Rating of the best checkweighers and combi-checkers for 2025

In order to carry out reliable packaging and weighing of various products in a warehouse or food production environment, high-quality control of such operations is required. To perform such labor-intensive processes, special control and weight equipment called "checkweighers" (or its more advanced modifications - "combi-checkers") are used. These devices are designed to carry out the function of continuous weighing and, being fully integrated into the workflow, they easily and accurately carry out the weighing of various items that pass through the belt conveyor, while simultaneously accounting / controlling the entire cargo flow. As a result, with the help of this equipment, the efficiency of work and, as a result, the profit of the enterprise increases.

Content [Hide]

General information

Checkweighers are a complex dynamic weighing system that determines the weight of a packaged product or piece of goods on a conveyor belt quite accurately and quickly. The process of determining the weight of the load occurs at a high speed and does not affect the order of movement of objects on the belt. At the same time, using the checkweigher, it is possible to sort the goods by weight, check the labeling of the goods (automatically check the correspondence of the label information indicating the weight, lot number or barcode with the current received data), as well as check the presence of foreign metal parts in the package (only combi-checkers) . In cases where the results of the check do not correspond to those originally declared, the goods will be rejected and removed from the general flow.

Of particular interest is the workflow of the checkweigher when working with bulk materials: if the set weight for each individual package is violated, the control module sends a signal about this to the dosing device, and it can correct the weight for the next batch of goods.From this it is clear that the company thus gets rid of the overweight / underweight, thereby removing the risk of ultimate losses.

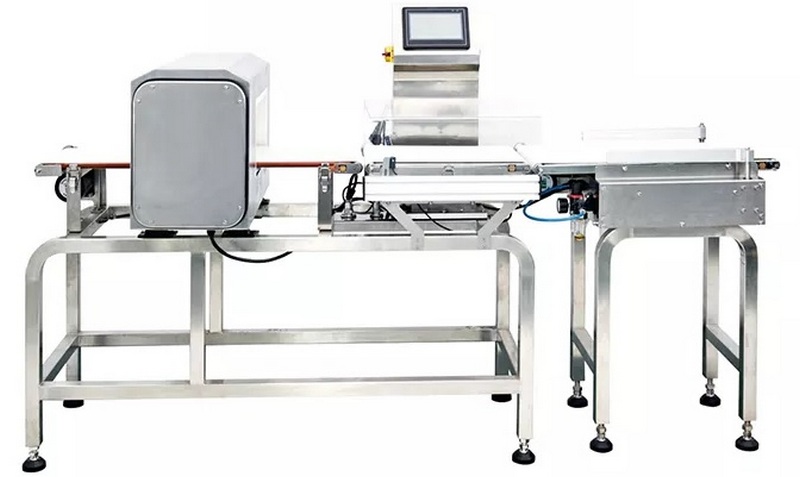

Combicheckers are, in fact, the next generation of checkweighers and they combine 2 devices - these are automatic scales and a metal detector. They are used more often in industrial production and are designed to help get a verified unit of goods that fully corresponds to the declared weight and does not contain foreign fragments.

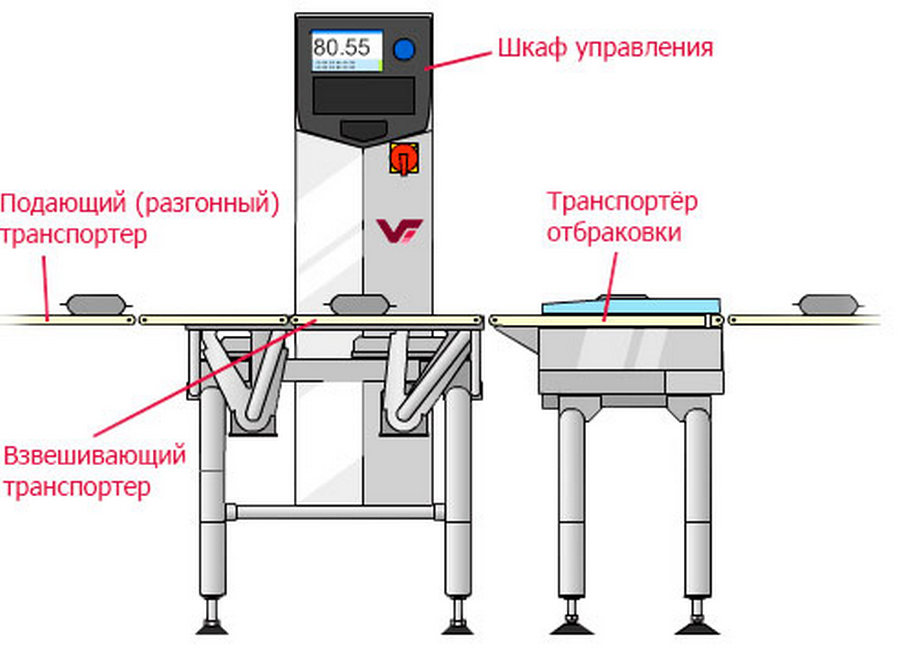

Checkweigher device

Conventionally, its design can be divided into several modules:

- Accelerating (feeding) conveyor - is a conveyor used for continuous supply of products to the area above the control scales;

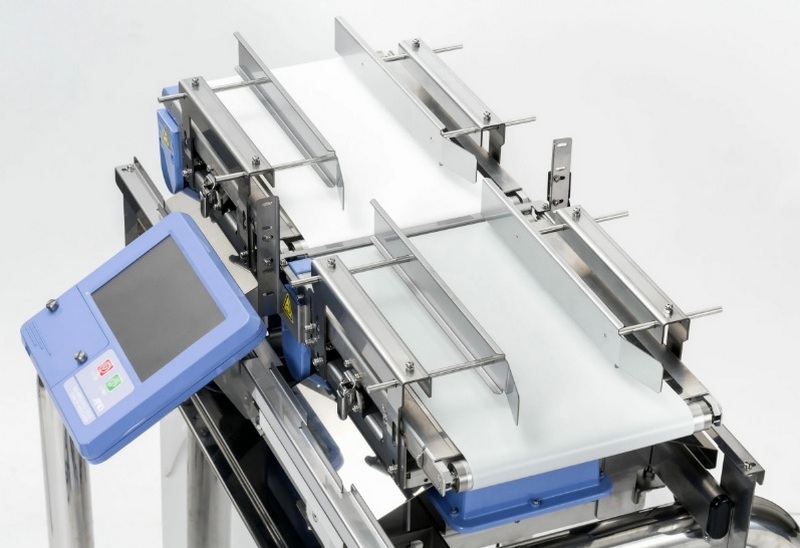

- A weighing conveyor is a simple roller table or belt conveyor designed to determine the mass of goods during transportation along a special section of the checkweigher;

- Control module - it includes a board for analyzing incoming data on the weight of products, which, after processing the information, issues a control signal for further operations with the goods;

- The reject module is a special mechanism that distributes already weighed goods into different weight zones. Rejectors can be "flippers" (moving an item sideways from the main line to another product area), "droppers" (dumping the product from the line down) or "pushers" (pushing the product from the main line to the reject line).

Strain gauge weight sensors are considered the main component of the weighing conveyor. The type and models of these devices used depend on the total load on the weight section, and also depend on the design features of the device as a whole, as well as on the installed protection against flaws according to the IP standard.Modern checkweighers use single point (L6N, L6E3, L6G, L6D) or beam (H8C, BM11, BM8D) sensors.

Further, the information released from the sensors is sent to the weight controller located in the control module. But already there the development of control and control signals is carried out, namely:

- Accounting for the results of weighing and presenting data about it on the display;

- Comparison of the received data with the established standards and making a decision on the rejection of products;

- Transmission of a signal to act on the mechanism of the rejecter;

- Saving the results on a permanent storage device, transferring them to external gadgets (PC or PDA), connecting additional devices (for example, a metal detector).

It is worth noting that some modifications of checkweighers may have the following additional option (although it is most often found on combi-checkers):

- Label printer;

- Feedback board with dosing device (for bulk products);

- metal detector;

- Rejector (instant rejecter, not suitable for separating goods into zones).

Advantages of checkweighing equipment

Of its undoubted advantages, we can mention:

- Increased weighing accuracy, and hence dosing;

- Accelerated workflow, which is achieved by digital information processing;

- Simple operation and the presence of a display for visualization of production operations;

- The presence of a permanent storage device for storing the results of processing;

- It is possible to distribute products in different sorting zones (up to 10 zones);

- Self-diagnosis and troubleshooting option.

Array of executable functions

Any modern checkweigher or combi-checker is capable of:

- Carry out control of a single product in order to identify overweight / underweight or understaffing in a group warehouse;

- Distribute the flow of goods in different zones, depending on the installed mass;

- Analyze the performance of the line, keep records of products, collect data to determine the total weight of a good product and marriage;

- Analyze the weight of the final product in order to adjust / control technological procedures (change in dosage, change in processing technology, etc.);

- Monitor compliance with technological standards, metrology, standard requirements, as well as determine permissible errors;

- Perform precise control of the mass of the final product at the final production stages.

The fulfillment of all the above functions will prevent poor quality products from reaching the buyer, reduce the costs of the technological process, which may be caused by incorrect operation of the dosing unit in terms of packaging and excess weight of individual products.

Scope of application

The considered type of automatic checkweighing equipment is simply indispensable at various production stages:

- Pre-packing stage - it divides products into shares (for example, dough before freezing). The checkweigher allows connection with the molding module, which will be controlled by it and signal the dosage;

- Primary packaging stage - here the individual tubes are weighed before they are packed. The device will screen out a product with an inappropriate weight, which will clearly reduce the percentage of possible defects, despite the fact that at the next stage the cost of production will not increase;

- Secondary packaging stage - at this production stage, the machine checks the completeness of the warehouse;

- Group packaging stage - here the equipment is responsible for the correct filling of boxes with groups of packages, i.e. monitors their surplus or shortage.

Modern classification of checkweighing equipment

Both checkweighers and combi checkers are used in mass production on their respective production lines. They are aimed at ensuring the accurate weighing of each commodity unit for its subsequent release for sale (or further sorting) or for its rejection due to manufacturing errors. As a result, the equipment in question may differ:

- By the presence / absence of the static weighing option - this will depend on the technical capabilities of the device or on the direct restriction of such a function by the manufacturer;

- By type of line - these can be devices with a roller conveyor, automatic conveyor scales, rotary scales used to control goods enclosed in tubes (bottles, cylinders, cylindrical cardboard packaging);

- According to the minimum / maximum determined weight;

- According to the maximum / minimum speed of passage for weighing (hence the difference in accuracy and discreteness).

Features of preventive testing

To increase the service life of automatic checkweighers, they must be constantly (once every six months) inspected for physical defects and confirm the accuracy of the issued metrological data. When visually inspecting the equipment, it is mandatory to establish:

- The presence / absence of visible deformations of both the bearing parts and the electrical wiring;

- General compliance with the documented completeness of mechanisms;

- Compliance with the division value on the summing device, according to GOST No. 30124;

- Compliance with the requirements for the quality of the coating of the conveyor belt, its dimensions, the labeling of goods issued, as well as optional devices (for example, a cutter).

Also, it is necessary to check the possible angle of inclination of the conveyor belt, for which a goniometer is used. It is set at the beginning and at the end of the tape, then the arithmetic mean value is calculated from the two results obtained. The possible slope error is regulated in the accompanying documents for the equipment and recommended by the manufacturer in advance. It is forbidden to exceed this error, because this will lead to inaccuracies in weighing. If the model works on a roller conveyor, then the permissible angle of inclination is calculated there by a similar method for the initial and final rollers. External inspection is also subject to:

- control equipment;

- Display units, measurements and signaling devices;

- Idling devices.

The completion of the visual check will be an idle start of the equipment for 10-15 minutes in order to fix the complete and trouble-free rotation of the entire belt, its proper tension, as well as the operation of auxiliary devices responsible for its cleaning.

Testing the accuracy of metrological indications

For this, a mark is made on the conveyor belt. During the passage of this mark through an arbitrarily chosen fixed point of the line, the stopwatch is turned on and the readings of the summing weight module are recorded. In total, at least three such runs are performed and an average value is selected from the data obtained, which should not exceed the permissible error established by technical standards.

Mounting Recommendations

The equipment under consideration belongs to a type of products whose final assembly, commissioning, pre-production testing and possible fine-tuning can only be carried out at the place of permanent deployment with reference to a specific production system of an industrial facility. Therefore, competent and proper installation of equipment will directly affect the error of operation. Accordingly, during the installation of the checkweigher, it is necessary:

- Properly ensure the tension of the conveyor belt;

- The tape surface must be firmly glued at the junction or vulcanized;

- The conveyor must occupy a section with a length of at least 10 meters and not have bends in both the vertical and horizontal planes. It should not be influenced by any nearby mechanisms (electromagnets, scrapers, loading devices, etc.);

- The maximum tilt angle should not exceed 20 degrees.

Difficulties of choice

Due to the fact that checkweighers and combichecks are very complex systems and are extremely expensive, before purchasing them, you should decide on the main nuances of the future application:

- The total number of functions is only weighing and transport, or sorting, marking or dosing adjustment will be required;

- Required power supply for the selected model;

- Demandingness of the chosen model to communication channels and access to peripheral equipment;

- The size of the permanent storage device and the period of storage of the results;

- The ability of the tape to skip and track goods in a package of a certain type (i.e. non-standard);

- Whether a group tare function is required;

- What type of control interface will be preferred - touch or keyboard;

- The total number of devices to provide multiple lines.

Also, you should pay attention to the fact that the equipment is suitable for its application. For example, food checkweighers are suitable only for food products, while industrial checkweighers are suitable for industrial products. This provision is enshrined in the relevant Sanitary and Hygienic Requirements of the Russian Federation.

Rating of the best checkweighers and combi-checkers for 2025

Checkweighers

4th place: "Universal METALLAR WU-500"

votes 0

In this model, a control unit and a tape with a strain gauge of increased accuracy are installed on the supporting frame, which allows weighing in motion. If the result obtained differs from the specified one, then the goods are immediately removed to the rejecter located nearby and removed. The model is able to work with products weighing up to 20 kilograms, and the throughput is up to 75 units of product per minute. It is possible to set a manual order for rejecting products. The basic equipment is equipped with a "pusher". The machine is characterized by increased productivity, fast tape speed, digital data processing accuracy. The recommended cost for retail chains is 612,000 rubles.

- The speed of the workflow;

- It is possible to print the log of work for the last session on paper;

- Easy control, Russian-language interface, high-quality display image;

- A wide range of settings and special features to adapt to certain types of products.

- Not detected.

3rd place: "A&D AD-4961"

votes 0

This sample is endowed with the latest digital load cell, and also has a high-speed processing unit for incoming information. Thanks to the presence of such components, the manufacturer managed to achieve a weighing accuracy of 0.08 g.(with a standard of 1 year). Increased accuracy will reduce the skipping of products that exceed the specified values, which will reduce production costs. Structurally, the model consists of 4 assembled blocks (conveyor scales, loading conveyor, control module and base unit), so the entire assembly does not take much time. Accordingly, the global repair of the equipment will not be needed - you just need to replace the failed unit. You can enter the parameters manually or select a predefined template for a specific type of product. The recommended cost for retail chains is 635,000 rubles.

- 7-inch color touch control panel;

- Preset processing templates for 1000 kinds of products;

- Complete washing of the entire apparatus is allowed;

- Unique modular design;

- Relatively small weight and dimensions allow you to quickly move the device.

- Not detected.

2nd place: "Chaoqiang CQ-XP210"

votes 0

Such a sample is directly focused on working with frozen food products. Able to easily match existing markings to checkweighing. If discrepancies are found, the goods are sent to the defect zone by means of a cutter. The device can work with almost any packaging, both molded and shapeless. The result of its use will be a tangible reduction in production costs. The recommended cost for retail chains is 646,000 rubles.

- There is a self-diagnosis function;

- No special tools are required for cleaning;

- Full compliance with environmental standards of the Russian Federation;

- Automatic emergency stop possible;

- The body is made of high-quality steel, which increases the overall service life.

- Not detected.

1st place: "Hualian IXL-400"

votes 0

This device is designed for continuous weighing of products, which makes it possible to simplify and automate their accounting. Easily rejects raw materials that do not meet the specified parameters, simultaneously entering data about this into a static log and taking them into account when forming the final calculation. It is characterized by clarity and sufficient accuracy of information collection, speed of operations. It has the possibility of expanding the functionality and can be additionally equipped with a label printer and applicator. The recommended cost for retail chains is 655,000 rubles.

- Weighing limits - from 0.2 to 10 kg;

- Maximum productivity - 100 units / min;

- Accuracy - (+/-) 0.5-2.0 g;

- Platform dimensions - 400x600 mm.

- Not detected.

combicheckers

4th place: HDM AC-MDC-A Food Industry MCD-F500QD

votes 0

This equipment is a combined unit of a metal detector and automatic control scales. It perfectly combines compact design, light weight and wide functionality. Two floppers are placed on the conveyor for sorting and removing substandard units. The detector perfectly tracks the presence of foreign fragments. The model is directly focused on working with food products. The recommended cost for retail chains is 496,000 rubles.

- Sorting accuracy - 1 g;

- Processing speed - 45 units per minute;

- The weighing range is from 5 to 9000 grams.

- Small allowable weight of processed products.

3rd place: "Kenwei JW-GC215-1-1"

votes 0

The model is widely used for processing food, pharmaceutical, chemical, textile products, as well as various toys and rubber products. It is equipped with a metal detector combined with automatic control scales. The tandem use of both devices will increase the efficiency and reliability of production, eliminating unnecessary costs. The interface is designed for 32 languages and is controlled via a 7-inch touch screen. Fully complies with Russian industry standards. The recommended cost for retail chains is 615,000 rubles.

- The processing speed is adjustable, there are three different modes;

- Independent entry of test results regarding the useful mass and foreign fragments present;

- The conveyor belt is easy to remove and easy to clean.

2nd place: «METALLAR MDW-400»

votes 0

The sample is an apparatus integrated into the production line, combining the functionality of automatic scales and a detector for detecting foreign elements. It copes well with the control of underweight / overweight of products. It is possible to expand the functionality by installing an X-ray add-on. Ideal for the cosmetic, pharmaceutical or food industries, whose lines are limited by the size of the working area. It is characterized by high productivity - about 400 weighings per minute. The recommended cost for retail chains is 723,000 rubles.

- Easy assembly and replacement of parts;

- Resistant to moisture and dust;

- Increased tuning accuracy and the presence of a self-diagnosis function;

- The case is made of "stainless steel" and cannot harm the processed goods.

- Not detected.

1st place: "NCB490 NowSystems for food"

votes 0

This model is a comprehensive solution for quality control of goods and is based on a checkweigher and a metal detector. The working process is carried out by the machine in two directions at once - checking the correctness of packaging and weight with the simultaneous detection of foreign fragments. There are several industrial interfaces available, which allows the device to be connected to various types of the organization's local network (for uploading information about the progress of work and their results in real time). The design uses the smallest possible number of bulky parts and assemblies, which saves space. The recommended cost for retail chains is 786,000 rubles.

- 3 operating frequencies;

- Aludetektor function (for the analysis of packages from aluminum);

- Functional diagnostics.

- Not detected.

Conclusion

In our age of automation, dynamic control scales are considered an essential attribute of any streaming production. They are especially useful when packing bulk products, and not necessarily consisting of too small fragments. It can be either cereals for food production or plastic bolts for construction. Accurate weighing and packing will allow the company to avoid unnecessary costs, which are very difficult to identify manually.

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131648 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127687 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124515 -

The best men's sneakers in 2025

Views: 124030 -

The Best Complex Vitamins in 2025

Views: 121937 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114978 -

The best paint for gray hair - top rating 2025

Views: 113393 -

Ranking of the best wood paints for interior work in 2025

Views: 110317 -

Rating of the best spinning reels in 2025

Views: 105326 -

Ranking of the best sex dolls for men for 2025

Views: 104362 -

Ranking of the best action cameras from China in 2025

Views: 102214 -

The most effective calcium preparations for adults and children in 2025

Views: 102009