of the cable, it is possible to detect: shorted wire pairs, open wire pairs, crossover pairs, reverse wires, misaligned wire pairs, as well as their possible splitting.The model is included in the State Register. The country of origin is Russia, the cost set for retail stores is 1100 rubles.

- Power is supplied from one battery type "Krona";

- The maximum length of the test cable is 300 meters;

- Ergonomic design, small size, light weight.

- With intensive use, there may be problems with the light indication.

1st place: "MEGEON 40060"

votes 1

A very powerful professional tool. Its main task is to control telephone lines and network cables. It is able to remotely monitor the condition of the cable, as well as check its status, look for faults in the wiring, and check for the presence of cable voltage. The device is able to detect short circuits in the cable and measure positive and negative voltage. The maximum possible length of the cable to be monitored is 1 kilometer. The country of origin is Russia, the recommended cost for retail chains is 3900 rubles.

- There is a headphone jack;

- Power supply charge indicator;

- Adjustable volume and sensitivity;

- The display can be backlit;

- Small dimensions and weight.

- No carrying case (only plastic bag).

Twisted-pair termination and cross-connect packing tools

3rd place: "Cablexpert T-431"

votes 1

Using this tool, it is convenient to put any type of network cable into a socket, to carry out high-quality laying in a box. The spout is made of durable metal and is oriented for different forks. Small weight of the device. Its small dimensions allow it to be used even in confined spaces. The body of the handle is made of durable plastic.Great for cutting cable wires. The country of origin is China, the recommended cost for retail outlets is 590 rubles.

- Small cost;

- Reliable handle;

- Good cutting qualities.

- Not found.

2nd place: "Pro'sKit 8PK-3141A"

votes 1

A good tool with a narrow specialization and is specially designed for twisted pair cables to cross. The design is made of durable ABS plastic, and the cutting blade is made of 65Mn spring steel. The type of head used is "Krone" with a hardness on the Rockwell scale of 50 kilogram-force. Perfect for intensive network cabling work. The country of manufacture is Taiwan, the established cost for store chains is 690 rubles.

- Powerful knife in the design;

- Suitable for everyday work;

- The body is durable ABS plastic.

- Not detected.

1st place: "Krone LSA-PLUS 6417 2 055-01"

votes 1

This tool is completely universal and maximally automated. On the handle are several additional devices, such as a level, support and a magnifying glass. The blade is made of the strongest tool steel, which indicates the possibility of everyday and intensive use. Its small weight and modest dimensions make it possible to use the tool in confined spaces. The country of origin is Germany, the established cost for retail chains is 2200 rubles.

- Quality knife steel;

- Rugged housing;

- Possibly intense work.

- High price.

Instead of an epilogue

It is preferable to select a tool for working with twisted pair depending on the set of actions that need to be performed. At the same time, you should pay attention to which wires, terminals and modular connectors will have to be processed. Usually, for standard pulling and installing networks, tools for installing the connector and checking the quality of the connection are suitable. When large-scale work is expected, and even more so outdoors, the combined device will be the best choice.

As for the fullness of the market of the devices under consideration, representatives of domestic companies are the undoubted leader in the segment of precision measuring instruments. This situation has become possible because they have created conditions for facilitating the passage of state registration. At the same time, the segment of crimping tools is more focused on Western designs, and it is difficult to identify a clear leader. However, representatives of Asian companies turned out to be cheaper and less reliable. In the segment of devices for laying twisted pair, models from an Eastern European manufacturer are in unequivocal demand, despite their rather considerable cost. Of course, that rather high price is offset by the presence of many additional devices and workmanship.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131649 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127688 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124516 -

The best men's sneakers in 2025

Views: 124030 -

The Best Complex Vitamins in 2025

Views: 121937 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114978 -

The best paint for gray hair - top rating 2025

Views: 113393 -

Ranking of the best wood paints for interior work in 2025

Views: 110317 -

Rating of the best spinning reels in 2025

Views: 105327 -

Ranking of the best sex dolls for men for 2025

Views: 104363 -

Ranking of the best action cameras from China in 2025

Views: 102214 -

The most effective calcium preparations for adults and children in 2025

Views: 102010