Ranking of the best stainless steel chimneys for 2022

One of the most important elements of any heating system is the chimney. For a long period of human development, a variety of materials were used for its manufacture - wood, brick, asbestos cement. Recently, the stainless steel version has gained particular popularity.

Today, there is a wide variety of stainless steel models on the domestic market, which differ not only in product quality, but also in price. It is very difficult for non-specialists to figure out which chimney is required in each case, because they all look almost the same. This overview will help make your choice of model easier by presenting basic basic information about these products, as well as product ratings from leading manufacturers of such products.

Content

Basic information

A chimney is an engineering structure for removing combustion products from working sources of thermal energy into the atmosphere for safe removal from buildings and people.

During the combustion of fuel in the furnace, smoke, soot, various resins, water vapor, ash, ash, soot, as well as parasitic air, which is not involved in the combustion process, are removed. In the case of improper formation of the inner walls or hypothermia, they settle on the surface and can further impede the passage of gases. Therefore, it is very important to maintain a smooth, even surface inside, without protrusions, gouges or crevices.

The principle of operation is based on the creation of natural or forced draft, which moves the emerging smoke to the mouth of the pipe. Ensuring its normal value is in relation to the height and cross section of the channel.

To create natural draft in the heating system, the outlet temperature must be more than 100⁰С. In this case, hot layers of air are replaced by cold ones.

What do they connect to

Universal flue systems are suitable for all known household heating appliances, including:

- fireplaces;

- furnaces;

- heating furnaces;

- bath stoves;

- boilers;

- cooking and heating furnaces;

- kitchen ovens for baking.

The safe removal of combustion products of any fuel is carried out: coal, gas, diesel fuel, firewood.

Basic parameters

According to the main characteristics of operational and fire safety, the design should:

- correspond to the specific type of heating equipment used;

- be made of non-combustible material;

- ensure complete combustion of fuel;

- withstand operating and maximum temperatures from heating equipment;

- endure temperature fluctuations, as well as the negative impact of the environment;

- easy to install and maintain;

- be sealed and isolated in areas of passage through floors, walls, roofs;

- have a long service life.

Varieties

1. Single-walled (single-circuit) - an ordinary pipe with a socket for connection. Application is limited due to small wall thickness. Requires insulation to prevent condensation.

2. Sandwich (double-circuit) - a modular design of two devices with different diameters and a layer of cotton-mineral insulation 20-60 mm thick.

3. Round - to create a new chimney.

4. Oval - when lining a brick chimney.

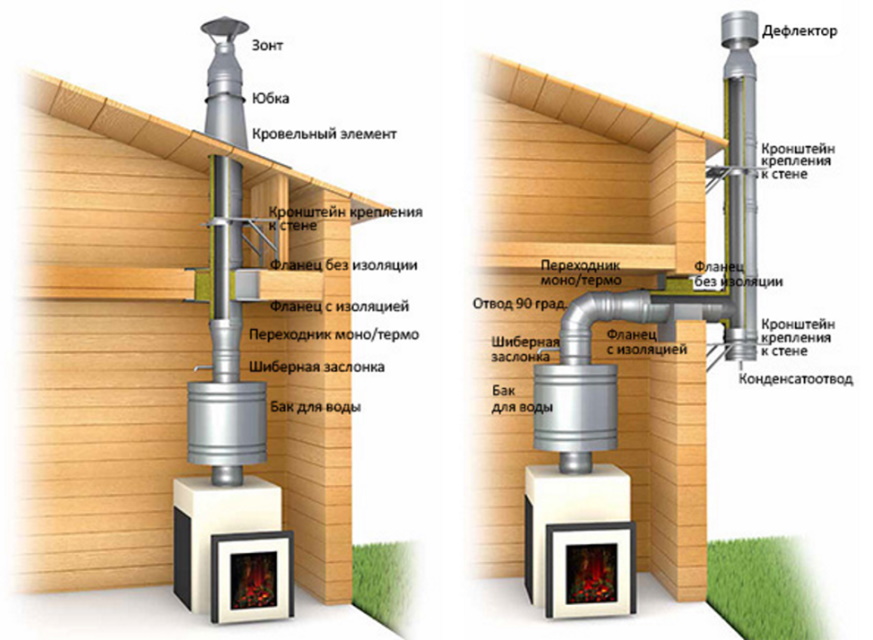

Structural elements

Stainless steel devices can be used to create flue gas outlets of any length, shape, with turns, bypasses and offsets. The creation of such structures is possible due to the presence of a wide range of components:

- A straight pipe is the basis of the structure along which smoke is removed, usually 33-100 cm long.

- Elbows at an angle of 45⁰ or 90⁰ - for vertical deviation or transitions between horizontal and vertical sections.

- Tees for 45⁰ or 87⁰ - for connection in areas of planned condensate collection.

- Condensate collector - installed at the bottom of a vertical pipe, collects water that appears in the process of cooling the smoke.

- Deflector - installed on the head to protect against the effects of precipitation and wind, helping to optimize traction, as well as increasing efficiency by about 20%.

- Clamp for stretching - provides reliable fixation of the system at an elevation of more than 1.2 meters above the roof and allows you to create structures with any height.

- Skirt - seals the exit section of the device from the roof, protects the connections of the chimney and the roof unit from precipitation, and also serves as a decorative decoration.

- Roof pass-through unit - installed for the passage of the roof.

- Connecting clamp - provides reliable docking of modular components to each other.

- Flange - isolates and protects combustible materials in areas of contact with the elements of the chimney.

- Mounting bracket - securely fastens the barrel to the wall surfaces.

- Revision - provides cleaning from soot and soot.

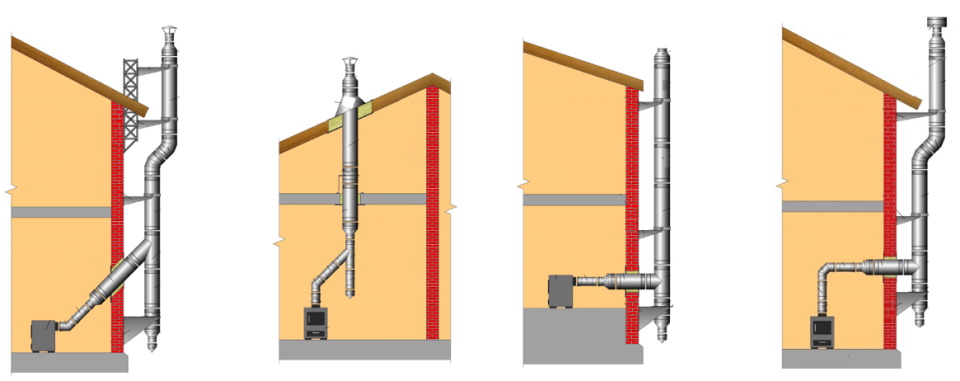

Laying methods

In a residential building, a chimney can be installed:

- Passage through the attic floor and roof.

- Only inside the building and with the removal of the walls.

- Bypassing interfloor ceilings with an output through the roof.

- With fixing to the walls or with support on the stove or boiler.

- Strictly straight or offset vertically.

The configuration is selected based on the location of the heating source, the layout of residential premises, individual design and architecture features.

A specific option is recommended for each case.

Advantages

The main advantages are in the basic parameters:

- universality of operation in any climatic conditions, incl. with the negative impact of the environment;

- resistance to increased loads, gusts of wind, precipitation, pressure changes, temperature changes, frost;

- heat resistance to high temperatures up to 1000⁰С;

- high anti-corrosion properties, non-susceptibility to condensation, oxidation, destruction;

- ease of installation, maintenance;

- modular design;

- the possibility of laying tracks with any configuration, diameter, length;

- can be installed at the initial stage of building construction or erected in finished structures;

- reliable fire insulation made of basalt wool;

- long service life (minimum 15 years) and guarantees in some cases up to 50 years;

- application of innovative technologies and equipment in the manufacturing process;

- acceptable cost;

- light weight that does not require the construction of a special foundation;

- high degree of fire safety;

- stylish design.

building codes

Basic rules for construction:

- The length from the top point to the grate can not be less than five meters. An exception is allowed for buildings without attics in the presence of stable forced draft.

- The optimal height with all possible bends is five to six meters.

- The gap between the chimney and the structure of combustible building materials should not be less than one meter.

- The horizontal outlet from the heat source must be less than one meter.

- For the passage of walls, ceilings, roofing for the arrangement of the channel, only non-combustible materials are used.

- The connection of metal elements is carried out only with a heat-resistant sealant having a working temperature of more than 1000⁰С.

- The elevation of the chimney above a flat roof must be at least 0.5 meters.

- In the case of the construction of a chimney above 1.5 meters above the roof, it must be strengthened with brackets and stretch marks.

- Any horizontal and sloping sections reduce traction.If the device cannot be made straight, then offsets and bends should be made from inclined components with a total slope of up to 45⁰.

- In the case of placing a chimney and ventilation shafts above the roof in one structure, a common cap is not placed above them. The smoke extraction must be higher than the ventilation, so as not to reduce the draft and not suck the smoke back into the room.

Criterias of choice

In order not to make mistakes when choosing, experts recommend paying attention to the following points:

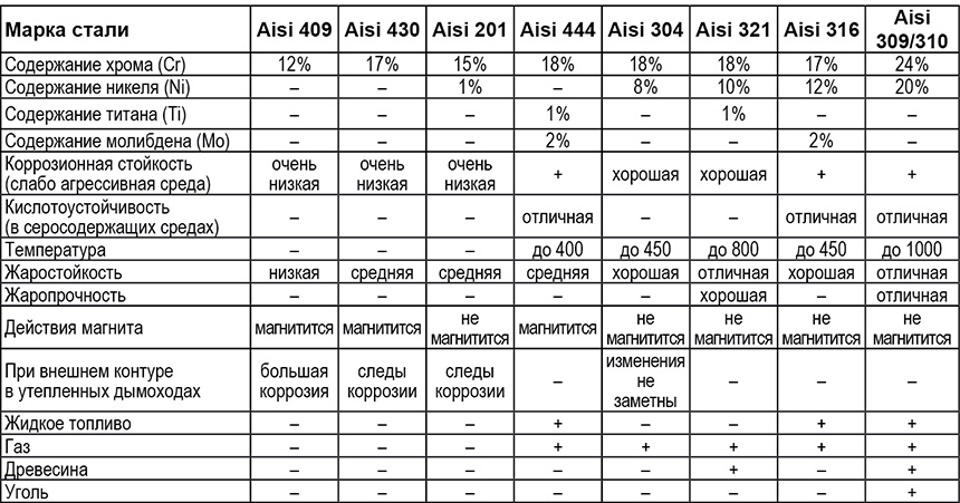

1. Characteristics of steel.

The brand determines the chemical composition suitable for the corresponding type of fuel:

- heat-resistant austenitic (AISI 310, 316, 321) - no need to replace after a few years due to through corrosion or burnout;

- ferrite (AISI 430, 439, 444) - save if necessary, but be ready to replace in a few years.

The main characteristics are presented in the table.

The thickness of heat-resistant austenitic steel for various heating units has the following optimal values:

- 0.5 mm - on diesel or gas fuel;

- 0.5 - 0.8 mm - on pellets;

- 0.8 - 1.0 mm - on wood.

2. Tightness is achieved only by laser welding or butt welding in argon atmosphere. In other obsolete cases (on a point or a fold), the desired result will not be obtained, and precipitation and condensate will flow into the sandwich heat insulator.

3. The presence of the correct basalt heat insulator - non-shrink or classic. Popular values of its thickness for heating units:

- 2.5 - 3.0 cm - low-temperature boiler or ventilation when passing the channel inside the room;

- 5.0 cm - low-temperature boiler or wood-burning stove outside the building;

- 10.0 cm - a powerful stove in the bath.

In the case of a free-flowing type (based on vermiculite or perlite), it will be necessary to install steel bridges between the inner and outer contours so that the material does not spill out. However, due to the redistribution of temperature, the meaning of the sandwich will then be lost.

Where could I buy

Popular models can be purchased in specialized departments selling heating equipment. Visitors are offered novelties from the best manufacturers with the opportunity to get acquainted with the characteristics, compare parameters. Consultants will give valuable advice - what are there, how to choose, which company is better to buy, how much it costs.

In addition, many offers are available for ordering online on the pages in the online stores of manufacturers or leading aggregators, such as Yandex.Market. There you can read the description in advance, study the diagrams and photos, see customer reviews.

The best stainless steel chimneys

The rating of quality devices is based on the opinions of users who have installed these designs. The popularity of models was determined by the number of positive reviews, functionality, technical characteristics, efficiency, durability, maintainability, as well as price.

The review includes ratings among the best stainless steel single-wall devices and sandwich products offered by leading manufacturers in the Russian market.

TOP 4 best single-wall chimneys

Rosinoks

Brand - Rosinox (Russia).

Producer - LLC "Dymokhod" (Moscow: plant - Moscow region, Klin).

Modular non-insulated stainless steel structures that allow you to create any configuration with a diameter of 13 to 18 cm.They are usually used in already built buildings, where a brick channel is allocated for the chimney. In this case, the steel pipe is used as a liner, which heats up quickly, providing a rapid overcoming of the “dew point” by the temperature of the exhaust gases. In this way, the efficiency of the heating source is significantly increased while simultaneously solving the problem of soot deposits. Manufacturer's warranty - 10 years.

The price of parts is from 148 rubles. (collar) up to 20,797 rubles. (silencer low-frequency 32 dB).

- universality of use with any heating equipment;

- quality performance;

- application of German technologies

- high performance;

- work in a wide temperature range;

- excellent indicators of vapor and gas impermeability;

- ease of maintenance;

- good maintainability with the possibility of both complete replacement and individual parts of the structure;

- fire safety;

- long service life;

- aesthetic appearance.

- not identified.

About Rosinox:

Phoenix Mono

Brand - Phoenix (Russia).

Producer - LLC "Phoenix" (Moscow region, Vidnoe).

A line of universal models of oval or round cross-section for lining existing stone chimneys or connecting a heating unit to the main duct. Non-insulated structures are placed inside heated rooms. Outside and in unheated buildings, the chimney must be insulated with heat-insulating non-combustible material. Stable traction and low soot formation are achieved by a smooth surface and sectional shape. The use of a single-wall construction reduces heat loss, reduces the formation of condensate, preventing the destruction of the brick pipe.Warranty period up to 15 years.

Main characteristics:

- steel grades: AISI 310, 316, 321, 409, 430;

- thickness, mm: 0.5 - 1.0 (depending on the heating unit);

- diameter, cm: 10 - 100;

- heat resistance: up to 1000⁰С.

The price of one element is from 357 rubles.

- completely sealed seam thanks to innovative TIG welding technology;

- the tightest connection of the socket system;

- a wide range of steel grades;

- quality performance;

- individual selection of material;

- versatility of use with different heating devices;

- high heat resistance;

- resistance to corrosion;

- geometry accuracy of parts;

- light weight;

- a large selection of accessories and parts;

- easy installation.

- The cost of a complete set can be quite significant.

Demonstration "Phoenix" at the exhibition:

ROSST IN

Brand - ROSST®IN (Russia).

Producer - PKF METKON LLC (Moscow region, Ruza).

A line of single-wall models made of stainless steel of various sections and with different thicknesses of steel. They are mainly used with boilers running on diesel fuel or gas. However, with a thickness of 0.2 cm, they are also used for fireplaces. The design includes not only chimneys, but also all kinds of functional modules - protection from precipitation, cleaning, thermal insulation. Components can be manufactured in any design forms and types that the company develops. Warranty period up to 25 years.

The price of one element is from 767 rubles.

- a large range of proposed systems;

- universality of application with any heating equipment;

- heat-resistant steel 0.05 thick; 0.1; 0.15; 0.2 cm, withstanding temperatures up to 600⁰С;

- resistance to condensate and soot fire;

- longitudinal welding seam;

- the tightest possible connection with a crimp clamp;

- a wide range of accessories;

- quality manufacturing;

- light weight;

- simple installation;

- stylish design.

- The price of the kit is very high.

Installation of ROSST IN for a gas boiler:

Craft series GS, HF, HF-P, HT

Brand - Craft (Russia).

Producer - LLC "Universal" (Voronezh).

Universal models are used both in large boiler rooms and collective heating systems, as well as in private use. They are suitable for any units that operate on different types of fuel. The modular structure with easy assembly makes it easy to assemble the structure regardless of the season. The implementation of a project of any configuration and complexity is carried out thanks to a wide range of fasteners and parts. The estimated service life is 100 years, the warranty period is 10 years.

The main characteristics are presented in the table:

| Series | GS | HF | HF-P | HT |

|---|---|---|---|---|

| Coloring | No | No | black color | No |

| Working temperature, hail. | 450 | 600 | 600 | 800 |

| Diameter cm | 13; 15; 50; 25 | 11,5; 12; 13; 15; 20; 25 | 11,5; 12; 13; 15; 20; 25 | 12 |

| Adapter diameters, mm | 10; 11; 11,5; 12; 14; 16; 18; 22; 23 | 10; 11; 14; 16; 18; 22; 23 | 10; 11; 14; 16; 18; 22; 23 | 11.5 |

| Recommended fuel | gas | coal, firewood | coal, firewood | firewood |

| steel grade | AISI 316L | AISI 316L | AISI 316L | AISI 310L |

| Thickness cm | 0.05 | 0.08 | 0.08 | 0.08 |

- the use of high-quality heat-resistant austenitic steel, not subject to corrosion, and also resistant to aggressive influences;

- versatility of use with any type of heating units operating on solid or liquid fuels;

- laser welding technology;

- thin weld

- production on an automated line;

- ideal shape geometry;

- low marriage rate;

- easy installation;

- high reliability;

- long service life.

- not detected.

Craft production:

TOP 4 best sandwich chimneys

Baltvent

Brand - Baltvent (Russia).

Producer - MSD Baltvent LLC (Kaliningrad).

The warmed models for work with heating units on various type of fuel. Used both outside and inside the premises. Design features do not allow the formation of condensate in large volumes. High performance properties are achieved by using an outer pipe made of austenitic steel AISI 304, and an inner pipe made of acid-resistant AISI 316, 0.5-1.0 mm thick. Basalt non-combustible wool Rockwool Wired Mat is used as insulation, which can withstand up to 1000⁰С.

Warranty period - 15 years, service life up to 25 years.

- the use of austenitic stainless steel, resistant to chemical and mechanical stress;

- sealed seam with TIG butt welding;

- double-sided technological ridge as an additional stiffener and fixing the system modules with a tightening collar;

- socket connections to improve tightness;

- quality assembly;

- fast installation;

- delivery throughout the country;

- stylish design.

- high shipping cost.

Baltvent production:

Ferrum

Brand - Ferrum (Russia).

Producer - LLC "Universal" (Voronezh).

The optimal range of double-circuit modular designs of economy class to work with any type of heating equipment with high efficiency and low flue gas temperature. Thanks to the standard set of elements, you can create a chimney of almost any configuration. 400 series stainless steel is used.The parts are connected to each other in a bell-shaped pattern, ensuring tightness. Diameter range: 80 – 300 mm. As thermal insulation, mineral wool with basalt fiber is used, which has a working temperature of up to 600⁰С.

- excellent functionality;

- excellent aerodynamic characteristics;

- the ability to change the route;

- quality assembly;

- operational safety;

- high tightness;

- easy installation;

- ease of maintenance;

- a wide network of dealers;

- durability.

- overcharge.

Double-wall "Ferrum":

Jeremias DW

Brand - Jeremias (Germany).

Producer - LLC "Eremias Rus" (Moscow region, Shchyolkovo).

Insulated and gas-tight stainless steel systems for gas, liquid or solid fuel heating units, condensing equipment, ventilation systems, furnaces, emergency generators.

Lineup designs:

- standard (DW-FU);

- budget with work under vacuum (DW-ECO);

- standard with silicone seal (DW-AL);

- universal with conical connection (DW-KL);

- universal with outside seal (DW-POWER);

- design without crimp collars (DW-VISION).

The main characteristics are shown in the table:

| DW-FU | DW-ECO | DW-AL | DW-KL | DW-POWER | DW-VISION | |

|---|---|---|---|---|---|---|

| Steel grade: | ||||||

| outdoor | AISI304 | AISI304 | AISI304 | AISI304 | AISI304 | AISI304 |

| internal | AISI316L | AISI444 | AISI316L | AISI316L | AISI316L | AISI316L |

| Surface | glossy | glossy | glossy | glossy | glossy (matte, textured) | satin (matte, glossy, painted) |

| Thickness: | ||||||

| outer, mm | from 0.5 | from 0.5 | from 0.5 | 0,5 - 1,0 | from 0.5 | from 0.6 |

| internal, mm | from 0.5 | from 0.5 | from 0.5 | 0,5 - 1,0 | from 0.5 | from 0.6 |

| Inner diameter, mm | 80 - 1200 | 100 - 300 | 80 - 1200 | 80 - 600 | 100 - 500 | 80 - 250 |

| thermal insulation | min. cotton wool | min. cotton wool | min. cotton wool | min. cotton wool | segmented min. cotton wool | min. cotton wool |

| thickness, mm | 32.5; 50 and 100 on request | 32.5 | 32.5; 50 and 100 on request | 32.5; 50 and 100 on request | 50 | 32.5 |

The warranty period is 25 years. The price of one part is from 182 rubles. (crimp clamp) up to 9,998 rubles. (tee 87° D130).

- versatility of the system for removing combustion products;

- a large list of diameters;

- resistance to condensation and soot ignition;

- a wide range of accessories and parts for laying various configurations;

- operating temperature up to 600⁰С;

- high tightness without additional seals;

- smooth surface;

- simple installation;

- light weight;

- attractive design.

- not found.

Jeremias chimneys with a twist:

Volcano

Brand - Vulkan (Russia).

Manufacturer - LLC "Dymohod" (St. Petersburg; plant - Leningrad region, Tosnensky district).

A model range of universal designs compatible with combustion products of any type of fuel (solid, liquid or gaseous) with equally good removal of exhaust gases and steam from various heating units: bath or home stove, fireplace, boiler, diesel power plant. It is installed both inside buildings and outside with fixing on the wall or to special masts. Thus, the system can be mounted depending on the characteristics of the room according to an individual project. For the manufacture of the outer contour, high-quality galvanized or austenitic steel AISI 304 with a thickness of 0.5-0.8 mm is used. For the inner contour - austenitic steel with a thickness of 0.5-1.0 mm grades AISI 316, 321 or 310 on request.Basalt wool 5.0/10.0 cm thick from the Finnish brand Paroc and the Danish company Rockwool is used as thermal insulation. Tightness improved with silicone ruts.

Warranty period up to 50 years.

- universality of application with various heating units and types of fuel;

- the use of acid-resistant heat-resistant grades of austenitic steel;

- high-quality fire-resistant thermal insulation;

- execution of docking profiles for socket connections;

- absolute tightness with geometric accuracy of docking units;

- high strength;

- light weight;

- long service life up to 100 years.

- not detected.

Installation "Volcano":

Features of self-assembly

Technically, it is not difficult to assemble a chimney with your own hands. In addition, there are many videos and step-by-step instructions on the Internet pages for performing basic actions. The construction kit consists of parts and accessories - steel pipes of various diameters with a layer of thermal insulation.

Assembly order:

- As a rule, the standard length of one segment is 100 cm. A part with a larger diameter is inserted into a part with a smaller diameter. The connection is made from the heater from the bottom up.

- A transition pipe up to 500 mm long or an adapter is installed on the heating unit. When outputting through a wall in a horizontal position, an outlet with a slope of 3⁰ is additionally placed.

- The adapter or adapter is connected to the first element, and then the installation of other pipes into each other is performed.

- Complete sealing is performed by joining two elements.

- The joints are carefully sealed with couplings, and with the help of clamps, the structure is securely attached to the wall.Installing support brackets every 1.5 meters will prevent possible system shifts.

Happy assembly. Take care of yourself and your loved ones!

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131651 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127690 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124518 -

The best men's sneakers in 2022

Views: 124033 -

The Best Complex Vitamins in 2022

Views: 121939 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114980 -

The best paint for gray hair - top rating 2022

Views: 113395 -

Ranking of the best wood paints for interior work in 2022

Views: 110318 -

Rating of the best spinning reels in 2022

Views: 105329 -

Ranking of the best sex dolls for men for 2022

Views: 104366 -

Ranking of the best action cameras from China in 2022

Views: 102215 -

The most effective calcium preparations for adults and children in 2022

Views: 102011