Rating of the best deep penetration primers for concrete for 2022

A proper level of finish can be achieved only through competent preparation of the treated surface. In this process, the final step will be the application of a primer. However, for each type of base, its own type of primer is suitable, which is especially important for complex surfaces, which include porous concrete. They do not get along very well with standard primers, so deep penetration soils will be the best solution for them.

Content [Hide]

General information

Most non-professional builders mistakenly believe that concrete is a very strong material and does not need an additional level of protection. In practice, everything turns out differently, and concrete, despite its high strength and extended service life, can also be very easily destroyed under the influence of aggressive environments and other adverse effects.

Through concrete pores, moisture easily penetrates into the base, which becomes the root cause of delamination and the formation of rather large cracks. In addition, some concrete slabs are reinforced with reinforcement, which, under the influence of infiltrated moisture, begins to suffer from corrosive processes. These negative factors are especially susceptible to concrete floor coverings, in which the outer layer is usually too loose and the first to undergo destructive metamorphoses. Accordingly, the floor ceases to maintain the necessary operating conditions, and the spread of internal mold will also affect the health of people nearby. It is deep priming that will help to avoid such problems and protect the surface for a long period.

Deep priming functions

When performing such processing, the processed base will have the following advantages:

- The applied layer will not allow dust to linger on the surface, from which the level of cleanliness will only increase;

- The concrete plane will be reliably isolated from moisture, from the formation of fungus and mold;

- Deep primers will help to increase the quality of adhesion with the finish layer by several times, which dramatically minimizes the risk of cracks, chips and other defects;

- Even with future repairs, newly applied finishing layers will have a better adhesion rate, and this will reduce the consumption of paint and varnish material;

- A deep action primer will help to reliably seal even the largest pores, which will prevent the development of harmful manifestations of the external environment, for example, the formation of a fungus;

- The surface of the concrete base will become much more durable and will be able to withstand maximum mechanical loads.

Summing up, we can say with confidence that the use of deep primers for concrete is a necessity, and not just a variable solution.

Areas of use of deep compositions

If we talk about domestic use, for example, as part of an apartment renovation, then depth samples will be required if it is planned to paste over the walls with heavy wallpaper. In this case, it is simply necessary to increase the adhesion index between the wall and the wallpaper, because even the strongest glue cannot withstand heavy wallpaper on an unprepared vertical wall.

Also, deep primers will perfectly enhance the bearing properties of materials derived from real concrete - we are talking about blocks of aerated concrete or foam concrete. At the same time, good properties can be given to brick and various plastered bases.

It is worth noting that today's market is trying to provide not specialized, but universal formulations in order to expand the range of consumers and scope.In general, the material in question is highly recommended for processing rooms where there is an increased level of humidity, because it is able to successfully fight the formation of mold / fungus. In addition, starting from the middle price segment, antiseptic additives are also included in the structure of the compositions under consideration, which give the primer a better biological protection.

Advantages and disadvantages

Any primer should serve to increase the level of adhesion on porous or weak surfaces, acting as a bonding element between the base surface and the finish. For deep variations, two more positive functions are added - this is dust removal and a maximum increase in the strength of the base base, not to mention the mandatory decrease in water absorption indicators, which decrease by at least 10%.

The main advantages of penetrating concrete soils include:

- Full readiness for use - most solutions are immediately ready for use after opening the container, you just need to mix the working mass a little in order to obtain a homogeneous consistency.

- Relevance - penetrating primers can be used for both external and internal work. The variation of the concrete bearing element does not matter (wall, floor, ceiling or something else).

- Profitability - the film formed by the composition reliably fills all the pores, which means that there is no need to apply repeated layers, and this, in turn, indicates saving the consumption of the working mass, simplifying and accelerating the finishing process as a whole.

Of the shortcomings, only one can be noted, which is the unpleasant odor characteristic of some formulations during the drying period.It is formed due to the presence of synthetic additives in the structure of the material, designed to provide even greater strength. Usually, these additives are included in the composition of deep primers for external work. The manufacturer directly makes a footnote about this quality in the informative part of the package and gives his recommendations regarding the possibility of using a primer for interior treatment.

Types of deep primers

Today's market is able to offer many consumables under consideration, which may differ in their chemical composition and functionality. If we are not talking about universal products, then some characteristics are important to consider when choosing.

- Acrylic.

These deep penetration materials are fast curing. The application of the finishing layer on them is already possible 3 hours after the completion of the initial work. Such mixtures are odorless and therefore recommended for residential premises. Acrylic products will help obtain maximum adhesion to the final coat. However, they are not suitable for overly damp rooms.

- Polyurethane.

They are able not only to qualitatively fill ordinary pores, but also to fill in quite deep building defects and cracks. All this will lead to an increase in the reliability of the coupling with the final finish. At the same time, these compositions will increase the percentage of wear resistance of concrete, reliably eliminate dust formation and prevent certain types of pollution. They are recommended for use in industrial premises (for example, work shops).

- Epoxy.

These compounds are aimed at enhancing the protection of the treated plane from excessive moisture and chemically aggressive substances.Upon completion of processing, concrete will additionally be able to withstand considerable mechanical loads. Epoxy compounds can also be used as an independent layer, as well as being a link for finishing. These compositions are recommended for work with self-leveling epoxy floors. However, an unpleasant synthetic smell will be present during drying.

- Alkyd (acrylate).

This product has a very high penetrating power and even after a long time will perfectly maintain the integrity of the concrete base. The reason for this is the high strength of the formed film, as well as the increased quality of frost resistance. Of the minuses, only the duration of the curing / drying process, which will take at least 12 hours, can be noted. Acrylate deep primers not only increase the strength of the machined surface, but can also effectively eliminate dust with good retention of adhesion for subsequent layers. Ideal for fixing complex loose coatings such as plaster.

- Latex.

They will perfectly support the strength of the treated substrate in the long term, while preventing the formation of fungus and mold. With their help, it is possible to significantly reduce the amount of finishing materials used. This product is recommended for preparing concrete substrates for the application of any type of paint, putty or tiling. It is also excellent for floor coverings if the latex primer is used as a self-levelling protective compound. After drying, it will form a transparent and thin film with excellent absorption properties.Accordingly, taking on all the negative effects of moisture, the concrete surface itself is not subject to destruction. Latex is able to qualitatively and evenly fill even relatively large cracks, which will positively affect the future operational process. In addition, the resulting protective layer will be extremely heat-resistant, which indicates the possibility of using such primers in industrial premises with high temperatures, for example, in smelters. Its great advantage can also be called ecological cleanliness, fire safety, the absence of toxins in the composition and clearly expressed unpleasant odors. All this allows the use of latex primers in specialized indoor areas (kindergartens, hospitals, etc.).

- Acrylic structural.

These primers are distinguished by a rather high cost, since their adhesive properties are enhanced by inclusions of quartz. Such qualities make it possible to qualitatively impose even the most loose decorative plaster on concrete. At the same time, structural acrylic is also a universal composition that is able to work not only on pure concrete - both gas and foam concrete blocks, and bases already painted with complex materials (putty and plaster) are subject to it. Structural acrylic on the treated surface creates the most rough and velvety layer, which qualitatively improves the adhesion. Supplied exclusively as a bright white working mass. Its main advantage lies in the fact that it easily equalizes the color differences that concrete may have, forming a completely uniform surface. A plus can also be called an increased degree of vapor permeability.

- Polyvinyl acetate

They are most often used in cases where concrete needs to be coated with glue and very sticky paint, such as oil paint, or paintwork materials containing the PVA structure. They are intended exclusively for internal work, with external application they will not last long. The advantage is fast drying, which takes a maximum of 60 minutes.

- Concentrated soils.

An extremely budget option for this type of consumables. Available only in light blue or beige and intended for outdoor use. Perfectly protects the surface from moisture, at the same time allowing to reduce the volume of materials for finishing. Probably the only modern deep penetration primer that requires pre-treatment in the form of diluting the dry concentrate with water. The proportions for this operation must be indicated on the informational part of the package. Application is allowed only in positive ambient temperatures, and only rollers or brushes can be used as an application tool.

- Polystyrene.

Their main distinguishing feature is fast drying. However, they have a sharp and unpleasant odor, therefore they are recommended for outdoor work. However, indoor use is also allowed, but only in those that have constant and good ventilation (applies to industrial spaces).

Features of applying deep primers

Deep action consumables should be applied only after the preparation of the base to be treated, when the surface is as clean as possible, and the largest cracks have been successfully sealed with a special compound. Even if the mixture is positioned as already completely ready for use, it is still preferable to stir it to a homogeneous consistency.The application itself, depending on the characteristics of the soil, can be done in most cases with a roller or brush, although spraying with a spray gun is also often allowed.

The latter method, i.e. work with an airbrush, will be justified if processing of large areas is required. At the same time, the working mass should be made more liquid by diluting it with water by at least 5%. This will help prevent the working mass from getting stuck in the hoses and nozzles.

When applying, it is necessary to monitor the uniformity of the distribution of the layer over the surface, making it as continuous as possible. After painting / spraying, the primer layer must certainly dry completely, for which the time specified by the manufacturer of the mixture in the accompanying documentation is maintained. In some cases, and for very complex substrates, the primer can be applied in two layers.

All work should be carried out at positive temperatures, the ideal indicator is +25 degrees Celsius, and the humidity should be 60%. It is these indicators that will allow the primer to qualitatively lie on the base base and will not allow it to foam during processing. However, this does not apply to polyurethane types of deep soil, which are universal and little dependent on environmental conditions.

Rating of the best deep penetration primers for concrete for 2022

Budget segment

3rd place: "Glims DeepPrime 5 l"

votes 0

The mixture perfectly levels, strengthens the surface, increases adhesion, prevents the appearance and development of fungus, reduces the consumption of paint and wallpaper glue. Easily suitable for brick, concrete, aerated concrete, plastered, putty, plasterboard or asbestos-cement surfaces and applied in layers of plaster, putty, glue or paint. Serves as an excellent dust binder.The recommended cost for retail chains is 502 rubles.

- Reduces the absorbency of the base, preventing the appearance and development of the fungus;

- Provides uniform coloring, reducing the consumption of paint or wallpaper glue;

- Increases the water resistance of the bases.

- Does not form a film, only fills the pores.

2nd place: "Ecolux for concrete walls and ceilings, pink, 3.5 kg"

votes 0

This indicator mix is intended for use as an adhesive adhesive primer for pre-treatment of dense, non-absorbent substrates - monolithic concrete, massive concrete ceilings, before applying gypsum, gypsum-limestone and gypsum-cement plasters. Can be used as a bonding primer for tiling. The primer under the wallpaper has a high penetrating power. The surface to be primed must be free of old whitewash and paints. Stirring is required before use. The recommended cost for retail chains is 532 rubles.

- Suitable for outdoor and indoor use;

- Forms a rough surface;

- Improves adhesion of subsequent finishing layers to the surface.

- Complete cleaning of previous coatings is required.

1st place: "Vetonit Prim Wall for walls 10 l"

votes 0

This primer helps to qualitatively prepare the surface for finishing: strengthen the base, reduce absorbency, increase adhesion with paintwork materials, decorative plaster, wallpaper adhesives and polymer waterproofing. Can be used for indoor and outdoor work.The composition can be applied in one or two layers on a dry, grease-free and oil-free surface, the temperature of which is not lower than +10 °C. The recommended cost for retail chains is 760 rubles.

- Drying time of each layer - 1-2 hours;

- Coating density — 1 g/1 cm2;

- Consumption - 70-100 ml / 1 m2;

- Shelf life - 12 months.

- Not detected.

Middle price segment

3rd place: "Bergauf TiefGrunt 10 l"

votes 0

Designed for absorbent substrates and for strengthening loose (weak), porous, highly absorbent surfaces, removes dust and reduces water absorption. It can also be used to prepare various surfaces before applying plaster, self-leveling floors, tile adhesive and other types of finishes. Can be used for both indoor and outdoor work. Does not contain volatile organic solvents, non-toxic and fire and explosion proof.

A 10 l canister is enough to process up to 100 m2 when applied in 1 layer. The recommended cost for retail chains is 780 rubles.

- Contains a complex of biocides;

- High penetrating power;

- Strengthens the base;

- Reduces consumption of finishing materials;

- All season formula.

- Not detected.

2nd place: "Knauf Tiefengrund 10 l"

votes 0

The product is used to increase the adhesion of the base to various finishing materials, such as tiles, putty or wallpaper. This product is ready for use and does not require further dilution. Great for renovation work. The surface must be thoroughly cleaned before use.Works well with very hygroscopic bases, including branded Knauf sheets. The recommended cost for retail chains is 890 rubles.

- Can be used both indoors and outdoors;

- Relatively fast drying (about 3 hours);

- This material is safe for health.

- Not detected.

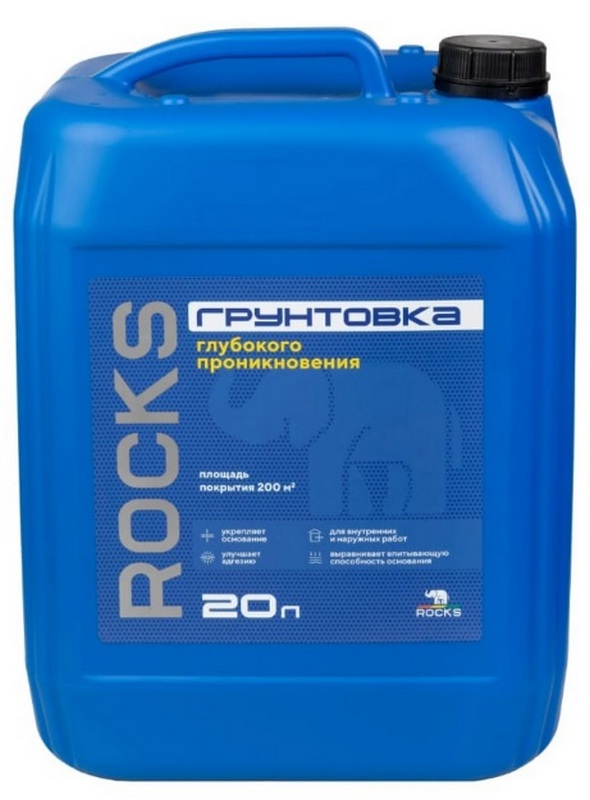

1st place: "Rocks 20 l"

votes 0

The product has a high penetrating power and is excellent for priming finely porous materials. It is used in various interior and exterior building works: to strengthen the surface, reduce absorbency, increase adhesive properties before puttying or applying a finishing layer of paint / decorative plaster, laying tiles and porcelain stoneware. It is also used for processing cement, concrete and gypsum screeds, plasters, fillers, AQUAPANEL boards, joints of GKL, GKLV with chamfered, etc. The recommended cost for retail chains is 1100 rubles.

- Environmental Safety;

- It has a high penetrating ability to a depth of 10 cm;

- Does not reduce vapor permeability.

- Not detected.

Premium class

3rd place: "SUMMER acrylic 10 l deep penetration"

votes 0

The mixture will perfectly prepare fragile, highly absorbent and old concrete bases for the application of paintwork materials or mortars, for processing wood materials, bricks, stone, concrete, gypsum boards and gypsum boards, putty and plaster. The mass is universal, made on an acrylic basis. Suitable for most surfaces. The recommended cost for retail chains is 2390 rubles.

- For interior and exterior use;

- Differs in high penetrating ability;

- Strengthens loose and chalky bases, reduces absorbency;

- The color marker allows you to control the application;

- Interlayer drying - 30-40 minutes, subsequent finishing can be started after 3 hours.

- Not detected.

2nd place: "CT17, pink, 10 L"

votes 0

This working mass is intended for preparation for applying the finishing decorative coating of concrete, cement screed, porous gypsum or lime plasters during interior finishing work. It can also be used to treat surfaces made of cellular concrete and gas silicate. Thanks to this composition, the paint lays better on the surface. The recommended cost for retail chains is 2460 rubles.

- Penetrates deep into porous materials;

- Reduces paint consumption;

- Can be used for finishing floors and walls;

- Increases the adhesion of the finish coat.

- Not detected.

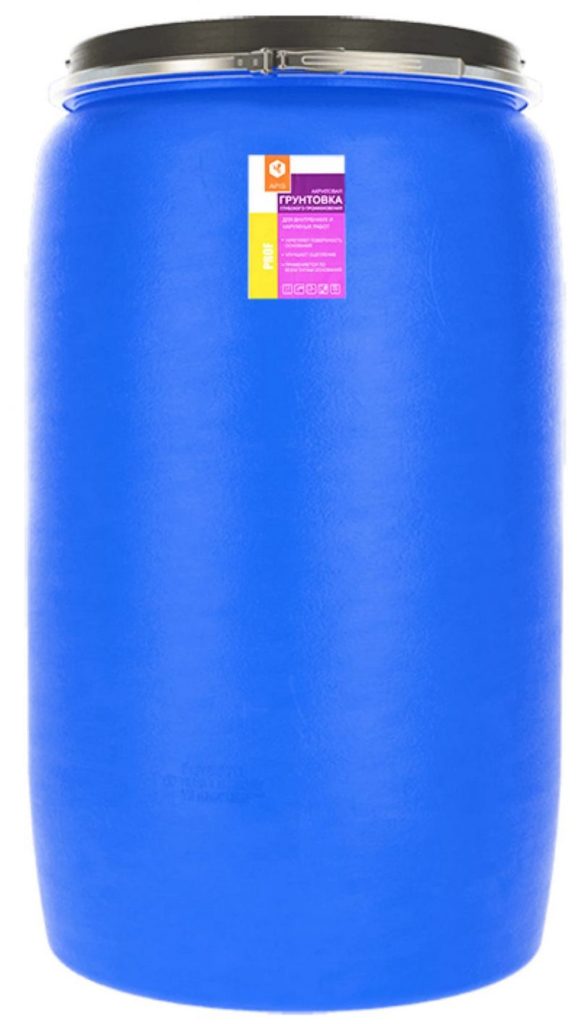

1st place: "APIS Prof, white, 125 kg drum"

votes 0

This composition is widely used for intermediate treatment of walls, floors and ceilings, indoors and outdoors. The composition significantly improves adhesion and reduces the consumption of finishing paints and varnishes (including wallpaper glue). The product strengthens and removes dust from loose bases, forming a high-quality and durable coating. The recommended cost for retail chains is 10,780 rubles.

- Extremely large delivery container;

- Focus on industrial applications;

- Multifunctionality.

- Not detected.

Conclusion

Concrete has low water absorption.Because of this, soluble finishing materials do not give moisture to the base, they cannot adhere to it. Because of this, peeling of plaster, wallpaper or paint occurs. The problem can be solved only through deep penetration soil.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131649 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127688 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124517 -

The best men's sneakers in 2022

Views: 124031 -

The Best Complex Vitamins in 2022

Views: 121938 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114978 -

The best paint for gray hair - top rating 2022

Views: 113393 -

Ranking of the best wood paints for interior work in 2022

Views: 110318 -

Rating of the best spinning reels in 2022

Views: 105327 -

Ranking of the best sex dolls for men for 2022

Views: 104363 -

Ranking of the best action cameras from China in 2022

Views: 102214 -

The most effective calcium preparations for adults and children in 2022

Views: 102010