Rating of the best glitter grout for 2025

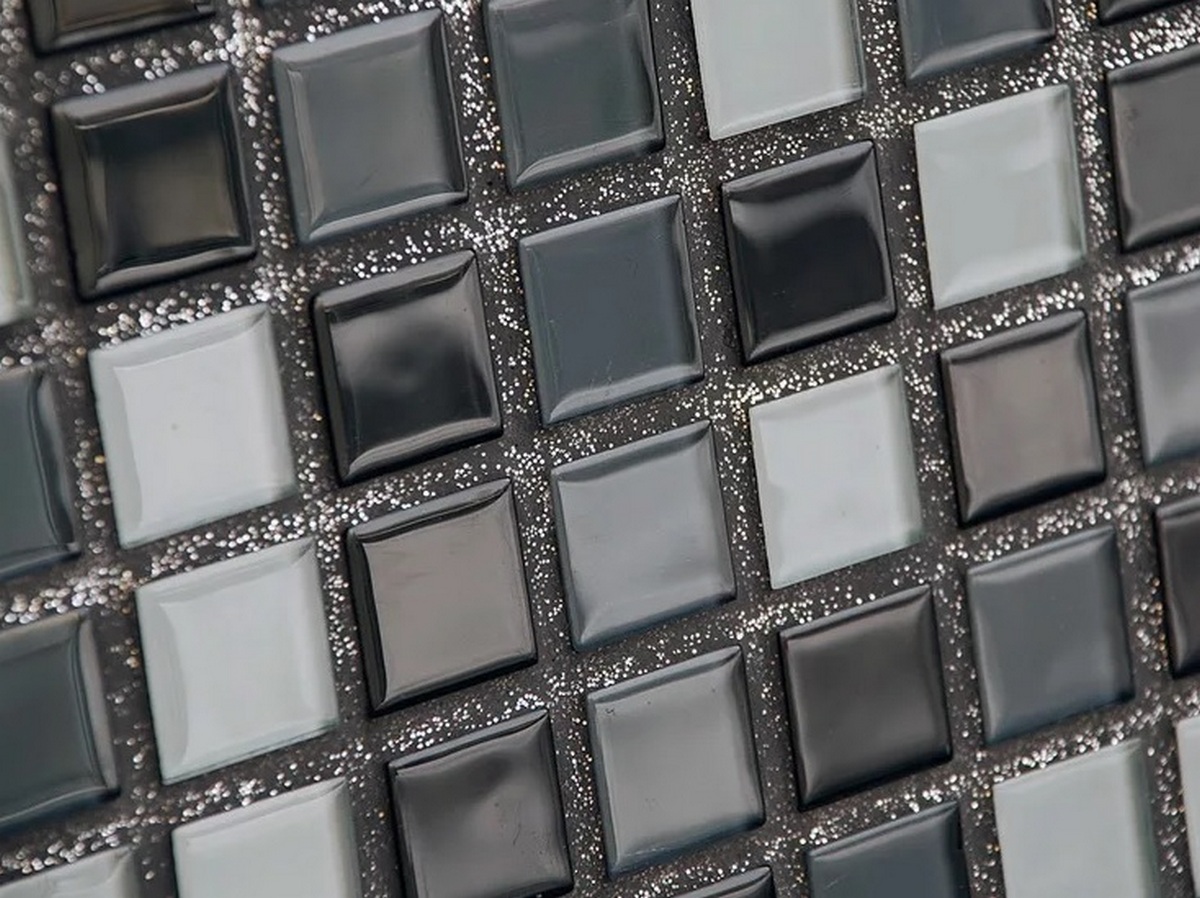

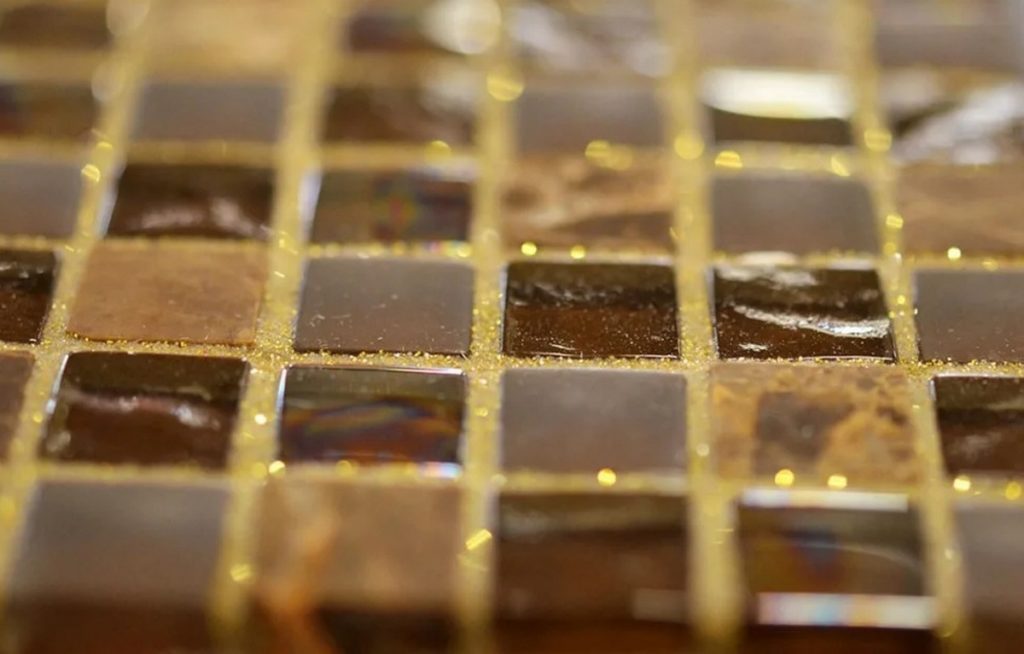

Grouting tile joints should not just fix all the elements, filling the voids. It should also contribute to the range of shades of the finished room, and at the same time it does not play a big role where the cladding is installed - on the floor or on the walls. More recently, with the help of grout, they only shaded or repeated the base tile color, so they were not considered the leading component of decoration. Today, silver, gold, multi-colored sequins (they are glitters) in the structure of the grout have become a fashionable finishing trend. At the end of construction work, during the design of the premises, do not forget about this fashionable option. Glitter stitching will help bring a spark of fun to the whole picture and add an adventurous touch to any room, right down to the bathroom or living room.The material in question looks best when metal or glass tiles are used - this is how you can enhance the sense of shine. However, like any sparkling design, glitter grout will require careful care.

Content [Hide]

- 1 Glitter grout - general information

- 2 Creating Glitter Grouts and Using Visual Effects

- 3 Technical parameters of glitter grouts and their properties

- 4 Mortar preparation and surface cleaning

- 5 Applying grout

- 6 DIY Glitter Filler

- 7 Difficulties in pricing

- 8 Rating of the best glitter grout for 2025

- 9 Conclusion

Glitter grout - general information

If we are talking about laying out tiles based on glossy and shiny surfaces, then the use of glitter at the seams will be the right decision. The grout material itself must match the quality and style of the tile.If premium-class tile modules are used, then the seams must be made from the same expensive substance, otherwise it is possible to spoil the entire future layout. For this situation, the Fugasim mixtures are best suited, which are easily applied between the tiles, visually they look expensive, easy to clean, and the gold or silver blotches present in the structure will allow the mixture to blend harmoniously with the mosaic of any design and tone. The same mixtures can also be found with phosphorus components in the composition, which will glow in the dark, giving the room an unusual effect of filling the space with fireflies. It is worth noting that it is through the use of phosphorus fillers in the room that it is possible to mark the locations of sockets or switches - this way it will be easier to find them in the absence of general lighting. At the same time, mixtures with glitters can be put on the seams even along the outer lining - the reflection of the rising sun will intricately play on small inclusions.

The most popular today are fillers with the presence of gold, silver, bronze and luminescent sparkles in their composition. However, you can also play with reflections using ordinary colored grouts - for this you just need to choose the right light and calculate the direction of lighting. To be fair, colored glitters produce little sparkle under natural light, sometimes they will only be fully effective under artificial light.

Most often, buyers purchase a single-color grout separately and a separate package with sparkles, from which they create their own mixtures. However, this solution is not universal and is more intended to be added to epoxy grout.As long as such glitter additives are inert, they will not affect the working qualities and properties of the filler, but then the final mixture will have to be made much thicker and more thixotropic.

Creating Glitter Grouts and Using Visual Effects

The gloss effect of the filling mixture was developed exclusively as an original decorating component, with which, at first, they tried to diversify the overall range of the developed material. For example, when a new color and shade of a filling substance appeared in the sales line, the manufacturer enhanced its artistic effect by filling it with sparkles. Thus, it was possible to create a finish with an original design solution, and in the process of updating an existing one, to give an unusual and finished look. Most designers in the decorating world find that glitter grout helps separate tiles into a coherent whole, while highlighting all the advantages of a tiled material or laid out mosaic. Even a boring wall tiled with standard tiles will sparkle with new colors if you renew the seams between the modules with a sparkling substance.

Creating a sparkle effect in grout

It is provided by special flakes or lenses that have a golden or silver tint. The result is a substance that, as it were, begins to flicker, which is especially noticeable during the movement of the beholder. At the same time, a rather original effect is created - the flickering occurs unevenly. This illusion arises due to the fact that the lenses or flakes included in the mass have unequal shapes and sizes.To be honest, all this technology is not particularly complicated and consists only in adding certain inclusions to the general viscous mass, but the visual impression created after applying the grout increases the artistic value of the entire finish. It should also be mentioned that the introduction of glitter has practically no effect on the performance properties of the aggregate, but only if it is done in an industrial production environment. There are limitations for making glitter grouts at home.

Use in the interior

It is fundamentally wrong to perceive the tile and grout to it as separate elements of the cladding, especially in today's time. Modern trends suggest interpreting them as a tandem as a whole. Therefore, manufacturers are trying, with the help of color matching and both elements, to create an overall harmonious picture in which the seams would not stand out at all from the general background. But glitter fillers have a completely different task - they just have to emphasize the contours of the tiled material, and where necessary - to highlight entire fragments of a large image. Thus, the considered substances with sparkles are more intended for working with mosaic layouts, especially those that require additional artificial lighting due to the design idea. Such a solution, for example, can be attributed to the finish of a closed shower cabin, where glitter grout under running water and lamp light will sparkle with varying degrees of intensity.

Making a better visual perception of sparkles

This property can only be achieved with the help of well-placed artificial lighting. But the matter does not end there, because with thin seams, the sequins will look static.To give them the illusion of movement, the seams should be wide enough so that the effect is better manifested. Also, the room being designed should not be too narrow - a large space is needed to create a better panorama.

Technical parameters of glitter grouts and their properties

The most popular in today's market are epoxy glitter aggregates produced on the basis of aluminous cement. This material has an increased resistance to ultraviolet radiation, does not attract dirt, and successfully resists chemically aggressive detergents. It also has a number of special qualities:

- Brocade effect - it is created through the use of a unique formula in the production and consists in the intensity of glitter flickering when the viewing angle of the viewer or the direction of the light source changes;

- Protection against fungus - most modern mixtures with glitter by default contain components that will protect the future seam from mold, fungi, algae growth, etc., such protection will allow the entire tiling to maintain visual aesthetics for a long time without reducing gloss;

- Curing speed - this factor is very relevant when finishing the flooring with shiny grouts, due to the use of shimmering lenses in the composition, their effect will begin to visually manifest itself already 3 hours after the end of grouting, and the practical load on the laid tiles can be given only every other day;

- Elasticity - this quality is very important, as it is responsible for the reliability of fixing the cladding on plasterboard and wooden surfaces, given that the grout also performs an adhesive role, the screed made through it should work even on heated surfaces, additionally holding tile modules;

- The width of the seams - it can vary from 1 to 25 millimeters, which will depend on the size of the tile module or the need to create wide seams to give the layout the illusion of a dynamic transfusion of glitters.

Thus, the material in question can be successfully used for filling joints between ceramic tiles (terracotta, mosaic or glazed tiles), as well as between natural stone, agglomerate, concrete tiles, glass mosaics and luxfers (glass blocks). Glitter solutions are waterproof and can be used in both dry and wet areas. Depending on the consistency, glitter mixes are proportionately resistant to the formation of scratches, cracks and general abrasion. A simple substance preparation technology, plasticity and ease of use will allow you to quickly and easily fill the inter-seam distances without scratching the surface of the cladding.

Mortar preparation and surface cleaning

The process of grouting the joints should begin immediately after the adhesive hardens under the tiles, however, this should not occur earlier than after 24 hours. In the case of using a special quick-drying adhesive, the filling of the joints can be started already after 4 hours. It is worth noting that all existing gaps have the same depth. The preparatory procedures will consist of three important steps:

- It is necessary to thoroughly wash off dust and any dirt from the recesses, and clean the surface of the tile itself with a sponge;

- The second stage will be a slight moistening of the seam distances;

- The third step is to mix the solution. To do this, a dry mixture is poured from a bag into a bucket containing a sufficient amount of water.As a rule, the proportions are 250 milliliters of water per kilogram of the mixture. Then the whole mass is mixed until a homogeneous consistency is formed. Then the substance settles for five minutes, after which it is mixed again. The resulting solution should be used within the next 120 minutes.

Applying grout

The entire mass is applied tightly and to the full depth into the grooves with a rubber spatula (or a conventional trowel). Excess should be collected diagonally from the edges of the tiles. After hardening, the seams are wiped with a damp sponge along with the tiled surface itself. During the implementation of these works, the room should not be exposed to drafts. The first 2-3 days after the application of the filler, the joint distances should be washed with a small amount of clean water.

IMPORTANT! If a moisture-absorbing tile material (e.g. marble) has been used for the cladding, a test on an inconspicuous area should be carried out prior to suturing in order to detect possible discoloration of the tile edges after they come into contact with the grout. To avoid such situations, for “capricious” materials it is required to use special filling mixtures recommended by the supplier. At the same time, it is worth remembering that too frequent washing of such a layout with a glitter joint filler can generally lead to the dissolution and washing out of the entire superimposed mixture from the grooves.

It is possible to determine the quality of the glitter solution applied to the seams by applying a directional light of medium brightness to it. A special contrast will be noticeable for eclectic and glamorous interiors.As a result, all lenses in the grooves should flicker, sparkle and shimmer, it will be important to check this effect in motion.

DIY Glitter Filler

The whole process consists of several steps:

- Selection of the necessary props and tools - you should prepare a container, the dry mix itself and packaging with sparkles. Moreover, sparkles can even be non-specialized, they will need 20 grams for about 0.5 kilograms of mass.

- It is best to cook the mass in portions, because it hardens very quickly. To do this, it is preferable to use a measuring cup and observe the above proportions. Initially, you need to stir the grout itself, and then just add sparkles to it.

- The mixing process must be carried out very carefully - no lumps should be observed in the resulting substance.

- The main rule is that each portion should be as equal as possible to the previous one both in terms of the mass of the dry grout mixture, and in terms of the volume of water used, and in terms of the number of glitters poured in.

- By applying the resulting solution on a rubber spatula, perform uniform rubbing of the distance between the seams.

- Upon completion of each stage of work (i.e., on the consumption of each portion) - remove excess mass from the surface of the tile.

Difficulties in pricing

Naturally, a ready-made factory mixture with glitters will cost much more, especially if you select it for a specific type of tile. Here, the premium class is considered to be "native" solutions from the manufacturer for tiles based on metal and glass. The average volume is 2 kg. such a grout will cost from $ 50 and up.The most budget option would be to purchase glitter powder separately and then mix it yourself with any monophonic mixture. The cost of such a purchase can be 3-4 times cheaper. However, if the mixing technology is not followed, it is possible not to achieve the desired effect at all, therefore, it is necessary to strictly follow the mixing instructions, which are placed exactly on the package with sparkles!!!

Rating of the best glitter grout for 2025

Middle price segment

4th place: "Ceresit CE 40 Aquastatic 2 kg silver gray 04"

votes 0

This cement mixture has mineral fillers, brilliant pigments and polymer modifiers. Designed for grouting ceramic, glass and stone finishes on floors and walls in civil and industrial construction. It is used in rooms that are operated in conditions of periodic humidification (in bathrooms, showers, kitchens, etc.). Can be used on deformable substrates (eg chipboard and plasterboard) and on surfaces subject to temperature fluctuations (heat-insulated floors, balconies, terraces, outdoor pools, etc.). The recommended cost for retail chains is 560 rubles.

- Reduced water absorption;

- Washes well;

- Versatility of application.

- Not detected.

3rd place: "Weber Decor 2 kg G101 anthracite"

votes 0

Designed for filling tile joints on walls and floors (including with the "Warm floor" system). It has gold inclusions in its composition.It is used for lined surfaces made on the basis of mosaics, ceramic, porcelain stoneware and glass tiles, natural and artificial stone, in rooms with normal and high humidity, as well as for indoor and outdoor work. The “life” time of the mixture is 90 minutes, it is possible to apply general loads a week after the completion of all work. The recommended cost for retail chains is 830 rubles.

- Possibility of work on systems of a "heat-insulated floor";

- Operational cycle - 100 seasons;

- Long "life" of the solution.

- Inclusions only work for dark tones.

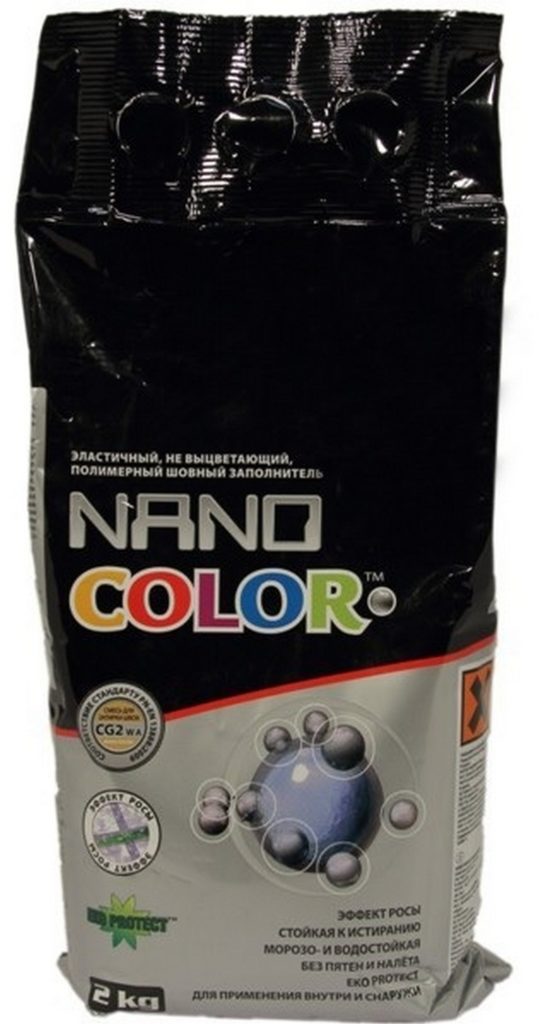

2nd place: NANOCOLOR BRILLIANT WITH Glitter

votes 0

This piece stands out with a specially selected blend of high-quality, polymer-based glitter pigments and special additives based on nano-technologies. The Eco Protect system is responsible for the distribution and filling of microparticles, as a result of which the resulting structure creates an impermeable system that protects against the development of fungi and mold. Easily provide a smooth surface when processing. It has excellent adhesion to ceramic tiles, porcelain stoneware, stone and glass mosaic. Has high resistance to influence of sunshine. Meets all requirements for increased abrasion resistance and provides the ability to apply jointing on high-traffic substrates. The recommended cost for retail chains is 1300 rubles.

- Suitable for many types of tiles;

- Withstand heavy loads;

- Application of nano-technologies.

- Not detected.

1st place: "A-Crystal Lite 1 kg color #51 silver gray"

votes 0

This two-part sample is made from epoxy resin with silver glitters. Prevents the formation of fungi and bacteria. Has especially high resistance to attrition, is steady against influence of chemicals. Scope of application: for indoor and outdoor work, filling tile joints is possible with a width of 0.5 to 15 mm, in wall and floor finishes with ceramic tiles, porcelain stoneware, mosaics, etc. It is used for application in conditions of exposure to aggressive media (solutions, vegetable and animal fats, chemicals), as well as in containers with drinking water. The recommended cost for retail chains is 1600 rubles.

- Versatility;

- Waterproof;

- Special strength.

- Not detected.

Premium class

4th place: "STARLIKE DEFENDER Ardesia C.480"

votes 0

This sample is formulated with SPOTLIGHT Glitter, a special compound that contains a water-repellent two-component epoxy-based mixture with improved antifungal properties. It is applied to external and internal works. Can be used in rooms with high humidity. The recommended cost for retail chains is 3400 rubles.

- Frost resistance;

- Innovative technology of glitter structure;

- Antifungal protection.

- High price.

3rd place: "STARLIKE EVO Tabacco S.225 (C.280) + silver glitter additive"

votes 0

This filler has (except for silver sparkles) antibacterial, water-repellent, frost-resistant properties. Separately worked out resistance to substances with high acidity.Can be applied to ceramic tiles and glass mosaics. The color of the composition is plain gray. The recommended cost for retail chains is 3,700 rubles.

- Many protective qualities;

- Ability to process glass tiles and mosaics;

- Uniform composition.

- High price.

2nd place: "OSNOVIT PLATESAVE XE15 E 014 + additive 014/1 (Russian gold)"

votes 0

This unique aggregate is a combination of a two-component epoxy mix and a special additive that gives the finished mortar an exceptional shade with golden crystals. The kit is used to work with seams with a thickness of 1 - 15 millimeters, has extended water-repellent properties and acid resistance. It can be used when working with any kind of ceramic tiles. The recommended cost for retail chains is 4800 rubles.

- Golden flakes in the composition;

- solid color;

- Variability of suture work;

- The best ratio of price and quality.

- Not detected.

1st place: "LITOKOL STARLIKE Mela C.410 + SPOTLIGHT silver glitter additive"

votes 0

This special set consists of a two-component epoxy and a special additive that gives the finished mass an exceptional color tone. The set is used to perform work with seams with a thickness of 1 to 15 millimeters, has enhanced moisture protection properties and is extremely resistant to aggressive environments. The recommended cost for retail chains is 7400 rubles.

- Large volume of containers;

- The exclusivity of the shade;

- Special resistance to hostile environments.

- High price.

Conclusion

Glitter effect filler can be used not always and not everywhere. It gives the room a rather elegant look due to its unusual appearance, and here the owner must make an independent decision whether such material will be appropriate in a particular room, or whether it is better to give preference to more standard and more traditional grouting options. Nevertheless, it is useful to know that such an elegant grout exists.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131650 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127690 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124518 -

The best men's sneakers in 2025

Views: 124033 -

The Best Complex Vitamins in 2025

Views: 121939 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114979 -

The best paint for gray hair - top rating 2025

Views: 113394 -

Ranking of the best wood paints for interior work in 2025

Views: 110318 -

Rating of the best spinning reels in 2025

Views: 105328 -

Ranking of the best sex dolls for men for 2025

Views: 104365 -

Ranking of the best action cameras from China in 2025

Views: 102215 -

The most effective calcium preparations for adults and children in 2025

Views: 102011