Rating of the best ABS sensors for 2025

Almost all modern cars are equipped with electronic systems - directional stability, traction control and others. Together, they constitute an active safety system to assist the driver in the process of driving. The most important component in it are the sensors of the anti-lock braking system (ABS), which measure the speed of rotation of the front or rear wheels. It is their readings transmitted to the control unit that become the basis for decision-making by "electronic brains" when controlling the behavior of the machine in an emergency.

Content [Hide]

What it is

The ABS sensor is a non-contact device for measuring the number of revolutions (frequency, speed) of rotation of one or several wheels on a vehicle.

The functionality of the device allows you to record as close as possible the moment of possible wheel blocking to maintain controllability during emergency braking by sending a signal to change the hydraulic pressure in the brake system. This allows the machine to maintain driving stability, and on roads with a reduced coefficient of adhesion to reduce the braking distance. In addition, the car, even with the brake pedal depressed, does not fall into a skid, but remains controlled.

Based on the readings, the following systems work:

- adaptive lighting;

- anti-lock;

- anti slip;

- tire pressure measurements;

- exchange rate stability;

- automatic transmission control;

- other.

Many automotive systems and mechanisms may not work correctly if the ABS sensors fail.

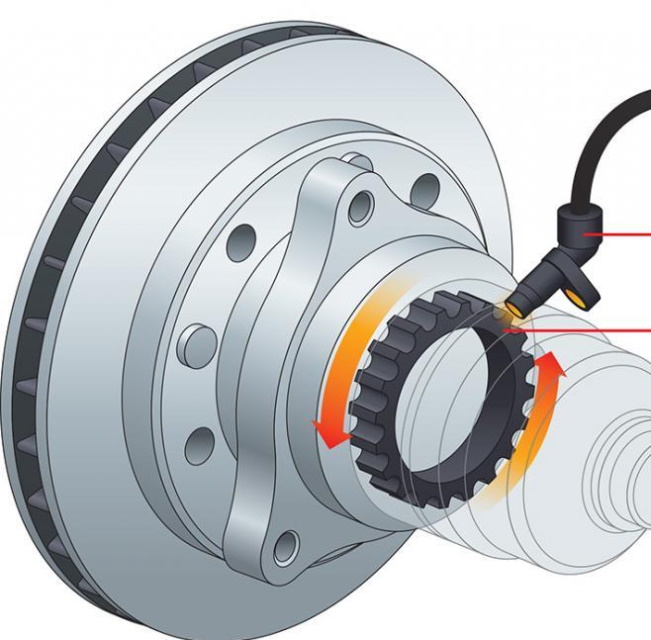

The design consists of two main elements - the device itself, installed next to the wheel, and a rotation indicator mounted on the hub, hub bearing, CV joint, etc. Any type of automotive equipment is equipped with these devices - cars or trucks, as well as motorcycles.

What are and how they work

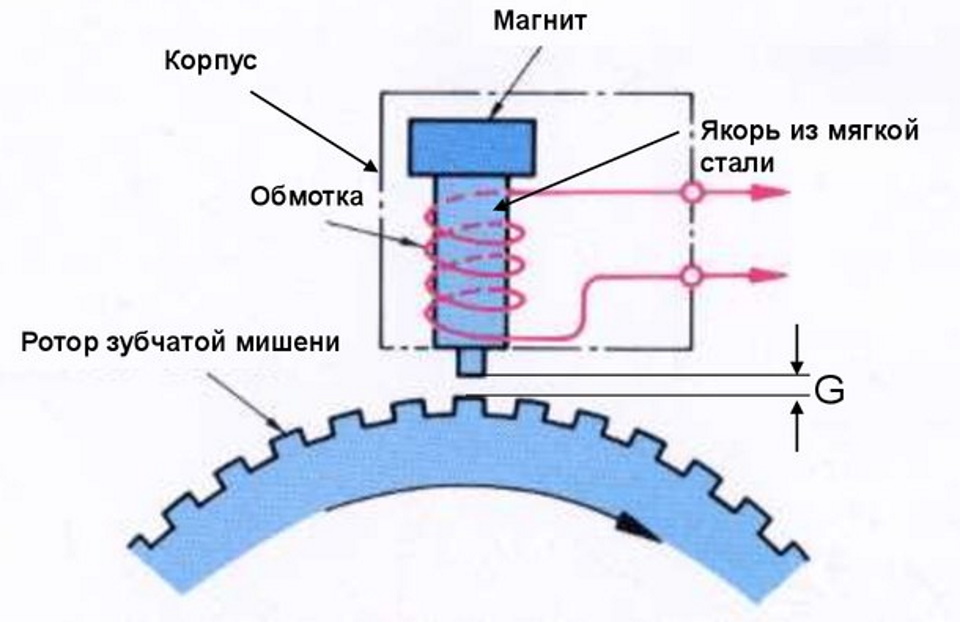

Inductive

Sensors are passive devices that operate without power sources.The device operates on the principle of using electromagnetic induction - the appearance of an electric current in a conductor located in an alternating magnetic field.

The basis of the design is an inductor with a metal core. The effect is enhanced by placing a permanent magnet inside the coil.

The sensor is installed in front of a master ferromagnetic disk with teeth, which is fixed on the hub.

During parking, a constant magnetic field acts around the coil and there is no electric current in it. When the wheel starts to move, the teeth of the driving disk pass by the sensitive element and an alternating magnetic field is created. Due to the effect of electromagnetic induction, an alternating electric current appears in the coil, which is used when measuring the number of revolutions (speed, frequency).

- simple design;

- small cost.

- large enough;

- low accuracy;

- does not turn on until the speed is up to 5 km / h.

It is rarely installed on modern cars due to frequent failures.

Anisotropic magnetoresistive

The sensor uses an anisotropic magnetoresistive effect to function. The principle of operation is to change the resistance of objects made of ferromagnetic materials during rotation in a constant magnetic field.

The design is based on a microcircuit containing a set of permalloy plates (an alloy of nickel and iron) with metal conductors on the surface. It is mounted against a plastic ring with magnetic dots attached to the hub.

During parking, the resistance of the plates in a constant magnetic field does not change.When the wheel starts to rotate, the magnetized points pass by the sensing element, the field changes and the resistance also changes. In the microcircuit, the signal is measured and converted to a convenient form. Work begins immediately after the first revolution.

- determining not only the frequency, but also the direction of rotation;

- high measurement accuracy and reliability;

- good efficiency.

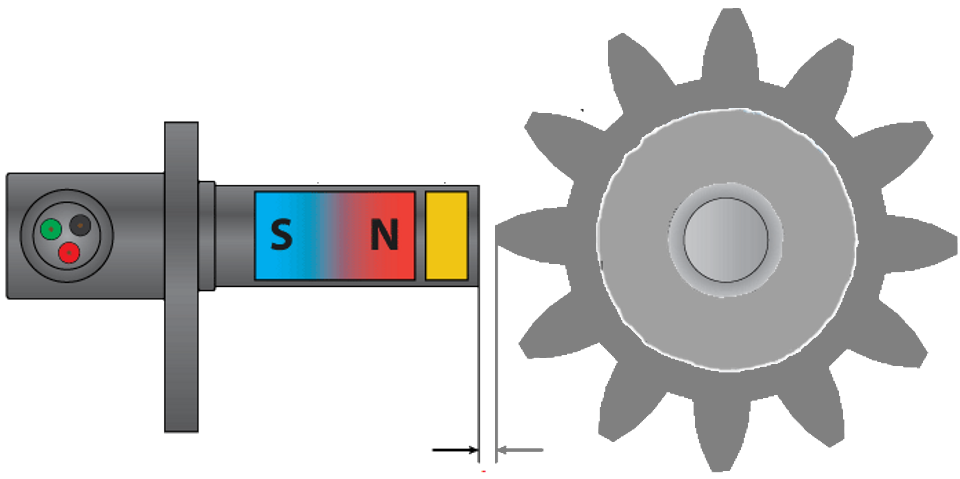

Hall type

For functioning, the effect of the occurrence in a flat conductor placed in a magnetic field of a transverse potential difference is used. In the integrated circuit, named after the discoverer, the American physicist Edwin Hall, the plate is located in a metal core between the poles of a magnet. It is installed opposite the rotor in the form of a toothed disk or ring with magnetized dots.

When parking in a constant magnetic field, a signal of a certain shape, characteristic of the rest phase, is generated in the microcircuit. When the wheel starts to rotate past the sensing element, the teeth or magnetized points of the setting disk pass. Accordingly, the magnetic field changes, and the microcircuit generates a new signal, which is transmitted digitally to the control unit.

- ease of manufacture;

- constant voltage, not having a pulse character%

- high accuracy;

- low cost;

- immediate readiness for work.

- sensitivity to electromagnetic interference;

- reduced reliability.

By execution, they can be:

- straight (axial, end) - a rod or cylinder with a sensitive element on one end and an electrical connector on the other;

- angular (radial) - a cylinder with an angular connector, a plastic or metal bracket for mounting.

Reasons for incorrect operation

There is no specific regulation for replacing sensors. The device, if used properly, can work for a very long time. It can fail for the following reasons:

- unsatisfactory condition of the master impulse disk, which can crack, rust or become clogged with dirt;

- malfunction of the controller unit or broken wires on the sensor;

- voltage fluctuations due to the battery;

- strong vibrations due to aggressive driving style and bad roads;

- mechanical damage.

During operation, pay attention to the following points:

- frequent activation of the signal indication;

- system operation during normal braking - old rubber has poor grip on the road surface and sensitive electronics immediately react;

- chaotic operation of the system - due to the state of the bearing or impulse ring, which closely interact, therefore, with backlash, the device may not function correctly.

Symptoms of a malfunction:

- image of the ABS error code on the on-board computer monitor;

- blocking the wheels during emergency braking;

- lack of characteristic vibration and sound when pressing the brake pedal;

- activation of the handbrake alarm in the disengaged position.

Criterias of choice

In order not to make mistakes when choosing, it is recommended:

- search for the necessary spare parts by VIN code;

- determine compatibility using electronic catalogs indicating the brand of car, body, year of manufacture and engine type;

- read the code on the body of the old sensor to select a similar or closest analogue in terms of characteristics;

- pay attention to the shape of the part, which may only fit a specific wheel for the left or right side of the installation or be universal;

- look at the right device among the products of trusted reliable manufacturers.

Where could I buy

Popular models and novelties can be purchased in specialized stores and salons selling spare parts and accessories for motor vehicles. Managers will explain in detail, as well as give useful advice and recommendations - what kind of sensors are there, which company is better to buy, how to choose, how much it costs.

If it is not possible to buy the necessary spare part at the place of residence, the best inexpensive models are always available to order online in the online store. This can be done easily through the Yandex.Market aggregator or leading online trading platforms that offer to select the right product according to various parameters - VIN code, car make or model, etc. At the same time, there is always the opportunity to look at the description, study the characteristics, reviews and photos, as well as consider the possibility of selecting analogues of original parts.

The best ABS sensors

The rating of high-quality models is compiled according to the opinions of customers and based on their feedback in the Yandex.Market aggregator, which presents different types of products from the best manufacturers of ABS sensors. The popularity of models is due to their accuracy, reliability, service life and price.

The review presents ratings of the best budget models at a price of 300 to 1,000 rubles, as well as in the middle price segment up to 6,000 rubles.

TOP 4 best ABS sensors in the budget segment

Meyle 1009270004

votes 4

Brand - Meyle ("Wulf Gaertner Autoparts AG", Germany).

Producing countries - China, Germany.

Compact model of the right front passive ABS sensor for Audi, Skoda, Seat, Volkswagen cars. Equipped with two connectors, supplied without cable. Resistance 1.1 kOhm.

Packing dimensions:

- width - 5.0 cm;

- length - 5.5 cm;

- thickness - 4.0 cm;

- weight - 46 grams.

The price is from 440 rubles.

- quality manufacturing;

- good accuracy of indications;

- moderate price.

- not detected.

StartVOLT VS-ABS 1039

votes 7

Brand - STARTVOLT (MC CARVILLE, Russia).

The country of origin is China.

Universal model for installation on the front axle of Ford Focus cars.

Packing dimensions:

- width - 7.3 cm;

- length - 3.5 cm;

- thickness - 5.5 cm;

- weight - 19 grams.

The price is from 563 rubles.

- compliance with the landing dimensions of the original parts;

- extended service life;

- use of quality materials;

- automated assembly.

- not detected.

Car sensors StartVolt:

Bosch 0 265 008 922 universal

votes 4

Brand - Bosch (Robert Bosch GmbH, Germany).

Producing countries - Germany, China.

Universal model of the active type Hall sensor with cable drive on the front axle of the installation for Renault and Dacia car models. Supplied with 56.4 cm cable. Operating temperature range -40⁰C to 150⁰C.

Packaging Details:

- width - 17.4 cm;

- length - 17.2 cm;

- thickness - 7.8 cm;

- weight - 107 grams.

The price is from 549 rubles.

- good accuracy;

- reliability of work;

- long service life;

- quality manufacturing.

- high sensitivity to electromagnetic interference.

Bosch ABS sensor replacement:

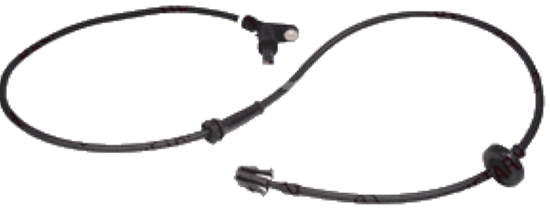

Delphi SS20031

votes 3

Brand - Delphi (Delphi Automotive PLC, UK, USA).

Producing countries - China, USA, Brazil.

Model of a passive rear sensor made in China for installation on Volkswagen cars. Robust housing made of impact-resistant plastic has 2 pluggable contacts. Cable length 105.6 cm.

Packaging Details:

- width - 11.8 cm;

- length - 22.4 cm;

- thickness - 4.7 cm;

- weight - 138 grams.

The price is from 793 rubles.

- weather-resistant contacts with good protection against external influences and corrosion;

- galvanized connectors with improved conductivity;

- tested in extreme conditions;

- exact match to the original components;

- anti-corrosion coating of fasteners;

- simple installation.

- not detected.

TOP-5 best models in the middle price segment

ABE CCZ1383ABE

votes 7

Brand - ABE (Poland).

Country of origin - Poland.

Model of a universal device for installation on the left or right on the front axle of FIAT, Opel, SAAB cars.

The price is from 1,200 rubles.

- quality manufacturing;

- exact match to the originals;

- good operational resource;

- a small number of fakes;

- acceptable price.

- not detected.

Hoffer 8290197

votes 2

Brand - Hoffer (MEAT & DORIA, Italy).

Producing countries - Italy, China.

Model of inductive front ABS sensor with two poles for Mercedes, Volkswagen LT II cars. Length 227 cm, mounting depth 5.7 cm. Resistance 1.75 kOhm. Weight 120 grams.

The price is from 1040 rubles.

- simple design;

- easy connection;

- acceptable price.

- often there are low-quality fakes.

VAG BOSCH 0 986 594 505

votes 3

Brand - Bosch (Robert Bosch GmbH, Germany).

The country of origin is Germany.

German-made active device model for Audi, Volkswagen cars. Seat, Skoda. Cable length 6.6 cm. Operating temperature range from -40⁰С to 150⁰С.

Packing dimensions:

- width - 3.7 cm;

- length - 7.9 cm;

- thickness - 3.6 cm;

- weight - 20 grams.

The price is from 2,506 rubles.

- high accuracy of determination of low speeds;

- the ability to determine the direction of rotation;

- compact design;

- maintaining stability during emergency braking;

- improving braking efficiency.

- no cable included.

MANDO EX0K08E43701

votes 1

Brand - Mando (HALLA Group, Republic of Korea).

Producing countries - Republic of Korea, China.

Model of the front right ABS sensor from a foreign manufacturer for Kia Sportage cars.

Packing dimensions:

- width - 18.0 cm;

- length - 20.0 cm;

- thickness - 1.0 cm;

- weight - 100 grams.

The average price is 2,790 rubles.

- reliable fastening;

- high measurement accuracy;

- long service life;

- compact dimensions;

- rarely forged;

- simple installation.

- not detected.

HONDA 57455-TF0-003

votes 3

Brand - Honda (Japan).

Country of origin - Japan.

Compact front left ABS sensor for Honda passenger car models.

The price is from 4,110 rubles.

- quality manufacturing;

- high accuracy of measurement of rotation;

- long service life;

- reliability;

- simple installation;

- easy dismantling.

- not detected.

Self check

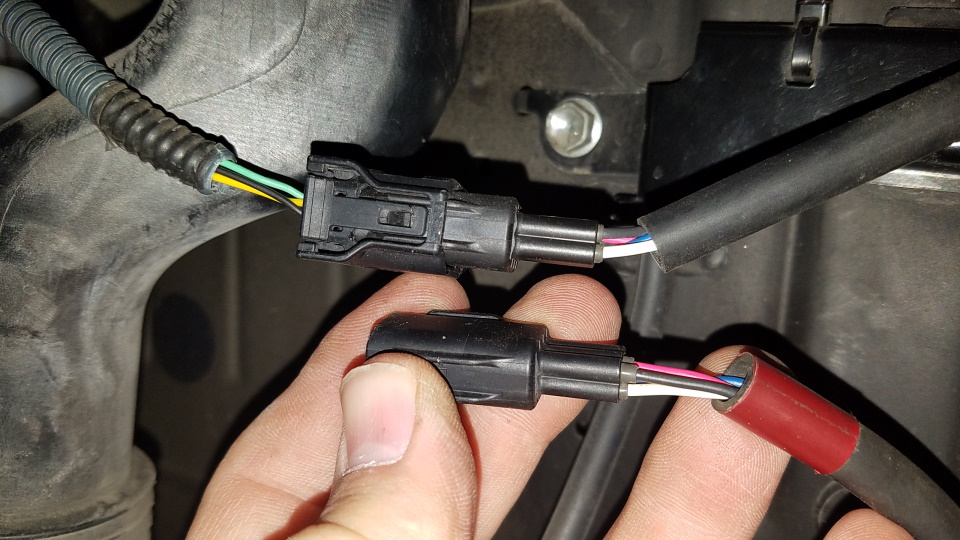

If you have the tools, you can perform diagnostics yourself without visiting a car repair shop.This will require a tester, heat shrink, repair connectors and a tester.

Checking order:

- The vehicle is installed and fixed on a flat surface.

- The wheel of the checked ABS sensor is removed.

- The connector is disconnected, and the contacts are cleaned.

- Wires and their connections are inspected to identify places of damage to the insulation and the presence of abrasions.

- The tester is connected to measure the resistance.

- The probes are brought to the output contacts to take readings. Under normal conditions, the display will show numbers corresponding to the data sheet of the sensor. In the absence of the norm, values in the range from 500 to 2,000 ohms are considered.

- After that, the wheel scrolls and readings are also taken. In a serviceable device, as the speed increases, the resistance changes more.

- The tester switches to measure the voltage.

- When rotating at 1 revolution per second, the value should be between 250 and 500 mV. The voltage increases as the rotation speed increases.

- Checking other devices is carried out in the same sequence.

The performance is determined by the resistance readings:

- below normal - the device is faulty;

- at zero or very small - the circuit of the turns in the coil;

- change when the wiring is bent - damage in the wiring cores;

- tend to infinity - a break in the coil or conductor.

Large differences in the readings of one device from the rest indicate a malfunction.

In addition, the performance is checked by the presence of a magnetic field. Any metal object is applied to the sensor and the ignition is turned on. Under the influence of the field, it should be attracted to the device.

Incorrect operation can be caused by dirt and oxidation.

Enjoy the shopping. Take care of yourself and your loved ones!

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131657 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127697 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124525 -

The best men's sneakers in 2025

Views: 124041 -

The Best Complex Vitamins in 2025

Views: 121945 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114984 -

The best paint for gray hair - top rating 2025

Views: 113400 -

Ranking of the best wood paints for interior work in 2025

Views: 110326 -

Rating of the best spinning reels in 2025

Views: 105334 -

Ranking of the best sex dolls for men for 2025

Views: 104373 -

Ranking of the best action cameras from China in 2025

Views: 102222 -

The most effective calcium preparations for adults and children in 2025

Views: 102016