Rating of the best epoxy adhesives for 2025

Epoxy adhesive as an adhesive is widely used for industrial and domestic purposes, is a very popular synthetic-based substance and can be included in the structure of various primers, putties and tile compositions. In such an adhesive, the solvent, polymers and the resin itself are well combined, and their percentage is perfectly balanced, which is enshrined in the regulatory and technical documents on the requirements of the production process. Due to the unique polymeric substance, this tool is perfect for bonding various dense objects, which can be made of plastic, leather, concrete, wood, rubber or metal.

Content [Hide]

- 1 Epoxy adhesives - general information

- 2 Modern types of glue based on epoxy resin

- 3 Technical properties of epoxy adhesive

- 4 "Cold welding" as a type of epoxy adhesive

- 5 Epoxy glue: features of preparation, work and storage

- 6 Rating of the best epoxy adhesives for 2025

- 7 Conclusion

Epoxy adhesives - general information

Technical employees of various production areas constantly use the composition in question for the adhesion of various dense objects. At present, the market can provide users with an adhesive material with better properties, but "epoxy" is still in demand, because it is able to make various connections with proper quality.

The substances under consideration consist of two elements - resin and catalyst. When they are mixed, a material is formed, through which various dense surfaces are easily glued together, including their non-inert variations. This type of resin mixture was developed at the beginning of the twentieth century and received the commercial brand "Araldit-1".In the future, the composition was subjected to repeated improvement, went through many functional and universal modifications, as well as began to successfully withstand use in conditions of various temperatures. The joints produced by him began to have greater strength, which clearly increased the service life of the structures being glued.

Advantages and disadvantages of "epoxy"

Its undoubted advantages include:

- Versatility - it easily bonds most hard materials, which include ceramics, wood, stone and metals;

- Elasticity of the seam - the resulting seam is not subject to destruction / cracking even when subjected to strong mechanical loads;

- Frost resistance - can withstand temperatures down to -30 degrees Celsius;

- Heat resistance - maintains its operational properties up to +250 degrees Celsius;

- Resistance to water - after hardening, the seam does not collapse from interaction with steam, moisture, condensate;

- Strength - able to successfully withstand the effects of chemically aggressive substances, and a frozen seam can be drilled, sanded, coated with paintwork materials;

- The presence of dielectric qualities - does not conduct electric current.

Of the particularly critical shortcomings, only three can be distinguished:

- Fast curing - after mixing the product, the user has only a couple of minutes to apply the composition. Solidification occurs very quickly, then this substance can only be removed mechanically with the use of effort;

- Destroys soft materials - the epoxy resin present in the composition dissolves Teflon, polyethylene, silicone;

- Toxicity - this composition is forbidden to glue surfaces, which will later have contact with food.

Scope of application

The material under consideration is used in various fields of construction and production:

- Capital construction - erection of reinforced concrete structures, creation of three-layer panels, filling of cavities in concrete bases;

- Repair of rooms and design work - gluing tile modules, coupling plastic, glass and metal bases for rigid fixation, interior restoration;

- Mechanical engineering - body repair work, fixing brake pads, as well as various skins;

- Aircraft design - assembly of small aircraft, mounting of solar panels and thermal protection elements;

- Shipbuilding - impregnation of ship hulls, assembly of fiberglass boats, installation of fasteners, creation of moisture protection conditions.

But in everyday life, epoxy glue is also often used for:

- Shoe repair;

- Bonding of broken ceramic objects;

- Creation (assembly) of souvenir objects;

- Sealing of various joints and gaps of engineering and technical significance.

Modern types of glue based on epoxy resin

Conventionally, they can be classified into three categories:

- Compound;

- Consistency;

- Curing method.

The current market considers the following types of mixtures to be predominant:

- Based on one component - produced in one, ready-to-use, tube, which contains a resin with a solvent. Preliminary heating of the surface for work is not required (although this may be separately specified by the manufacturer in the instructions).

- Based on two components - the kit contains two tubes, one of which contains the resin, and the second contains the hardener. Also, the kit may contain a tool - a special spatula for application.

- Gel (liquid type) - it is supposed to be used immediately after opening the tube (no prior preparation is required).

- In the form of a paste - two-component adhesives belong to this category, but they need to be applied for a short time, because they harden very quickly.

- Plastic - in their viscosity they are somewhat reminiscent of classic plasticine and are produced in plastic tubes. To use them, you need to cut off a piece of the required length, knead it, moisten it with water and get a viscous paste.

The catalyst contained in the adhesive is primarily responsible for the drying of the mixture, for this it is necessary to heat the object to the desired temperature. On this basis, the following types of "epoxy" can be distinguished:

- Special strength - subject to "hot" drying at temperatures from +140 to +300 degrees Celsius;

- Modified - the curing temperature should be in the range from +60 to +120 degrees Celsius;

- Without the need for heating - the name speaks for itself.

Technical properties of epoxy adhesive

The physical qualities of the material in question are completely dependent on the type of resin and hardener that make up such a substance. Thus, different brands will differ in their characteristics, however, there are a number of basic properties that are inherent in all epoxy adhesives:

- The resin in the composition does not change its operational properties even at temperatures above +250 degrees Celsius. The glued parts can be used at this temperature, but glue can be applied at a temperature of -20 degrees Celsius.

- The mixture is resistant to interaction with chemically aggressive substances, which makes it possible to clean the glued surfaces with household chemicals.

- Thanks to plasticizers, it is possible to qualitatively hold elements that have undergone displacement.

- The epoxy joint cannot pass moisture, which makes it an excellent waterproofing agent.

- By means of polymer types of glue it is possible to connect even wood with concrete.

If we focus on greater accuracy, then the list of all properties is very diverse and it will be easier to identify the main exceptions. The adhesive seam must be processed in the same way as the object of gluing itself. It can be coated with paintwork or polished, used as an insulator, because it is a dielectric. However, "epoxy" is not considered the best choice, for example, because of its rapid curing. Quick drying, often, does not allow for high-quality and proper work, because. the user simply does not have time to glue all the necessary elements.

IMPORTANT! Prepare for the work ahead. If the composition has already hardened, then it can only be broken, but not melted or melted.

"Cold welding" as a type of epoxy adhesive

This product is considered quite functional and has a high solidification rate. It is produced in the form of a gray paste, but sometimes it can be white in a liquid form. The material was invented relatively recently, but managed to gain well-deserved popularity and is used equally with traditional welding in the field of repair work. Thanks to “cold welding”, objects can be glued together without the need for heating. The agent is distinguished by a special density, and before use, the cut piece of plasticine mass should be brought into a soft state. During work, you need to occasionally moisten your hands in water so that the composition does not stick to them. Upon completion of work, it is required to provide the composition with 24 hours for drying and adhesion.The product itself comes packaged in boxes and often has a light shade. The substance is able to cope with most materials recovery work, for example:

- Filling cavities in damaged surfaces;

- Repair of individual parts;

- Sealing leaks in water supply lines;

- Repair of glass and ceramics;

- Restoration of household appliances and furniture.

Epoxy glue: features of preparation, work and storage

It is always worth remembering that epoxy compounds receive their performance only after polymerization, for which a special hardener must become a catalyst. The standard workflow includes the following steps:

- Objects and surfaces to be processed are cleaned, degreased and, if necessary, polished;

- Prepared (if necessary - mixed) adhesive;

- The substance is applied to the surface / object, the clutch is fixed;

- The completion of the polymerization process is expected and the glued structure is ready for use.

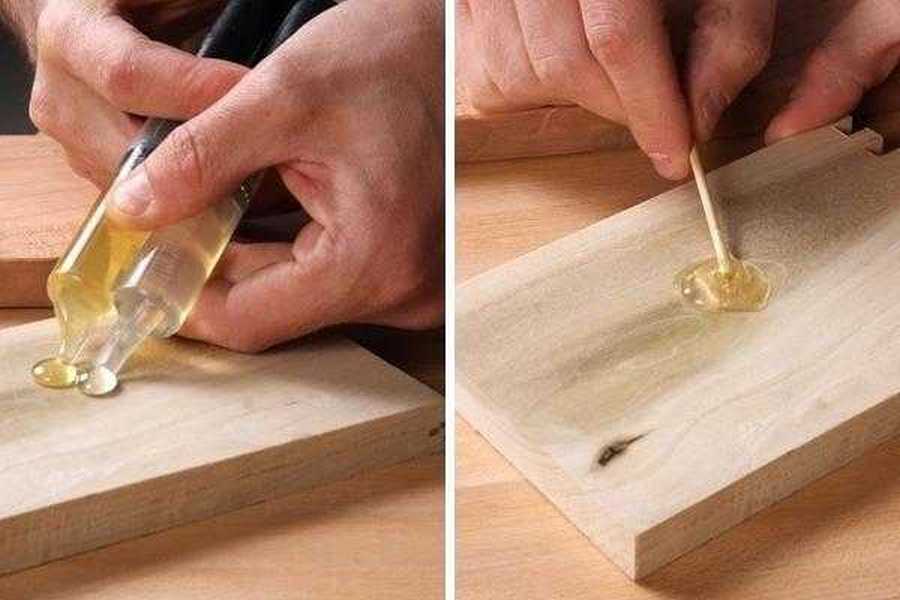

Preparation of the working mass

All the nuances of working with the described adhesive substance are set out in the instructions for the product, which must be strictly observed. If we talk about two-component compositions, then for them the standard proportions will be mixing 1 part of the catalyst-hardener for 10 parts of the resin. The process should begin with the addition of the hardener to the resin mass, and not vice versa. Then, as the resin begins to dry out through the mediation of the catalyst, the process will become irreversible. From this it is clear that the resulting remedy must be applied as quickly as possible, otherwise it will simply deteriorate.Professional masters advise preparing solutions in small portions, exactly for the required amount of current work.

Safety

It must always be remembered that epoxy products will become completely safe for humans only when they are completely cured. When working with a ready-made fastener, you must adhere to the following simple rules:

- Work should be carried out in a ventilated room or where it is possible to ventilate the space upon completion of work;

- In the process, you need to use personal protective equipment - goggles, gloves and a respirator;

- All manipulations must be carried out in working clothes with long sleeves, made of dense material;

- All objects that have come into contact with the mixture (dishes, containers and tools) must be properly cleaned.

Epoxy Storage and Disposal Tips

All manufacturers recommend storing such products in a dry place, placing the container / container with it vertically. The integrity of the packaging must be observed, otherwise air may get inside, which will adversely affect the performance of the product. Storage is only possible at room temperature. Shelf life in proper packaging can be from one to three years, but in any case, over time, the composition will lose its useful qualities. The process of working with such glue involves the use of personal protective equipment, because it is extremely difficult to wash it. If the substance is still in a liquid state, then it can be washed with soap and water or acetone. At the end of polymerization, it can only be scraped off. However, it is permissible to apply the following removal methods to the cured "epoxy":

- Warming up with a building hair dryer or household iron - some compounds can be softened with high temperatures for easier removal;

- Freezing - when frozen, the seam will become very fragile and will easily break away from the object of application;

- Use of solvent - the seam is wetted with toluene, ethyl alcohol or aniline, which will try to dissolve it for easier scraping.

Rating of the best epoxy adhesives for 2025

Budget segment

3rd place: "Cold welding for plumbing repair Almaz AZ-0119"

votes 0

The product is designed to restore lost fragments and connect damaged parts. The mass can effectively eliminate leaks, seal fistulas and cracks in main pipes. The product can be used in high humidity conditions, for the installation of oily surfaces, ceramic sinks, faience countertops, water faucets, cracked covers and shelves. Suitable for repairing decorative ceramics and porcelain. The recommended cost for retail chains is 63 rubles.

- Extremely budget price;

- Sufficiently high-quality action;

- Household scope.

- Small weight and volume.

2nd place: "Universal cold welding Almaz AZ-0035"

votes 0

The paste is intended for quick and durable bonding of various objects made of metal, wood, plastic, glass or ceramics. The product is suitable for restoring lost items and damaged objects. The composition has a fast curing, which ensures proper installation even on oily surfaces in high humidity conditions. The recommended cost for retail chains is 82 rubles.

- Ability to work with greasy surfaces;

- Ability to process various materials;

- Adequate price.

- Small tube volume.

1st place: "Cold welding" On "universal, 60 gr. 17-04-001"

votes 0

The product is intended for durable and tight, as well as reliable adhesion of elements made of ferrous / non-ferrous metals, plastics, glass and ceramics, wood and marble, concrete and granite, plexiglass. Bonds dissimilar materials, while providing increased adhesion and strength, including on wet and oily surfaces. Perfectly eliminates leaks in main pipes, tanks, radiators and gas tanks (directly along the incoming fuel). Great for gardening tools. It can provide repairs in hard-to-reach places or in cases where disassembly / dismantling of the object is not possible (a). Turns brown after curing. The mixture is maximally adapted for domestic use. Easily mixed by hand. The composition includes 2 components: hardener and epoxy resin. Drying time - 60 minutes, after which the seam can be processed, drilled, threaded, painted. The final strength is reached after 24 hours, after which the treated surface can be subjected to mechanical stress. The recommended cost for retail chains is 104 rubles.

- Wide area of use;

- Good value for money;

- Creation of super strong seams.

- Not detected.

Middle price segment

3rd place: "Moment Super EPOXY Formula 5 transparent 14 ml syringe B0022995"

votes 0

This is a reliable and fast epoxy adhesive in a syringe with a mixer attachment that can cure in 5 minutes. The product is immediately ready for use. The special mixer attachment has internal mixing technology, which ensures that all components are mixed quickly and correctly. Able to provide increased heat resistance, does not shrink and does not expand when solidified, 100% moisture resistant, highly resistant to various oils and solvents. Suitable for combination gluing of glass and fiberglass, porcelain and ceramics, faience and crystal, metal and wood. It is possible to bond with subsequent processing of marble, stone, concrete, all types of metal, their alloys, rigid PVC, polystyrene, plexiglass, polycarbonate, polyamide, ABS and other plastics. Ideal when used to repair missing parts, filling, dents, chips, cracks. Can be used to restore all building materials, tiles, marble, cement, stone, concrete, brick, natural and artificial stones, etc. The recommended cost for retail chains is 207 rubles.

- Work with various materials;

- Fast drying;

- Acceptable price tag.

- Not detected.

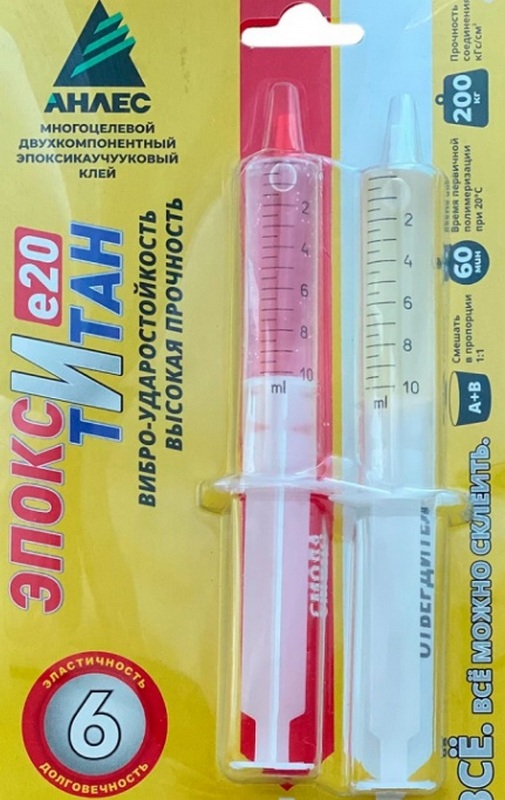

2nd place: "Anles EpoxyTitan 20 ml 70020"

votes 0

Another sample, supplied in a convenient package in the form of prepared building syringes. Focused on minimalistic options for repair work at the household level. It just pours on and dries quickly. It has a yellow-brown color. Bonded materials: metal, plastic, wood, glass, ceramics, porcelain, stone, concrete. The adhesive base is epoxy resin and hardener.The recommended cost for retail chains is 246 rubles.

- Convenient delivery container;

- Focus on home use;

- Neutral color.

- Drying occurs every other day with the obligatory observance of temperature conditions of +20 degrees Celsius.

1st place: EPC from NPK Astat LLC EDP 140 gr. 00-00000553"

votes 0

The composition is intended for gluing almost any objects, with the exception of dishes and objects that have direct contact with food. Suitable for the repair of sports equipment, fiberglass bases, bumpers, boat hulls, cars, modeling, can be used for the production of self-leveling flooring. It is characterized by extremely high mechanical strength, low shrinkage, high level of adhesion to materials, moisture resistance, excellent electrical insulating properties. The recommended cost for retail chains is 271 rubles.

- Excellent absorption properties;

- Versatility;

- Excellent adhesion.

- Not detected.

Premium class

3rd place: "UHU SCHNELLFEST 35g 40381"

votes 0

This two-component product does not contain a solvent in its composition. It is used for reliable connection of metal and glass, porcelain and wood, rubber and plastic. The substance is resistant to precipitation, aggressive acids, alkalis, oils and solvents. The recommended cost for retail chains is 1365 rubles.

- Copes well with negative environmental conditions;

- Does not contain solvent;

- Low toxicity.

- Small container;

- Overpriced.

2nd place: "ULTIMA based on epoxy resin 1000 gr."

votes 0

The product is made on the basis of epoxy resin, supplied in a 1000 g container, is a universal thermosetting synthetic solution consisting of two components: epoxy resin and a special hardener. It finds its wide use in mechanical engineering, shipbuilding, as well as in everyday life for durable gluing of various objects. The product is characterized by increased mechanical strength, able to withstand any negative atmospheric influences. The recommended cost for retail chains is 1559 rubles.

- Container of large volume;

- The widest list of glued materials;

- Very high mechanical bonding strength;

- High heat resistance;

- Resistant to water, oil, gasoline.

- Not detected.

1st place: "LITOKOL Litofix Stone for stone 1.0 kg bucket 483700002"

votes 0

This product is two component. Both of its components, namely: a bag with a hardener (component B) + paste (component A), are supplied in a bucket. The components are packaged in the required proportions, for use they only need to be mixed. The recommended cost for retail chains is 2170 rubles.

- Sufficient container volume;

- Ability to work with heavy objects;

- Increased level of adhesion.

- Not detected.

Conclusion

It is not always possible to use nails, screws or traditional welding in order to fasten different objects. This is where epoxy glue comes to the rescue, which is able to provide the same reliable adhesion of homogeneous and inhomogeneous surfaces.The scope of this material is extremely wide - from creativity and domestic needs to the industrial sector.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131649 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127687 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124516 -

The best men's sneakers in 2025

Views: 124030 -

The Best Complex Vitamins in 2025

Views: 121937 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114978 -

The best paint for gray hair - top rating 2025

Views: 113393 -

Ranking of the best wood paints for interior work in 2025

Views: 110317 -

Rating of the best spinning reels in 2025

Views: 105326 -

Ranking of the best sex dolls for men for 2025

Views: 104363 -

Ranking of the best action cameras from China in 2025

Views: 102214 -

The most effective calcium preparations for adults and children in 2025

Views: 102010