Rating of the best epoxy grouts for 2022

Epoxy-based grouts have long been a worthy alternative to traditional cement samples. Epoxy variations are distinguished by a variety of textures and shades, moisture resistance and durability. Nevertheless, it is necessary to work with these solutions with special care, because they harden very quickly and the master needs to have time not only to fill the seams as soon as possible, but also to carefully remove the protruding excess grout from the surface.

Content

- 1 Epoxy grouts - general information

- 2 The main differences between epoxy and cement grouts

- 3 Proper application and removal of epoxy grout

- 4 Required working tools

- 5 Possible mistakes

- 6 Difficulties of choice

- 7 Rating of the best epoxy grouts for 2022

- 8 Conclusion

Epoxy grouts - general information

The considered type of material has more durable properties, it is more resistant to water than the traditional cement counterpart. Due to these qualities, the filler was mainly used only in the decoration of industrial premises, because it was believed that for living rooms its increased characteristics would be redundant. However, the general opinion soon changed and epoxy grouts began to be used for tile lining of domestic premises. The grouting process itself is the final step in tile finishing and is most often done in kitchens or bathrooms. Also, this material can be used in garages, boiler rooms and verandas.

This type of grout can also be called a resin filler, because it includes resin (which will make up a common viscous paste) and a liquid hardener. Accordingly, this solution will be two-component and can only be used after mixing both elements. The approximate proportion is 9 parts resin to 1 part hardener.In this case, it is necessary to note some similarity with the cement analogue, which also requires the mixing of two components - water and a cement-based dry mineral substance. The best epoxy grouts are considered to be two-component grouts, which simultaneously contain an additional portion of fine-grained quartz sand, which will be responsible for high adhesive qualities.

Technical properties

Their performance characteristics are most valuable in the implementation of interior decoration:

- Increased resistance to steam, condensate and water;

- The durability of the adhesive (binder, adhesive) substance and overall strength (low susceptibility to cracking, crushing, abrasion);

- Successful resistance to various dirt and stains (foreign substances cannot penetrate the structure of the grout due to its hard and smooth surface);

- Successful resistance to chemicals and the effects of fatty substances;

- The ability not to change their performance when changing the temperature regime;

- The presence of fungistatic and bacteriostatic qualities;

- Color stability.

Thanks to the above characteristics, these grouts are perfect for rooms with high humidity conditions - bathrooms and kitchens, as well as saunas and pools. Due to their high resistance to dirt, bacteria and fungi, they can also be used in hotels, restaurants, healthcare facilities - in general, wherever it is necessary to permanently maintain an appropriate level of hygiene (up to the level of complete sterility).

Areas of use

Epoxy grouts, although they are the best solution for interior decoration, but their technical features allow for use in the treatment of external surfaces, i.e. meaning the operation of the end result in open air conditions. Thus, such joint fillers can be used for:

- Filling joints between tiles in damp/wet rooms located inside structures (underground corridors, sanitary facilities, bathrooms);

- Finishing of pool bowls and other water structures (fountains, artificial dams, large aquariums, water slides), as well as for grouting mosaics located there;

- Finishes of building structures that are constantly subjected to significant mechanical stress during operation (floors and stairs, etc.);

- Grouting of joint spaces with a width of up to 15 millimeters, which can be formed, for example, during the installation of a “warm floor” system.

Advantages and disadvantages of resin grouts

Their undoubted advantages include:

- Resistant to direct sunlight;

- Weak susceptibility to shrinkage after curing;

- Long operational periods;

- Increased strength;

- Ability to work properly in various temperature conditions;

- Possibility of processing with chemically aggressive detergents;

- The presence of the required level of hypoallergenicity.

Among the shortcomings, the following can be distinguished:

- Too fast hardening, which makes it impossible to immediately prepare large portions of the working material;

- The requirement for the master to have at least a little, but experience, for the correct mixing of the mass and maintaining proportions;

- Due to the toxicity of the resin composition, work should only be carried out using special tools and personal protective equipment;

- The difficult process of dismantling a completely frozen result (it provides only mechanical destruction);

- The high cost of the material, when compared with cement counterparts.

The main differences between epoxy and cement grouts

The composition of cement options is quite simple. These dry mixes are created on the basis of cement (which becomes an astringent substance), to it (together with water) fillers from marble chips / fine fraction sand, coloring pigments, polymer inclusions are mixed, and all of them endow the composition with certain properties (from protection from moisture to giving a certain color). At the same time, to increase the level of the desired property, the proportion of the corresponding component in the composition simply increases.

In the structure of epoxy grouts, two elements appear; when mixing, their proportions must be observed. The first can be a colored mixture of quartz sand or a translucent inert filler with a color tint. The second component will be a resin catalyst-hardener, which, when interacting with the first, initiates the curing process and the entire mass will begin to solidify. Due to the fact that mixing causes a chemical reaction, epoxy compounds are also called "reactive". Due to the exceptional adhesion characteristics of reactive joint fillers, they are several orders of magnitude ahead of those of cement samples. From this it is clear why resin products are recommended for finishing pool bowls, where they will be in constant and direct contact with a large volume of water.

The marking of reactive compounds is indicated on the packages by the letters "RT2", which indicates that the result of the use of the material will be the creation of a dense and monolithic seam. And such a seam is able to increase the strength and durability of the treated structure several times. Also, unlike cement samples, resin samples do not fade or fade under the influence of ultraviolet radiation. The resulting seam surface in its texture will approximately represent fiberglass in terms of tactile sensations, which means complete water resistance. But the cement joint will be noticeably porous, so it will have to be further processed in order to prevent the penetration of moisture into the pores. Moreover, such processing will have to be repeated periodically.

Proper application and removal of epoxy grout

When performing this work, the most important condition is the exact observance of the manufacturer's instructions, both in terms of application and in terms of preparing the grout mixture. In any case, it must be remembered that whatever the epoxy mortar, after mixing it, the curing process begins immediately (the final result is achieved within half an hour). Therefore, the joint filling material should be prepared in small portions and immediately applied to the prepared surface. All such actions should be carried out as carefully as possible, with high accuracy, because the substance that has fallen past the suture gap will not be easy to remove. In addition, the resin solution will require the use of special tools, which can be either a rubber grater, or a silicone spatula, or even an ordinary sponge. You will also need viscose and cellulose, through which profiling and wiping of finished butt distances will be carried out.The easiest way is to apply the prepared mass with a trowel or spatula, and then quickly rinse the surrounding surface with warm water. After washing, profiling should be carried out immediately, while not forgetting to remove the resulting excess.

Epoxy grout removal

The increased durability of the material in question is both its advantage and its disadvantage. This type of joint filler is very difficult to remove after complete curing. However, the removal procedure is possible. It is carried out with the help of special tools, which are called so - "Liquids for removing epoxy grout".

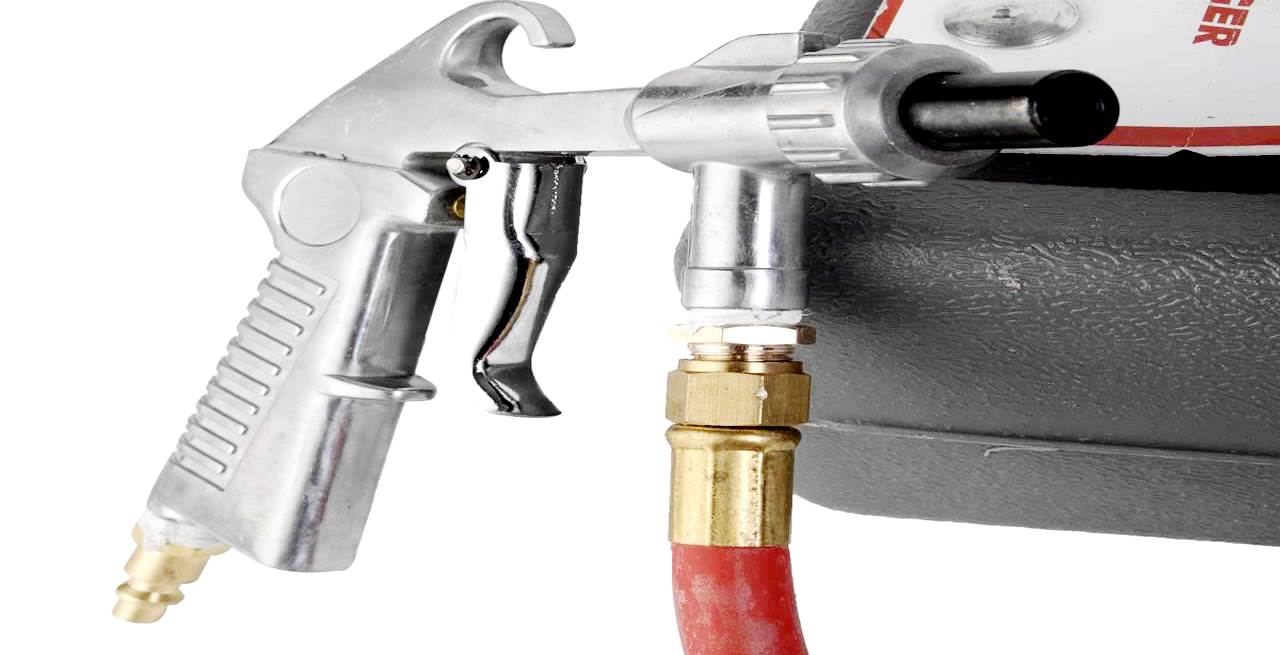

They contain extremely strong chemicals that are capable of breaking down a dense resin layer at the physical level. Another way is to use an angle grinder. This method involves the mechanical destruction of the resin layer. However, the use of a grinder comes with some risk, which is the possibility of inadvertent damage to the surface of the tile itself. And the last, but expensive and reliable way, is to use a special thermal electric gun to remove old resin substances. Under the influence of very high temperature, the seam becomes relatively soft and it is somewhat easier to remove it from the inter-tile space.

Required working tools

In order to carry out professional grouting with epoxy fillers, you should use:

- Rubber spatula or grater with a rubber tip (for laying the mass in the space between the tiles);

- A clean pallet / container for mixing the solution;

- Foam rubber sponge (finish cleaning of tiles and elimination of stains);

- Accurate scales (preferably electronic) to maintain proportions of 1:9 when mixing;

- A hard washcloth or grater with a cellulose nozzle - to form even seams;

- Container for warm water;

- Mixer (drill with a mixing nozzle) to obtain a homogeneous mass when stirring the composition (in extreme cases, the procedure can be carried out with a spatula for mixing);

- Chemical solution for erasing the smallest grout residues from the surface;

- Rubber gloves to protect the skin of the hands.

The time of troweling procedures, the consumption of the filler mixture, and the overall solidity of the cladding will directly depend on the quality and availability of the tools used. Also, it is necessary to attach importance to high-quality final cleaning, which will undoubtedly affect the final appearance of the coating.

Possible mistakes

When working with the type of grout under consideration, the most common mistake professionals call a violation of the proportions of the mixed components. Also, the use of improper tools and untimely cleaning of excess can become a problem.

The first mistake (non-compliance with proportions) leads to a decrease in the quality of the functional mass of the filler. The second mistake (choosing the wrong tool) will have an extremely negative impact on the overall quality of the finish and the coating itself. The third mistake can be almost fatal, since it is extremely difficult to eliminate an already hardened epoxy mass.

Difficulties of choice

The choice of color for grouting paste should be carried out only after deciding on the color of the tile itself. The pigment content of the paste is determined by an extremely wide variety of tile shades, from which it can be difficult to choose the right one.Seams, on the other hand, are able to give a completely different look to the entire tiled layout, making it both inexpressive and faded, and very original in artistic terms. In addition, a well-chosen shade will help visually overshadow minor flaws, emphasizing obvious advantages. Professionals, at the time of purchase, recommend relying on the following tips:

- A light composition, executed in pastel colors, will help to externally make a single whole out of individual tiles. The dark mass, on the contrary, will emphasize the division of the surface into separate elements, between which the boundaries will be clearly traced.

- If there is a bright and large image on the tile, then the dimensions of the room should be taken into account for the proper performance of the grouting operations. For small rooms it is better to use the lightest mass, and for large rooms it is allowed to use the darkest shade available in the pattern.

- If we talk specifically about ceramic cladding, then the shade that prevails in the surrounding interior items is suitable for it, however, it should be as close as possible to the same range as the layout itself.

- If we are talking about a multi-colored mosaic, then it is preferable to use gray, beige or white paste on it. The same colors can become universal in cases where it was not possible to find the most suitable composition. However, white, beige and gray are not recommended for floor joints as they will quickly get dirty.

It is worth noting that today's market is able to offer not just colored epoxy grout, but also samples with a different filler, for example, with sparkles, metallic or mother-of-pearl.Also, the user has the opportunity to purchase separately tinting compounds and include them in the resin grout when kneading.

Rating of the best epoxy grouts for 2022

Budget segment

3rd place: "LITOKOL EpoxyElite E.04 PLATINUM 482260002"

The set of this product contains a dry mixture + a liquid component, it is used for outdoor and indoor work. The basis is a two-component epoxy resin. Drying time - 1 day. The properties of moisture resistance and frost resistance are present. The color of the color scheme of the composition is platinum. The recommended cost for retail chains is 1394 rubles.

- Protective qualities - available;

- Work with external / internal finishes;

- Convenient container and volume.

- Not detected.

2nd place: "Art And Play epoxy solar white 1 kg"

The product is intended for grouting tiles in damp areas such as kitchens, hallways, bathrooms and shower rooms. No alternative for use in the bath, hammam and pool bowls. Can be used to secure tiled joints more securely on terraces or outdoor areas. The width of the seams can be from 0.5 to 10 mm. It can be applied to the flooring, which is equipped with a "warm floor" system. Two-component grout: component A + component B. The recommended cost for retail chains is 1453 rubles.

- Universal color;

- Adequate price;

- Ability to work with wide cavities.

- Not detected.

1st place: "Founding" PLITSAVE ULTRA XE15 E "bahamas" 031, 1 kg 90427 "

The sample is designed to fill and protect tile joints with a width of up to 15 mm on floors and walls in residential, public, industrial premises, medical institutions and premises with increased traffic. It is used for internal and external works. It is allowed to work on concrete, cement-sand, cement-lime bases, gypsum boards, particle boards, bases subject to deformation during temperature changes and in conditions of periodic moistening (according to the “warm floor” system, showers and bathrooms, kitchens, swimming pools, saunas and hammams on terraces and balconies). Especially recommended for use in areas exposed to chemically aggressive substances. It is used for filling joints of all types of glass tiles and mosaics, incl. for ceramic tiles, porcelain stoneware, natural and artificial stone (including clinker tiles), glass blocks. The recommended cost for retail chains is 1573 rubles.

- Does not fade;

- Does not scratch the surface;

- Resistance to abrasion and aggressive environments;

- Work gloves in each jar.

- Not detected.

Middle price segment

3rd place: "HIMFLEX 2F C70 (beige) 2 kg"

The product is intended for filling tile joints with sizes from 1 to 10 mm. Provides protection against the effects of chemically aggressive substances for one-piece acid-resistant products (for example, acid-resistant ceramic tiles, acid-resistant bricks). Suitable for surface cladding of building structures and structures and lining of process equipment. Use in rooms of food appointment (without direct contact with food) is possible.The material is suggested to be used only according to the manufacturer's instructions. The recommended price for retail chains is 2138 rubles.

- Without smell;

- Does not stain the surface of tiles, including those made of finely porous acid-resistant ceramics and clinker;

- Accelerated curing in the early stages of curing.

- Large fragmentation of loose base.

2nd place: "LITOKOL STARLIKE EVO S.100 BIANCO ASSOLUTO 485110002"

The sample is a two-component epoxy acid-resistant, alkali-resistant product used for grouting tile joints with a width of 1 to 15 mm. Can be used as an adhesive for all types of facing tiles and mosaics. Component A is a mixture of epoxy resin, colored microfragments and special organic additives. Component B is an innovative organic catalyst (hardener). After mixing the components, a creamy, comfortable composition is formed. After the final polymerization, it has an unsurpassed smoothness of the seam, increased resistance to mechanical and chemical influences. Scope: grouting, laying tiles or mosaics, metal pools. The recommended cost for retail chains is 2209 rubles.

- Unique patented technology;

- Ease of use and cleaning;

- Color constancy;

- Environmentally friendly material;

- Resistant to adverse weather events.

- Not detected.

1st place: "LITOKOL STARLIKE C.280 GRIGIO FANGO 478610003"

This two-component acid-resistant compound is used for indoor and outdoor applications.The tool can solve several problems at once: laying tiles / mosaics, grouting tile joints, wall decoration. The wide scope and versatility of the product make it possible to use it at various facilities, including in wet rooms, in rooms with increased hygienic requirements, with aggressive chemical environments, and with intensive operational loads. Suitable for professional use. The recommended cost for retail chains is 2537 rubles.

- Adequate value for money;

- Ability to withstand excessive mechanical stress;

- Resistant to aggressive chemicals.

- Not detected.

Premium class

3rd place: "Sika SikaCeram White 2 kg"

This chemically resistant epoxy compound is intended for indoor and outdoor grouting of wall and floor tiles. Work can be carried out on facings that are made of: glass mosaic, ceramic tiles, porcelain stoneware. It can be used for residential and public premises, premises with permanently high humidity (bathrooms, showers, hammams, kitchens, laundries), swimming pools and reservoirs, industrial and food production workshops, heated floors, surfaces in contact with aggressive chemicals. The recommended cost for retail chains is 2664 rubles.

- The presence of decorative additives;

- Sufficiently voluminous container;

- High chemical resistance.

- Not detected.

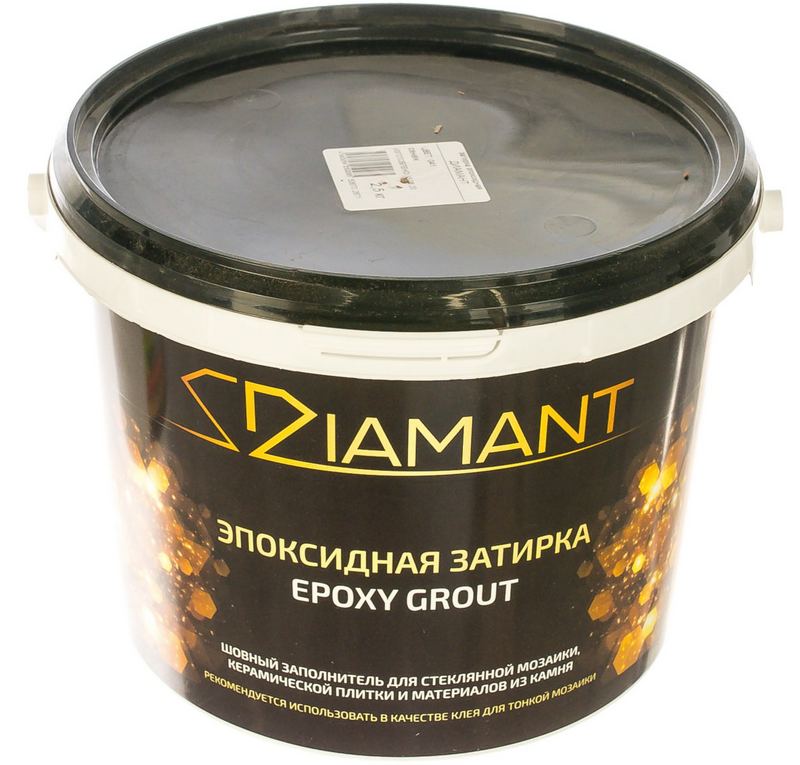

2nd place: "Live Paint 041 Diamond Senezh 2.5 kg 002041"

This product contains biocidal additives that prevent the formation and development of harmful microorganisms (fungus and mold).The composition is used in rooms with high humidity and in rooms with a "warm floor" system. The product offers a high level of adhesion to most building materials and is suitable for all types of cladding modules: glass mosaics, ceramic tiles, porcelain stoneware modules, natural and artificial stone products. The recommended cost for retail chains is 3250 rubles.

- Fine filler fraction 100-200 microns;

- High strength indicators - 6.5 on the Mohs scale;

- Resistant to stains, acids and alkalis;

- Frost and moisture resistance, water tightness;

- Has a UV blocker.

- Not detected.

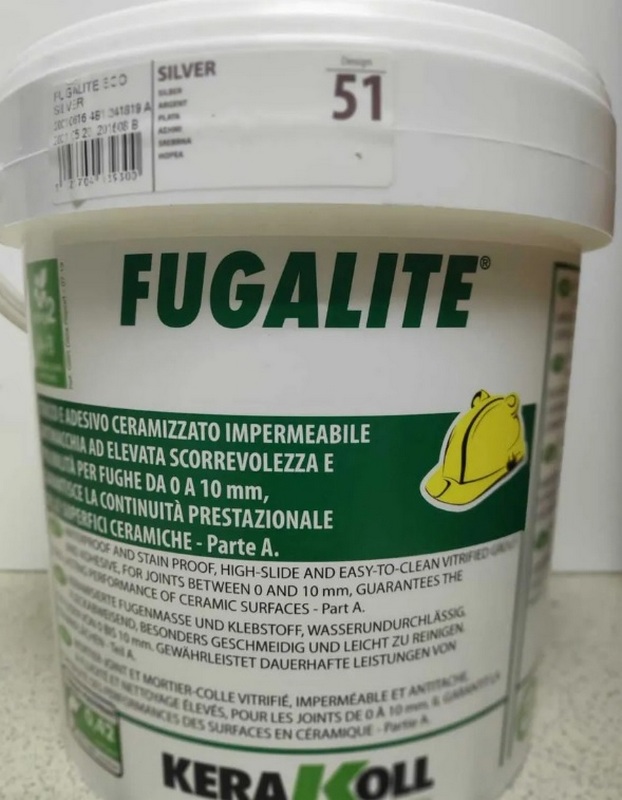

1st place: "Kerakoll for tiles 51 Silver Fugalite Eco 3 kg Silver 3 kg"

This is a certified ceramized filler (and at the same time glue), has increased fluidity, is easily washed off, has bacteriostatic, waterproof and non-staining properties, has increased chemical-mechanical strength, works along seams from 0 to 10 mm. Also, homogeneous and continuous jointing is allowed on any ceramic and glass facings. Environmental class - rating 2, and according to the European system - "A +". It is proposed for use in children's, preschool institutions, for surfaces in contact with food - countertops, kitchen aprons, showers, bathrooms, swimming pools, hammam, spas. The recommended cost for retail chains is 7200 rubles.

- The presence of an almost complete list of protective properties;

- Storage is possible at positive temperature;

- Shelf life extended to 2 years.

- Overcharge.

Conclusion

The imposition of neat tile seams that do not have a single flaw is the dream of any master. In the vast majority of cases, a cement mixture was previously used to fill the inter-tile joint cuts. But due to the low moisture resistance of this material, the finishers found an alternative. Many issues with high-quality filling of inter-seam distances are solved by epoxy grout. These compounds have increased strength and have a declared service life of 50 years.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131665 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127702 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124529 -

The best men's sneakers in 2022

Views: 124046 -

The Best Complex Vitamins in 2022

Views: 121951 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114988 -

The best paint for gray hair - top rating 2022

Views: 113405 -

Ranking of the best wood paints for interior work in 2022

Views: 110332 -

Rating of the best spinning reels in 2022

Views: 105338 -

Ranking of the best sex dolls for men for 2022

Views: 104378 -

Ranking of the best action cameras from China in 2022

Views: 102226 -

The most effective calcium preparations for adults and children in 2022

Views: 102020