Ranking of the best containers for chemical liquids for 2022

For the purpose of proper transportation and storage of various concentrated acids, salts, alkalis, alcohol, reagents and other aggressive liquid substances that are widely used in industry and in everyday life, it is necessary to use special containers made of special materials. Additional requirements are imposed on them: excellent strength, tightness, durability, etc. All these requirements are necessary to maintain the safety of human health and life, as well as to preserve the properties of liquids placed in containers. The items in question can be made of plastic or metal.

Content [Hide]

- 1 Varieties of containers for aggressive chemicals

- 2 Features of the design of metal containers

- 3 Household plastic containers for storing chemical liquids and their color marking

- 4 Difficulties of choice

- 5 Ranking of the best containers for chemical liquids for 2022

- 6 Conclusion

Varieties of containers for aggressive chemicals

The most popular are:

- Reservoirs for placing reagents with varying degrees of aggressiveness - from acids and water to their mixtures and alkalis;

- Special reactors - this is the name of the containers in which the stored substances undergo a reaction;

- Electroplating baths - they are used when working with large volumes of aggressive working substances at elevated temperatures (the passage of galvanic processes);

- Filters - they are used to process and prepare solutions for further technological procedures.

Manufacturing materials

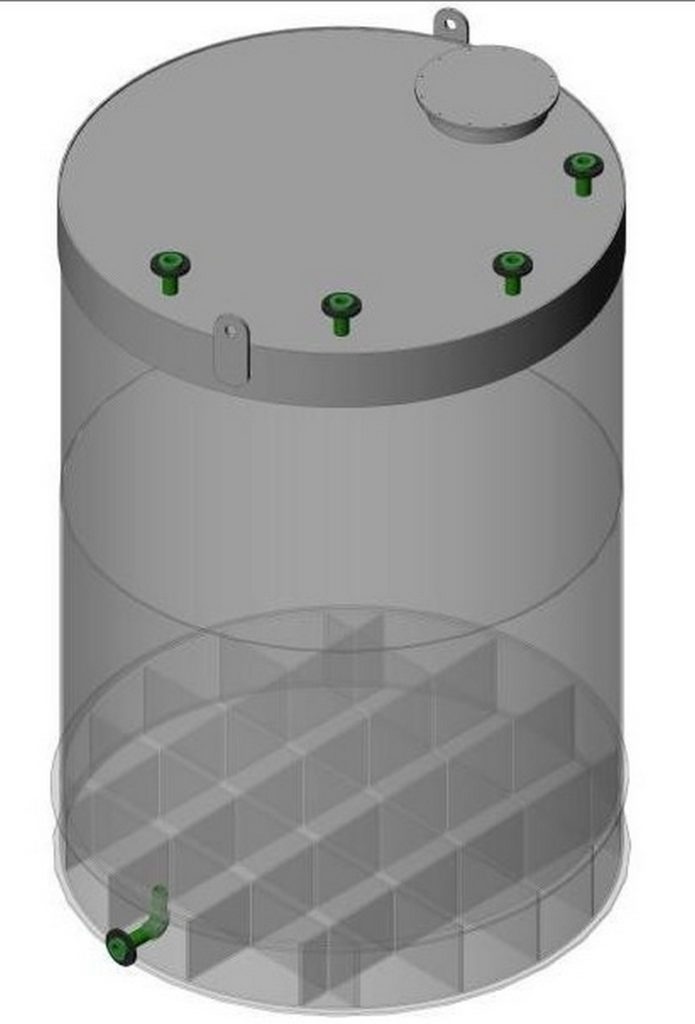

For these purposes, polymer containers are most often used, made of:

- Polypropylene is a durable and stable material, perfect for most aggressive substances due to its own chemical neutrality;

- Polyethylene - this material is considered more resistant to ultraviolet rays and is used when storing substances in the open;

- PVC - it is used for various chemical processes, which include galvanic;

- PVDF is a fluoroplastic used only for very aggressive substances. It is distinguished by its high cost, but the period of its operation is much superior to analogues made of steel and other materials.

IMPORTANT! Experts call polyethylene and polypropylene containers the most affordable, because they are suitable for solving most household tasks. Steel and iron are mainly used in industrial production.

Purpose of chemical containers

Both in everyday life and in industry, tanks are used that can withstand the effects of active working environments for a long time, so they are characterized by the following parameters:

- Tightness and integrity - the container must not allow leakage of the stored substance;

- Chemical neutrality - the material of manufacture should not react with the stored substance and not change its composition;

- Durability - the tank must constantly maintain its strength and technical qualities during operation.

As mentioned above, polymeric chemical products are best suited for everyday tasks. Their sizes can be absolutely any, up to the most non-standard forms. Most often, these are rectangular, round, cylindrical samples with a conical lid. Their bottom can be either conical or flat, and the installation method is vertical or horizontal. Depending on the scope of use, reinforcement of the product with metal or plastic is allowed. As a rule, the considered samples are suitable for storage:

- Oil products;

- Bulk substances;

- Aggressive liquid substances;

- Alkalis and acids.

Any tank must comply with the following parameters:

- Be safe for the environment and humans;

- It can be used in demanding procedures (manufacturing of chemical substances, storage of products);

- Easy operation - simple washing and cleaning, no odor retention, no corrosive processes;

- The ability to properly retain heat and resistance to temperature changes;

- Long operational life (both for samples from synthetics, and for metals).

Each tank consists of:

- Vessel;

- Service hatch;

- Drain pipe.

Additional equipment may include auxiliary hatches and pipes, as well as heating and insulation systems.

Features of the design of metal containers

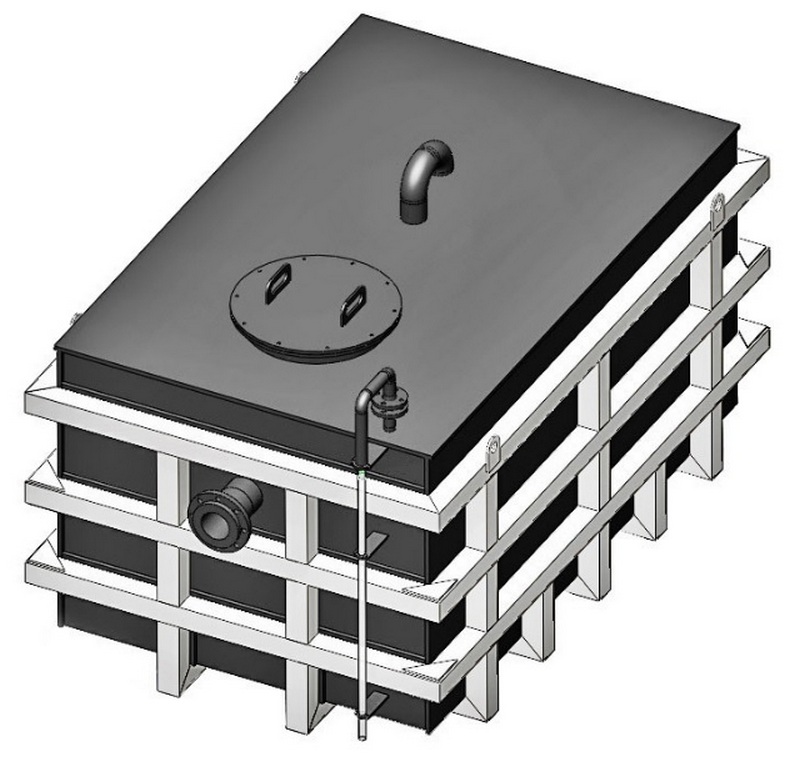

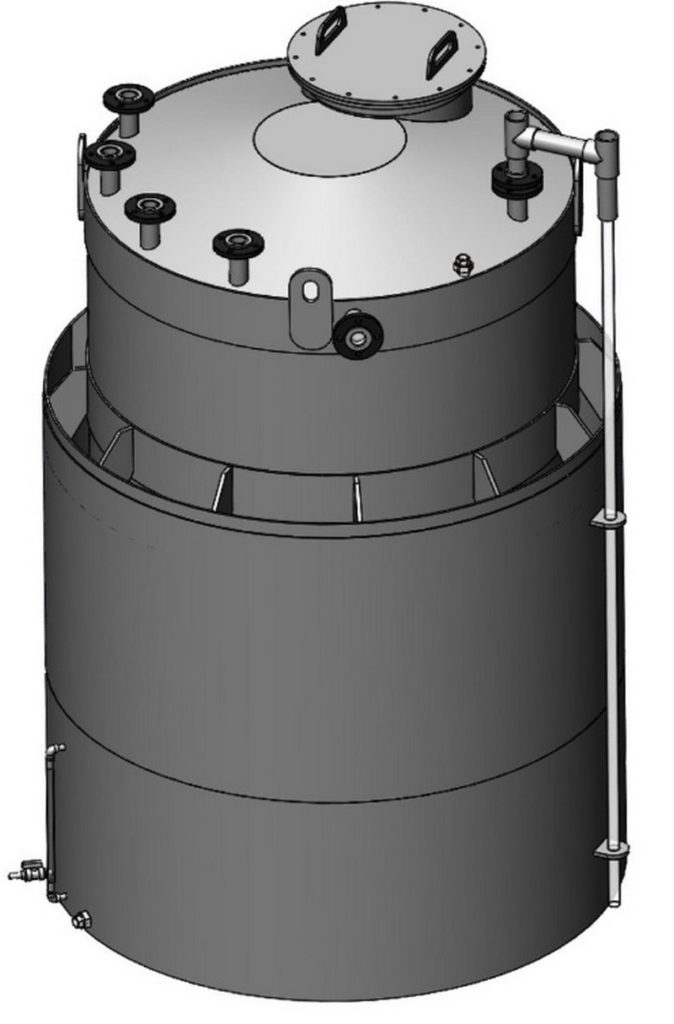

The body of these samples is traditionally made from shells (metal blanks). The assembly is carried out by joining the shells and their automatic welding. Welds are subject to mandatory inspection by ultrasonic controllers. According to the type of execution, metal products can be:

- Horizontal arrangement - they often have the shape of an ellipse, torus (donut) or be a conical shape. This type is characterized by the installation of steel stiffeners inside, which prevent deformation;

- Vertical arrangement - they may have additional hatches, nozzles and necks, stairs and even observation decks (for especially large models). They are easier to equip with pumps, alarms, level sensors, pressure gauges and valves, as well as auxiliary pipelines.

Storage and installation can be both ground and underground.The number of walls inside varies from one to two.

Types of metals used

The following types of metals are used for the manufacture of highly resistant tanks:

- STZ-steel - recommended for operation and temperatures of at least -40 degrees Celsius;

- 09G2S-steel - recommended for areas where temperatures can drop below -40 degrees Celsius;

- Stainless steel is a fairly versatile type of metal that sometimes won't even require protective coatings.

IMPORTANT! It should be noted that the steel grades of the first two types are subject to inner surface treatment with a special coating, which does not allow the stored substance to enter into a chemical reaction with the walls and bottom of the product, while the chemical composition of the substance itself does not change.

Thermal insulation and heating of metal samples

Depending on the storage conditions, the metal products in question may be equipped with an auxiliary heating system. The heating process itself can be carried out by:

- Heated electric cable - a special thermal cable with automatic adjustment is fixed to the tank wall. The whole device consists of a heating module, a distribution module with temperature sensors and a control unit.

- Coil - it is a closed system of internal pipeline with a water-steam coolant.

In addition to direct devices for heating, passive types can also be used. These include:

- Lining with polyurethane foam - in the classic version, a layer of the above plastic is simply applied to the outer surface of the tank. This type of insulation can simultaneously perform the function of additional protection against rust and the function of waterproofing;

- Cladding with mineral wool is the usual bonding of this material to the steel structure from the outside.

Specialized anti-corrosion protection

In order to increase the service life, black steel tanks always undergo anti-corrosion treatment over their entire outer surface. It consists in applying several ground layers, epoxy coating or special enamel, coupled with waterproofing. In some cases, this option can be provided by means of bituminous mastic. But the inner surface can be processed only depending on the substance to be stored or exclusively at the request of the customer.

Mounting and installation

Vertical and horizontal containers with small volumes and dimensions can be shipped from the production line in a completely finished form. The installation of the tank is recommended to be carried out on a concrete base, for which support lodgements are provided in the metal structures. Anchor bolts are used for fastening. If underground installation is supposed, then the installed tank is additionally strengthened with metal clamps, because otherwise, as a result of groundwater exposure, the tank can simply float up.

Household plastic containers for storing chemical liquids and their color marking

In the modern market, a special place is occupied by products made of polyethylene and polypropylene, which are distinguished by reliability and durability, as well as chemical neutrality. They tightly pressed products from other materials. Therefore, these samples can be safely recommended for use both in domestic and industrial scales. It is worth noting that the color of plastic models is of fundamental importance, because it orients the user according to the operating conditions of this product.

Orange, red and yellow colors

According to the State Standard, such plastic tanks are designed to store disinfectants or agrochemical solutions - acidic and low-aggressive substances (PPP, UAN, ZhKU). They have thickened walls of 15 millimeters or more and are better suited for storing liquids with a maximum density of up to 1.5 g/cm3. Such containers are used in hospitals, public utilities, agricultural enterprises and construction sites. The surface of the container is not susceptible to the effects of acids, organic fertilizers, alkalis, and is also not afraid of sunlight and temperature changes. Perfect for agricultural purposes, as well as for the preparation of fertilizers or chemical compounds.

White and blue colors

These tanks are designed to store food and water. They can also be used for filling with viscous, granular and liquid bulk solids, which have a maximum density of 1 g/cm3. A container of such colors will prevent the penetration of ultraviolet light inside, which means that the liquid retains its chemical properties and inhibits the "bloom" of water. They are supposed to have a standard wall thickness, but they can be additionally strengthened, which will significantly expand the scope of use. Walls with a seal increase the overall strength of the product and allow the container to store more aggressive substances. Among other things, they can even be buried underground. The main areas of use are wineries, catering companies, canteens, farms. Storage of brines, marinades, honey and drinking water is allowed.

Black color

Samples with a similar color are perfect for storing fuels and lubricants, diesel fuel and various oils.They have an internal white coating, on which you can clearly see the changes in the quality of the stored substance, as well as its level. The great advantage of black containers is that if you store drinking water in it, then in the sun it heats up very quickly. At the same time, water retains its chemical properties and is suitable for watering plants. At the same time, a container with this color can be used in rooms that are not particularly clean - the dirt on the tank will not be too noticeable. Also, this color is good to use on tanks for a summer shower in a personal plot, for storing various septic tanks at gas stations and garages, boiler rooms and transport facilities.

Green color

According to their characteristics, these containers do not differ much from orange and white colors - they are also well able to store water without changing its composition. Basically, the green color plays an aesthetic role, because it easily fits into the countryside landscape, merging with the surroundings. A similar type is chosen to provide guest houses, estates and cottages, tourist centers. The green coloring harmonizes well with the natural style and expands the possibility of using the tank.

Difficulties of choice

When buying the products in question, you should pay attention to their volume. Household models can have an indicator of up to 100 liters, and models up to 2000 liters already have an industrial purpose. 6000 liters is the volume for transportation. 200 liter samples are perfect for a summer shower in the country. Tanks of 500 liters are able to satisfy any household needs - from watering to washing dishes. The maximum volume can be 10,000 liters. It should be understood in advance that plastic tanks are much lighter than metal ones, but they will not have the same strength.

As for the operating temperature, its boundaries are in the mode from -40 to +60 degrees Celsius (the most common variations). Unlike their iron counterparts, plastic ones are produced by rotational molding, which provides a completely seamless technology. It is this design that ensures the reliability of the tank. In any case, each container for storing chemical liquids must be provided exclusively with a hinged or screwed lid (manhole) in order to ensure the utmost tightness.

Ranking of the best containers for chemical liquids for 2022

household samples

Container for collecting chemical liquids 500 ml yellow

votes 0

Producer: Samara plant of plastic products.

This container is intended for collection and storage of Class B liquids and has a yellow body. The volume is 0.5 liters and is made of durable polymer material, with curved edges, stiffeners, fastenings to the surface, thickened with the lower third of the body. There is a label on the case for information about the contents. The lid has a re-opening indication - a sealed lid and a single-use button. Versatility of the container - it can be successfully fixed to both horizontal and vertical surfaces, which will reduce the risk of tipping over (fixing on a table, infusion stand, wall or side of the table). The recommended cost for retail chains is 160 rubles.

- Versatility;

- Ribs on the body;

- Fastening variability.

- Small volume.

Radivas — Plastic barrel / can / 51 l

votes 0

This flask has a volume of 51 liters. Designed for transportation and storage of food products and household chemicals. It can be used in a wide temperature range, has high strength characteristics, tightness, chemical resistance and increased transportability. The wide mouth of the flask ensures the convenience of packing and unloading bulk and pasty goods. The sealed lid is very handy. Two hinged handles are provided for manual movement. The bottom of the can and the upper edge of the lid can be structurally combined, which allows you to stack products. Material - polyethylene, color - white. The recommended cost for retail chains is 1600 rubles.

- Sufficient volume;

- Increased portability;

- Stackable.

- Not detected.

Storage tank ROF-WT08 for 5 liters 210X210X310(H)

votes 0

Manufacturer: Suntrade.

This product is intended for the accumulation and storage of clean water (permeate) that has undergone reverse osmosis and other liquid substances. The total volume is 5 liters. The material of the accumulative chamber is a neutral polymer, the material of the diaphragm (membrane) is impregnated food grade rubber. Working temperature limits — from +3°С to +45 °С. The recommended cost for retail chains is 6600 rubles.

- Rubberized inner surface;

- Availability of additional options - cleaning membrane;

- Sufficient temperature limits for work.

- Small volume;

- High price.

Retractable container for household chemicals Gollinucci Laundry 6. LAB1150

votes 0

This compact, built-in storage accessory for bathrooms or home laundries. The accessory is equipped with dividers for a rational and convenient arrangement of liquids and other substances for small items. Can be built into a base with a minimum width of 300 mm. For care, you can use water and aggressive detergents. There are two mounting options - to the bottom of the frame or to the facade universal (left / right). The recommended cost for retail chains is 8700 rubles.

- Possibility of storage of substances in various states of aggregation;

- Double fastening method;

- The presence of separators.

- Somewhat overpriced.

industrial designs

GLOBALSMP-EP-P/P/PPS-1.0-1200.1000.1000-1.2-40

votes 0

The model is designed and manufactured according to high quality standards and is designed for long-term operation (up to 20 years), after manufacturing it undergoes multi-stage hydraulic tests and technical control. The technology uses European DVS recommendations, there is a precisely calculated number of shell belts with a successive change in thickness depending on the height, there is no bandage that adversely affects the strength of the walls due to local changes in stiffness. Height welds are kept to a minimum for high product strength. The recommended cost for retail chains is 10,000 rubles.

- Additional capacitance enhancement;

- Full technical quality control;

- Compliance with European standards.

- Not detected.

GLOBALSMP-EDV-K/P/PVC-1.0-1.05/1.50-1.2-40

votes 0

The tank is vertical-cylindrical, double-walled, made of high-quality PVC, designed to collect and store particularly aggressive media. The double wall prevents the contents from spilling if the main body breaks. The material and wall thickness is selected based on the conditions and features of operation. The design is thoroughly tested for reliability and strength in special CAD programs. Cutting of the material is carried out on high-precision CNC milling machines, which ensures perfect joining of parts. Cylindrical parts are made on special butt machines with high welding precision. The estimated service life is at least 20 years. The recommended cost for retail chains is 15,000 rubles.

- Thick walls;

- Double protection;

- Long service life.

- Not detected.

GLOBALSMP-EV-N/P/PPS-0.6-0.80/1.30-1.0-40

votes 0

This fixture is resistant to wear, does not corrode and rot, and can withstand prolonged exposure to aggressive chemicals. Differs in resistance to shock loadings and low temperatures. Possesses reduced sensitivity to cracks in case of stresses and resistance to UV radiation. It is characterized by light weight, easy installation and easy transportation. Completely environmentally friendly. The recommended cost for retail chains is 20,000 rubles.

- Excellent qualities of durability;

- Easy installation;

- Environmental Safety.

- Not detected.

Horizontal tank G 2500 liters

votes 0

Manufacturer: Polymer Group.

This horizontal cylindrical tank with a capacity of 2500 liters is designed for storing drinking and technical water, diesel fuel. It has special support legs, thanks to which special stability and reliability are ensured in terms of operation. The product can be used in industrial, agricultural and private sectors. The sample can be completed with the necessary taps. Drilling technological holes and installing bends is very simple. The recommended cost for retail chains is 35,000 rubles.

- Variability of stored liquids;

- Versatility of application;

- Large volume.

- Not detected.

Conclusion

In the chemical industry, in medicine and in agriculture, plastic or metal containers are used to store, collect and transport various chemical substances. These models differ in their features and must meet a number of requirements. They must be durable and airtight, made of especially durable materials, have thicker or double walls. Products must be protected from possible leakage of chemically aggressive solutions and provide them with long-term and safe storage. In order to increase ease of use, they can be equipped with additional equipment (chemically resistant fittings, pipelines, taps, various automation, etc.). For the convenience and safety of transporting chemicals, they can be placed in a strong frame. If necessary, the tank can be equipped with wheels.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131651 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127691 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124519 -

The best men's sneakers in 2022

Views: 124033 -

The Best Complex Vitamins in 2022

Views: 121940 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114980 -

The best paint for gray hair - top rating 2022

Views: 113395 -

Ranking of the best wood paints for interior work in 2022

Views: 110319 -

Rating of the best spinning reels in 2022

Views: 105329 -

Ranking of the best sex dolls for men for 2022

Views: 104366 -

Ranking of the best action cameras from China in 2022

Views: 102216 -

The most effective calcium preparations for adults and children in 2022

Views: 102011