Rating of the best harrows for walk-behind tractors for 2025

After plowing, the soil always needs high-quality loosening, which is necessary for the complete destruction of weeds, trimming the surface, and reducing moisture loss. In addition, loosening contributes to the saturation of the soil with additional oxygen, which has the best effect on the cultivation of crops and plants. Such a procedure is called harrowing, and the tool through which the whole process is performed is called a harrow (or, in the common people, drags). The harrow can also be manual, but with large volumes of cultivated areas or with high soil density, it is recommended to use it in conjunction with a walk-behind tractor.

Based on its design features, the drag can be mounted or directly installed on the base parts of the walk-behind tractor.In order to understand how to correctly purchase this equipment in order to carry out loosening work quickly and efficiently, you should familiarize yourself with some features and the generally accepted classification in this area.

Content [Hide]

The usefulness of attachments

The walk-behind tractor itself is a unit consisting of a frame, an engine, wheels and a steering wheel. Additional equipment can be attached to it, in this case a harrow. This tool is installed without interfering with the design of the motor unit, which greatly facilitates the upgrade process. The harrow is one of the tools that improve the quality of the soil in the process of cultivating the land. With its help, it is easy to process large areas for planting both grain and vegetable crops.

What are the types of harrows?

In general, they differ in types and are of special purpose and general purpose.

The first ones include:

- Meadow, consisting of links with teeth on the rings, which are designed to remove moss and weeds in meadows and fields;

- Mesh, consisting of a frame, braided with wire - extremely useful for leveling the soil after plowing heavy types of soil, but little adapted to the work of crushing pieces of soil;

- Garden, equipped with special mechanisms for removing the tool from tree trunks in the process of direct use.

The second ones include:

- Circular (considered the most effective due to the arrangement of the teeth in a spiral, which allows you to better break the earth clods into smaller pieces);

- Zigzag (all structural elements of the frame are curved in the form of a zigzag, they also break large clods of earth well, but are more likely to get stuck);

- Standard, ordinary (the simplest option, consisting of directly installed teeth. Quite functional, but due to rare teeth, they require two or three times processing of the same area to achieve acceptable quality).

Estimated load weight per one hoe (tooth, disc, star, plate, etc.) allows us to classify this tool as a light, medium or heavy class.

Working bodies of the harrow

These organs are the cutting elements of the tool, which directly crush the earth clods. There are three types of them: disk, tooth, rotary.

In turn, depending on the type of cultivated soil (loose, soft or dense), the type of fastening of the working body may also change. It can be fixed rigidly, spring or hinged, staggered or in a parallel straight line.

Disc harrow

Its peculiarity lies in the fact that the discs are mounted specifically at an angle (the so-called "angle of attack") to the frame, being slightly arched for greater efficiency.The direction of the "angle of attack" is determined by a smooth or notched edge. The sharpness of the angle is set depending on the complexity of the soil and the condition of the soil. Additionally, discs can be equipped with special needles - they are ideal for stubble control. Disks mounted on the same parallel are called a "battery", for their better penetration into the ground, special spring mechanisms or weights are used.

Tooth harrow

The most common, with an elementary structure, but over time, the tool has not lost its effectiveness. Due to its popularity, this model should be considered in more detail.

It consists of trough-shaped or rectangular strips, at the intersection of which teeth are attached. The teeth should be arranged in such a way that each of them can make a separate furrow. The distance between the furrows is determined by agricultural needs and can be from 22 to 49 mm. To prevent clogging of the tool with clods of earth, adjacent teeth of the same row should be located at least 15 cm apart from each other. Oval and round teeth have a rounded side in the direction of movement, square teeth have ribs, knife-shaped teeth have a wide or narrow edge (depending on the complexity of the cultivated land).

Square teeth are more often used in heavy motorcycle equipment, oval and round teeth in amateur motorcycle equipment, and knife-shaped teeth can generally be used for manual harrowing.

The working elements of the dental tool work like dihedral wedges: the front part splits the pieces of soil, while the back part at this time crushes, pushes and mixes the particles of the earth, destroying large lumps. As a rule, dental instruments have a rigid hinged frame.

Knife-shaped teeth are most effective when working in conjunction with a walk-behind tractor. The teeth located along the oblique cut in the opposite direction to the direction of movement deepen better, since the vertical component of the soil reaction increases, which is why the soil tends to push the tooth out on its own.

The soil is usually processed with a tooth tool to a depth of 3 to 12 cm. The diameter of the lumps after their work is unlikely to exceed 5 cm, with an even furrow depth of 3-4 cm. They are extremely good for spring loosening of the earth after harvesting winter crops: the topsoil is perfectly processed and dead plants are removed. The teeth are also excellent at combing grass, cutting turf, crushing and pulling away molehills.

Harrow rotary

Belongs to the class of attached professional equipment, used on walk-behind tractors and heavy agricultural machinery. Specially designed for working on virgin soil, removes the upper part of the soil layer with a depth of 0.7 cm. Good for processing thick stubble, initial leveling of the soil surface.

The rotary tool is a frame equipped with multi-pointed sprockets with pointed edges (beams), which are fastened together at a right angle. The "angle of attack" (the angle of entry into the soil) is adjusted by the curvature of the rays of the stars.

Rotary equipment works according to the following principle:

- When moving the walk-behind tractor, the stars begin to move;

- At the same time, each ray of the star deepens into the ground by 2-3 cm, destroying the dried soil;

- After the star system emerges from the ground, a small gap is formed in the soil, allowing air to enter;

- Then the nitrogen circulating in the air enters the middle layer of the fertile earth, thereby saturating it and being perfectly absorbed by it.

Upon completion of such treatment, an ideal environment is created for the plants in which their root system will develop with little or no obstacles. Also, the soil will be available for moisture. As a result, rotary models are the most efficient and professional solution for agriculture.

Important! Of all the considered harrowing tools, only the rotary one cannot be made independently. This is due to the fact that each sprocket beam must be machined evenly at the same angle. Otherwise, an uneven load on the engine of the walk-behind tractor may occur, which, in turn, will easily provoke a breakdown of not only the power plant, but the entire unit.

How to harrow

Each case of using a certain type of equipment is, of course, individual, but there are a number of general rules that should be followed in order to achieve the best result.

- Before starting work, it is necessary to carry out a trial run, checking whether the “angle of attack” is sufficient, whether the required depth of the tool entry into the ground is reached, whether the degree of crushing of the earth clods at the exit is sufficient.

- When working with a tool, it is always necessary to observe the sharpness of the “angle of attack”. If it reaches 90 degrees relative to the surface to be cultivated, then the system as a whole will not have enough effort to extract the earth, and it will simply drag the soil in front of it, clogging up with plant debris and clods of dirt along the way.

- In the case when it is necessary to make different types of furrows on the same field in different rows, then an elongated frame equipped with various working bodies (teeth or discs) should be used, coupled with a variability of fastening (rigid hinged or spring).Then, by loosening/tightening the fastenings, it is possible to achieve different types of furrows in the same field.

- You should constantly ensure that the teeth, disk recesses, rays of rotor stars are not completely clogged. If such a situation is detected, they must be cleared immediately. Thus, the service life can be significantly extended.

- It is important to ensure that the furrows left by the working bodies are uniform in those places when necessary (the exception is the case of using different working bodies on the same frame).

- The depth of the furrows can also be increased by increasing the weight of the walk-behind tractor itself.

The rest of the nuances and wisdom are achieved through practice and experience.

The main advantages of harrowing with a walk-behind tractor

Experienced gardeners have long known that if you do not harrow the ground, then you will not be able to get high yields in the fall. Through this simple operation, it is possible to reliably cover the seeds with a layer of soil, which will provide them with a uniform supply of moisture and sunlight. In addition, with the help of this process, it is possible to apply fertilizer evenly to the soil. The main thing is to observe the speed limit - it should not exceed 3 km / h.

Difficulties of choice

The choice of equipment should directly depend on the engine power of the walk-behind tractor: for rotary ones, a more powerful power plant will be needed, for toothed ones - weaker. The same can be said about the complexity of the work - for less pliable soil overgrown with turf, a professional expensive rotary one is suitable, and a light household tooth can also cope with a small summer cottage.

However, it may well be that the tool will cost more than the walk-behind tractor itself. First of all, this concerns frames with various working bodies and rotary models, especially high-precision sharpening.

It should be noted that equipment manufactured in foreign countries is not necessarily 100% of high quality. On the contrary, the agricultural countries of the CIS (Ukraine, Belarus, Kazakhstan) have long become leaders in this market, which provide products that have an excellent price / quality ratio.

Rating of the best harrowing tools in 2025

5th place: drag harrow for motor-blocks Neva and Salyut (station wagon)

votes 1

An easy-to-use drag harrow with a chain attachment. Does not require time-consuming actions for cleaning after work. The attachment feature provides for a certain freedom of maneuver when harrowing (for example, ease of rotation).

Specifications:

| Name | Index |

|---|---|

| Capture in width, cm | 40 |

| Manufacturer | Forza |

| Depth of processing, cm | 15 |

| Weight, in kg | 15 |

| Fastening | Chain (drag) |

| Price, rub. | 3850 |

- Increased coverage of the processing width;

- Simple fastening;

- Relatively affordable price.

- Excessive weight (requires preliminary loosening of the soil)

4th place: Tooth for motoblock Mobile K BM-0.9

votes 0

This tool is ideal for all models of walk-behind tractors produced in the CIS and can be used on more than 20 models. Light weight greatly facilitates the workflow. Can be applied even on dry soil.

Specifications:

| Name | Index |

|---|---|

| Capture in width, cm | 90 |

| Manufacturer | Mobile K (Belarus) |

| Weight, kg | 6 |

| Additionally | station wagon |

| Price, rub. | 3400 |

- Reduced weight;

- Universality for motoblocks produced in the CIS;

- Simplicity of design.

- Extremely large capture width (requires extremely slow processing speed)

3rd place: tooth B-5 for motoblocks Belarus MTZ 09N, 012WM

votes 0

The universal canopy is suitable for both domestic and imported walk-behind tractors. Belongs to the category of a light tool and is designed to perform work of little complexity in a summer cottage or personal plot. Easy to mount and does not require any special cleaning procedure.

Specifications:

| Name | Index |

|---|---|

| Dimensions in open position (LxWxH), mm | 550x1770x650 |

| Capture width, mm | 970-1670 |

| Max. processing depth, mm | 120 |

| Weight, kg | 10.5 |

| price, rub. | 3800 |

- Versatility;

- Ease of use;

- Design reliability.

- Small depth of processing.

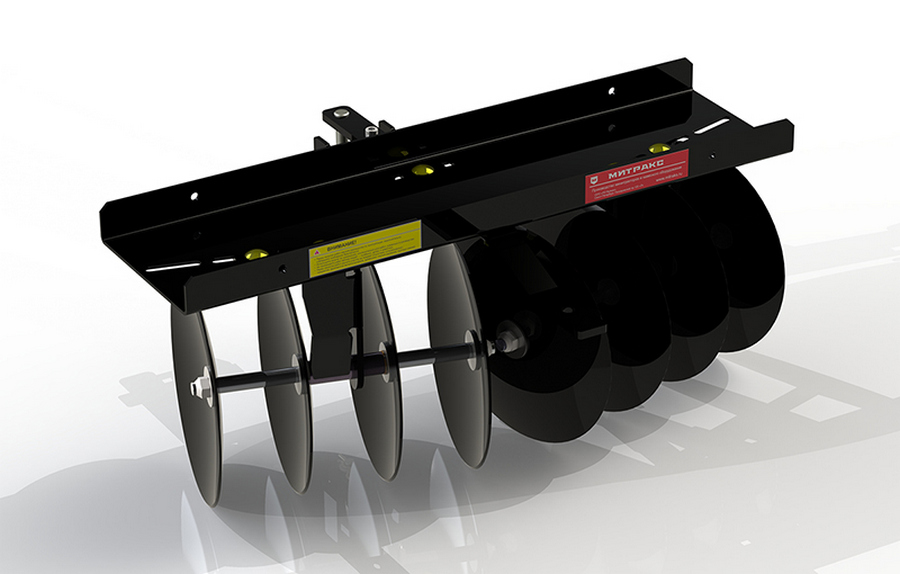

2nd place: Disk BD 850M Neva

votes 0

The tool is designed for loosening and preparing the soil for sowing in difficult conditions. Able to perfectly destroy weeds and grind rotten residues. Pre-sowing preparation with its help can be carried out even without preliminary plowing and harvesting of row crops with thick stems.

Specifications:

| Name | Index |

|---|---|

| Adjustable working width, mm | 700-800 |

| Adjustment of the "angle of attack" of the disks, degrees | 10,15, 20 |

| Axes of rotation | with teflon bearings |

| Additionally | 8 discs 300 mm with sharpening |

| price, rub. | 12000 |

- Adjustable width and "angle of attack";

- Relative ease of construction;

- The coupling is made by one fixing action without a locksmith's tool.

- The need to install lugs instead of wheels on a walk-behind tractor.

1st place: Rotary Neva RB3

votes 0

Designed for pre-sowing and post-harvest tillage. It is also capable of plowing green manure in the fall. The ergonomic design easily cuts the dried layers of the earth, and the stars following the main ones loosen this cutting. Produces the most even tillage.

Specifications:

| Name | Index |

|---|---|

| Weight, kg | 20 |

| Bushing dimensions, mm | 30.2x80 |

| Dimensions of the device itself | 320x700 |

| Maximum processing depth, mm | 200 |

| Price, rub. | 14000 |

- Increased depth of tillage;

- 8 powerful cutting 6-pointed stars-plates;

- Ability to work with firm types of the soil.

- Sections must be installed on the shafts of the walk-behind tractor gearbox.

Conclusion

As you can see from the rating above, finding the right hitch of any type is not difficult at all and it can be combined with various types of walk-behind tractors. However, it is better to purchase a specific hitch for a specific model, although in most cases you have to be content with universal models. It is best to purchase in trusted online stores - this way you can save a good amount, especially since the product is not technically complex.

For the same reason, they are not covered by a long-term warranty. But thanks to the simple design, it is easy to care for this tool. It is possible to extend its service life only by using it on the type of soil for which it is intended and by cleaning the working parts in a timely manner.

Summing up, it can be noted that a quality harrow does not always have to be expensive.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131649 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127687 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124516 -

The best men's sneakers in 2025

Views: 124030 -

The Best Complex Vitamins in 2025

Views: 121937 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114978 -

The best paint for gray hair - top rating 2025

Views: 113393 -

Ranking of the best wood paints for interior work in 2025

Views: 110317 -

Rating of the best spinning reels in 2025

Views: 105326 -

Ranking of the best sex dolls for men for 2025

Views: 104362 -

Ranking of the best action cameras from China in 2025

Views: 102214 -

The most effective calcium preparations for adults and children in 2025

Views: 102010