Rating of the best hydraulic presses for 2022

Often there are situations when it is not possible to independently carry out actions to service vehicles or have encountered difficulties during repair and installation work due to lack of physical effort. The best manufacturers have launched the production of hydraulic presses, which have become the most reliable assistants. At the same time, it is called a press conditionally, since it is often used in heavy industry (for stamping parts).

Content

general description

What it is? The hydraulic type press belongs to the category of special equipment designed to create increased pressure in the process of processing various materials and metals. The structural elements are several cylindrical vessels equipped with pistons of different diameters. The operation is based on the law of hydraulics, which involves the transfer of the indicated pressure indicator of liquids in containers in any direction. To improve efficiency, special oil is poured into the press, due to which the pressure indicator rises to the required indicator.

What are

The most common device of this type is considered to be jacks, which allow an ordinary person to lift a significant load without significant effort. A similar system of functioning for drives, shock absorbers, brakes and pumps. The unit gained popularity largely due to the ability to simplify the work of a person by transferring the indicated energy flow to flexible and thin hoses.

Several types of devices are available:

- piston (involving the use of oil as a working fluid);

- differential - plunger (needle or other system element passes through the active piston);

- reverse motion (fixed body, lower cylinder position).

Equipment classification is given in the comparative table:

| Options | Name |

|---|---|

| According to the location of the cylinders | Vertical and horizontal. |

| By type of work performed | Forging, stamping, bending and for beading and flanging. |

| By type of machine used | Rack and column. |

There are differences in the principle of execution, in connection with which the following types are distinguished:

- Universal.With all sorts of features. They are considered the best. It is supposed to be used in manual mode.

- Vypressovschiki. Main area of application: pressing in / pressing out, dismantling and assembly. The presence of small dimensions make such models popular due to the possibility of their use in any conditions.

- With an open frame. Processes details of inconvenient configuration and non-standard appearance.

- With closed frame. There are holes for fixing the device on the table. Widely used for straightening, pressing/pressing, bending.

If you look at the rating of quality goods, then all modern options are equipped with CNC. You can set the required operating mode and select the pressure. Permanent control of the machine by a person is not provided. This function passes to the computer.

Let us dwell in more detail on the main types of presses.

Electro-hydraulic

The main feature is the presence of an electric motor. Develops force from 50 tons. Widely used in manufacturing plants and for car service. Thanks to the electric drive, the speed of work is increased and the physical load on the operator is reduced.

Functional:

- assembly and editing.

- stamping;

- disposal;

- extrusion;

- crimping.

Areas of application of the unit:

- cold and hot stamping, as well as cutting metal, straightening defects;

- pressing of metal parts;

- pressing wood shavings and coal blocks;

- stamping of plastic, aluminum, steel and other parts.

Widely used in service stations and car services, performing the following functions:

- bends metal elements;

- pressurizes spare parts;

- stamps various details;

- eliminates defects in metal body parts;

- manufactures bushings and bearings.

The design features of the mechanism depend on the scope of use.

When purchasing a product, you need to consider the following technical features:

- The presence of an automatic return of the rod, accelerating the time of work and increasing ease of use.

- Chrome plating. This structural element affects the duration of operation, protects the unit from corrosion.

- Reliable stand. Of great importance is not only the high-strength material of its manufacture, but also the accuracy of sealing the seams. Otherwise, time will pass, and the frame may break.

- winch mechanism. Essential for adjusting the work table when dealing with large parts.

- The quality of the gauge. It allows you to evaluate the force of the device. It is worth taking a closer look at the glycerin manometer.

- Ability to move the cylinder and table. The presence of mobility is the key to effective work with non-standard parts.

- Safety valve. It will make the operation of the press safer by regularly releasing excess pressure in order to prevent an increase in load.

Before you start using the equipment, you must study the step-by-step instructions. There are general labor protection rules that must be strictly followed:

- Only those who have been instructed and medically examined can use the hydraulic press.

- Mandatory presence of special clothing.

- Constant monitoring of the volume of liquid and its possible leakage.

- Never place your hands in the work area.

- After use, close the valve and dry the tool thoroughly.

Desktop

The rating of compact devices is headed by desktop installations. They do not need to be placed on the floor, taking up free space. They screw into a workbench or countertop.The minimum parameters allow it to be used in very small rooms, including at home. The maximum gain is 15 tons. The main drawback is that the small size does not allow working with overall parts.

Pneumohydraulic

The recommendations of experts boil down to the fact that it is worth buying this product due to the presence of undeniable advantages:

- profitability;

- reliability;

- the possibility of using manual mode;

- work on compressed air;

- ease of maintenance;

- use in hazardous industries.

It should be borne in mind that this device can operate exclusively on clean compressed air.

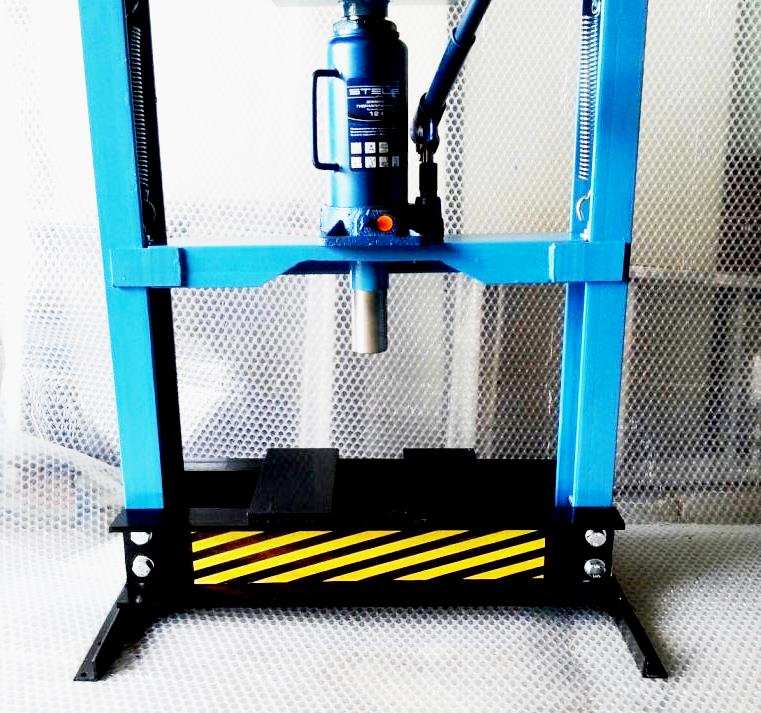

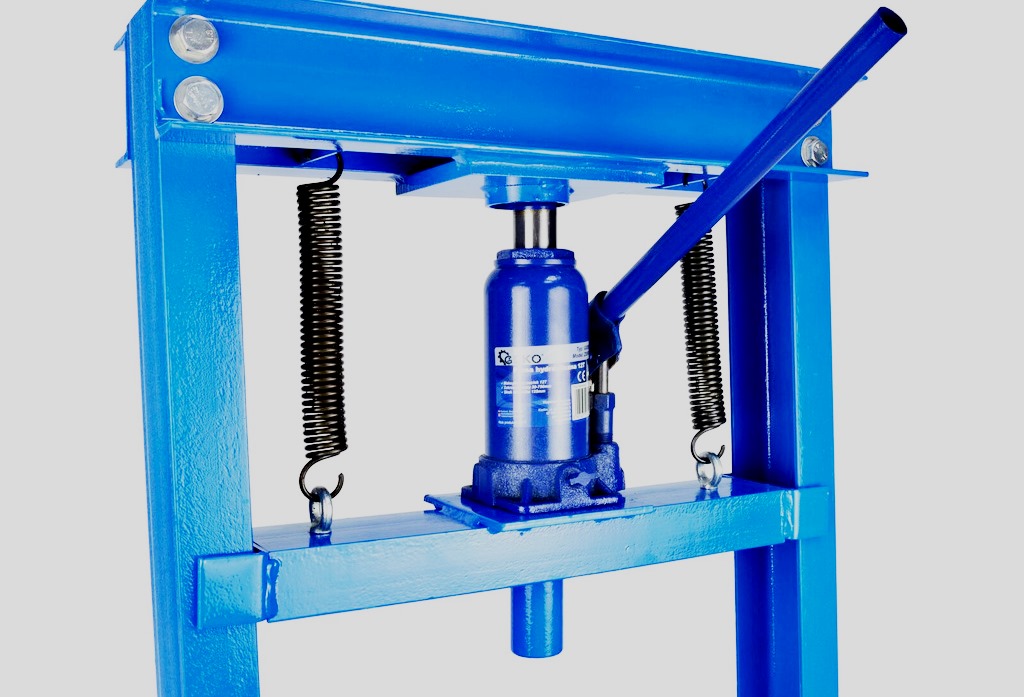

Vertical with manual drive

The most common option. It is a vertical double-sided installation with a foot or hand drive. It consists of a working surface and a manometer that controls the pressure in the system. What is it needed for? Mainly for garages and car service stations. Its capacity is about 20 tons, which is quite enough to lift heavy machines.

How to choose

Which unit to buy depends on many factors. But the main selection criterion is the scope of its application, and it can be varied, including:

- for forging;

- for oil extraction;

- for apples;

- for pressing.

How to make the device useful and last long enough? It is necessary to carefully study the review of new products, view the characteristics of the product, pay attention to reviews.

What should you pay special attention to when choosing a product? According to buyers, in order to avoid mistakes when choosing, it is necessary to evaluate the following parameters:

- power;

- the presence of a manometer;

- stem length;

- installation method;

- is there an automatic cylinder return system;

- type of security system;

- type of drive that pressurizes;

- the weight;

- manufacturing material.

Which company is better depends on the individual preferences of the master. As a rule, the question of where to buy a product is not worth it. A wide network of specialized sales outlets for the sale of this type of product has been opened, where you can see the assortment with your own eyes, communicate with the sales manager, learn about new products, and get qualified advice. You can opt for inexpensive models with limited functionality or at a significant price of a professional level.

It is worth considering the option of ordering the unit online in the online store. It will turn out to save a little on the average price, but no one will give a guarantee of obtaining quality products and without mechanical damage. Delivery may be difficult due to significant weight.

There is an option to make a device with your own hands, but only the simplest model. This will work for those who have certain knowledge and skills, as well as free time. In this case, the cost of the unit will be minimal, depending on how much the parts cost.

Manual models

KW SG - 100 tons

The design is two-fold. Belongs to the category of professional tools. With its help, connecting, tension and contact fittings are pressed. The indicator of maximum effort is 100 tons. The head is conveniently opened by turning the top cover. The manufacturer provides steel handles for ease of movement. If there is a need for hexagonal or round dies, they are made to order and purchased separately from the main equipment for an additional fee.

The average price is 136,290 rubles.

- reliability;

- strength;

- ease of use and operation;

- warranty period from the manufacturer - 5 years;

- multifunctional;

- works with steel-aluminum and aluminum wires for high-voltage power lines;

- significant maximum gain;

- piston stroke - 1.9 cm;

- packed in wooden box;

- light weight;

- two-valve design;

- combination of price and quality.

- not identified.

Nordberg N 3612

The floor device of the German manufacturer has excellent stability, does not overturn during operation due to the presence of an H-shaped base. The frame is metal, durable and rigid. The indicator of the maximum working range of the tool is 910 mm. The main feature is the height adjustment of the table due to the presence of a large number of mounting holes on its supports. The model provides an opportunity to work stably and achieve the desired results.

Main technical characteristics:

- working stroke - 1.8 cm;

- force - 12 tons;

- weight - 71 kg;

- drive - hydraulic manual;

- equipped with a pump;

- parameters - 1370 x 260 x 335 mm.

The goods are sold at a price of 18679 rubles.

- one year warranty;

- a budget option;

- the piston returns automatically;

- a safety valve is installed to protect the device from overloads;

- the presence of two trapezoidal plates;

- build quality;

- long service life;

- reliable;

- glycerine-filled manometer.

- not installed.

Wiederkraft WDK-HP 201 F

The homeland of the brand is Germany, but the products are manufactured in the Middle Kingdom. It has found its application in mechanical engineering, metalworking and industry.A distinctive feature is a very strong frame with a high rigidity index. 150 mm piston stroke. The tool is easy to use, actuated by a lever by changing its position.

Depending on the expected load, you can change the pump performance in automatic mode. Thanks to the foot pedal, there is no need to use the master's hands. The minimum and maximum rise of the frame is 205 and 1220 mm, respectively, the dimensions of the device are 1810 x 730 x 600 mm, and the weight is 97 kg.

The average price is 24990 rubles.

- controlled by hand and foot;

- the ability to move the cylinder horizontally;

- high quality manometer;

- installed on the floor;

- the piston returns automatically;

- the pump operates at two speeds;

- overload safety valve.

- not installed.

AE&T T 61220 F

Russian-made product with a solid metal frame and a pressure gauge that controls the load force. The position of the cylinder during use does not change. Special holes allow you to qualitatively attach the equipment to the floor, which guarantees its stability. The kit includes a pump. The product weighs 98 kg.

The average cost is 27,009 rubles.

- high performance;

- reliability;

- stability;

- zone width - 542 mm;

- the presence of anti-corrosion properties;

- working range - 4.2 - 100.2 cm;

- the presence of a foot pedal;

- long service life;

- quality assurance.

- missing.

Stalex HP-80

The Russian company produces high-quality products widely used in assembly, pressing, dismantling, riveting, stamping, bending and stretching.It is installed in repair and assembly shops. The double pump serves to pump oil, which makes it possible to increase the efficiency of the equipment, while saving 60% of energy.

Withstands a maximum load of 800 kN, equipped with a two-speed motor with a power of 3 kW. A piston with a diameter of 9 cm has a stroke of 26 cm, its speed is 17 mm/s. Structure weight - 1020 kg, dimensions - 700 x 1600 x 2000 mm, operates at a voltage of 380 V.

The price of products is 452517 rubles.

- simple;

- elementary to use;

- the working table is adjustable in height, which allows you to work with high details;

- Italian pump;

- reliability;

- long service life;

- high performance;

- multifunctionality.

- not identified.

Pneumohydraulic models

KraftWell KR WPR 50 A

The manufacturer is a Chinese company with a worldwide reputation, producing high quality products and a long service life. Model with fully welded frame, floor type, with manual drive and pneumatic pump. The cylinder moves horizontally. Working height - from 0 to 1068 mm, maximum force - 50 tons, weight - 264 kg. Found its application in industrial facilities and car service.

Sellers offer goods at a price of 137,567 rubles.

- the cylinder moves horizontally with the help of bearings;

- the work table is raised by means of a winch;

- the hydraulic pump is equipped with a pneumatic and manual drive;

- high-quality pressure gauge filled with glycerin;

- equipped with an indicator of the extreme position of the cylinder;

- built-in valve warns of overloads;

- there is an opportunity to adjust the height of the desktop.

- not installed.

Stankoimport SD 0805, 20 t

The Chinese company produces a product that is ideal for bringing light commercial vehicles, buses and trucks into proper condition. The main technical characteristics of the unit:

- stroke of the working rod - 185 mm;

- the possibility of horizontal displacement of the cylinder;

- gain (max) - 20 t;

- outdoor installation;

- working range - 68.5 - 1028.5 mm;

- bed 542 mm wide;

- withstands heavy duty;

- high productivity.

The cost of the tool is 25371 rubles.

- reliability;

- long service life;

- multifunctional;

- the pump and cylinder are connected by a reinforced hose;

- the presence of a compensating fluid in the pressure gauge makes it possible to withstand pressure fluctuations in the system;

- safe;

- quality assembly.

- not identified.

Mega PRP 50

Good quality Chinese products. Equipped with pneumatic and hydraulic foot drive. The work table is adjustable in height. Fast and accurate positioning is ensured by a screw-type extended stem. It creates a maximum gain of 50 tons, the working range is 470 mm, the stroke of the working rod is 120 mm. The main difference is that all hydraulic elements are located in one housing.

The maximum configuration includes:

- pneumatic pedal;

- working pedal;

- pedal of a fast supply of a rod;

- tray large removable with punches;

- lowering pedal;

- the presence of gas shock absorbers to move the desktop.

The average cost is 192,717 rubles.

- saving free space;

- protection during delivery to the destination;

- ease of access to hydraulic components;

- the desktop can be easily and quickly moved in height;

- the manometer is mounted at eye level;

- the cylinder moves horizontally;

- hydraulic foot pump;

- pneumatic drive pedal;

- V-shaped blocks;

- the piston returns automatically;

- operations for pressing parts are carried out in foot mode, leaving the hands of the master free;

- chrome-plated hydraulic cylinder;

- valve - load limiter.

- not identified.

Red Line Premium RHP 20A

A feature of this model is the presence of a pneumatic and manual drive. The frame is fully welded, robotic technologies were used in the manufacture, thanks to which the structure turned out to be as strong as possible. The cylinder moves horizontally, the height of the parts is 1018 mm, the vertical stroke is 145 mm, the reinforcement is 20 tons. The weight of the equipment is 102 kg.

The Chinese company offers goods at an affordable price - 37,757 rubles.

- equipping the hydraulic pump with pneumatic and manual drives;

- the desktop is adjustable in height;

- filling substance of the pressure gauge - glycerin;

- equipped with an indicator of the extreme position of the cylinder;

- the cylinder moves on bearings on a horizontal surface;

- overload protection is provided in the form of a built-in valve;

- the frame structure is fully welded;

- V-shaped blocks;

- reliability;

- long service life;

- high functionality.

- not installed.

Nordberg N 3645L

The pneumohydraulic device has a force of 45 tons. The cylinder moves along the horizontal area, the piston returns automatically. Stroke - 168 mm, bed lift 530 - 1260 mm (minimum and maximum), working range - 868 mm, optimum pressure - 7.5 - 8.5 bar.

The product can be purchased at a specialized store at a price of 77224 rubles.

- the piston returns automatically;

- equipped with two plates - trapezoids;

- the hydraulic cylinder moves horizontally;

- table height is adjustable;

- ease of use;

- durability;

- design reliability;

- foot drive at the hydraulic pump;

- glycerin-filled manometer;

- a special valve protects against overloads;

- delivery is carried out in a wooden box.

- missing.

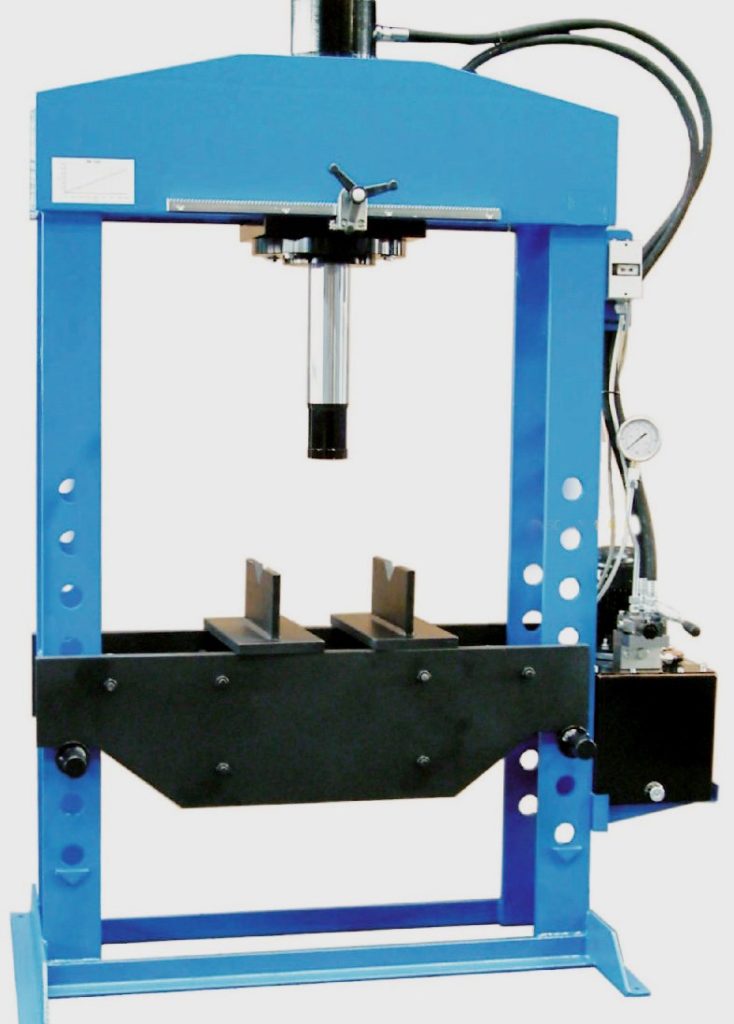

Electro-hydraulic models

OMA 665

Blue unit with electric drive 2050 mm high, 1200 mm wide, weighing 653 kg, with a force of 100 tons. shaped blocks. The surface of the hydraulic cylinder is chrome-plated. The device weighs 430 kg, power - 1500 W, force - 50 tons.

The average price of products is 196,000 rubles.

- high build quality;

- optimal power;

- good combination of price and quality;

- long service life;

- reliability;

- ease of use;

- performance;

- multifunctionality;

- significant effort.

- not identified.

K 100 E Mega

The manufacturer did a great job and launched the release of a tool with a functional design, compact shape, and excellent characteristics. All hydraulic elements of the structure are concentrated in one housing, which makes it possible to save working space and guarantee the absence of mechanical and other damage during transportation. Delivery is made in assembled form. The tool after installation is completely ready for operation.

The average price is 385,000 rubles.

- the pressure gauge is located inside the frame, so its protection is guaranteed;

- the desktop can be adjusted in height;

- the use of a winch makes it easy and simple to raise and lower the table;

- the hydraulic station has a two-speed electric drive;

- equipped with asynchronous four-pole motor 1400 rpm;

- oil level is controlled;

- the pressure gauge is located at the level of human eyes, which allows you to control and read readings at any time;

- built-in emergency switch in case of emergency;

- the spring allows you to return the piston back;

- equipped with a valve - load limiter;

- V - figurative blocks patented;

- chrome-plated hydraulic cylinder;

- reliability;

- durability;

- quality of assembly and material of manufacture;

- safety.

- not identified.

R 342 M1 - N

The electrohydraulic press has a portable foot drive. Widely used in manufacturing plants and service stations. It operates from an electrical network of 380 V. The maximum allowable force is 60 tons. Main technical characteristics:

- power - 3000 W;

- stroke - 200 mm;

- distance between the rod and the table - 800 mm;

- weight - 620 kg;

- dimensions - 1200 x 650 x 2510 mm.

Sellers offer to purchase goods at an affordable price of 170,000 rubles.

- reliable bed;

- quality manometer;

- convenient to use;

- you can raise the table to the optimum height;

- reliability;

- made of high quality material;

- anti-corrosion properties;

- long service life;

- good combination of price and quality.

- not installed.

Conclusion

Today there is no such production where hydraulic presses would not be used.This device is designed to perform numerous functions, such as:

- forging and stamping of various materials;

- sheet type stamping;

- material extrusion;

- assembly work;

- processing of metal waste.

It should be borne in mind that the design of the device is quite simple, and it is not particularly difficult to work on it. In addition, it completely mechanizes manual labor. Thanks to these characteristics, the tool has been very popular for a long time in various fields of life. However, working on it without prior preparation and listening to instructions, as well as without a medical examination and special equipment is not recommended according to safety regulations.

The main task of the device is to strongly compress the material, for which human strength is not enough. It is mainly used where there is a need to deform parts or pack materials into dense briquettes with the subsequent manufacture of various products.

The design has been used by our ancestors since time immemorial. It was endowed with special functions that allow you to quickly and efficiently squeeze grape or apple juice. It was an indispensable unit in the manufacture of butter.

There are many types of equipment that differ in size, weight, configuration, functionality, cost. Hand-held, compact versions are available for crimping workpieces with aluminum and copper tips. And there are massive ones, weighing up to half a ton, with significant dimensions and high power.These are installed in furniture factories and production workshops of large industrial enterprises, where they are used for the manufacture of plywood, plastic products, MDF sheets, and so on.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131655 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127695 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124522 -

The best men's sneakers in 2022

Views: 124040 -

The Best Complex Vitamins in 2022

Views: 121943 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114982 -

The best paint for gray hair - top rating 2022

Views: 113399 -

Ranking of the best wood paints for interior work in 2022

Views: 110323 -

Rating of the best spinning reels in 2022

Views: 105333 -

Ranking of the best sex dolls for men for 2022

Views: 104371 -

Ranking of the best action cameras from China in 2022

Views: 102220 -

The most effective calcium preparations for adults and children in 2022

Views: 102014