Rating of the best diesel burners for 2025

In the operation of the units, everything has its own certain period of operation. And heating boilers, the durability of which is difficult to doubt, eventually begin to become obsolete both technologically and morally. Replacing a heating boiler is a very serious expense item that hits the wallet very significantly. But you want to install a modern, cost-effective, environmentally friendly device for heating a residential or work space. And there is a way out!

If it is problematic to replace a completely outdated boiler, then you can achieve the desired results if you put new burners on it. Such a procedure will not only increase the service life of the heating boiler, but will also be able to provide an increase in fuel economy and an increase in efficiency.

Content [Hide]

Burner for heating boiler. What is it and why is it needed?

This is a device for mixing an energy carrier with air masses and then burning the mixture. At the same time, it burns exactly the amount of fuel that is necessary to obtain maximum efficiency and with low emissions of harmful substances.

The final performance of the heating boiler depends on the efficient operation of the burner product. Based on this, all modern burners have automation with safety control and control of the combustion of the fuel mixture.

How to choose?

- Devices differ from each other in the type of fuel that is burned in boilers. They are universal, gas, combined, and liquid fuel. When choosing a burner for a boiler, you should initially focus on the type of fuel. For gas burners are designed to burn gas, and liquid fuels usually work with diesel. Well, universal ones are used in both cases.

- Boiler type. When choosing a burner, it is necessary to take into account its compatibility with the boiler.

The universal and liquid fuel boilers have an increased combustion space, they are equipped with flame deflectors and gate valves with improved permeability and a large control range.Here a more suitable option is long-flame burners. In gas boilers, there is a small combustion space, there is no adjustment of the air supply, so complete combustion of gas is necessary in any case. Short-flame burners have been developed for them. - By power. Another of the selection criteria is the power of the burner itself. The power is determined by the heat introduced into the furnace space, which is equal to the product of the volume and the heat of combustion of the energy carrier. Based on the results of the analysis of calculations, the power of the heating boiler is determined. A burner is selected for it with the expectation of a loss of 15-20%. As a result, the burner power is selected in accordance with the calculations. At the same time, savings are obtained as a result of competent adjustment and proper maintenance of the boiler. If you install a burner with reduced power, the coolant will not be able to warm up enough. Excessive power will lead to the release of unburned fuel into the environment and the deposition of soot in the chimney.

- By type of automatic control. Automation is manufactured by equipment manufacturers for certain types of boilers. Usually, the buyer has the choice and opportunity to purchase a burner equipped with the automation he likes.

- The adjustment range of the mounting plate is a parameter that must also be taken into account when choosing. The higher the working regulation coefficient, the greater the range, and accordingly such a burner model is more attractive.

This article will focus on liquid fuel burners, in particular devices that run on diesel fuel.

Oil burners for heating boilers

These are devices that use liquid fuels for operation, such as various fractions of petroleum products or biofuels, waste oil.But the most popular are devices that use diesel fuel.

Advantages of a liquid fuel burner and its advantages over gas

If connecting to a gas main is a problem for you, or if it is a long-term project, then an oil burner is a worthy option, and sometimes the best alternative. One of its important advantages is that the output thermal power is a constant value. In addition, the capital costs for installing diesel heating systems are disproportionately lower. And the availability of diesel fuel: gas stations offering diesel are much more common than those with liquefied gas. And the disadvantage is the high price of organic fuel compared to the cost of natural gas. And the prices for liquid-fuel devices themselves, due to the peculiarities of their design, as a rule, are significantly higher than gas ones.

Of course, it is preferable to install gas analogues. But in the absence of gas supply lines or frequent interruptions, diesel burners are an almost indispensable option.

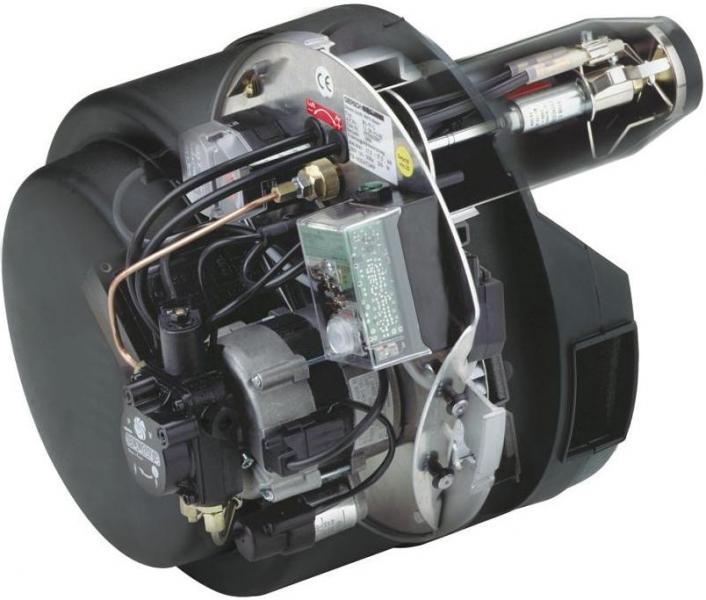

Diesel burners are pressurized. Therefore, they are characterized by the advantages and disadvantages that are inherent in pressurized gas appliances.

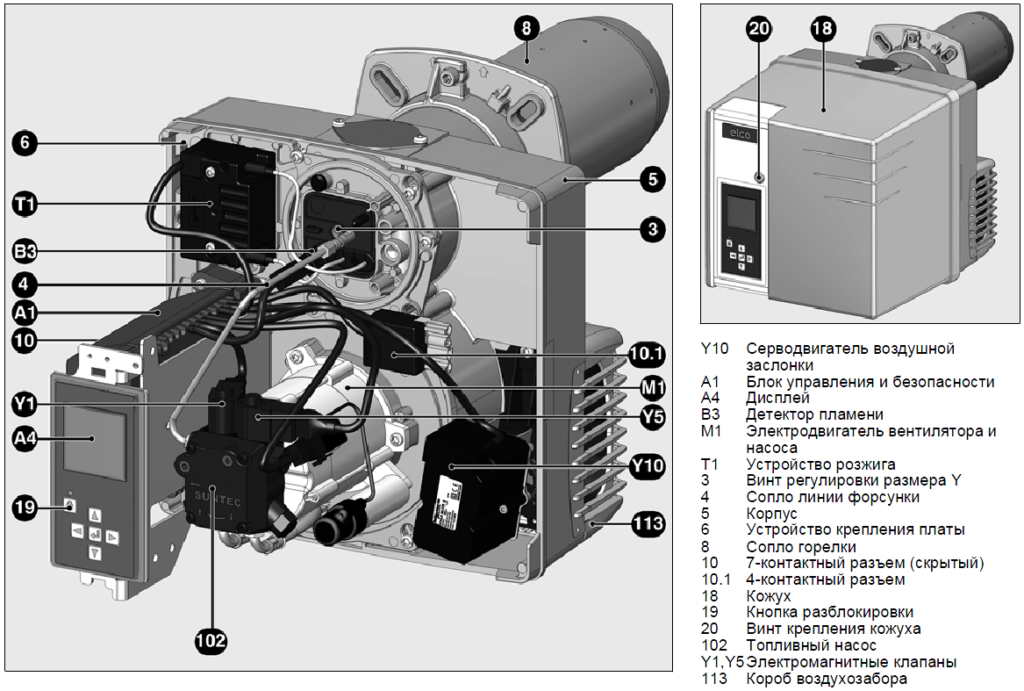

How it works in a nutshell

After the "start" command, the engine is turned on, the fan starts and the fuel pump starts to work, supplying a pressure of 10 - 15 bar, for the normal spraying of diesel fuel by the nozzle. At the next stage, the ignition transformer supplies an electrical load to the electrodes responsible for ignition. This is followed by the operation of the solenoid valve that supplies diesel to the nozzle for spraying. After the ignition of the fuel, the diesel supercharged burner switches to the nominal mode.If ignition does not occur, the burner is automatically blocked.

Normal and uninterrupted functionality requires strict adherence to the prescribed recommendations and rules of the instruction, so it is better to entrust the design and installation to specialists.

Types of combustion devices

All diesel burners that are on offer in the modern Russian market are divided into single-stage, two-stage, as well as modulating:

- Single stage - the most common. They have a simple design, resulting in a high degree of reliability and relative durability. They work in the same mode - at full capacity. Heating is limited as a result of turning the device on and off (usually, when cooling by 3-5 ° C).

- Two-stage - operate respectively in two modes: at full and at half power. Automation elements switch the operating modes of the boiler. The prices of such units for boilers are significantly higher, but the products are also designed for higher power. There are also smoothly two-stage devices, their power can be changed within 40% - 100%.

- Modulated. These are technologically sophisticated products, and therefore their price is high. Such liquid fuel burners are purchased mainly to equip heating systems for industrial buildings. These devices help to significantly save diesel fuel due to the optimal power output from 5% to 100%.

Diesel burners of heating boilers popular with consumers

Diesel burners Lamborghini

votes 0

The equipment for supplying heating to living and working premises of the Italian manufacturer Lamborghini Caloreclima is quite well known to the domestic consumer. Burners for boilers and air conditioners of the company have invested a drop of Italian warmth and comfort in the harsh climate of Russia.

The Lamborghini Calor research and production complex sees its future in intertwining the development of new technological developments with the expansion of the production range without compromising the strict control of its quality.

An important direction of production in the heating sector is the production of not only industrial, but also household diesel burners of low power from 16.6 kilowatts. Lamborghini burners are widely used in places with no gas supply.

The most popular series of Lamborghini diesel burners are ECO and LMB LO.

Burners with one stage are produced from 16.6 kW to 356 kW of power, two-stage burners are noticeably more powerful - from 83 kW to 585 kW.

They fit perfectly with all types of boilers thanks to their universal flange mounting. Almost complete combustion of diesel, minimal carbon monoxide emissions into the environment, thermal efficiency, high efficiency - these are the components that are inherent in Lamborghini burners.

A diesel two-stage burner from the manufacturer will be the best option for a boiler room in a small industrial premises, and products with one stage are perfect for a home autonomous heating system.

Lamborghini Calor Eco 3

votes 0

Lamborghini ECO 3 diesel single-stage, with a minimum level of noise, provides good efficiency and high environmental friendliness of the combustion process. It is installed in heat generators, heat guns, water heating boilers, etc. In the process of diesel combustion, the heat output is obtained under conditions close to ideal combustion.

Price — 48 834 ₽

Distinctive qualities:

- single-stage combustion;

- manual regulation of the air damper;

- damper with automatic shutter reduces heat loss when the device is turned off;

- there is a fan on the air supply;

- self-priming fuel pump;

- the shape of the combustion head gives excellent diesel combustion and low emissions of combustion products;

- automation is equipped with a control system for maximum safety;

- the casing acts as a sound insulator, as a result, the operation of the product is as quiet as possible;

- all components and parts of the device are easy to inspect without turning off the energy supply;

- installed on the boiler through a flange with a universal bore for boilers of various manufacturers;

- independence of the flange from the boiler body allows quick maintenance;

- the method of connecting electrical components eliminates the error when connecting;

- you can adjust the combustion head during boiler operation to achieve optimal combustion of diesel fuel;

- The kit includes a flame control photoresistor and an ignition electrode.

Automation functions

- fan control;

- control of the presence of a flame;

- cleaning of the combustion chamber before and after the working cycle.

- high efficiency;

- economical consumption of diesel fuel;

- service availability;

- autonomy of work;

- low noise level;

- workflow automation.

- high cost relative to gas;

- unregulated power.

Lamborghini LMB LO 1000 (2 st.-BL)

votes 0

Lamborghini LMB LO 1000 (2 st.-BL) is a digitally controlled two-stage diesel burner with high diesel combustion efficiency and low noise level. The presented device is ideal for installation in boiler rooms of medium and high power.

Price - 242,866 rubles.

Distinctive features of the device:

- two-stage, with an extended fire tube;

- low pollution emissions;

- suitable for inflatable boilers;

- the combustion head is regulated by a shutter;

- the air damper has an electric drive;

- ventilation is stabilized;

- optimal combustion is achieved through uniform distribution of the supplied air;

- the control panel displays the operating mode, codes for blocking and anomalies that occur;

- LCD display;

- safety valve;

- the ability to connect the pump;

- displaying the archive of failures in operation;

- protection in case of power surges;

- accounting of total hours;

- display of the total diesel consumption;

- display of flame intensity;

- adjustable postpurge time;

- electrical protection class IPX4D;

- simplified installation and easy maintenance.

- high percentage of efficiency;

- economical fuel consumption;

- two-stage;

- ease of maintenance of equipment;

- autonomy;

- reduced noise level;

- low emissions into the atmosphere;

- process automation.

- high price of the device.

Giersch burners (Hirsch)

votes 0

The German company Giersch produces fan diesel burners for pressurized heating boilers.

Giersch combustion devices show quality and excellent reliability in operation. The accelerated and safe start is provided with high quality of functioning of the equipment. The uniqueness of the system for regulating the supply of energy and the mixing mechanism allows you to immediately set the product to the desired mode. The exceptional quality and reliability of Hirsch liquid fuel burners are the result of a successful design decision by manufacturers of heating equipment. German order always reigns under the burner casing, provided with a competent design of technological equipment.

The capacities of various products range from 14 to 15,000 kW. The manufacturer offers the widest range of products with automatic and semi-automatic devices. When choosing the necessary equipment, it is necessary to study in detail the technical operating conditions without fail, and decide for what purposes different types of burners are intended.

Diesel single-stage Giersch R1-V-L

votes 0

The R1-V-L is designed for extended applications in small boilers in small single family residences, air heaters, dryers and baking ovens.

The R1-V-L is designed for extended applications in small boilers in small single family residences, air heaters, dryers and baking ovens.

The R1-V-L is equipped with modern blower technology. As a result of the increased air pressure, a safe, stable start-up of the equipment and a low emission level are ensured. The accuracy of the mixing mechanism ensures optimal mixing of diesel fuel with air. A feature of the single-stage version is the unique double air supply regulation system. The amount and pressure of air can be set with a single screw.

Beneath the rounded housing cover, the internal components are conveniently located for maintenance. All electrical connections are equipped with connectors. The defining detail of a well-thought-out design of the device is the service position, in which the burner finds itself when the shutters are opened. In it, all working elements, from the fan wheel to the disk with ignition electrodes, are freely available.

Price - 104,028 rubles.

- excellent efficiency;

- economical fuel consumption;

- ease of maintenance of equipment;

- autonomy in work;

- low noises;

- low emissions of spent combustion products;

- reliable process automation.

- high price;

- power is unregulated.

Two-stage diesel Giersch R30-Z-L

votes 0

The Hirsch R30-Z-L device has a power range of 95 - 273 kilowatts, designed for heating areas up to 2500 m². Increasing power and switching the burner is soft and smooth. Liquid fuel (diesel fuel) is used as an energy carrier, the viscosity of which should not exceed 1.5°E at 20°C. The model comes with an aluminum alloy body. The flame tube in the combustion chamber can be installed at any depth thanks to the sliding flange of the boiler. Installation of equipment is also possible both vertically and horizontally. The burner tube mixing device and the high-performance fan enable precise optimization of the combustion process of the supplied fuel.

You can buy a Giersch R30-Z-L diesel burner for boilers whose power does not exceed 250 kW. Price - 210 588 rubles

- excellent efficiency;

- two-stage;

- economical consumption;

- serviceability;

- autonomy of work;

- reduced noise level;

- low emission parameters;

- full automation of the process.

- high cost of equipment.

Baltur diesel burners

votes 0

Burner devices manufactured by Baltur are intended for hot water and steam heating boilers, air heating systems, used in drying chambers and technological furnaces. Solar oil burners are designed so that the output heat energy is generated by producing a mixture of fuel and air.

Baltur universal devices can be installed on heating boilers of different classes. The burner nozzles have a special shape, thanks to which the heated air-diesel mass circulates evenly.Diesel fuel is supplied from the fuel tank through an integrated pump. The burner product is equipped with a control system that controls the exact portions of the diesel and air supply.

BALTUR BTL 3 H (16.6-42.7 kW)

votes 0

These single-stage oil burners are characterized by high efficiency and low exhaust emissions. In the Baltur burner, stable combustion of the fuel mixture is observed. The product is equipped with a high-pressure fan, which makes it possible to work with increased resistance in the boiler combustion chamber. Price - 64 646 rubles.

These single-stage oil burners are characterized by high efficiency and low exhaust emissions. In the Baltur burner, stable combustion of the fuel mixture is observed. The product is equipped with a high-pressure fan, which makes it possible to work with increased resistance in the boiler combustion chamber. Price - 64 646 rubles.

Specifications:

- - capable of working with any combustion chamber of boilers;

- — for light oil products;

- — mechanical atomization of pressure of combustible material;

- - maximum combustion by regulating the air in the blower pipe and in the combustion chamber;

- — simplified management: removal of the spraying unit without dismantling the device from the boiler;

- — manual flow control.

- high efficiency;

- ease of maintenance of equipment;

- economical consumption of diesel fuel;

- autonomy in work;

- low noise level;

- process automation;

- low level of pollution.

- unregulated power;

- high price relative to gas devices.

BALTUR SPARK 35 DSGW (178-391 kW)

votes 0

These 2-stage diesel burners are universal and can be used with various types of boilers. Burner nozzles of this brand provide uniform atomization of the air-fuel mixture. The power of the SPARK 35 DSGW product (up to 391 kilowatts) allows it to be installed on boilers that provide heating for medium-sized residential and industrial buildings. Price - 157,248 rubles.

Design features:

- - the flow is regulated for the first and second stages by an electric servo motor with a valve closing delay, which prevents heat loss into the chimney;

- — fan blades are made of aluminum alloy;

- - fan - centrifugal, highly efficient;

- - automatic closing of the damper;

- — coupling flange for fastening the boiler with head adjustment for different types of burners;

- - adjustable air pipe with a nozzle;

- - the deflector disk is made of steel;

- — the electric motor of the fan and the pump monophasic;

- - gear pump with pressure regulator;

- - diesel stop valve;

- – automatic control and management complies with European standards EN230;

- - checking the presence of a flame with a photoresistor;

- — level of electrical protection IP40;

- — a protective cover with a noise-absorbing mat.

- high efficiency;

- two-stage;

- economical consumption;

- ease of care and maintenance;

- complete autonomy;

- almost silent operation;

- low emissions of gases into the atmosphere;

- workflow automation.

- plastic case cover;

- high price of the device relative to gas counterparts.

Results

Diesel burners of heating boilers have long been widely used in individual and industrial heating systems. Since the system is autonomous and independent of access to mains gas and electricity, it is used both for main heating and as a reserve. In the event of a power outage or gas outage.

In order to select the most suitable model of a diesel burner for a particular case, it is necessary to have at least a general idea of the possible design options for the product.As with gas burners, power control systems and air (oxygen) supply methods play a key role here.

Good luck choosing!

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131649 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127688 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124516 -

The best men's sneakers in 2025

Views: 124030 -

The Best Complex Vitamins in 2025

Views: 121937 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114978 -

The best paint for gray hair - top rating 2025

Views: 113393 -

Ranking of the best wood paints for interior work in 2025

Views: 110317 -

Rating of the best spinning reels in 2025

Views: 105327 -

Ranking of the best sex dolls for men for 2025

Views: 104363 -

Ranking of the best action cameras from China in 2025

Views: 102214 -

The most effective calcium preparations for adults and children in 2025

Views: 102010