Rating of the best woodworking machines for home and garden for 2022

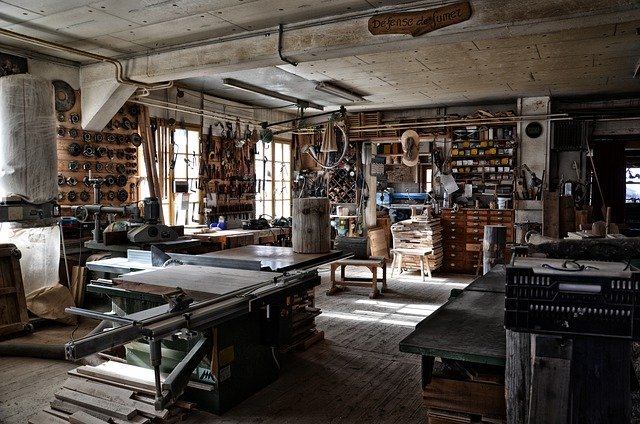

Home craftsmen create exclusive wooden items in carpentry workshops that are not inferior in quality and aesthetic appearance to factory products. They are produced, of course, with the use of great talent and subtle taste of the creator on specially selected equipment, which allows to bring the idea to life.

Content [Hide]

- 1 Capabilities of household and industrial equipment

- 2 How to choose the right equipment

- 3 Criteria for choosing milling equipment for summer cottages and at home

- 4 Rating of popular models of sawing machines

- 5 Rating of high-quality planer-thickness equipment

- 6 Rating of quality manual milling equipment

Capabilities of household and industrial equipment

Modern woodworking machines are high-performance devices that can be both universal and highly specialized. But they all have a number of advantages over manual processing:

- ultimate dimensional accuracy;

- high processing speed;

- high productivity per unit of time;

- high quality of the product;

- safety during processing;

- reduced noise level;

- ease of operation.

Processing equipment can have a narrow focus, there are also models with combined functionality to perform different tasks. How to choose exactly the device that best suits your goals?

There are several types of carpentry devices:

- sawing - cuts workpieces longitudinally, transversely, curvilinearly;

- pressing - makes materials from wood;

- planing - levels the surface of a wooden workpiece, profile-planar processing;

- drilling - creates holes of various sizes;

- milling - profiles elements, processes the contour and aesthetically improves the part;

- grinding - polishing parts.

How to choose the right equipment

A multifunctional machine for the home will cost less than a professional one. But it’s worth thinking about which company’s device is better to buy if the equipment is used frequently, for example, by a carpenter who is engaged in woodworking on an ongoing basis. For one-time work, you can purchase a machine with fewer options and cheaper.

When releasing serial products of the same type, the multifunctional device will not be fully involved, so you should think about buying a specialized professional unit. In addition, such models have greater accuracy and better performance than devices with many options.

Before buying equipment, analyze the amount of work that will be performed on it. Otherwise, the mechanism will not cope and breakdown will occur. Too much power of a professional device at a low load will also be expensive. The higher the power, the more expensive the mechanism.

Household woodworking machines

Specially designed and designed to work at home, at home, in the garage, in the country. They have compact dimensions, are additionally equipped with a worktop for convenience, operate from the mains, do not require special knowledge and are easy to operate, they can be purchased relatively cheaply, in comparison with professional samples.

- Stationary equipment is heavy and bulky and requires a separate room.As a rule, the manufacturer equips the unit with additional options for the convenience and safety of the process: clamps, chip removal, various stops, as well as a set of accessories for different types of work. Stationary mechanisms often have several engines - electric, gasoline, diesel, with a power of 3-5 kW. Such units are perfect for professional carpenters involved in woodworking at home.

- Desktop amateur machines, with a power of 0.9 to 3 kW, perform one, maximum two functions. But these models are inexpensive and are quite suitable for home use.

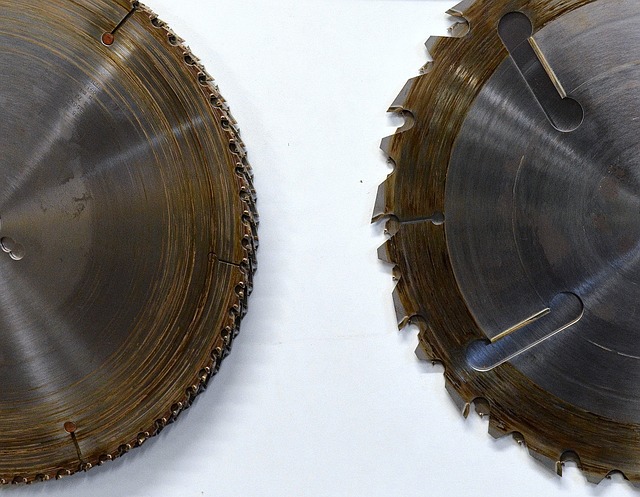

Sawing machine

It is used for cutting lumber, fiberboard, chipboard, wood of various hardness. The mechanism allows you to cut a wooden blank according to the desired dimensions along the longitudinal and transverse lines.

It is a frame with an electric motor and a saw element of various types:

- strip saw - a special frame of the saw element requires a large room, this type of equipment is suitable for large sawmills;

- circular saw - provides a neat thin cut without nicks and chips, and the mechanism can be equipped with several cutting edges for longitudinal sawing and increasing the speed of work;

- flexible saw - wire, band or chain saw elements provide high-quality cutting of workpieces, high processing speed, smooth cut, low noise level and safe operation.

Sawing equipment can be divided according to the type of construction. High-power stationary equipment is expensive, mechanisms with an extending table of the middle price category can be installed in small workshops, desktop units of small dimensions are perfect for homework.Low functionality is offset by an affordable price.

The following selection criteria should be taken into account when choosing a suitable sawing equipment option:

- Depth of cutting workpiece. Household appliances have a different range, so choose the right indicator based on the processing material.

- Cutting width. The lower this indicator when working with valuable wood species, the less waste is generated during work.

- Disk rotation speed. The higher the speed of the saw element, the higher the productivity.

- Setting options. Additional workpiece clamps and graduated rulers greatly facilitate the work of the master.

Planer-thickness equipment

Planing or planing machines are used for straight planing and leveling the plane of the workpiece, thicknessing equipment calibrates the board in thickness and makes the edges of the workpiece parallel.

It is very difficult to have two machines at home, both in terms of space, maintenance required and price. A novelty of manufacturers can be considered compact jointer-thickness machines that perform two operations at once.

Professional and domestic models of jointer-thickness equipment

The device has a cutting mechanism with 2, 3 or 4 knives, the same for planer and planer section. When a wooden block is fed in one direction, the machine planes and levels the surface. When the workpiece is fed in the opposite direction under the table, the equipment works like a thicknesser. The advantages of such a unit are obvious. Work can be carried out in a limited space, the machine is cheaper than a couple of mechanisms, and the quality of processing meets all standards.

Industrial and domestic models differ in size, power and working base, on which the width of the workpiece depends.Professional equipment is bulky, made of heavy cast iron and requires a three-phase 380 V output to connect it. Home installations are suitable for a 220 V power supply, lower in price, while, according to buyers, they are not inferior in quality to professional options.

If you purchase a device for a few works, you will use it only occasionally, the first thing you should pay attention to when choosing is cheaper models of a household group. If your work volumes involve heavy loads, choose an industrial machine with a powerful electric motor, a wide working base and high productivity.

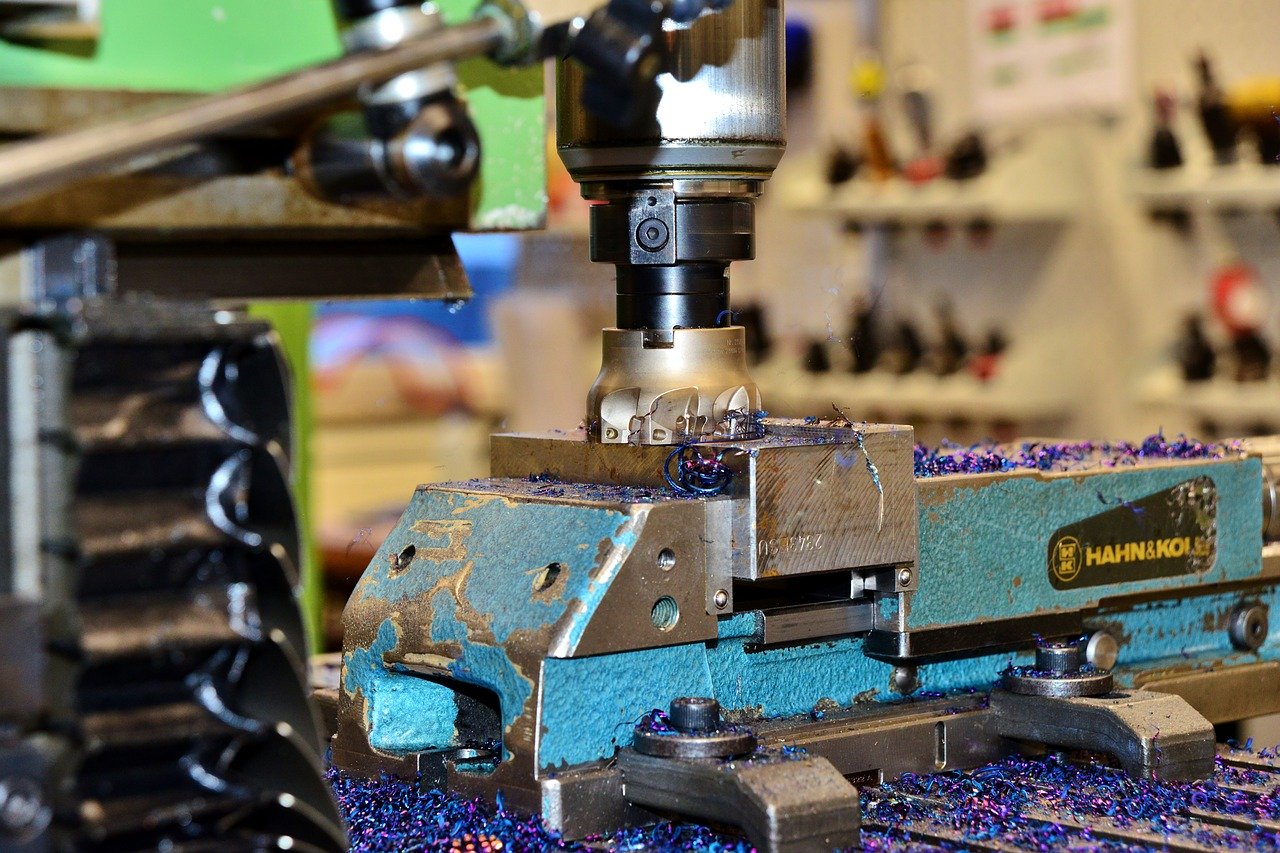

Milling machine

Turning and trimming wood with complex designs, curly cuts, edge rounding, drilling grooves are just a small part of what a cutter can do.

The market presents a wide variety of mechanisms from the best manufacturers and unknown novelties, differing in design, set of functions, principle of operation and a wide range of prices.

- A hand router is a compact electric tool, and inexpensive. It is impossible to process large batches on it. If you fix the main mechanism on the countertop, the hand tool turns into a full-fledged machine.

- CNC machines perform many operations on the processing of workpieces. The "smart" processor and operating system are responsible for the accuracy of work, therefore, it is possible to produce small, filigree details on such a device.

- Household desktop models have a full-fledged countertop surface. The mechanism copes with wood of varying hardness, can grind complex and small parts, souvenirs, grooves and holes on blanks.

- Vertical (submersible or rod) milling unit is a universal type. Copes with turning holes, grooves, processing edge planes, chamfering and countersinking.

- Copiers create exact copies of wooden blanks, even complex shapes. They are purchased by craftsmen involved in the creation of souvenirs, as they have a narrow focus.

- The edging (trimmer or edge) highly specialized mechanism is designed for making grooves, grooving, deep grooves, capable of accurately processing laminated or veneered parts.

- Rotary mechanism cuts holes in wood, drywall, and other materials, can process the edges of the product.

- The lamellar device is used only for the manufacture of grooves.

- The filler mill is used in furniture production to create paired holes.

Criteria for choosing milling equipment for summer cottages and at home

For the correct selection of the unit, the following technological features should be considered:

- The frame (steel, aluminum, cast iron) actively dampens the vibration that occurs during the operation of the mechanism. The larger and more massive the mechanism, the less vibration occurs during operation. When choosing a home option, do not forget that in conditions of limited space, the lighter the bed, the more mobile it is.

- Working surface. Your choice of the right size should depend on the type of product being produced. If it is small, then the desktop can be from 40 to 90 cm. In door production, it is better to purchase models with an increased surface of up to 130 cm.

- Engine power.In the manufacture of large cabinet furniture, it is worth choosing equipment from 5.5 kW, with frequent processing of large parts, a mechanism up to 3 kW is useful, for infrequent use at home, a 1.5 kW engine is suitable.

- Engine type. The stepper motor is installed in inexpensive models. The disadvantages are the lack of electronics, they are also inferior in accuracy and smoothness to another type of engine. The crescent type is more expensive, but has maximum precision and smooth movement in the process.

- Number of axles. Simple routers process the blank in three axes, more complex designs provide the ability to create relief in four or five directions, and the tool head has greater freedom of movement.

- Nozzle replacement. The best professional and semi-professional models have a nozzle store with several types of cutters to speed up the work process. If you change nozzles, any milling device will rarely work.

- Working voltage. For home use, it is better to purchase a mechanism with a 220 volt connection, but it will have less performance.

Where to buy the right mechanism? Take a closer look at the device in a retail store, feel its weight, ergonomic shape, as the device is rather big, and it takes a long time to work with it. At the same time, it is worth remembering that ordinary stores are limited in space, so make the final choice in the online store. There you can easily compare the options of the models you like, order online, pay and receive your purchase at a reduced price.

In our article, we examined the main features of popular woodworking devices. Based on the recommendations and customer reviews, a comparative rating was compiled for different types of machines.We hope that this review will help you understand what units are and how to avoid mistakes when choosing the right mechanisms and components.

Rating of popular models of sawing machines

| PARAMETER | BLACK+DECKER BES720-QS | BOSCH GTS 635-216 | HAMMER MFS900 |

|---|---|---|---|

| Power, W) | 1800 | 1600 | 900 |

| rotation speed(r/min) | 4800 | 5500 | 8500 |

| sawing element | disk | disk | disk |

| cutting height(mm) | 80 | 70 | 43 |

| Weight, kg) | 30 | 22 | 8 |

| approximate price (rub) | 16990 | 29499 | 9229 |

Sawing machine BLACK+DECKER BES720-QS

votes 2

Equipment with a flat, expanding cast table, stiffeners and stable strong legs has a cutting disc with a diameter of 254 mm. The parallel stop is clamped on both sides. The body of the mechanism is made of durable plastic with a metal insert for the disc.

The manufacturer gives two years of warranty service.

- with engine braking function;

- the ability to connect a vacuum cleaner;

- dust bag included.

- no soft start;

- there is no instruction in Russian.

Sawing machine BOSCH GTS 635-216

votes 1

The mechanism with a cutting disc with a diameter of 216 mm works neatly, creates a clean cut, draws small chips into the dust outlet, which is easy to clean. The compact body is made of thick, durable plastic. The working surface 500*658 mm has no additional extension.

In addition, there is a 12 month manufacturer's warranty.

- there is a soft start;

- vacuum cleaner connection function.

- high price.

Sawing machine Hammer MFS900

votes 2

The cutting disc with a diameter of 165 mm cannot change the angle of the cut, it cuts only at an angle of 90º.The supporting surface of 300*227 mm and the compact dimensions of the main mechanism make it possible to use it even in a limited space, as well as to easily transfer it from one place to another.

The popularity of the model is explained by the rich additional equipment: a spare set of carbon brushes, a wood disc, a diamond disc for ceramic tiles, a polishing disc, a water supply device, and a dust collector.

The device has the function of connecting a vacuum cleaner, during operation, small particles are collected in a dust collector.

- large additional equipment;

- smooth speed control;

- budget price.

- no.

Rating of high-quality planer-thickness equipment

| PARAMETER | JET JPT-10B 707410M | ZUBR SRF-254-1600S | METABO HC 260 WNB |

|---|---|---|---|

| Power, W) | 1500 | 1600 | 2200 |

| number of knives | 2 | 2 | double knives |

| max depth of planing (thickness/planing)(mm) | 2/3 | 2/3 | 3 |

| max cutting height(mm) | 3 | 3 | 3 |

| speed (rpm) | 9000 | 9000 | 6500 |

| Weight, kg) | 34 | 33.5 | 71 |

| approximate price (rub) | 35000 | 25839 | 89499 |

Planer and planer JET JPT-10B 707410M

votes 0

The 1.5 kW motor operates from a standard voltage of 220 V. The length of the table is 945 mm and makes it possible to work with large workpieces. The main surface is made of die-cast aluminum sheet, highly polished and resistant to wear. The thicknessing table is easy to set up with a special handle, it also allows you to control and adjust the depth of cut and the thickness of the board. The rip fence can be set at an angle of 0-45º and allows planing with a certain inclination.

In case of overload and critical temperature, the motor will automatically turn off.The small weight of the machine can be moved independently, while the rubber pads on the legs do not scratch the floor.

- temperature sensor;

- compact size.

- knives require frequent sharpening.

Jointing and thicknessing machine ZUBR SRF-254-1600C

votes 1

A Russian-made device with a maximum power of 1.6 kW can process wood up to 254 mm wide and 120 mm thick, so it is suitable for the manufacture of wooden furniture. The manufacturer has provided for the automatic advancement of the board during the thicknessing process, which facilitates the work of the master.

Cast tabletop polished, resistant to deformation. High speed blades can cut soft and hard wood species. The dust collector changes an arrangement for comfortable work. The device is mounted on a stand, it can be installed both on the floor and on the table.

- the possibility of processing non-standard blanks;

- blocking of inclusion at shutdown of the electric power.

- no.

Jointer and planer METABO HC 260 C WNB

votes 3

The worktop of the Japanese brand is made of cast iron, resistant to wear and damage. The movable handle makes it easy to set the desired height of the mechanism. Easy changeover from planer mode to planer mode.

Knives with double blades have a long service life, easily cut even hard rocks. The universal motor ensures uniform feeding of parts and high quality planing. The induction motor does not require constant maintenance and has a low noise level.

- blocking unintentional start during power outages;

- transport wheels.

- high price.

Rating of quality manual milling equipment

| PARAMETER | DeWALT D 26204K | Interskol FM-40/1000E DM | Hammer FRZ1200B |

|---|---|---|---|

| power consumption (W) | 900 | 1100 | 1200 |

| max milling depth(mm) | 55 | 44 | 55 |

| max cutter diameter(mm) | 36 | 30 | - |

| rotation speed (minimum / maximum) (rpm) | 16000/27000 | 10000/25500 | 16000/30000 |

| Weight, kg) | 2.9 | 3.1 | 4.3 |

| approximate price (rub) | 22570 | 5030 | 4089 |

Milling cutter DeWALT D 26204 K

votes 1

The vertical type milling machine maintains a constant speed under load. The presence of a revolving stop allows you to process a deep groove in several stages. Spindle lock facilitates quick and easy cutter replacement. The edge sole changes to round for subsequent installation on the table. The dust collector helps to remove small particles from the workpiece in a timely manner.

In a convenient suitcase made of thick plastic, according to the description of buyers, the device and two additional parallel stops, two vacuum cleaner adapters, two bases are placed. The manufacturer provides additional service for a 3-year warranty period.

- wide equipment;

- light weight;

- illumination of the working area;

- comfortable design.

- high price;

- no milling depth microadjustment scale;

- low power.

Milling cutter Interskol FM-40/1000E DM

votes 1

Russian-made branded equipment has rotation adjustment, a turret for changing the depth of the groove, as well as spindle fixation. Included with the main mechanism are 6 and 8 mm collets, a flat and roller copier, parallel guides - 2 pcs., A ruler.

It is possible to connect the vacuum cleaner to the dust removal adapter for cleaning from small particles.The manufacturer provides a 24 month warranty.

- wide functionality;

- increased equipment;

- illumination of the working area.

- the start button is inconveniently located.

Milling cutter Hammer FRZ1200B

votes 0

Powerful motor runs quietly. There is an adjustment of the rotation speed for working with cutters of different diameters. Features of the turret allow you to make grooves of different depths, and fixing the spindle makes it easier to change the cutter.

The kit includes an adapter for a vacuum cleaner that allows you to remove dust particles during operation, collets 6 and 8 mm, a copy sleeve, a parallel stop.

- powerful engine;

- inexpensive model;

- simple setup.

- no.

For a home workshop in which piece and rare work is carried out, it is rational to purchase multifunctional equipment with universal characteristics. This will allow you to perform several processes in a small area, save money, but at the same time reduce the amount of manual labor and increase productivity.

Proper operation, timely repairs and our selection advice will allow you to produce beautiful and high-quality products on a woodworking machine for a long time at a lower cost.

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131651 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127690 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124518 -

The best men's sneakers in 2022

Views: 124033 -

The Best Complex Vitamins in 2022

Views: 121939 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114979 -

The best paint for gray hair - top rating 2022

Views: 113395 -

Ranking of the best wood paints for interior work in 2022

Views: 110318 -

Rating of the best spinning reels in 2022

Views: 105329 -

Ranking of the best sex dolls for men for 2022

Views: 104366 -

Ranking of the best action cameras from China in 2022

Views: 102215 -

The most effective calcium preparations for adults and children in 2022

Views: 102011