Ranking of the best booklet makers for 2025

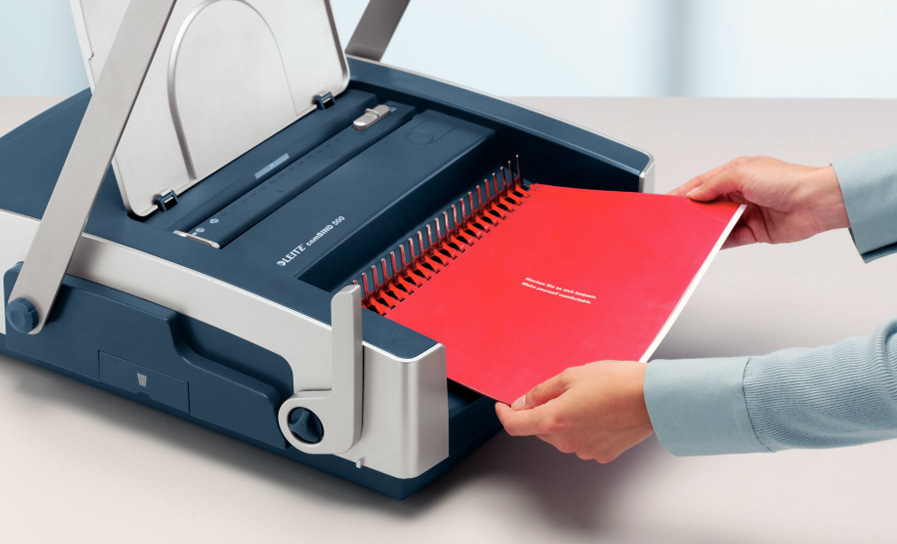

Binding is the traditional method for preparing and arranging paper raw materials. To use it, you will need a special device called a booklet maker. With it, you can easily fasten a paper pile (starting from 3 pages and ending with several hundred). For this, folders with a plastic top and a bottom made of thick cardboard with an adhesive composition are used, or they are replaced by metal or plastic parts.

Content [Hide]

Brochure what is it

Document binding device can be used in office and commercial companies, it is an indispensable assistant where it helps to put the documentation in order, research centers, engineering and design offices, printing companies. It is difficult to do without it where documents are subject to special storage requirements, or to create materials for presentations.

Its process is quite simple. It is necessary to collect the sheets in an even and neatly stacked stack, then put them inside the machine itself. Then you need to designate the location of the holes, making them manually or automatically, if the choice concerns a spring connection. The subsequent work will be done by the weaving machine, the machine will fasten the pages together on one side with a spiral or glue.

Types of booklet maker and binding methods

A binder or booklet maker is a device that binds sheets of paper together into a single document. It is used when preparing and arranging reports, research materials, training papers and other materials. In stores - a large variety of similar machines, differing in characteristics and price. How can a consumer decide on the optimal booklet maker and not pay extra money for features that are not needed? To do this, you need to know the similarities and differences between the models.

The distinguishing feature of the binder is contained in the paper binding technique. The first is a metal spring, the second is made of plastic, the third is an adhesive.

- plastic spring

Plastic bookmakers are quite popular in printing houses and small firms, where employees work with price lists and compile product catalogs. The springs are very strong, with repeated use. If necessary, the spring opens easily to add excess paper or reduce it. In order to be able to stitch on a plastic spring, there must be at least three pieces of paper sheets, but not more than 500 tons (we are talking about paper intended for work in offices, the density of which is 80 g / m). Such a plastic part is quite cheap in cost, it has a variety of colors and different sizes.

Disadvantages - too little rigidity, a limited opening angle of 180 degrees, and also a fairly cheap look.

- metal spring

A more presentable look has a metal spring stitcher, which is one of the main advantages. Such machines are distinguished by greater strength and significant cost. Papers bound with metal retain accuracy for a long time, the opening angle reaches 360 degrees, with 130 sheets inserted. Metal springs have proven themselves on the positive side in prestigious and status enterprises, in the preparation of documentation, or in printing houses, when colorful materials and records are being prepared.

The color component, as well as the dimensions of metal springs, are much smaller than those of plastic ones, but this disadvantage is fully compensated by strength and durability. There is also a significant minus: it is impossible to report or reduce the number of sheets to ready-made documents, because this will violate the integrity of the spring itself.Even if there is a special device that allows you to unbend a metal spring, it is then very difficult for it to take its original shape.

- Thermal binding

With the help of a thermal binder, you can build an interlacing of folders with an adhesive base. This type of booklet maker is in demand where high-speed operation prevails. In just a few minutes, you can make a very high-quality and solid binding. During the process, adhesive folders are applied. The press and a certain high temperature melt it, and during the drying process, the foot is connected, turning into a publication. The end result is a real paperback book.

Its disadvantages are the inability to reuse consumables and add or remove sheets.

When choosing a suitable binder, the punching option is also taken into account. It can be either electrical or mechanical, that is, manual. Penetration manually requires pressing the handle, which is located on the body of the machine, and the first method - automatic, is performed by pressing a key.

Perforation

Booklet maker owners know that the depth of perforation can be adjusted, and some models have this feature. The owner of the device with the ability to adjust can independently decide how far from the edge of the documents there will be holes. Especially often such devices are used by production managers with bulky packs of stitched paper. If the indentation is chosen correctly, the cover of the brochure will not break for a long time, and the reader will comfortably study the documents.

The number of bound sheets per 1 approach depends on the model of the booklet maker.Organizations involved in the creation of voluminous brochures are advised to pay attention to this parameter when purchasing.

Housing material

There will be a plastic binder or a metal binder - the quality of the firmware will remain the same. However, plastic is typical for budget models. More expensive devices are made with a metal or mixed case.

The plastic binder is suitable for those manufacturers whose brochure volumes do not exceed 120 sheets. Also, this option is good when the booklet maker is used from time to time, not on an ongoing basis. The metal makes the case resistant to damage, which means that such a device will last longer. Models with a metal case are characterized by high performance, they can be used on a regular basis. In addition, it is possible to bind volume packs, the thickness of which reaches 500 sheets.

The golden mean is a case made of a mixture of plastic and metal. Such a device is sufficiently resistant to constant load and allows you to staple thick stacks of documents. The price of such binders is slightly higher than plastic, but cheaper than metal.

Additional Booklet Maker Features

Buyers of booklet makers are advised to take a closer look not only at the main, but also at the additional parameters of the device:

- Possibility of turning off individual knives. If it is, then the user can work with atypical paper sizes.

- The separate binding and punching function saves time when creating a booklet.

- The presence of side limiters adds convenience when binding: it is easier to determine the maximum dimensions of the future brochure.

- The dimensions of the device also matter in deciding the nuances of its placement.The issue of dimensions is especially relevant in a small office or room.

When selecting the appropriate binder model, the following model properties may be important:

- Some devices can punch holes in a document placed vertically. This allows you to spend less effort when installing the pack, as well as avoid distortions in the future brochure.

- The selector, which helps to select the springs of the required diameter and thickness, significantly speeds up the binding process.

- Automatic flaps in the waste tray prevent it from being overloaded. Paper confetti has an unpleasant tendency to accumulate, and untimely release of the container leads to clogging of the cutting blocks, which can cause deformation of the knife. Fellowes approached the problem in a complex way and invented a mechanism that opens the flaps of the tray to notify that it is time to remove the waste.

- In some models, you can find a sheet format selector, with which you can quickly set the machine to the desired sheet format, as well as quickly switch from one to another. If the sheet format is chosen correctly, then the holes will be symmetrical and even. In addition, correctly set teeth on the comb contribute to quick and easy spring installation. Fellowes calculated the ideal angle for the teeth to be 15 degrees. In this case, the spring does not slip off the comb and is quickly installed on the document.

- Additional compartments for storing springs and covers are very convenient in the office, where it is important when everything you need should be at hand.

The best thermal binders for 2025

Unibinder 8.2 and 8.4

votes 1

The most common are the devices of the Belgian brand UniBind, founded back in 1979. The devices are known for the fact that they allow you to quickly and easily bind any paper materials up to 470 sheets in just 1.5 minutes.

UniBind thermal binders feature a modern, futuristic design rumored to be from Apple designers. In addition, it is known that Steve Jobs chose UniBind products for his Apple PhotoBook in 2006.

Together with the device, the manufacturer offers to purchase covers of the same brand, the assortment of which consists of 4 types: hard, plastic, soft under the skin and separately for binding. The difference between these covers is that they are based on a metal spine, which makes the binding strong, stable and neat looking. For this reason, every kind of UniBind cover can be considered a hardcover.

Format of bound documents: A3, A4, A5. The Unibinder 8.2 model is equipped with an automatic spine crimping function that gives the binding a “typographical” look.

All UniBind products are made in Belgium and are made exclusively from environmentally friendly materials, which explains the relatively high price of the devices. An additional bonus is that the official distributor of the brand in the Russian Federation provides a test drive for their equipment without any obligations - you can fully work with the device directly in your office and then make a purchase decision.

- All covers are equipped with a metal spine;

- Ability to edit the finished binding;

- Safety and environmental friendliness of products;

- Possibility of automatic crimping;

- Unusual stylish design.

- The high price of devices.

Bindomatic 5000

votes 0

The second most popular thermal binding machines are Bindomatic, which are produced by the large Swedish corporation Bindomatic AB. The most common Bindomatic 5000 binds documents up to 540 sheets quickly. The range of covers of this brand is quite wide: hard, plastic and cardboard covers meet the basic needs of standard office work.

Bindomatic covers, unlike UniBind brand covers, are equipped with a fabric or cardboard spine, without a metal base. With this technology, the glue firmly adheres the sheets, but at the same time does not leave the possibility of multiple editing. A cardboard spine is considered less stable and durable than a metal one, but according to the manufacturer, a document bound on a Bindomatic machine can withstand about 800 pages. Which sounds impressive compared to the world standard of 300 pages.

Thanks to its compact size and minimalistic design, Bindomatic 5000 will easily fit into an office interior, and the ease of operation of the device will allow any employee to quickly master the skill of thermal binding.

Format of bound documents: A3, A4, A5. All products of the Bindomatic brand are certified and manufactured in Sweden.

- The volume of the bound document is up to 540 sheets;

- Compact dimensions of the device;

- Wide range of covers.

Flaws:

- There is no spine crimping function;

- There is no possibility of multiple editing of the document;

- The high price of the device.

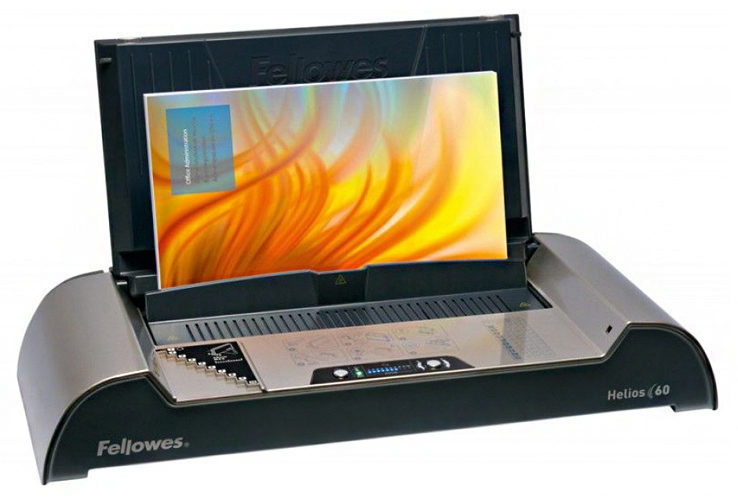

Fellowes Helios 60

votes 0

The American company Fellowes was founded in 1917 and is one of the world's leading manufacturers of office supplies, along with UniBind and Bindomatic. The most productive model Fellowes Helios 60 deservedly takes the third place in our rating - in 4 minutes the device can bind a document up to 600 sheets.

The device is supplemented with a function of mechanical document clamping, and a distinctive feature of the model is the automatic determination of the duration of the heating cycle, depending on the thickness of the spine. The range of Fellowes covers is much more modest compared to the brands that occupy the top positions of the rating - only plastic and cardboard with leather embossing, and only A4 format. The covers are based on a cardboard spine, without a metal backing.

Fellowes thermal binders are made in China and are low cost.

- Low price;

- The volume of the bound document is up to 600 sheets.

- Low strength of the cardboard spine at the base of the cover;

- Narrow range of covers;

- Binding only A4 format;

- There is no editing option.

Bulros T50

votes 0

Bulros is one of the largest brands in the budget office equipment category in the Russian Federation. The brand belongs to the Bulgarian company of the same name and was founded in 2002. The most popular and productive Bulros T50 model can bind a document of up to 500 sheets in 4 minutes - this includes the machine's heating time and binding time. For convenience, the device is equipped with an indicator ruler, which allows you to select the thickness of the thermal folder.

The Bulros consumables range includes only one type of cover - a transparent plastic sheet on the front side and a white glossy cardboard on the back side. The covers are equipped with a thin cardboard spine. Bound documents format: A4.

Part of Bulros products is produced at its own factories in Bulgaria and part (including thermal binders) - at specialized factories in China.

- Low price;

- The volume of the bound document is up to 500 sheets.

- Low strength of the cardboard spine at the base of the cover;

- Only one kind of covers;

- Binding only A4 format;

- There is no editing option.

Office Kit TB400

votes 0

The Chinese brand Office Kit is owned by Kopitan, which has been supplying various types of office equipment from the Asian to the Russian market since 1995. The company specializes in shredders and spring binders, but also supplies two models of thermal binders. One of them, Office Kit TB400, closes our rating.

The machine can bind a document of up to 400 sheets in 2.5 minutes. Additionally, there is an automatic clamping function - after the prepared document is inserted into the binding slot, the cover is clamped and the binding process begins.

The range of branded covers for the Office Kit TB400 is relatively narrow - only one type of softcover, like Bulros. The cover consists of a transparent plastic sheet as the title page and white cardboard on the back. The spine, on which the hot-melt adhesive is applied, is made of cardboard. Bound documents format: A4.

All Office Kit products are made in China and have a low price.At the moment, there are practically no stores on the Russian market that offer to buy consumables for Office Kit thermal binding, but it is quite possible that these are temporary supply difficulties.

- Low price;

- The volume of the bound document is up to 400 sheets.

- Low strength of the cardboard spine at the base of the cover;

- Only one kind of covers;

- There are few cover suppliers in Russia;

- Binding only A4 format;

- There is no editing option.

The best models of binders for the office

ProfiOffice Bindstream M08

votes 12

A mechanical device makes the binding of brochures with plastic springs. At the same time, the unit copes with the punching of 8 sheets, and the edition can bind up to 150 sheets. Perforations are limited to 29.7 cm. The manual perforation with 3 mm penetration is great for small brochures.

It is not designed to change the depth of perforation, but the functions of opening the spring and a convenient perforation lever are combined for ease of use. There is also a retractable container designed for cutting sheets. The weight of this binder is just over one and a half kilograms.

- great for small brochures;

- convenient to work.

- depth does not change.

ProfiOffice Bindstream E25 Plus

votes 6

The device is electrical and maintains weaving with a plastic, flexible spring. The productivity of the unit will allow binding up to 450 sheets in a short time. The device has an accurate perforator capable of punching up to 25 sheets of paper at a time.The advantage of this model is that the perforation depth can be changed and ranges from 3 to 9 mm. Durable blades can be switched off at any time. The number of knives is 21 pieces.

The machine has a separate hand lever that opens the springs so you can easily add or subtract paper. Spring diagonals vary from 6 to 51 mm. A retractable plastic tray for scraps is also included. The average weight of the unit is 17.4 kg.

- the accuracy of the perforator;

- perforation depth changes.

- not detected.

Fellowes FS-5622001 Galaxy

votes 2

Quite a productive device with mechanical action and binding with plastic springs. This unit in a durable, metal case shows itself perfectly in comparison with similar units from other manufacturers. It is capable of binding 500 sheets, 25 of which are punched at the same time. The diagonal of the springs is 6-50 mm. Perforation is carried out with a depth of 3 and 5 mm. The design takes into account the separation of stapling and perforating devices. The spring size selector will align stapled documents to the desired edge. The presence of a box for springs and a special tray for paper waste are also advantages of this design. Detachable sheet binding module enhances instrument performance.

- productive device;

- durable, metal housing.

- not detected.

Fellowes Pulsar E

votes 4

A budget-priced binder designed for small businesses. It has high productivity and can bind up to 300 standard A4 sheets.Punches 15 sheets simultaneously with electric perforation. The size of the springs is 6 - 38 mm. The design of the container for collecting scraps of paper with an opening door, through which it is convenient to get rid of debris. The stapler teeth are at a 15-degree angle for fast binding. Booklet maker weight: 10 kg.

- good performance;

- light weight.

- not detected.

Gladwork BUSINESS WB-25D

votes 3

The productive unit binds brochures with the help of metal springs. Ideal for the production of wall calendars and can be used both in the office and in a small print shop. Binds 120 sheets and the spring size is limited to 14mm. The largest sheet size that this device works with is A4 format. 40 quality knives can be turned off as needed, and the perforation indentation can be varied from 2 to 5 mm.

- the indentation of the perforation can be varied;

- suitable for the production of wall calendars.

- not detected.

Geleos BP-13

votes 3

This machine binds materials with plastic springs. Punching up to 13 sheets at once is enough for a medium-sized office. It will be a great help for small businesses. Binds up to 500 sheets. Works with A4 size documents and smaller.

Reliable manual perforation with a depth of 3 mm allows you to bind small prints without loss of quality. The work of the knives cannot be turned off, but there is a convenient lever for opening the springs and a tray for paper scraps. Perforation depth is adjustable (3 modes). The body of the device is made of durable metal and is located on a stable base. The weight of the unit does not exceed 1.6 kg.

- suitable for medium size office;

- reliable manual perforation.

- perforation depth is not adjustable.

Orion FS-56426

votes 4

This powerful booklet maker binds publications with plastic springs. At maximum performance, it can process 500 sheets in one work cycle. Designed for an office where you want to make brochures of various types. The productive perforator punches up to 30 sheets at the same time. You can easily change the perforation depth in four levels: 3, 5, 7 or 9 mm. Knives in this device are turned off at the request of the client.

With the handy lever attached on the side, you can add or subtract the number of bound sheets. Spring with a diameter of 6-51 mm. A handy box for paper scraps completes the design. The mains connection cable is 1.5 m long and the cord from the binder to the pedal is 1.4 m. This booklet maker weighs just over 13 kg.

- there is a box for scraps;

- there is a function to add sheets.

- not detected.

Quasar-E FS-56209

votes 0

Mechanical binder with binding on a plastic spring. Good performance makes it the best in its price segment. It is capable of binding documents containing 500 sheets. 20 sheets are subject to punching at the same time. The shape of the perforation is rectangular. The body color of the device is grey. Spring with a diameter of 6-50 mm, and the depth of the perforated material from 3 to 5 mm.

- quality device with good performance.

- not detected.

The correct choice of a booklet maker depends on how clearly the criteria for the necessary device are formed.The presented list is not exhaustive, but it greatly facilitates the decision to purchase a binder.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131650 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127688 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124517 -

The best men's sneakers in 2025

Views: 124031 -

The Best Complex Vitamins in 2025

Views: 121938 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114978 -

The best paint for gray hair - top rating 2025

Views: 113393 -

Ranking of the best wood paints for interior work in 2025

Views: 110318 -

Rating of the best spinning reels in 2025

Views: 105327 -

Ranking of the best sex dolls for men for 2025

Views: 104363 -

Ranking of the best action cameras from China in 2025

Views: 102214 -

The most effective calcium preparations for adults and children in 2025

Views: 102010