Rating of the best side cutters for 2022

For processing (cutting) various cables, electrical wires, or for working with a simple wire - you may always need such a simple tool as side cutters (they are also side cutters). Structurally, they are only a pair of parallel cutting planes. They are convenient for biting cables and stripping them of insulation. The best models are characterized by high quality workmanship, sharp cutting jaws, have dielectric handles and can withstand the application of great effort to them.

Content

General information

Side cutters are easy to recognize by their appearance, since their pointed working edges are on the same plane as the handles (and only infrequently a small angle is allowed between them in the design). They are used to cut wires or wires of small diameter in diameter, they are able to make small cuts on metal and plastic surfaces, which is necessary during installation work or when installing wired equipment. When using this tool, its cutting force is controlled by moving the workpiece closer/further in relation to the fastening hinge. The handles of the fixture are specially made large, despite the fact that the cutting jaws are much smaller than them. So it is possible to increase (by pressing) the cutting force due to the application of the "lever" effect. For example, if you need to bite a small wire of small diameter, then it is located closer to the initial edge of the sponges. And for biting a thick cable, on the contrary, it is placed closer to the fastening hinge of the tool. The cut itself occurs due to pressure on the handles by hand (palm), from which the working edges are compressed and, in fact, the incision.

Yet, no matter how simple the device of side cutters may seem, it has a clear nomenclature of the names of all its working parts and consists of:

- two handles;

- Springs;

- heels;

- side part;

- Sponges cutting;

- The back surface of the base;

- stiffening ribs;

- Pyatnik.

All working elements are connected by means of a special lock with a reinforced structure. The spring (if provided) is characterized by increased elasticity and is located between the two handles. Its function is to bring the cutting edges to their original position, which is performed immediately after the end of the cut. In serviceable side cutters, the jaws are always completely closed at the end of the action. The swivel is responsible for ensuring the smooth running of the movement of all parts, which facilitates the work with the device.

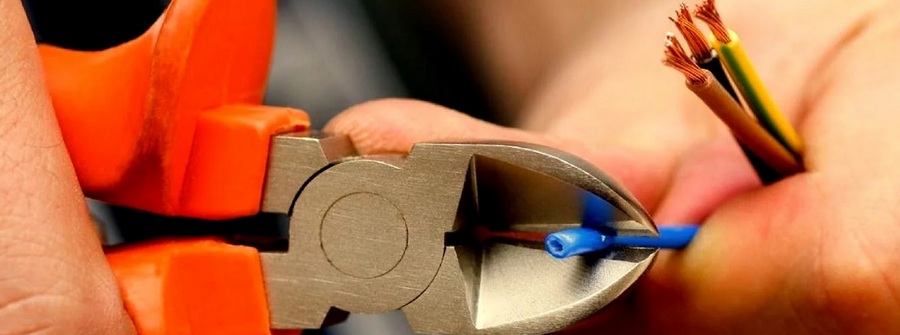

The type of tool in question is often used for cutting:

- cables;

- Cables of small diameter;

- small chains;

- bare wire;

- wires with insulation.

Also, they can play an auxiliary role in the cut:

- plastic parts;

- Tin blanks;

- Products based on durable cardboard;

- Tarpaulin and veneer;

- rubber and polyethylene.

The difference between side cutters and nippers

They are distinguished from the classic wire cutters by the location of the working jaws. Lateral samples have cutting edges that are relative to each other in parallel planes, while in classic models they are at a perpendicular angle. Although for side models in some designs a small angle is allowed. In addition, side cutters are specially designed for processing solid and stranded wires with a large cross-sectional diameter and are generally focused on working with electrical cables. Classic wire cutters are considered a more versatile tool, but they are poorly suited for fine work with some types of electrical wires.In general, this is why you can often find side cutters without dielectric protection on the handles (it is made in the form of insulating covers made of rubber and similar non-conductive materials). Classic wire cutters usually do not have such protection, so it is not possible to work with live wires with them. Often, some security of the “classics” is provided by polymer covers on wire cutters, but they are not a full-fledged insulator in the full sense of the word.

Modern varieties

There are several types of current models of the type of tools in question on the market today, which differ from each other in design and purpose.

- Standard.

This is the most common type of side cutter, which is easy to find in any building supermarket. They are intended for processing wires with a cross section of not more than 2.5 millimeters.

- Reinforced.

These models are designed to perform professional work in plumbing or assembly. Their cutting edges are made on the basis of high-strength alloy steel, and they have undergone finishing production processing in the form of a special hardening, which gives them greater strength.

- Isolated.

They are used by professional electricians, telephone technicians, in general, by all workers whose activities are related to the processing of live cables. Samples with specialized dielectric insulation are allowed to work with live wires up to 1000 volts.

- Miniature.

Such mini side cutters are used by computer network installers, radio amateurs, system technicians, and others. They are small in size and very comfortable to operate in tight spaces.

Summing up, it can be noted that the devices under consideration can have different sizes and versions, and more specifically, they can differ in the shape of the cutting parts. It is this factor that will influence the working orientation of the model. If the sponges are long and thin, then it is convenient to work with thin wires located, for example, on electronic circuit boards. If the working sponges are characterized by a greater breadth of their surface, then they are better suited for removing the insulating coating from cables.

Side cutter safety issues

Despite the fact that side cutters, at first glance, have a rather simple design, certain rules and requirements should be observed when working with them:

- The tool must always be at a 90 degree angle to the cable being cut;

- Do not apply excessive force to the handles. The device must be held very carefully, pressing should be done with care so that the cutting edges converge evenly.

- It is always necessary to monitor the correctness of the cutting procedure and the movement of the device during operation. If there are people on the opposite side of the master, close to him, then it is necessary to change the direction of the side cutters so that the cut piece does not accidentally fly towards unauthorized persons.

- In cases where it is required to bite a wire with a large cross section, it is better to place its base in a special recess of the jaws, which are closer to the connecting node.

- At the end of the cut, the cutting parts must completely close. If this does not happen, and they go to different planes, then this tool is considered unusable, it will easily break at the next operation, they need to stop working immediately.

- When handling reinforced models, it is better to use the help of a second person who will support the cut object and remove it in time. A similar situation is extremely relevant when performing work on an industrial scale, but in everyday life with standard models, such assistance is unlikely to be required.

Features of tool care

Upon completion of work with side cutters, it is necessary to perform several preventive measures:

- Assess the condition of the cutting parts - inspect them for fatal damage, the presence of deep burrs and grooves, as well as cracks in general.

- Examine the condition of the fastener and spring - they must move freely, not create jamming situations, function with the application of exactly the amount of muscular effort as necessary to cut the wire of a certain diameter.

- Check the tightness of the blades - they should completely close at idle, snugly adjacent to each other. As long as the tightness of the fit is at the right level, then even until then the tool will cut thin wires and threads with high quality. It is worth mentioning that it is difficult for the naked eye to assess this condition of mini-side cutters, therefore, in such a situation, it is better to use a magnifying glass or even a microscope.

- Examine the surface of the edges for the presence of foci of corrosion - this is especially important if the work is often carried out in conditions of high humidity (for example, the work of a telephone technician in an outdoor distribution cabinet in the rain).

Sharpening Tips

It is no secret that no matter how intense the cutting tool is, someday its edges will become dull, which will affect the quality of the operations. For side cutters, it is allowed to sharpen the sponges yourself.Although they can be sharpened on a special grinding machine, at home (due to the small area of the cutting surface) this can be done using ordinary sandpaper. The device is brought to the abrasive surface of the paper from the back side, and then slow forward and backward movements are carried out along the cutting edge in order to machine their working base. It is also possible to sharpen with a whetstone, but due to the small size of the device, this will be problematic. Therefore, this option should be considered only as a last resort. It must be constantly remembered that each type of side cutter is designed to process a certain type of material. If miniature models are not used on thick steel wires, they will last much longer. Moreover, most of the existing samples are designed for processing mainly copper and aluminum cables and conductors.

Difficulties of choice

Nowadays, in any building supermarket, as well as on a specialized trading platform on the Internet, you can easily find and buy the desired model of side cutters. However, before buying, you need to decide on the future scope of use, carefully study the specifics of the design of the tool you like, and familiarize yourself with the possibilities of its working stroke. If intensive use of the device is expected, then it is better to prefer ergonomic samples that will be more comfortable to use. If infrequent operations at the household level are supposed, then miniature models will suffice for them.

- Purpose.

For home labor-intensive operations, mini side cutters are easy to use, which will successfully cope with the repair of electronics or household appliances.If processing high-voltage cables is required, then tools with dielectric handles are indispensable. In addition, they should have convenient sizes and solid cutting blades. So they will become a traveling tool for a professional electrician. For cutting knitted wire during industrial-scale operations, it is better to use reinforced models that will easily bite through a wire with a cross section of 6 millimeters. And their most powerful samples, called cable cutters, are able to cut through stranded wires with a diameter of 200 to 400 millimeters. Cable cutters, in addition to their prominent dimensions, are also easy to recognize by the diagonal shape of the working jaws. It should be clarified that some experts recommend using only a specialized tool called "sector shears" for large and stranded wires. Its working boundaries start from a diameter of 130 millimeters.

- Design.

Side cutters can be double-hinged or single-hinged. The latter have the simplest design, which shows a sufficient level of reliability in any conditions. Double-hinged samples are more complex, but are characterized by the fact that they do not have to apply excessive force when handling them. This circumstance is especially important if the work is carried out intensively with the shortest breaks, and a wire with a large cross section is under processing. On double-hinged models, a spring is installed, which independently returns the handles to their original position, “unloading” the physical tension of the master’s hand.

- Maximum working stroke.

This characteristic depends on the length of the edges.For processing network cables, operations with small electronic boards or small conductors, an indicator of 1.6 - 5 millimeters will be enough. To install the electrical wiring network when arranging an apartment, you will need a length of 5 - 15 millimeters. The largest models are those with a working stroke of up to 150 millimeters - they are designed for processing large-diameter stranded wires.

- Comfort at work.

Usually, this parameter is determined by the ergonomics of semicircular handles, which should fit comfortably in the palm of the master. To ensure more confident action, it is better to choose a product equipped with covers made of 2-component material. Its relief can very simply provide additional protection against accidental slipping in the palm of your hand. Also, dielectric handles will also be useful - they will not interfere with normal operations, but they will be useful when processing live wires.

Rating of the best side cutters for 2022

Budget segment

3rd place: "MIRAX 120 mm 22036-5"

An excellent sample, which is useful both in everyday life and for production tasks. It has found its wide application in public utilities and the industrial sector. Suitable for operations with automotive electrics as part of the activities of a small car service, as well as for plumbing and assembly work. Designed for processing medium thickness wires. The total length is 120 mm, the case material is steel. The recommended cost for retail chains is 210 rubles.

- Extremely democratic price;

- The presence of oil and petrol resistant casings on the handles;

- Wide area of use.

- Not detected.

2nd place: "STANDARD 200 mm"

This fitting and assembly device is characterized by a special versatility, it can be used to perform a wide range of tasks. It is made using final hardening at a high temperature mode, the main body material is carbon steel grade "45". The hardness of the edges is 45 HRC, the functional surface is 48-52 HRC. The handles are two-component and equipped with an anti-slip coating. The recommended cost for retail chains is 340 rubles.

- Durable manufacturing material;

- Ergonomic anti-slip handles

- Has no backlashes and gaps.

- At first, the move is somewhat tight.

1st place: "YATO, with stripping function 140mm, 65Mn, HRC48-54, YT-22640"

The model is made of high quality spring steel, has two two-component overlays on the handles. The case is solidly "fitted" into these ABS pads, which are equipped with an additional non-slip and tactilely pleasant TPR material. The whole structure is characterized by the presence of a massive and large connecting rivet, which is designed to minimize the lateral tear along the cutting edges, which makes the incision more precise and visually recognizable for its continuation. Both the body and jaws are made of 65 Mn steel, at the same time both are hardened to 48-54 HRC. The recommended cost for retail chains is 380 rubles.

- There are seats for wires with different cross-sections;

- General reliability and functionality;

- Good return spring.

- Not detected.

Middle price segment

The sample is designed to remove the insulating protection from single-core / multi-core cables, and can also cut wires. The jaws are bent at an angle of 45° to the main plane, which ensures an accurate flush cut even in hard-to-reach areas. Also, it should be noted that the cutting jaws are hardened using high-frequency currents, which increases the overall service life of the fixture. The recommended cost for retail chains is 420 rubles.

- A powerful spring allows you to apply less effort to open;

- The structure is made of spring-type steel;

- Ergonomic handles are wrapped in thermoplastic rubber sleeves for a secure grip.

- Not detected.

2nd place: "Kubis ProGripper 180mm, CrV, HRC 47-52"

The model is able to work on materials of different hardness, remove the insulating coating from the wires, and cut through the wire of medium thickness. It is made on the basis of chrome-vanadium steel, and all working units are hardened by high-frequency currents up to HRC 47-52. The case has a nickel-plated finish, the handles are two-component and are additionally equipped with anti-slip stops. The recommended cost for retail chains is 620 rubles.

- Quality workmanship steel;

- Good value for money;

- Ease of use.

- Not detected.

1st place: "YATO 115mm, YT-2081"

The sample is focused on the use of wires made of aluminum, copper and other non-ferrous metals. They can be used for cutting individual sections of cables, as well as for making small cuts on metal or plastic substrates.The edges are made of high quality steel, and the handles are covered with anti-slip plastic covers that are able to maintain a secure grip when working even in difficult weather conditions. The recommended cost for retail chains is 680 rubles.

- Small dimensions;

- Comfortably lie in the palm of your hand;

- Adequate price tag.

- Not detected.

Premium class

3rd place: Dielectric VDE 1000V 160 mm VIRA RAGE

This model is capable of cutting through wires, wires, cables. Safe work with objects energized up to 1000 Volts is guaranteed. The goods are certified by the German quality standard "VDE" and "GS2". The "VDE" (Verband Deutscher Elektrotechniker - "Association of German Electrical Engineers") brand is considered documentary evidence of the fact that power tools are safe. The body of the working part is made on the basis of chromium-nickel steel grade "52", there is a double-sided polishing, the body has passed a 2-stage process of electrophoresis. The handles are made of specialized TPE plastic, which allows you to work with objects under tension. The recommended cost for retail chains is 999 rubles.

- Perfectly sharp working edges;

- Convenient shape of handles;

- Easily bite even thick cables.

- It is necessary to constantly monitor the formation of corrosion centers.

2nd place: "CrV Cam Teflon Skrab 22044"

These combination side cutters are made of chrome vanadium steel type "Chrome Vanadium 58-63 HRC TEFLON".The design is made in a special way and has a displaced axial center ("eccentric") and is able to carry out work with the application of human muscular effort by 30% less. Sharpening is made by a special faceted method, there are additional cutting planes for perpendicular cuts. Handles are dressed in a teflon antiskid covering. The device is highly resistant to corrosion. The recommended cost for retail chains is 1080 rubles.

- German quality;

- Ergonomics in three labor areas (grip, cut and protection);

- Requires 30% less effort.

- Not detected.

1st place: "HAUPA dielectric VDE 180 mm, fully insulated 210302"

Very expensive side cutters that are designed for any kind of work with large diameter electrical wires. The entire body is completely clad in a protective dielectric coating and has a total length of 180 millimeters. The insulation is two-color, produced by the double immersion method (outside red, inside yellow). The recommended cost for retail chains is 19,300 rubles.

- A wide range of tasks performed;

- Full body ergonomics;

- German quality standard.

- Very high price.

Conclusion

Side cutters belong to the group of pliers and are designed to work with conductive materials based on soft metals - copper and aluminum (including most non-ferrous metals). With their simple models, you should not work on steel wire, because in this way the cutting part of the device will become dull very quickly.Therefore, for each type of operation, it is necessary to correctly select a certain type of cutting tool.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131649 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127687 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124516 -

The best men's sneakers in 2022

Views: 124030 -

The Best Complex Vitamins in 2022

Views: 121937 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114978 -

The best paint for gray hair - top rating 2022

Views: 113393 -

Ranking of the best wood paints for interior work in 2022

Views: 110317 -

Rating of the best spinning reels in 2022

Views: 105326 -

Ranking of the best sex dolls for men for 2022

Views: 104362 -

Ranking of the best action cameras from China in 2022

Views: 102214 -

The most effective calcium preparations for adults and children in 2022

Views: 102010