Rating of the best concrete contacts for 2022

Today's concrete monolithic bases are characterized by their rather smooth outer surface. It is this property of them that makes it difficult to finish with decorative and paintwork materials. Such material will definitely peel off after application, despite the fact that it does not play a special role how it was applied - horizontally or vertically. In order to eliminate this problem, a special composition was developed to ensure the maximum degree of adhesion - concrete contact (abbreviated as BK). It is a particularly strong mixture for the treatment of concrete-cement substrates.

Content [Hide]

- 1 General information

- 1.1 Technical parameters of concrete contact

- 1.2 Areas of use

- 1.3 Technological basis of the composition

- 1.4 The main advantages of BC

- 1.5 Features of release and flow control

- 1.6 The specifics of processing by means of BC planes with previously applied oil paint

- 1.7 Inefficiency of concrete contact on certain types of foundations

- 1.8 Errors at work

- 1.9 Application tools

- 2 Rating of the best concrete contacts for 2022

- 3 Conclusion

General information

The type of reinforcing composition under consideration is essentially a primer, which contains polymer-cement fragments. They provide reliable adhesion of the finishing coating with the original concrete. Concrete contacts, as a group of adhesive solutions, may contain:

- Silicates, acrylics or polyvinyl chloride, which, after curing, form a tight polymer film that will create a proper adhesion to the finish coat;

- Portland cement, which is characterized by a good (by the standards of the cement substance) level of endurance and reliability;

- Mineral chips or quartz sand - their smallest fraction prevents the layer of dried paint from shedding;

- Additives in the form of plasticizers, which are responsible for proper frost resistance and moisture resistance.

When applied, betokontakt fills all cracks and chips on the working plane at an equal level.Such uniform filling saves up to 35% of the finishing material.

Technical parameters of concrete contact

In compositions from different manufacturers, they can differ dramatically. However, for the most part, for any type of material under consideration, indispensable qualities can be distinguished:

- The release form is always either a ready-made composition or a set of dry components that must be diluted with a solvent or plain water.

- Application is possible both manually and mechanically, for which a foam rubber roller, brush or spray gun is used.

- The color of the finished mixture varies from light pink to pure white. The presence of pigments qualitatively simplifies the application process, as it makes it easy to distinguish between untreated areas.

- Standard curing time ranges from 2 to 4.5 hours. This property is directly affected by the level of humidity and ambient temperature.

- The temperature mode of operation "starts" from +10 degrees Celsius. Although today such mixtures have been developed that allow operation at negative thermometer readings.

- The usual consumption of the material in question is from 0.15 to 1 kilogram per square meter. The consumption is influenced by the consistency of the solution itself and the porosity of the processed structure.

- The storage temperature should be only positive and be in the range from +10 to +40 degrees Celsius.

IMPORTANT! The put solution in the environment with low humidity dries in 120 minutes. If plasticizers are present in it, then this circumstance will increase the drying time. Only with the complete formation of the film is it possible to proceed to the final decoration.

Areas of use

After applying the concrete contact, a rough film with abrasive inclusions is formed on the plane, which makes it possible to apply such whimsical materials as putty or plaster on it. Abrasive fragments are crystals or grains of sand, and thanks to them, the finishing material receives an additional basis for fixing. The main task of such a primer is to ensure adhesion on difficult surfaces. However, efficiency can only be achieved on certain grounds, which include:

- Smooth (virtually without pores) concrete. From it, the corresponding panel walls and floors in apartment buildings are traditionally made. If a friable/extremely porous type of concrete was used for their manufacture, then a different type of primer will be required to process it.

- Ceramic tiles. Even if it is old and has served its time, then concrete contact can be applied on it without resorting to its dismantling. In extreme cases, to improve the quality of the coupling, it is only necessary to carry out a coating in two layers.

- Some wooden surfaces. Sometimes situations arise when there is nothing more to cover the wood with. This is necessary in cases of finishing it with plaster. The only requirement is that the area to be primed must be absolutely dry.

- Metal. This is a complex material that has no pores at all and does not absorb liquid substances well. However, a special type of BC has been developed for it (information about this possibility must be placed on the packaging).

It is worth noting that the above types are an exhaustive list. Naturally, you can try applying it to other bases, but this will at best increase the cost of the work, and at worst will not give the proper result.As for metal elements, they should be processed exclusively in fragments, for example, only protruding small beams and structures can be processed.

Technological basis of the composition

It consists of the smallest fragments of quartz or sand, due to which increased adhesion is achieved. Depending on the size of the fractions, BC can only be intended for internal work, smaller inclusions are more suitable for external processing, and there are also universal combined samples that allow any use. Information about the size of inclusions should always be indicated on the informational part of the package, and in this case it is not worth neglecting the manufacturer's recommendations - application in the right conditions is the key to reducing primer consumption and obtaining a proper working result.

Pigments are also the most important component of the consumable in question, because with their help it is easy to track untreated or poorly treated areas visually. Pigmentation is classically done in either white or pink. There are also completely transparent samples, but it is extremely inconvenient to work with them, especially when the film hardens and the treated area becomes outwardly indistinguishable from the treated one.

Any of the domestic concrete contacts must comply with the requirements of the State Standard No. 281 of 1996. In it, concrete contact is defined as a water-dispersion composition with acrylic copolymers. It should be noted that foreign manufacturers may deviate from the stated standards, and if there is no information on compliance on the packaging, then in certain Russian realities the material may not be suitable.

The main advantages of BC

These include:

- Environmental friendliness. The material does not have an unpleasant odor, does not emit fumes harmful to human health. It can be applied without the use of personal protective equipment.

- Resistant to aggressive substances, including strong alkalis.

- The presence of waterproofing qualities.

- It allows oxygen to pass through, allowing you to maintain the proper level of ventilation indoors, which means reducing the risk of mold.

- The ability to resist the development of flexible and vital activity of parasites.

- Relatively fast curing - from 2 to 5 hours (maximum).

- Long-term operation - at least 80 years (however, then the layer will begin to invariably collapse).

- Wide working temperature limits - from +10 to +40 degrees Celsius at a humidity of 60-80%.

Features of release and flow control

The type of material in question is commercially available, usually in containers of 3, 5, 20 or 50 liters. Can be supplied ready-mixed or as a dry mix to be mixed with water or solvent. In any case, both mixtures must be stirred before work to a homogeneous consistency, so that the fine-grained filler is evenly distributed throughout the volume. In addition, during operation, the composition also needs to be stirred periodically.

The volume of the consumed amount of BR will directly depend on the size of the constituent fragments and the porosity of the treated plane. As a result, you need to adhere to the following recommendations:

- For a highly porous surface (building bricks or lower grades of concrete), the consumption can be up to 500 grams or more per square meter. For them, deep penetration BC should be used.

- Surfaces of medium porosity (finishing brick or standard concrete slab) will require consumption in the range of 300 to 350 grams per square meter;

- A slightly porous substrate or generally smooth (for example, glass, metal, previously painted surface) can be treated with an amount of 150 grams per square meter.

The specifics of processing by means of BC planes with previously applied oil paint

It is also allowed to process such grounds through the BC. Nevertheless, professionals advise to remove the oil layer in order to improve the quality of adhesion. However, there may be situations where it is not possible to separate the oil layer. Then the workflow must be carried out in the following steps:

- Preliminarily completely degrease the working plane;

- Give it additional abrasiveness with a metal brush or coarse sandpaper;

- Perform additional notches with a chisel or ax;

- Carry out thorough dedusting;

- Apply the primary layer of BC and dry completely;

- Apply a second layer of BC and dry completely again;

- Now it is permissible to impose any, even whimsical material, such as plaster.

Inefficiency of concrete contact on certain types of foundations

Of course, concrete contact can also adhere to particularly smooth surfaces, but it does not tend to penetrate their structure. Also, it should not be used on loose substrates, which include foam and aerated concrete, plaster and the like. Often concrete contact can be used to further strengthen the tiled surface, but it is better to do this with a special adhesive.The reason lies in the quality of adhesion, which is 0.9 megapascals for specialized adhesives, and only 0.5 megapascals for BC. Accordingly, the use of a layer of BR on a normally absorbent surface will only lead to an increase in the cost of work.

Sometimes it may seem that the sticky surface formed by BC will only strengthen the decorative layer applied on top. To do this, they use BC and a cheap brand of tile adhesive, hoping that such a tandem will cost less and last longer, since these two components will complement each other. Practice shows that the result of such an application is very difficult to predict: it is possible to achieve the desired effect, but more often such a joint use turns into a disastrous result. It is easier to use specialized glue, which contains primer elements. Such products are labeled with the informational inscription “for complex bases”, characterized by deep penetration into the structure, which is why the setting occurs, as they say, “tightly”.

It is also not recommended to use concrete contact on self-leveling floors. Conventional cement primers may give the best effect, while gypsum variations will have to be applied in large volumes in order to obtain the best result in this way. Moreover, the concrete contact applied on the self-leveling floor will crack in a short time or the formed film will simply swell, and with it the finishing decorative layer.

Errors at work

Quite often, when working with the material in question, users make the following mistakes:

- The dry composition is diluted with too much water, indeed, the application process is facilitated by this, but then the strength of the formed film begins to suffer;

- It is allowed to apply the mixture on a frozen base;

- Application is made on collapsible structures, without their preliminary separation (processing of each individual part is required);

- It is allowed to apply the mixture on a wet base;

- Working periodic mixing is not performed, which is why the consistency ceases to be uniform;

- It is allowed to apply a finishing finish to a plane that has not dried after BC;

- It is allowed to carry out work at an ambient temperature below +10 degrees Celsius with standard, and non-specialized compositions;

- A large amount of dust gets on the drying surface, which reduces the level of coupling. Re-processing will be required to fix the problem;

- Expired BK materials are used.

It should also be noted that the BC used must always be of good quality. The level of its effectiveness can always be checked on a small inconspicuous area. It is better to check the quality in a practical way than to completely trust the information assurances of the manufacturer, even if his reputation is not in doubt.

Application tools

The chemical composition of this type of material is quite environmentally friendly and sometimes does not require the mandatory use of personal protective equipment. If it is supposed to work with a roller or brush, then the master will need overalls only in order not to get dirty himself. Another thing is working with a spray gun.The atomization will take place in the form of a fine dispersion, which means that the particles of the mixture can remain in the air for a long time before they completely settle. When working with a spray gun, protection of the respiratory organs, eyes and mucous membranes is more than recommended, as well as justified.

Rating of the best concrete contacts for 2022

Budget segment

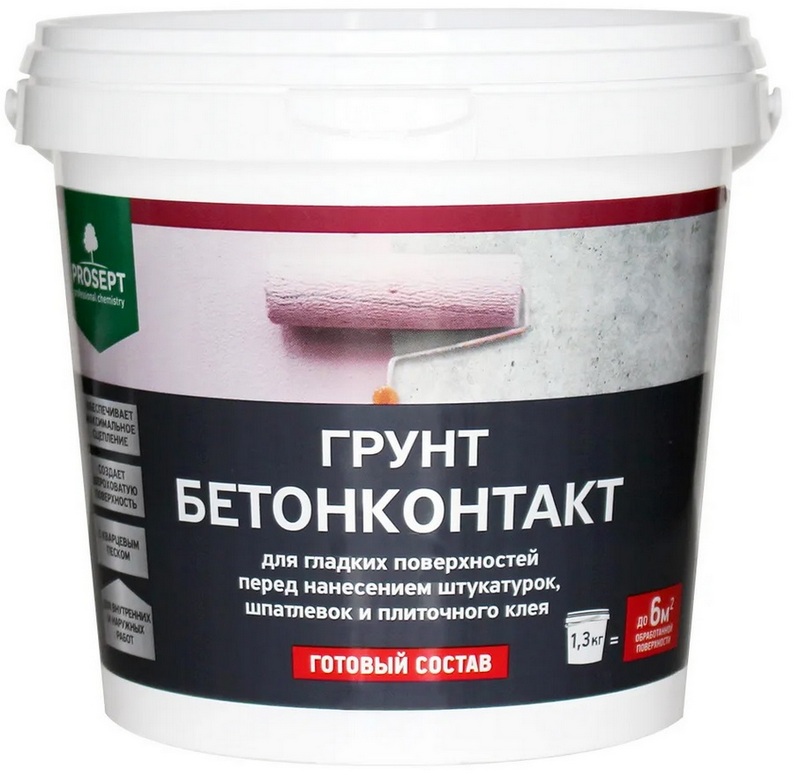

3rd place: "PROSEPT for smooth surfaces before applying plasters, putties and tile adhesives"

votes 0

The product creates a reliable adhesion of finishing materials with smooth dense surfaces - monolithic concrete, etc. It contains acrylic dispersion, functional additives and quartz sand with various granule sizes, which makes adhesion maximum and prevents subsequent sprinkling of plaster, putty, tiles, gypsum, and others. coatings. Contains color pigment to help control even application. Does not contain solvents, safe for humans and animals. Designed for pre-treatment of dense, slightly absorbent substrates - cast-in-situ concrete, concrete slabs, reinforced concrete ceiling slabs, floors, bricks, cement products, lime materials, gypsum boards, substrates with oil or alkyd paint, tiles, etc. Suitable for interior work in rooms with normal humidity - rooms, corridors, offices and other commercial premises, for work in rooms with high humidity - bathrooms, kitchens, basements, etc., as well as for outdoor work, subject to the temperature regime of operation. The recommended cost for retail chains is 248 rubles.

- Sufficient volume;

- Excellent adhesion;

- Fast drying.

- Not detected.

2nd place: "PROFI anti-mold and universal BC"

votes 0

Suitable for pre-treatment of dense substrates that poorly absorb moisture (monolithic concrete; concrete blocks, slabs and ceilings; brick; cement products; lime materials), to prepare areas for plastering, tiling, decorative stone. External and internal works are possible. It can be applied on old oil and alkyd coatings, on old tile facings. Prevents sliding of thick-layer coatings from smooth vertical planes. Forms an adhesive layer with increased resistance to mechanical stress. As a result, the coating does not crumble, does not peel off, the quality and service life of the coating system improves. The recommended cost for retail chains is 429 rubles.

- Does not allow the base to absorb excess moisture;

- moisture resistant;

- Contains a biocidal complex to fight fungus and mold.

- Not detected.

1st place: "FARBITEX PROFI (PINK adhesive primer, concrete primer, wall primer 4300008927"

votes 0

The product is characterized by a good quality-price ratio. The drying time of each layer at a temperature of (20 ± 2) ° C and normal humidity is no more than 3-4 hours. As the temperature and humidity decrease, the drying time increases. The area intended for priming must be cleaned of dust, grease and other contaminants. It must be dry and free from contamination. Peeling old paint or loose whitewash should be removed. Before use, the primer, if necessary, is thawed at a temperature of (20 ± 5) ° C and thoroughly mixed.The primer is applied with a brush, roller on a dry prepared base in one layer. Incompletely set primer can be washed with soap and water or collected with a spatula. The recommended cost for retail chains is 493 rubles.

- Pink indicator to identify treated areas;

- Prevents the formation of efflorescence and the destruction of the plaster layer;

- Improves the quality and increases the service life of the coating;

- Prevents the appearance of mold and fungus;

- Eco-friendly, does not contain organic solvents, odorless.

- Pink color is not suitable for liquid wallpaper (it will shine through).

Middle price segment

3rd place: "Akrimax 3 kg, adhesive, for outdoor and indoor use"

votes 0

The composition is applied on smooth bases: concrete, reinforced concrete ceiling slabs, floors, thermal insulation, drywall, bricks, etc. The application of primer is a preliminary step before applying gypsum and cement plasters, putties, laying ceramic and tile. Betonokontakt has a pink color to identify the treated areas. Site Preparation: It must be clean, sound, dry, secured and free of grease. Before application it is necessary to remove exfoliating old fragile bases. The recommended cost for retail chains is 519 rubles.

- Consumption - 200-300 g / m2, depending on the surface;

- Drying time - 4-6 hours, at a temperature of +20 C and a relative humidity of 65%;

- It is an environmentally friendly, fire-, explosion-proof, non-toxic product.

- Not detected.

2nd place: "Profilux Betonokontakt coarse 2.5 kg"

votes 0

The product is completely ready for use. It has excellent penetrating power and good binding properties. Penetrates into the work surface, forming a protective film. Strengthens porous and fragile surfaces. Improves adhesion of finishing material. Has a good coefficient of adhesion. Resistant to alkalis. Forms a rough surface, easy to apply. Forms a vapor-permeable coating. The recommended price for retail chains is 579 rubles.

- Well strengthens porous and fragile areas;

- Improves adhesion of the finishing material;

- Has a good coefficient of adhesion;

- Resistance to alkalis;

- Easy to apply.

- Not detected.

1st place: "Concrete contact with quartz filler 2.5 kg"

votes 1

Composition with quartz filler, completely ready for use. Designed for pre-treatment of dense, non-absorbent substrates (concrete, concrete blocks, concrete ceilings, floors, bricks, etc.), before applying plasters and other finishing materials, as well as for processing coatings on old facing ceramic tiles. The soil forms a textured rough base and creates favorable conditions for increasing the adhesion of the plaster mixture to the plane, provides a reliable and durable coating. It is used for external and internal works. The recommended price for retail chains is 700 rubles.

- Multifunctionality;

- Increased adhesion;

- Sufficient volume.

- Not detected.

Premium class

3rd place: "Glims BetoContact"

votes 0

This adhesive primer with quartz filler is intended for interior use. Can be used for preliminary preparation of smooth and slightly absorbent substrates. Creates a developed rough surface on concrete, cement, brick substrates for the subsequent application of gypsum or cement materials. The recommended cost for retail chains is 785 rubles.

- Work with many different bases;

- The price is relevant for the volume provided;

- Application in any way - from a roller to an airbrush.

- Not recommended for liquid wallpaper.

2nd place: "Bitumast 20 kg"

votes 0

This adhesive product is used for indoor and outdoor applications, it forms an excellent rough coating. Designed for processing dense, slightly absorbent, smooth substrates made of cast-in-situ concrete, concrete blocks and beams, bricks, drywall, old plasters and surfaces. It is used before applying gypsum, lime-gypsum, cement-lime plasters, masonry and adhesive mixtures. Contains acrylic latex and minerals. The recommended cost for retail chains is 5733 rubles.

- Large volume of containers;

- Completely prepared composition;

- Ecological structure.

- Not detected.

1st place: "Plitonit 15 kg"

votes 0

The product is intended for pre-treatment of bases with low water absorption (monolithic concrete, floor slabs, concrete blocks, cement plasters, etc.) before plastering, facing and flooring works.Provides improved adhesion applied over coatings - cement, gypsum, lime-cement, lime-gypsum and polymer compositions. Ready-to-use composition. For interior and exterior use. The surface to be treated must be free of dirt, dust and grease. Loose material and old, weak coatings should be removed. Surfaces infected with fungus and mold must be pre-treated. The recommended cost for retail chains is 6930 rubles.

- High-quality European material;

- Sufficient volume;

- Work with loose bases.

- Somewhat overpriced.

Conclusion

A group of concrete-contact primers has firmly established itself on the construction market today, allowing you to skip the reinforcement process. Their peculiarity lies in the property to stick to almost any surface. At the same time, the pull-off force (0.4-0.5 MPa) is sufficient to keep the subsequent type of finish. At the same time, the primer itself, due to the introduction of quartz sand into the composition, has good adhesion to plaster or tile adhesive, which makes it extremely popular.

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131655 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127695 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124522 -

The best men's sneakers in 2022

Views: 124040 -

The Best Complex Vitamins in 2022

Views: 121943 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114982 -

The best paint for gray hair - top rating 2022

Views: 113399 -

Ranking of the best wood paints for interior work in 2022

Views: 110323 -

Rating of the best spinning reels in 2022

Views: 105333 -

Ranking of the best sex dolls for men for 2022

Views: 104371 -

Ranking of the best action cameras from China in 2022

Views: 102220 -

The most effective calcium preparations for adults and children in 2022

Views: 102014