Rating of the best centrifugal pumps for 2025

A well or a well in a suburban area will solve many issues related to water supply, especially in cases where there are no other sources of water. However, it is rather inconvenient to draw water with a bucket, especially in the age of advanced technologies. The situation can be significantly improved if a good centrifugal pump is used for water intake - it will be quite capable of providing water to the family in a private house at any time and taking into account the needs of the residents. Nevertheless, in order to choose the right model, you should carefully study all the characteristics and features of this type of equipment.

Content [Hide]

- 1 Centrifugal pumps - general information

- 2 Features of operation of centrifugal pumps

- 3 Installation rules

- 4 Performance calculation

- 5 Automation systems for centrifugal pumps

- 6 Centrifugal pumps and their sensitivity to impurities in the flow

- 7 Difficulties in choosing a centrifugal pump regarding technical characteristics

- 8 Rating of the best centrifugal pumps for 2025

- 9 Instead of an epilogue

Centrifugal pumps - general information

When operating a well (well), certain nuances may arise that must be taken into account when using a centrifugal-type pump for them. The well is equipped only where the water level in the soil is close enough to the surface. Thus, the depth of wells rarely exceeds 15 meters. Water can enter the pumping device from specially equipped walls or directly from the bottom. All this will depend on a certain type of unit design and can be recruited in significant volumes.

Centrifugal pumps are not subject to any special size restrictions and the list of related equipment for them is extensive. At the same time, it is worth considering the "debit" of the well, i.e. pumping out water should occur at such a speed at which the well cannot quickly become shallow.In turn, the operation of the pump in the grinding well will sooner or later lead to its failure. It must be remembered that it is extremely difficult to increase the productivity of a well mine artificially.

Before installing a centrifugal pump in a well, you need to decide on some of the most important characteristics of the latter:

- The water level in the mine - as an average indicator, you can take the depth of the water mirror at the moment when water is not taken;

- Dynamic water level – i.e. the level to which the mine can be permanently replenished;

- Sectional area of the mine - this parameter is necessary to establish the degree of efficiency of the well volume when calculating its real debit.

The main positive qualities of centrifugal pumps are:

- Relatively quiet operation - especially for the latest models;

- The presence of overheating protection systems - these can be either simple ventilation grilles or entire electronic modules;

- Easy installation;

- Possibility of water intake from great depths;

- Exclusion of the risks of idling (air masses will be pumped);

- Possibility of automatic switching on/off (the model can be supplied with a special float relay).

IMPORTANT! Centrifugal pumps should only be used if the water level in the mine is at least 8 meters!

Features of operation of centrifugal pumps

Experts believe that the best type of centrifugal pump will be its deep modification, i.e. equipment that is immersed in a mine or well. The main functional feature of such a unit is the presence of one or more wheels. These parts are located inside the housing and are fixed on the shaft.They are paired discs that are connected to each other with their blades. The entire space inside such a device is always filled with water, which is affected by centrifugal force during the rotation of the disks. With the help of centrifugal force, an area of increased pressure is formed closer to the edge of the working vessel, and an area of reduced pressure is created in its middle. Due to the resulting pressure difference, water is sucked in by the equipment and then poured out of it.

Installation rules

Before operating a submersible centrifugal pump, a hose is attached to its body. The depth of lowering of the unit and the purpose of its use will determine the length required for the hose. The maximum degree of pressure injected by the apparatus should not exceed the maximum pressure height for a given pipe structure.

It is preferable to use a standard hose for situations where water is supposed to be used only for watering plantings and filling various containers. The hose is mounted on the pump by means of a special plastic coupling. In order for regular operation to be possible, the pumping apparatus is installed permanently. Dismantling will be needed only for repair and maintenance work.

It is also possible to use iron or plastic pipes. After connecting them, you need to fix the electrical cable. Experts recommend leading the wire to the pressure pipe using staples in order to avoid excessive tension on the hose. Staples will help to avoid accidental damage to it.

It is not recommended to hang the device directly on the power cable. For reliable fastening of the device, a cable with a special spring suspension is threaded into the special eyelets of the body.The pump is then lowered into the well shaft (if all the preliminary safety steps have been completed). In order to eliminate the risk of a pressure drop when supplying water, too sharp refractions of the hose must be avoided.

The centrifugal pump housing itself is best placed at a height of at least 20 centimeters from the base. The suction line can be provided with a special filter. In order to determine the need to use a filter, it is necessary to calculate the functional indicators on the suction and discharge pipes. They can be equipped with easily removable couplings. The diameters of these nozzles should be approximately equal, and in cases where there is a big difference, the presence of filters is mandatory.

IMPORTANT! In emergency situations, the use of a non-return valve can become a justified necessity!

Performance calculation

Under the calculation of performance, one must mean the volume of liquid that a particular pumping device can pump over a certain period of time. In this matter, the best solution would be a calculation made by a professional. And now, based on the results of the calculation, it will be possible to determine the level of demand for water supply for both the site and the house.

In principle, these calculations can be performed independently. The main reference point is an indicator of 200 liters of water per person per day. It follows from this that the quantitative composition of the inhabitants of the house should be taken as a basis. Further, it must be taken into account that one tap is capable of pouring about 5.5-6 liters per minute, and the flow rate in the shower corresponds to a minimum of 9 liters per minute. At the same time, the average rate of simultaneous use of several plumbing fixtures should not exceed 21 liters per minute.As a result, you should carry out the standard arithmetic operation of division and calculate the time of use per person.

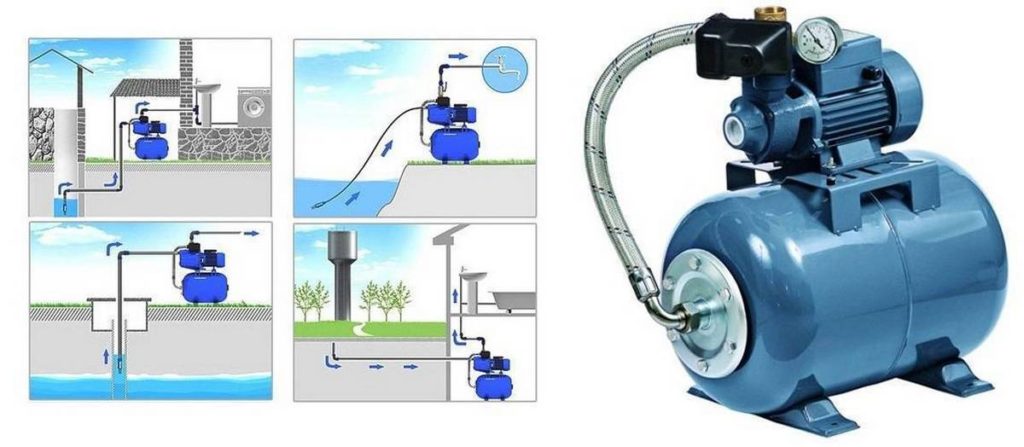

Automation systems for centrifugal pumps

Experts recommend giving preference to devices, the delivery set of which includes a special float, which is responsible for turning off the device in case of a critical decrease in the volume of liquid in the source. Automatic shutdown is a reliable and important option, because. helps to avoid idle operation of the device. Idling threatens to overheat the unit, which will lead to the failure of some of its components. At the same time, centrifugal models can be equipped with such useful accessories as:

- Accumulation tank - it is an expanded tank or pressure tower with a volume of up to 1 cubic meter of water (the figure may vary depending on the wishes of the owner);

- Fullness sensor - according to its principle of operation, it is similar to a pressure sensor, but it functions in the interests of a water pressure vessel. The size of the water column is responsible for the water pressure in the entire system. So that the tank does not overflow, such a sensor should be installed, and it will turn off the pumping device when the limits are reached;

- Pressure switch - it is mounted on an additional container. With the help of this device, the entire operation of pumping equipment is optimized, and the process of supplying water at home can become uninterrupted. The essence of the switch is to maintain a certain pressure in an additional vessel, so that it is possible at the right time to supply water from it under the appropriate pressure. And when all the water pours out of the tank, it will begin to fill again with the injection of the required pressure;

- A special temperature switch - it is installed in order to comply with the protection of the device from overheating. When the allowable limit is reached, the pumping equipment is switched off.

All of the above devices will ensure not only high-quality water supply, but also extend the life of the centrifugal pump.

It is no secret that it is centrifugal pumps that have proven themselves to be the best and most reliable means of supplying water to private residential buildings. And their use, coupled with optional devices, can show efficiency worthy of centralized water supply systems.

Centrifugal pumps and their sensitivity to impurities in the flow

It must be recalled that when pumping water from open reservoirs or wells, the water mass will always contain a certain amount of sand, silt, and other debris fragments. With not very high concentrations of impurities in the stream (up to 10 grams per cubic meter, with fragment dimensions of at least 2 millimeters), a centrifugal-type pump is able to operate without serious harm to hydraulic elements. If the concentration of impurities increases (and the garbage fragments themselves become larger), then increased wear of the working disks, as well as other components, is simply inevitable. In order to avoid premature repairs, when the above situation is detected, special filters should be installed on the equipment.

Difficulties in choosing a centrifugal pump regarding technical characteristics

Actually, the selection process must be started based on the required capacities, which will be determined by the volume of upcoming tasks. Further, it is required to calculate the required degree of pressure that the device will have to give out, and this degree is directly dependent on the length and horizontal and vertical parts of the pipeline system.

Professionals believe that for most of the usual tasks of providing a private house with water supply, a device with a pressure of 40 to 50 meters at a flow rate of 50 to 55 liters per minute is quite suitable. This model is almost universal, provided that it will be used in conjunction with automation for protection against idling. Still, the most ideal solution for any capacity based on a centrifugal pump will be a full-fledged pumping station.

- Required suction hose diameter

The inner diameter of such a pipe on the suction line should not be less than the conditional transition of the thread connection on the body of the entire device. With a decrease in the diameter index, a decrease in the suction depth and liquid flow in general occurs. For the suction line, it is preferable to use a pressure hose with a diameter of one inch or a HDPE pipe with a diameter of 32 millimeters.

- Required diameter for pressure hose

Here the choice can be made according to the same algorithm as for the suction hose. Also, it is necessary to select a pipe, in which the conditional passage will be no less than that of the threaded connection. This parameter should not be neglected, because it must be remembered that with a decrease in the diameter of the pipe, the degree of hydraulic connection will increase, which, in turn, will lead to a decrease in pressure and total flow for the pump.

Selection of valves

In this case, the following principle should work: the main thing is not to reduce the internal pipe passage! If you install valves with a smaller diameter, then cavitation will certainly occur (the process of formation of voids in liquid media, in other words, bubbles). And this will negatively affect the operation of the entire pumping system.

Rating of the best centrifugal pumps for 2025

Budget segment

3rd place: Caliber NBTs-1050Ch

votes 0

This sample of domestic use with a centrifugal type of operation is made of high-quality materials with an anti-corrosion coating. The model meets all international standards and does an excellent job of pumping fluid within its capabilities. The device works from a single-phase network, in a set the electric cable 20 meters long is delivered. Within 60 minutes it is able to withstand about 20 restarts. Installation is possible both in horizontal, and in vertical position. Can be used to pump dirty water. The recommended cost for retail chains is 3800 rubles.

- The motor is equipped with thermal protection and a capacitor;

- Single-stage suction system available;

- Saving electricity;

- Increased throughput;

- Easy assembly.

- Flimsy carrying handle;

- Problems with the selection of spare parts.

2nd place: "P.I.T PSP015027-550/23"

votes 0

Such a device can easily cope with the problem of water supply of a suburban area and any private house. It is used for wells with a permissible shaft diameter of 11 centimeters, it can also be used for wells. The device works rhythmically, does not create excessive noise.Differs in durability and quality of a design, the case is made of corrosion-proof metal which perfectly resists corrosion. The working functionality has been expanded. The recommended cost for retail chains is 4800 rubles.

- Thermal protection available;

- Ease of operation;

- Stable stand;

- Long electric cable;

- There is a remote launch pad.

- Excessive electricity consumption;

- There may be problems with the safety channel.

1st place: "Unipump JET 100LA"

votes 0

This model should only be placed on the surface. It has an integrated injector module and is used to draw clean water from well sources. It can be applied in systems of automatic water supply. The set includes parts for self-assembly. The work is relatively quiet, transportation over short distances is possible right in the process of work. It has small overall dimensions. The manufacturer provides a 5-year warranty. The recommended cost for retail chains is 10,300 rubles.

- Weak tendency to overheat;

- High-quality starting block;

- Good equipment;

- Relatively quiet operation;

- check valve available.

- Extremely sensitive to the presence of impurities;

- High body.

Middle price segment

3rd place: "AquamotoR ARMH 1100"

votes 0

This pump has a multi-stage design and is characterized by increased performance, which is achieved due to the increased number of working disks. The device is used for pumping out exceptionally clean liquid, free from foreign impurities, large fragments and aggressive chemical elements. It can be used for both irrigation and domestic water supply. Able to be integrated into the system of automatic supply of objects with water. Complete set is sufficient, self-assembly is possible. The recommended cost for retail chains is 13,000 rubles.

- Comfortable control and management;

- Overheating protection available;

- wear resistance;

- There is an adjustment of various levels;

- The body has an anti-corrosion coating.

- There are cases of pressure drops;

- Overloads are possible during intensive use.

2nd place: "JABSCO50840"

votes 0

An excellent device that has earned a reputation for unpretentious and reliable unit. The body and impeller are made of stainless steel. The pump can be installed to serve shallow wells, while maintaining a minimum water flow of 10 liters per minute. Shows extremely unstable operation in sandy well conditions. Sensitive to voltage drops, which indicates the need to purchase a stabilizer. It is considered an average option for providing water to a private house. The recommended cost for retail chains is 29,000 rubles.

- Quiet work;

- Overheating protection available;

- There is a built-in capacitor;

- Can work with partial immersion;

- Little sensitive to foreign impurities.

- Does not have idle protection;

- It has a single stage suction system.

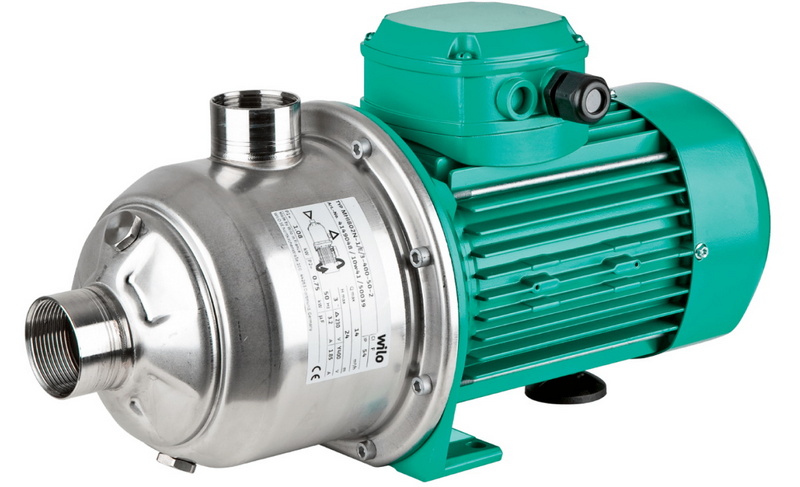

1st place: "Wilo Economy MHI203"

votes 0

This device has a surface-based system, equipped with a stable electric motor and an open rotor pump. The body is made of cast iron, the working shaft is made of stainless steel. Mounting is very easy thanks to the spring terminals.In order to prevent premature failure of the equipment, it is required to regularly clean the filter from foreign fragments. Optionally, it is possible to install an idle speed sensor (not supplied). The recommended cost for retail chains is 48,000 rubles.

- Long service life;

- There is protection against voltage surges;

- Sufficient wear resistance;

- Possesses anticorrosive protection;

- Easy installation.

- During prolonged use, excessive noise may appear;

- During the procedure for pumping air, stops are possible.

Premium class

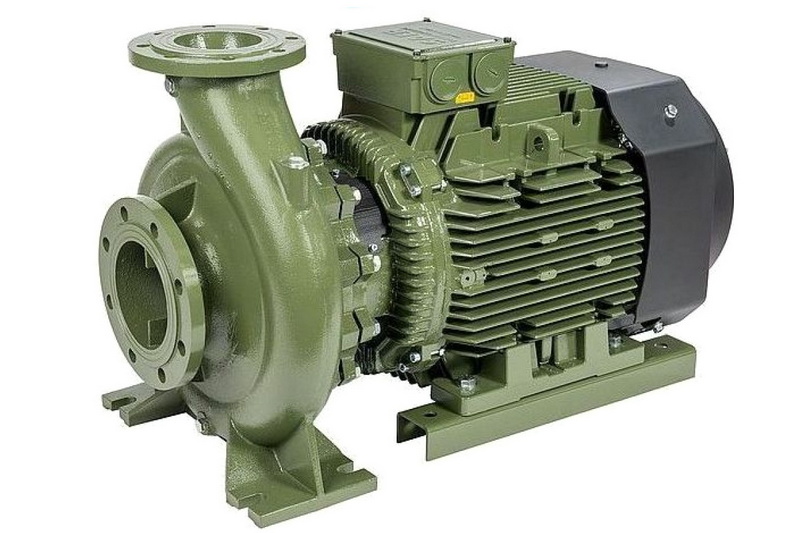

3rd place: "SAER ELETTROPOMPE Ir40-160nc/a"

votes 0

This monoblock pump can be used in various fields: for air conditioning and heating systems, for irrigation and water supply. The instrument is capable of handling lightly contaminated liquids, including small chemical impurities. The device is installed both in horizontal and vertical position. The engine is located at the top of the machine. In the manufacture of this equipment, stainless steel was used, which is able to qualitatively withstand chemically aggressive substances. The recommended cost for retail chains is 61,000 rubles.

- Smooth start;

- Quiet running;

- Energy efficiency;

- The capacitor box is distinguished by endurance.

- Relatively small pressure;

- Requires frequent filter cleaning.

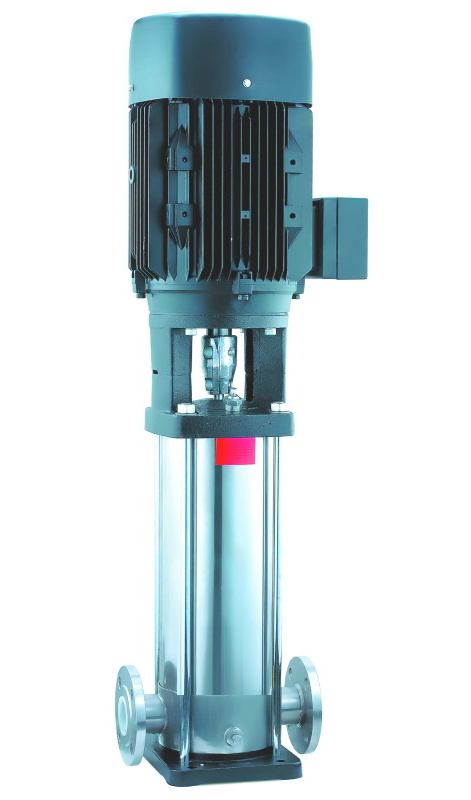

2nd place: "CNP CDL 65-60-1 F1SWPC"

votes 0

This vertical centrifugal type instrument undergoes strict post-production quality control, is subject to mandatory certification, and has a 5-year factory warranty.The device is made of cast iron and is intended for pumping out chemically non-aggressive liquid. It can be applied both in industrial and in household sphere. The engine is reliable, energy resources are spent economically. The model has a high build quality, performance is at a decent level. The recommended cost for retail chains is 434,000 rubles.

- wear resistance;

- There is a voltage stabilizer;

- Possibility of pumping water with minor impurities;

- Design with multi-stage suction system;

- Increased device power.

- There is no check valve;

- The pressure depends on the voltage in the network.

1st place: "PEDROLLO F 65/250B"

votes 0

This unit is made in the form of a cantilever monoblock with nozzles. It is designed to pump out any type of liquid, both dirty and clean. Can be used for circulation and irrigation. Ideal for industrial and agricultural applications. The birthplace of the brand is Italy, which guarantees long-term operation and European quality. The manufacturer provides a two-year warranty. The recommended cost for retail chains is 460,000 rubles.

- Can serve several points of water intake;

- Economy in electricity consumption;

- There is protection against overheating;

- Smooth start of the motor;

- Enhanced performance.

- Electric cable with European plug;

- Single stage suction system.

Instead of an epilogue

The analysis of the market of the devices under consideration found that this market is far from the cheapest, even in relation to the budget segment.This circumstance is connected with the technical complexity of pumping centrifugal units, the need for their mandatory certification. It is gratifying that it will not be difficult to find a model whose functional qualities will be worthy of its own price.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131649 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127688 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124516 -

The best men's sneakers in 2025

Views: 124030 -

The Best Complex Vitamins in 2025

Views: 121937 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114978 -

The best paint for gray hair - top rating 2025

Views: 113393 -

Ranking of the best wood paints for interior work in 2025

Views: 110318 -

Rating of the best spinning reels in 2025

Views: 105327 -

Ranking of the best sex dolls for men for 2025

Views: 104363 -

Ranking of the best action cameras from China in 2025

Views: 102214 -

The most effective calcium preparations for adults and children in 2025

Views: 102010