Rating of the best balancing machines and stands for 2022

The history of balancing machines began more than 50 years ago. The design was developed by American engineer Lee Hunter, he was the first to think over the design of an automated wheel balancing machine, without which no modern tire shop or car service can do.

Content

An indispensable attribute for the service sector

Previously, such nuances were solved using a static method. It is understood that the wheel was put on a special rod, after which it was spun. Stops were marked. To determine the site of imbalance, such manipulations were repeatedly repeated. It could take a whole day to service one vehicle. In addition, it should be noted the high level of error, which was overcome years later. How often do you need to use these services?

According to the inhabitants, if the car regularly drives on city roads, then you need to contact the car service at least once every six months. Such trips coincide with the seasonal replacement of tires, which saves money. However, if the vehicle often drives off-road or in the suburbs, then it is recommended to visit the machine once every few months. Balancing favorably affects not only the operation of the “wheels”, but also:

- crankshaft.

- cardan shaft.

- Compressors.

- Pulleys.

- Coupling.

- Rotors.

The point is that debugging can be aimed at the functioning of individual elements of the machine. How to understand that such manipulations are necessary? For those who have just recently driven, this question is more than relevant. In order not to make common mistakes, you need to pay attention to how the car goes at speed, and whether there is vibration in the steering wheel area. These bells are the first thing that a motorist should pay attention to, and in the near future visit a tire fitting shop.

Experts advise balancing after each hit of the wheel in a large hole. If the blow is really strong, and there is a visible deformation of the disk, then you simply cannot do without stands. In addition to leveling the damaged surface, you should resort to the services of specialists.

Timely appeal to specialists will help to avoid many problems, including:

- Suspension deterioration.

- Accelerated wheel bearing wear.

- Tire tread wear.

- Reinforced steering loads.

The main task of the tire fitting worker is to identify the imbalance and eliminate it. In this case, compensating loads on certain parts of the disk are eliminated. In addition to the personal experience of the employee, an important criterion is the availability of high-quality equipment from the best world manufacturers. The average cost of work will depend on the diameter of the wheel. The amount of 200 rubles does not seem so big, especially when it comes to the safety of yourself and others. What are the settings?

Equipment types

Popular models designed for passenger cars are in the greatest demand. During rotation, the X and Y axes of the wheel must remain unchanged. Otherwise, the centrifugal force will be directed to other elements of the car. Imbalance may occur due to a meeting with a serious bump, hole or other type of load. In the case of considering situations related to trucks, excessive vibrations of the body itself, which occur during the transportation of goods, should be added to the general list. Such moments negatively affect the suspension and tire life.

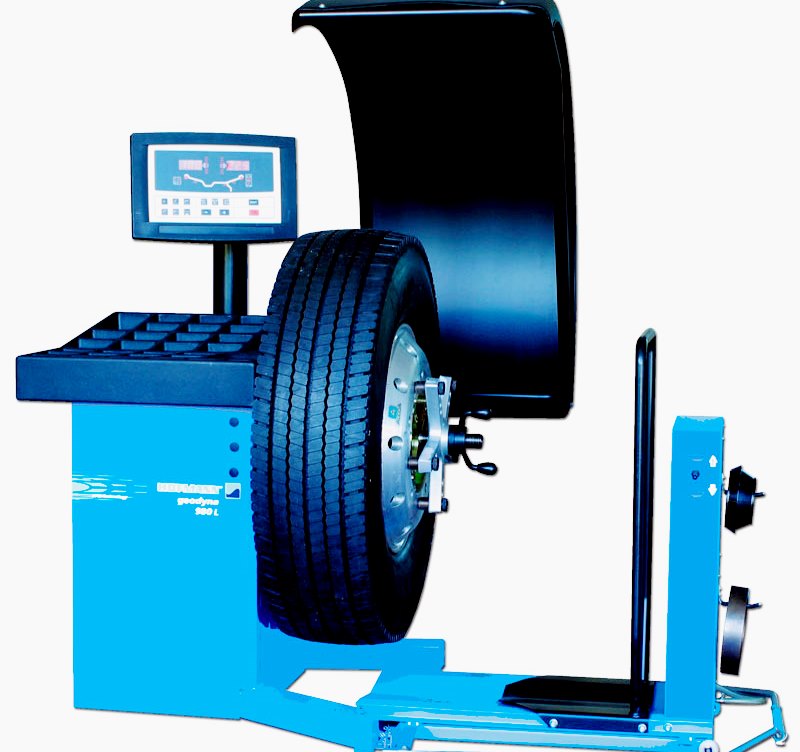

Installations designed for trucks are classified as specialized.On conventional machines, the tasks set will not work. In addition to more accurate balancing recognition, they can significantly increase the life of rubber and other vehicle components. After a series of successful manipulations, there are fewer vibrations on the body, the load on the chassis and hub is reduced, and an increased ride smoothness is observed. Unlike conventional stands, machines for trucks are equipped with a reinforced frame.

How does it work

Without equipment of this type, it is extremely difficult to imagine a modern tire fitting shop. Even in small workshops there is a place for a device that will take up to 3 square meters. m area. Preliminary strengthening of the foundation is also not required. The base of the structure is reinforced. On one side, the shaft for the wheel is mounted. A protective cover is attached to the top. Depending on the power of the electric motor and the dimensions of the casing, the size of the wheel that is attached to the stand depends.

The principle of balancing is to spin the wheel, in which axle deviations are detected during rotation. In each of the models, this happens in different ways.

For convenience, below is a comparative table with an overview of the main indicators.

| type of drive | Description |

|---|---|

| Auto | The best solution for most enterprises in this service sector. The necessary operations are performed automatically - by the machine. The wheel is spun by a shaft. Measurements are taken with an electronic ruler. The detected deviations are displayed on the monitor. After a short processing of the data, the installation locations of the weights are determined automatically, as well as their weight. For more convenient control, voice commands can be used. |

| semi-automatic | The spin-up of the tire also occurs automatically.Outside efforts should not be made for this. Regardless of the brand, data will have to be entered into the computer manually. |

| Manual | The shaft is spun manually. To measure the basic parameters, you need a mechanical ruler. The information obtained is compared with the GOST manual for deviations. |

What should you pay special attention to when choosing popular models? On the manufacturer, consumer reviews and the cost of the basic kit. Most modern enterprises rely on the quality of equipment, thereby reducing the number of employees. In this case, preference should be given to expensive and fully automated designs of Russian or Chinese production.

Such devices in one cycle are able to identify problems and eliminate them if necessary. More customers will be served per shift, which means that the income will be higher. Customers spend less time visiting service stations, which means they prefer to return there again.

Rating of high-quality and inexpensive balancing machines

AE&T B-500

The model is used to troubleshoot the wheels of cars, small trucks and motorcycles. Functions in static and dynamic mode. An excellent solution for small and developing centers. It is based on advanced technology that allows you to carry out all the necessary manipulations in one cycle, even if the weights are close. In addition to the calibration mode, there is the ability to work with alloy wheels (three modes). The panel is equipped with a large and user-friendly display.

For the price, such a kit is profitable, because the purchase will cost 48,000 rubles.

- after lowering the casing, auto-start occurs;

- numerous operating modes;

- automatic calibration function;

- modern technology for installing weights and taking measurements;

- data entry by means of a measuring arm;

- the presence of dynamic and static mode.

- significant ones are missing.

START Sivik SBMK-60 E

The model belongs to the budget category. In addition, the device positions itself as reliable and extremely easy to use. It should be noted that the operator may be without proper work experience. There is a proprietary protection against power surges - "power guard". To start the system, you must press the appropriate button or close the cover. The electronic ruler is responsible for determining the diameter and distance. A special sensor is responsible for the amount of work performed. Based on numerous reviews, the 40 mm spindle assembly deserves special attention.

You can buy the device in the online store at a price of 52,000 rubles.

- strength;

- build quality;

- ergonomics;

- the set contains different-sized cones, a caliper and a casing;

- warranty - one year;

- noise reduction option.

- "split" with limited functionality.

SOROKIN 15.21

It is used for servicing trucks, cars and motorcycles. The unit is designed for medium and light workloads. The model will not pull the active stream. Information can be found on the display with a Russian interface. When the weights are installed, a sound notification occurs. The program is launched after entering the data. Calibration is performed independently by the operator. The noise figure is 70 dB, which is considered an acceptable indicator. The diagonal of the display is 24 inches, which allows for visual and informational control.

Cost - 53,000 rubles.

- convenient display;

- in the kit you can find a caliper, pliers, flange, clamping nuts and cones;

- insignificant error in 1 g;

- eliminates both dynamic and static imbalance.

- parameters are entered manually;

- build quality.

AE&T B-520

The unit is capable of servicing 10-24 inch wheels used by light trucks, cars and motorcycles. It is this model that is better to buy for working with alloy wheels. It is characterized by the output of indicators of increased accuracy during self-calibration and conventional diagnostics. Measurements are taken automatically. The control panel is equipped with a color display, cells and a desktop where weights are placed. The shaft is made of high-strength materials and has an increased strength index. There are three separate programs for working with aluminum wheels. There is also a static and dynamic mode. Auto start when lowering the cover.

How much does a model cost? The purchase will cost 62,000 rubles.

- automatic ruler for measurements;

- high-precision equipment with minimal error;

- high strength shaft;

- separate modes designed to work with alloy wheels.

- not identified.

AE&T B-820

A novelty in the world of balancing stands, it has a modern look and a set of features that will help a novice mechanic to start his own business. Works with discs 10-24 inches, which is considered the standard for small trucks, cars and motorcycles. Designed to work with cast structures. It is characterized by the presence of a high-precision apparatus, which is used to install self-adhesive weights.Excellent performance was revealed both during self-calibration and diagnostics. The computer takes measurements. The product is equipped with a color display, special cells for weights and a work table.

The purchase will cost 87,000 rubles.

- stability;

- steel case;

- automatic ruler;

- high-precision equipment;

- accuracy and strength of the shaft;

- a separate program for alloy wheels;

- accuracy in work with weights.

- not identified.

TOP of the best balancing machines of the middle price segment

PULI PL-6579WR

A well-known branded product from a Korean manufacturer, it is based on the latest integrated circuits. It is a full-fledged diagnostic complex that displays information in real time. Equipped with a 15 inch display. The operating system has a design of its own production, which indicates the high accuracy of the measurements. Weights are added automatically, for this the machine stops the wheel. Shaft rotation is fixed separately. The laser pointer is responsible for the correct position.

Cost - 95,000 rubles.

- illumination of disks in the course of check;

- automatic switching on, stopping and suspension of weights;

- over 10 modes;

- durable case;

- clear management;

- tire self-adjustment.

- price.

AE&T B-600

A high-quality product from a well-known and time-tested manufacturer. In addition to modern design, it should be noted that there is a set of programs that can cope with the indicated functions. Responsible for balancing the wheels of cars, trucks, motorcycles in both static and dynamic modes. The perfect solution for new and small service stations.A two-pin measuring ruler is responsible for the placement of balancing weights and measurements. The "autoprogramm" option helps to set the layout. Illumination is provided by LEDs located on the body. The computing unit is built on a Texas microprocessor, which belongs to the high-performance category. The electromagnetic type brake significantly reduces the time allotted to stop the wheel.

Cost - 99,000 rubles.

- electromagnetic brake;

- memory function;

- the presence of a laser navigation system;

- LED lights;

- two-coordinate measuring system;

- "autoprogramm" option;

- "moto" function;

- digital display.

- not identified.

AE&T B-823

A modern device that allows you to balance the wheels of cars. Equipped with surge protection and self-diagnosis. The machine detects any malfunctions quickly and displays them on a convenient display. The interface of the application used deserves special attention, which will be understandable even to a person who has never dealt with such equipment before. There are several modes of operation, which will help you easily cope with everyday tasks. Marking and self-calibration is carried out by the system.

Price - 101,000 rubles.

- numerous operating modes;

- interface;

- automated ruler;

- display;

- assembly;

- work speed;

- manipulation quality.

- small diameter wheels.

NORDBERG 4523A

It is such a company that it is better to buy automated equipment if the company has enough funds.One of the main selection criteria is the characteristics, this model is at its best. We are talking about the distance, width and diameter of the serviced elements. All the necessary information is displayed on a convenient 17-inch LCD display. Powered by 220 V. Key elements are assembled and manufactured in China. However, already assembled equipment is being tested in Europe, as evidenced by the relevant certificates. In the set, a potential buyer can find a measuring instrument, compasses, tongs, weights and nuts.

Price - 114,000 rubles.

- high-quality set with everything you need inside;

- low noise figure (70 dB);

- Comfortable LCD display;

- table with separate compartments for weights;

- a separate program is responsible for the hidden installation function, which is mounted in a niche located near the wheel spokes;

- tire position optimization;

- self-calibration;

- self-diagnosis;

- workplace illumination;

- versatility (suitable for both a small workshop and a large service station).

- not identified.

AE&T B-829

A popular model from a well-known manufacturer. An excellent choice for small and semi-professional workshops that service cars and other small vehicles. Provided that the company's budget allows, then you should give preference to high-quality and time-tested equipment at an affordable cost.

The average price is 119,000 rubles.

- self-diagnosis;

- protection against breakage and power surges;

- system input of three main parameters;

- ruler included;

- numerous modes;

- comfortable LCD display of optimal size;

- system labeling and calibration.

- not identified.

Master Tires MT-1200

The balancing structure is designed for servicing trucks. It should be noted the presence of a pneumatic lift, which is so necessary for working with large-sized equipment. Allows you to identify the imbalance of both cargo and passenger wheels. It is distinguished by the presence of a powerful microprocessor, which has an error of 0.005 kg.

Cost - 142,000 rubles.

- high-speed processor with a stable clock speed;

- for the safety of the operator, a durable casing is provided;

- error codes during calibration are displayed on the screen;

- built-in pneumatic lift;

- clear interface.

- missing.

Rating of the best premium balancing machines

CORGHI EM 9250 CompactLine PREMIUM

One of the highest quality products on the market today. However, the quality fully justifies the cost. If necessary, the model can be ordered online directly from the manufacturer's website. Allows you to identify imbalances in minivans, motorcycles and cars. The operator's work is simplified as much as possible due to built-in programs that independently work with weights on the tire. All the necessary information is displayed on the panel with LED backlight. The disk is shown in section, after which the system independently determines the balance plane.

Cost: 220,000 rubles.

- build quality;

- the speed of the necessary manipulations;

- time-tested product from a famous brand;

- sensors are responsible for reading data;

- standard body color;

- processing of tires weighing up to 75 kg;

- if necessary, you can purchase auxiliary stands designed for wheels of a larger diameter and size;

- reinforced rotation drive;

- the ability to use four wheels at the same time;

- three types of cargo.

- not identified.

John Bean B9200

The perfect solution for small businesses and small workshops that have just begun their journey to universal recognition. According to most experts, such a purchase is an essential step towards success and high income. The design allows you to carry out the necessary manipulations in a short time period, without much labor.

Price - 430,000 rubles.

- comfortable placement of weights and other balances;

- convenient display, which displays the necessary information;

- application of VPI technology (virtual planes);

- after measurements, the system applies the brake;

- hidden placement of weights;

- identifying the exact location of the problem;

- semi-automatic measurement of diameter and input;

- ergonomics;

- equipment;

- no need to purchase lifting equipment;

- mobility.

- manual drive of rotation of the tire.

HOFMANN GEODYNA 7600L

A frequent visitor to tire shops, urban service stations and dealerships with a high and medium volume of daily work. The perfect solution for servicing motorcycles, SUVs, minibuses, small trucks and cars. The system independently makes a preliminary selection from the list of available modes. To simplify the input of information and the setting of balances, a backlight is used.The monitor is built-in, touch type, with a convenient graphical interface.

Price - 468,000 rubles.

- convenient tire mounting;

- start-stop (short cycle);

- accelerated data processing time;

- VPM technology;

- a wide choice of programs;

- cover for balancing;

- the rim is equipped with lighting for easy cleaning;

- EasyALU function;

- smart sonar;

- fast data entry;

- accuracy of measurements and problem area;

- touch monitor.

- not identified.

Hunter GSP9700 with Road Force Measurement

A balancing stand that contains all the necessary characteristics and functional features that really high-quality balancing stands should have. Both lateral and radial impact on the disk are measured, after which the system issues recommendations for solving the indicated problem. Such aspects may concern both the undercarriage of the machine and other key elements that conventional equipment may not be enough to solve the problem. It is rightfully considered the best equipment for determining tire slip forces, measuring basic indicators, balance quality, loaded runout and radial forces.

Price - 1018000 rubles.

- Wheel Countering Check option;

- after pressing the pedal, there is an instant transfer of information;

- split weight mode;

- laser pointer;

- split-spoke mode;

- tire stability on the machine.

- not identified.

HOFMANN geodyna 9000P

The installation is used in professional workshops, service stations and dealerships, in which there is an endless stream of customers.The system first checks the level of fit of the tire and the correctness of its location on the disk. The axial and radial runout of the tire and rims is also measured. The system checks the tread pattern, which is then displayed on the screen. In the set, you can find auxiliary clamps of the electromechanical type. The screen is wide, built-in and color.

Price - 1250000 rubles.

- the ability to manually adjust the geometric fit and ride;

- contactless input of necessary information;

- VPM technology;

- checking axial runout and radial tire and disc;

- the correct fit of the tire is checked by the system;

- search for damage to the side element;

- search for flat wear;

- easy to use program;

- the ability to use equipment without prior training;

- numerous programs and settings;

- color and wide monitor;

- clamping device in the set;

- diagnostics (data) are saved automatically;

- printout of measurements;

- tire wear rate.

- missing.

Conclusion

In the process of choosing equipment that is so necessary for service stations, a balance should be found between the quality and cost of the proposed product. Which model is preferable to purchase for a small or newly opened enterprise? The range of such products is extensive. In addition to the cost of the machine, it will not be superfluous to read the numerous customer reviews or find out which design is in high demand in the modern market.

At the start, almost no one has sufficient financial resources, but it should be noted that not a single service center will be able to function without high-quality balancing equipment.Perhaps you should purchase a model of a high price category, which will allow you to expand the range of services offered by the service and recoup the costs of its purchase in the near future. Good luck in your endeavors!

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131662 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127701 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124527 -

The best men's sneakers in 2022

Views: 124045 -

The Best Complex Vitamins in 2022

Views: 121948 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114986 -

The best paint for gray hair - top rating 2022

Views: 113403 -

Ranking of the best wood paints for interior work in 2022

Views: 110330 -

Rating of the best spinning reels in 2022

Views: 105336 -

Ranking of the best sex dolls for men for 2022

Views: 104376 -

Ranking of the best action cameras from China in 2022

Views: 102225 -

The most effective calcium preparations for adults and children in 2022

Views: 102019