Rating of the best fuel level sensors for 2022

Such sensors have become widespread both on stationary objects and on mobile ones. The first category includes stationary storage (for example, gas stations). The second category includes vehicles, from passenger cars to professional equipment, such as ships and aircraft.

The abbreviated name of such equipment looks like FLS. The FLS device is necessary for the most accurate measurements of the fuel column in the tank. Given the readings provided by the sensor, the program is able to calculate the following items:

- Fuel volumes inside the tank.

- Fuel consumption relative to a given distance.

- Average fuel consumption (l/100 km).

- Fix replenishment or draining of fuel.

Sensors in detail

There are several subtypes of FLS on the market. For 2022, the most popular subtypes among buyers are:

- Regular type (float type);

- Modular (stand-alone installation), the category includes capacitive and ultrasonic sensor types.

The float type is installed in the tank in the order of the factory. Measurement data is displayed on the corresponding screen on the control panel. Depending on the configuration of a particular car, the location of the screen and the amount of data vary. The FLS of this category does not differ in terms of accuracy, the float displays only an approximate analysis. Drivers with experience in operating such a meter claim that float deviations reach up to 30% in terms of indicators.

The category of capacitive and ultrasonic meters is considered the most accurate. To acquire such a device, the car owner needs to purchase a specific model and pay for installation in the tank. The cost of equipment in this category is an order of magnitude higher than the average price of a float, and installation will also require financial investments. For the money spent, the driver will receive accuracy with deviations not exceeding 2%.

float category

A similar spare part is integrated into the car system in the order of the factory. The location of the part is inside the fuel tank. The principle of operation is shown in the name of the part: the position of the sensor is controlled by the position of the fuel inside the tank. The most common materials for this part are plastic or metal alloys. This detail is divided into 2 subtypes:

- Lever type.The float is connected to the main meter by means of a metal alloy lever mounting. The volume of fuel sets changes in the device by increasing or decreasing the volume, the device fixes the amount of liquid due to voltage drops. This type is universal, which allows the use of lever devices in cars of the most common configurations.

- tubular subtype. A pipe is placed in the tank into which the float is immersed. Changes in fuel volumes directly affect the pipe inside which the float moves. Specific trajectories are preset for the movement of the sensor. The movement of the FLS is fixed by wires that transmit information to the main meter. Such structures are necessary in order to fix the volumes of fuel in the conditions of moving a car along sharp turns or descents and ascents.

The sensors are directly connected to the vehicle's on-board system. When the mass is connected to the FLS and the power supply system of the machine is de-energized, measurements are not possible. This is important to take into account for drivers who put the car in a long parking lot, because in such scenarios, the fuel drain will remain unfixed. To avoid this situation, just connect the meter directly to the battery.

Sensor pdu-n201-80 (float)

The model is notable for its miniature dimensions and wide functionality. Also, the float will protect the pump from excessive dryness and will help in automating the operation of filling and draining the tank. The model is resistant to bubble type liquids, length is 8 cm, diameter is 2.8 cm.

- Quality material;

- Compatible with liquids with complex chem. connections;

- Affordable price.

- Analytical error.

Review:

“A good device for the economy category, but you should take into account the high measurement error. Suitable as a temporary solution, in the future I recommend installing a more advanced device. I recommend it to anyone who is looking for a quality device in the economy segment!”

Sensor from Benza 500 mm model

The model is notable for the possibility of mechanical adjustment relative to the height of the tank. Simply put, trimming the meter is allowed to achieve the required dimensions. It should be borne in mind that after mechanical impact, the sensor will require calibration.

- Adequate cost;

- Possibility of cropping;

- Positive reviews.

- The need for calibration after trimming.

Review:

“The model does an excellent job of measuring fuel. I cut the sensor to the right size, after which I calibrated it, and now the analysis is quite accurate. I recommend it to everyone who is looking for a reliable FLS among floats!”

Pdu-i.100 sensor

This sensor produces a standard data analysis regarding the level of fuel inside the tank. Made of stainless steel, connected by 2-wire circuit, protected from moisture in accordance with the IP65 standard.

- Acceptable cost;

- IP65 moisture protection standard;

- Operation under conditions up to +125 ° is allowed.

- Mixed reviews.

Review:

“The device does the job, but there are better ones in this category. The functionality is ascetic, suitable as an intermediate option. I recommend it to anyone who is looking for a temporary means for measuring fuel levels!”.

Ultrasonic category

Meters of this category are arranged according to the principle of devices such as emitters. A wire is attached to the sensor, which transmits information to the tracker (GPS).The design is placed on the outer wall of the tank. It is important to understand the principle of ultrasonic FLS analysis. The device creates a wave impulse (ultrasonic type) that is directed directly into the liquid, overcoming the wall of the container. Reaching the point of contact between air and liquid, the signal is reflected and recorded using a meter. The calculation of the indicators of the volume of fuel is made on the basis of the time spent on the reflection of the impulse.

The accuracy of such a technique is an order of magnitude superior to float devices, but a number of specifics must be taken into account. These specifications include the following:

- The contact between the sensor and the tank wall does not allow deviations. Otherwise, the pulse feed will be subject to incorrect propagation.

- The installed structures inside the tank will affect the correctness of the pulse propagation. In addition, the material of the reservoir also affects the quality of the ultrasonic analysis. It is not recommended to install an ultrasonic meter on a tank that contains additional baffles.

- The quality of the analysis will suffer if defects (mechanical damage) are present on the surface of the container. Bumps, chips, roughness will directly affect the measurement.

- Tank bottom sediments also affect the quality of the analysis. Accumulated particles interfere with the propagation and reflection of the ultrasonic wave.

In addition, the installation of this type of device will require the intervention of professionals. It is not recommended to install ultrasonic equipment yourself.

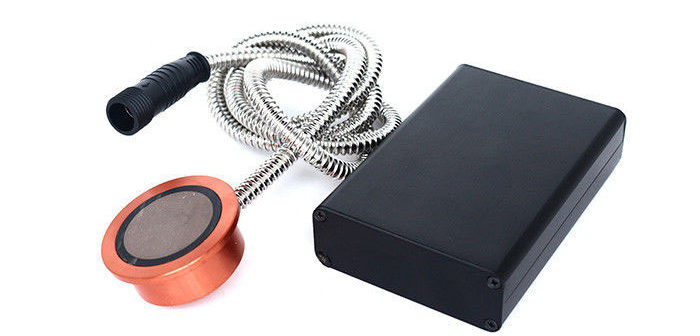

Ultrasonic sensor-0.8 (Тс Sensor)

On sale, this model is available at a price of 8.5 thousand rubles (on average), installation will require from 3.5 to 6 thousand rubles. The model features a fastening technology that eliminates drilling of the tank.The manufacturer excluded direct contact of the device with the liquid, and also provided this instance with technology that eliminates the fire hazard. Users note the high accuracy of the analysis and the ability to connect the device to both Glonass and Gps.

- High accuracy of analyzes;

- Fastening without drilling;

- Connection to Glonass/Gps.

- Expensive.

Review:

“Great device, produces fairly accurate measurements. The absence of drilling provides additional tightness, the sensor does not directly contact the liquid. I recommend it to anyone who is looking for a quality FLS!”

Proline sensor model Pr-uod8fq

A wide range of devices of the company for different categories of equipment is noteworthy. Under this brand, devices for agricultural machinery, professional vehicles, cars are available. For convenience, the model is equipped with a centralized data collection system that allows you to record any operations related to the replenishment or consumption of fuel.

- Convenient information collection system;

- Wide range of products;

- Accuracy of measurements.

- Not found.

Review:

“Not a bad device, accurate measurements, convenient control system. Although similar equipment can be purchased cheaper, the model shows strong quality, worthy of the designated price tag. Would recommend to anyone looking for a reliable sensor!”

Sensor Uzi-2.5 (Tc Sensor)

The model in most aspects corresponds to its predecessor (Uzi-0.8), but with the correction of imperfect mechanics. An improved version of the sensor from the Sensor increased in price by 4 thousand rubles. and costs from 12 thousand rubles (on average). For this price, the user receives an improved ultrasonic testing system and a number of warranties from the manufacturer.When properly connected, the sensor is capable of autonomous operation of up to 30 days, which is useful for drivers who stop for a long parking.

- Fastening eliminates drilling;

- Manufacturer's warranties;

- Battery life up to 30 days.

- Expensive.

Review:

“I bought this model because I often stop for long parking. For such events, it is necessary to have a fuel control device, because drains occur regularly without my knowledge. I recommend it to anyone who is looking for a FLS with the ability to work autonomously!”

capacitive category

A capacitive device (electronic) is placed in the tank, depending on the desire of the buyer. This category of meters guarantees the highest accuracy of analysis. In addition, the owner of such a device has access to information regarding the replenishment of fuel, unforeseen drains. The architecture of the device consists of tubes connected to the main condenser. The tubes are attached to the capacitor board in the upper compartment. The gap between the tubes is necessary for filling with liquid. The capacitor bank is supplied with electric current. The resistance indicators (specific) of the fuel are an order of magnitude lower than those of oxygen. Based on this, small volumes of fuel are reflected in the charge rate of the capacitor unit.

The FLS electronic board inside the tank calculates the charging time. Based on the information received, the meter calculates the height of the fuel column inside the tank (as well as inside the condenser unit). The measurement system is connected to the tracker (GPS). The device transmits information about the analysis directly to the tracker. The flow of data is controlled by the user.It is allowed to submit in real time, as well as in a delayed order.

Ets sensor model Rs-485

The capacitive sensor will provide the most accurate analysis results, it can be used with third-party equipment of the appropriate standard. Users note the reliability of the device, user-friendly interface and high measurement accuracy.

- High accuracy;

- Convenient interface;

- Strong quality.

- Expensive.

Review:

“I purchased a capacitive sensor to get the most reliable information regarding fuel volumes. This model does an excellent job, besides, I use it in conjunction with sensors from other manufacturers (the specifics of the tank design) and the results are excellent. I recommend it to anyone who is looking for a device for the most reliable measurements!”

Sensor from the company Omnicomm model Lls-af4 for 700 mm

This model has become widespread both in the environment of stationary tanks and transport ones. The working part is made of aluminum alloy, which excludes rust, the communication means are protected by appropriate technologies. The sensor is protected from all types of contaminants.

- Reliable protection of the device;

- Manufacturing quality;

- Analytical accuracy.

- Not found.

Review:

“I have been using this model for a long time, and the quality suits me. Protection of the electronic part guarantees a long service life, so I do not plan to change the device in the near future. I recommend it to anyone who is looking for a high-quality capacitive FLS!”

Outcome

To choose the best option, the buyer should study the principles of operation of fuel meters.After studying the specifics, it is important to correlate the characteristics of a particular model and car. When buying a device directly, the following factors must be considered:

- Dimensions of a particular tank. It is important that the device freely reaches the bottom, otherwise measurements of small volumes of liquid will not guarantee accurate readings.

- connection method. Both digital and analog options are available on the market. The latter do not guarantee wide functionality, unlike the former, so it is recommended to take a closer look at the digital options. Also, there are hybrid models (both digital and analog connections are allowed). The choice of sensor interface depends on customer preference.

- There are situations when the most optimal solution is to install several FLS:

- Transport involves the presence of several tanks for fuel. This is found among trucks of a cargo type (at least 2 containers) or all-terrain vehicles (at least 3 containers). The driver will receive correct information about the volume of liquid only if there is a separate meter for a separate tank. With proper installation, the program will allow you to get acquainted with the standard analysis (the total amount of liquid and the volume of a specific container) and with additional features.

- Transport assumes a layered capacity architecture. This is found among agricultural equipment (the tank is divided into 2 compartments). This architecture will not allow accurate measurements of one sensor, so it is recommended to install several.

- Transport involves a non-standard form factor of the fuel compartment. Similar occurs among trailers.The non-standard shape of the tank provokes an uneven distribution of liquid, in view of this, the sensor is not able to produce an accurate analysis. Professionals recommend getting a pair of FLS for a tank of this configuration. It should be installed on opposite walls of the tank.

There is no most precise recommendation regarding the type of FLS. The final choice remains with the car owner, but it is worth studying in detail the types of meters and the specifics of specific models. Also, it is necessary to correlate the characteristics of the selected FLS and the machine.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131650 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127688 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124517 -

The best men's sneakers in 2022

Views: 124031 -

The Best Complex Vitamins in 2022

Views: 121938 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114978 -

The best paint for gray hair - top rating 2022

Views: 113393 -

Ranking of the best wood paints for interior work in 2022

Views: 110318 -

Rating of the best spinning reels in 2022

Views: 105327 -

Ranking of the best sex dolls for men for 2022

Views: 104363 -

Ranking of the best action cameras from China in 2022

Views: 102215 -

The most effective calcium preparations for adults and children in 2022

Views: 102010