Ranking of the best diamond cups for 2022

The diamond cup is designed for grinding structures made of durable materials. It has the necessary hardness. Thanks to this, it is possible to process marble, brick, concrete and many other products. To carry out the grinding procedure, you will need a tool. A simple electric machine with a power of at least 1.5 kW is suitable. During the work there will be a very high concentration of dust.

Content

Device

The diamond cup resembles a metal disc containing diamond coating. Due to this, it has increased strength and hardness. It is able to handle complex surfaces. Choosing a device is not easy. To do this, you need to know all the characteristics of diamond cups.

The device is divided into 2 groups. The first option includes circles that have a wide range of applications. The second type includes devices that are more whimsical and require special care. The working part is made of a bond and diamond coating. If the diamond wears off, the cup stops working effectively. In order for it to start functioning again, it is necessary to pass through it with abrasive material.

The same model can affect the processed materials in different ways. If it polishes granite perfectly, then on marble the efficiency will be much lower. You can ruin your work surface. It will appear a large number of various pits and irregularities. The product must be selected according to its intended use. So, models made for working on marble will not work in the case of granite. The diamond wears off quickly. Grinding will lose its effectiveness.

Also grinding cups have differences in the fraction of diamonds. The smaller this characteristic, the more “clumsy” the product is made. If it is necessary to level large ruts, then it is better to take a disc that has a rough coating. After processing, you will have to grind the surface again, but with a model with a finer fraction. If the surface to be treated has a flat base, then a part with a fine texture should be used immediately.

The working discs also differ in the quality of the diamond. Not always an expensive option will be more effective than a cheap one.But often a budget diamond will wear out faster, sharp notches will appear. The more expensive option will definitely last longer. However, being new, both cheap and expensive options can be equally effective.

Working discs have a different segment shape. The small distance between the fractions means a cleaner surface finish. Such models are recommended for grinding fragile materials. The procedure eliminates the appearance of chips and bumps. A large distance between the segments indicates faster processing. However, the quality of the sanding will be slightly worse.

Types of diamond wheels

The cups may have a different number of diamond segments. Depending on this parameter, several types are distinguished. Each model has its own narrow specialization and purpose.

Wheels with sections arranged in 1 row are light in weight and highly efficient, but they are very difficult to keep on the surface to be treated.

On some models, the segments are arranged in 2 rows. This design is ideal for roughing, it will quickly clean off all the roughness and irregularities, and carry out rough grinding. To bring the surface to be treated to an ideal state, you will have to use a nozzle with a different coating.

On sale you can see cups of the “square” type. They have a large mass and are produced for roughing the work surface. During grinding, a chipping effect takes place. This speeds up the process and reduces wear on the diamond blade. Most often used for roughening and surface preparation for spraying polymeric material. The "square" design leaves behind a rough plane. This has a positive effect on adhesion with other components.

Models are available for roughing very dense and strong materials. This design is called "Typhoon". With a small weight, it has a high margin of safety and wear resistance. Its shape is made in such a way that the cut particles are discharged at a high speed.

Manufacturers present models for finishing materials. This includes the segmented Turbo model. Nozzles are used in cases where it is necessary to achieve the ideal quality of grinding. Suitable for creating beautiful edges and chamfers on granite and marble. The cup is used by engravers-masons. They make curly stone monuments. By means of a nozzle it is possible to put beautiful bends on various products. On sale you can see devices with which precise processing is performed. Their diameter is about 100 mm. Such devices are wear-resistant and will last a long time.

Disks "Boomerang" are intended for finishing grinding. The work requires careful handling of the material. They are usually bought by professionals. The products have a variety of fine-grained diamond elements. This technology allows you to get a high quality end result.

Types of fasteners

The working disc must be installed on the electric tool. The most common types of fasteners are m14 and m22.2. Most grinders have such seats. Some manufacturers present on the market a tool with an unusual type of fastener (m16 or m24). This is done for a specific purpose. Owners of such machines will have to buy consumables only from this manufacturer. This fact can be devastating. After all, such products, as a rule, cost good money.

Products are produced in different circles.Before buying, you need to make sure that a cup with a certain diameter can be used on an existing grinder.

Scope of use

Diamond cups are in the first place when processing hard rocks and materials, they will help to carry out roughing and finishing of brickwork, slabs, concrete. They are ideal for polishing natural rocks such as granite or marble. First of all, rough processing is carried out. After that, do the final cleaning.

Diamond discs perform the following functions:

- cleaning of irregularities;

- removal of protruding elements;

- alignment of joints;

- seam polishing;

- smooth cleaning of the surface;

- finishing;

- elimination of old layers.

Good to know! When grinding, it is worth using a vacuum cleaner or pouring water onto the surface to be treated. This procedure will greatly facilitate the work. The amount of deposited dust will decrease significantly.

Handling advice

During grinding, moderate pressure should be exerted on the grinder. Pressing too hard can overheat the bundle, which will negatively affect further processing and reduce the resource of all elements. The pressure should also not be too low. In this case, the second layer of diamonds on the working surface of the cup may not open after erasing the first one.

If the product stops removing the processed layer, then you should not throw it away. Most likely, it is necessary to remove the upper bond and the new diamond layer will open itself. When working with granite stone, the disc often rubs and stops grinding. In this case, the best option would be to run a spinning cup over the plaster. The latter will act as an abrasive. The worn layer will be removed. After that, the disk will be able to process the surface further.

Selection Tips

The quality and speed of the work depends on the nozzle. In addition to the selection of technical characteristics, it is necessary to match the mounting holes on the grinder and the disc. The standard cup has a circumference of 125 mm. The diameter of the inner hole is 23 mm.

Of great importance is not only the power of the grinder, but also the speed. It is necessary to compare 2 characteristics. The instructions must specify the maximum degree of rotation. This indicator must match the characteristics of the grinding machine. Otherwise, the safety of the work being done can be called into question.

Usually, an adapter washer is included with the cup. With this simple device, the disc can be placed on different tools. Grinding is carried out, first of all, roughing, and then finishing. It all depends on which model the user has purchased.

During the purchase, you need to focus on the balance of the disk and its mass. And also look at the heat dissipation rate. Strong heat will shorten the life of the product. If you work under normal conditions, then it will last a long period without losing its original characteristics.

Rating of quality diamond cups for 2022

Inexpensive

Trio Diamond TCW153

Double row, used in tandem with angle grinders. Professionals use it to level concrete structures, brickwork, granite and stone sculptures. During operation, no water supply is required to cool the surface.

The design of the disc allows you to operate it for a long period. The performance is much more than the simple model. Users typically do rough sanding with electric machines.

The cost is 550 rubles.

- no water supply required for cooling;

- long period of operation;

- qualitatively removes an uneven layer.

- not found.

Sibrtech 72955

Designed for installation on a hand-held electric tool, it can grind brick, concrete, stone, granite and marble with high quality. After processing, the surface will have good smoothness. Small roughness will disappear without a trace, the treatment area will please the eye with its mirror-like purity.

The design can remove a thick layer of concrete. Sagging and seams will be removed in a short period of time. If the thickness of the removed layer is very large, then the processing is done in several steps.

The cup is also suitable for rough grinding, creating a rough base (with the subsequent application of other materials), preparing for filling. The electric machine must have sufficient power. During operation, it is necessary to control the degree of pressure on the tool.

The cost is 660 rubles.

- high wear resistance;

- perfectly treats surfaces;

- you can perform a wide range of work.

- not identified.

SPARTA 729905

Double-row, capable of high-quality cleaning of such durable materials as granite, stone, marble, brick and concrete. Users purchase it for rough processing of material, it is able to remove a thick layer of hard surface. Seams and convex irregularities will be eliminated in a short period of time. After processing with this nozzle, the surface will become rough.

Double-row design is convenient to grind sandstone with stone. Many builders use it to remove excess screed. However, with this cup it is impossible to do fine grinding. The surface becomes rough. It can be covered with another material or finished.But this will require a different nozzle with different characteristics.

The cost is 457 rubles.

- it is convenient to remove large drops on concrete structures;

- can remove a thick layer of hard surface;

- irregularities will be eliminated in a short period of time.

- Impossible to do a clean cut.

Boomerang SIBRTECH 72956

Installed on a hand tool. You can grind stone, marble, concrete and granite. Designed for finishing, smoothing small differences and roughness.

This name is due to its appearance. Its diamond segments resemble the shape of a boomerang. The composition of the disk includes small diamond chips. The surface after polishing becomes a mirror. There are no roughness and notches on it.

The cup is light weight. This makes it convenient to use. Most often installed on an electric grinder. It is popular with professionals. The cup has a high performance, which is many times higher than other analogues. Many prefer the device because of its high wear resistance and lightness.

The cost is 580 rubles.

- long service life;

- excellent balance;

- easily copes with its tasks;

- during operation, the disk does not go to the sides and in depth;

- after processing 1.5 m2 surface thickness of the dick does not change.

- not found.

Turbo SPARTA 729955

It is carried out in two variations (turbo and solid). It is used for finishing surfaces that do not require cleaning of a thick layer. Materials such as marble, stone, brick and concrete can be sanded.

Diamond elements are mounted around the circumference, on the entire working plane. The cutters are located perpendicular to the direction of rotation of the disk. The distance between them is minimal. From the outside, it looks like a solid circle. The appearance of the "Turbo" cup is similar to corrugated material. A large number of segments will grind any surface. Therefore, the disk is used for fine grinding of concrete planes with small amounts of work being done. It is also used in the manufacture of various figures. The nozzle will help to polish corners, bends, create all kinds of chamfers and edges.

The cost is 460 rubles.

- you can make all kinds of shapes;

- performs a wide range of activities.

- not found.

average cost

AShK DIAMASTER COBRA Premium Ø 125mm concrete boomerang

Designed for hand-held grinders with a 22.2 mm seat. On the cup there are "Boomerang" segments, which are covered with diamond coating. It has a distinctive feature - an increased resource. Also, the circle quickly removes the top layer of the processed plane. Most often used for grinding concrete.

The form is optimal. This design allows you to clean large irregularities and drops in a short time. You can easily remove the sags that often remain after pouring the floor.

The cost is 1700 rubles.

- quickly removes the top layer;

- increased resource;

- quality.

- not found.

Diamond Segment Grinding

The cup has been heat treated. It has large grinding segments. It stands out for its high processing speed and long service life.According to the instructions, you can grind materials such as glass, granite, marble, ceramics, artificial stone and much more.

It is used for finishing buildings and rooms that have marble floors, decorated concrete walls, granite coatings. With it, you can remove chamfers, edges and cut geometric shapes.

Anyone is able to polish wooden structures, metal and many other materials with their own hands. The cup is established both on the electric, and on the pneumatic tool.

The cost is 1500 rubles.

- heat treatment;

- long service life.

- not found.

ZUBR Master 33376-125

It is installed on grinders with a power exceeding 950 W. It is designed for leveling surfaces and cleaning surfaces from paints and other hard materials. Granite, concrete, artificial and natural stone can be processed. The system does not require a water supply. The cup has the necessary wear resistance, it can be used for a long time.

The working part of the disc is a synthetic diamond, which is made using a special technology. The element has increased strength and hardness. The base is made of steel. In production, products undergo strict control. Quality is monitored by the best specialists. The cup during operation is gaining momentum. In this regard, the balance of the disk is of great importance.

The system does not require a water supply for cooling. Usually the working circle is installed on an electric machine. You can grind almost all types of hard surfaces.

The cost is 980 rubles.

- convexity of working segments 5 mm;

- can be sanded up to 700 m2 surfaces;

- the diamond element is arranged in 2 rows;

- there are holes that naturally cool the disc;

- enough to carry out a wide range of works.

- not found.

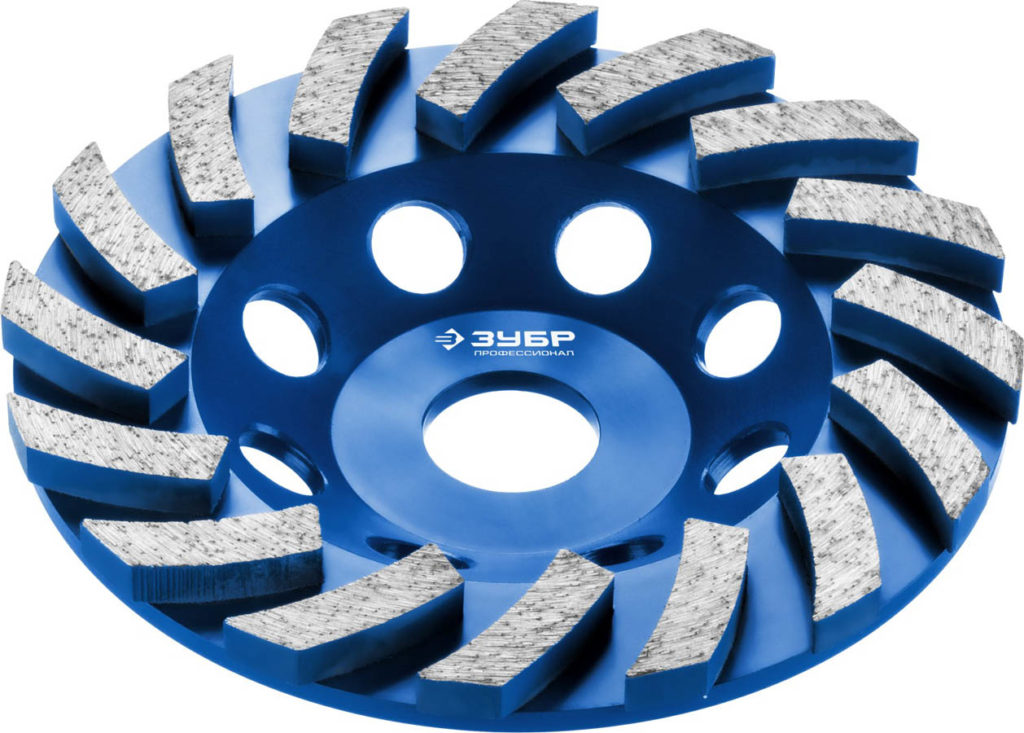

Turbo, series PROFESSIONAL Zubr 33371-115

It is possible to remove and grind all types of hard surfaces (granite, concrete, different types of stones). The base is made of specially treated steel. The surface is divided into segments. The system does not provide water cooling. The working part is stuffed with high-strength diamonds. This technology provides high performance and excellent grinding quality.

The cost is 1570 rubles.

- convexity of segments 6 mm;

- can be sanded up to 800 m2 surfaces;

- hard diamonds provide a mirror finish;

- the disc is perfectly balanced, which ensures ease of use;

- the cup is equipped with holes that perform a cooling function.

- not found.

Practice "Master" 779-615

Works in tandem with diamond grinders and angled electric tools. You can clean almost all types of hard materials, including paint. However, the exact information is better to read in the instructions. Operating speed - 12200 rpm. The innovative design ensures a long service life. There is a turbo layer on the cup, which will help the user to make a flat plane.

Disks can be classified as technologically advanced. They make the sanding process much easier. Nozzles are produced in different versions. This provides great benefits. Discs can be used in tandem with a variety of tools. The final result will be of high quality.

The cost is 850 rubles.

- long service life;

- turbocharged layer;

- processing quality.

- not found.

Expensive and high quality

Niborite-Beaver Ø125×22.2

Manufacturers presented another instance for rough surface treatment. With it, you can clean the surfaces of coatings such as bitumen, mastics, polyurethane compounds and paints. The cup in a short time will make the walls and ceilings of the room even. The working part is covered with special needles that are securely held in a metal base.

The mass of the product is only 180 g, which will facilitate the work of any user. It will be much easier to grind the surface in hard-to-reach places (corners, ceiling). The disk cleans the plane very quickly. This creates a large amount of dust and dirt. During the work you will need a vacuum cleaner.

The cost is 2680 rubles.

- quick cleaning of the old surface;

- quality alignment;

- suitable for floor repairs.

- a lot of dust.

Strong 98X20 gray

It is used in tandem with machines of various types, has 6 diamond segments. This makes it possible to polish mosaic floors and concrete pavements with high quality. The products are suitable for preparing the plane for coating with polymeric materials.

High quality guarantees sufficient wear resistance and high grinding speed. There are small gaps between the segments of the working surface. During operation, they are not clogged with dirt and dust. The cylindrical base is resistant to mechanical stress. Water supply is required during operation. This system ensures a long service life.

The effectiveness of the development is not in doubt.The disk will easily remove large drops and influxes. Diamond elements are made in the form of small squares. The working segments have a large thickness and an optimal distance. This makes it possible to cope with any protrusions, differences and bulges. Nozzle type "Square" will save a lot of time for roughing. Concrete and brick coatings will be polished in the shortest possible time. In this case, the wear of the diamond disc elements will be minimal.

The cost is 2150 rubles.

- save a lot of time for roughing;

- grinds quickly and efficiently;

- long service life.

- requires water supply.

AShK TNK Ø 100xM14 CUP №0

Designed for processing concrete and stone. The grinding process can take place with or without water supply. The product has a long service life. A rubber gasket is mounted at its base, which acts as a shock absorber. During operation, it reduces the runout of the rotating part. The product is convenient and comfortable to grind the surface. The rubber base allows you to quickly clean the top layer.

Steel discs are also produced. One segment is filled with resin. This design allows you to do finishing. Brittle materials can be cut.

The cost is 4100 rubles.

- convenient to use;

- excellent balance.

- high price tag.

In the construction industry, diamond cups are very popular. Often they are used during demolition work. The product will help to remove a layer of plaster, glue, gypsum and many other materials in a short period of time. The disk resource is designed for a long period.The device will save a lot of time, since it simultaneously removes the processed layer and aligns the plane.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131650 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127689 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124518 -

The best men's sneakers in 2022

Views: 124032 -

The Best Complex Vitamins in 2022

Views: 121938 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114979 -

The best paint for gray hair - top rating 2022

Views: 113394 -

Ranking of the best wood paints for interior work in 2022

Views: 110318 -

Rating of the best spinning reels in 2022

Views: 105328 -

Ranking of the best sex dolls for men for 2022

Views: 104365 -

Ranking of the best action cameras from China in 2022

Views: 102215 -

The most effective calcium preparations for adults and children in 2022

Views: 102011