Rating of the best PVC tiles for 2022

Classical floor coverings based on carpet, laminate or linoleum today are no longer able to fully satisfy some specific consumer needs. Therefore, niche manufacturers have to invent new composite coatings that could combine the best properties of old samples. One of the clearest examples of such a replacement was PVC floor tiles. It can be produced in various variations on the basis of vinyl, quartz-vinyl, laminate or linoleum with a special LVT coating. Such products combine in their structure a lot of useful and functional qualities.

Content

General information

Polyvinyl chloride is a conventional polymer, a conditional plastic, whose technical characteristics will depend on what additives its structure will be supplemented with. Properties such as, for example, high rigidity or good elasticity will depend on the composition. Traditionally, the most common vinyl-based floor covering is linoleum, which is produced in rolls and is made on the basis of a foamed polymer with a vinyl top layer. Its production technology is not complex, which implies a low cost of such a consumable. The only disadvantage of this classic variation is not always a convenient format for the release of goods. When laying from a roll, you will need to constantly monitor the correctness of the chosen direction, carefully measure the size according to the width of the floor, and this all negatively affects the implementation of original design solutions in interior design. Therefore, this type of PVC coating today is gradually fading into the background.

- Quartz-vinyl tiles.

This is perhaps one of the earliest and most worthy vinyl solutions, whose production has ceased to be tied to a roll format.The sample is a separate LVT-modules, the design of which consists of several layers of polymer content. At the same time, the base in them is vinyl with special strength additives. Such material is characterized by particular rigidity, which indicates the impossibility of its release in a rolled form. Sand (as well as other mineral additives) will add additional protective properties to the product. As a result, quartz-vinyl tiles have a standard thickness of 2.5 millimeters, which is thin enough and does not harm strength. It is the quartz-vinyl thickness indicator that is positioned by manufacturers as the main advantage over other samples, since it implies the possibility of laying tiles on the previous floor covering, and such an operation easily reduces the overall repair costs. However, quartz-vinyl, in order to achieve the highest quality adhesion to the floor, will require an extremely high degree of evenness of the latter.

- SPC laminate.

This variation of PVC tiles is designed to save the consumer from the shortcomings of the above fellow, which is achieved by increasing the thickness of the module. From this it is clear that it is possible to lay such consumables on a not quite even base. Limestone is often added to the structure of such products, which increases the density of the material, which is not achievable for pure quartz-vinyl. Various mineral inclusions can also be added, which help to establish the proper balance between density and elasticity, and this already indicates an expansion of the scope of use of laminate modules. It is worth mentioning that SPC laminate has a huge range from which it is easy to choose such a consumable that can properly interact with almost any type of floor.

Specification Features

The polyvinyl chloride base provides for the type of flooring in question special reliability and durability. The remaining additives and inclusions can play a purely decorative role, giving the product the desired color shade, or they can have an applied purpose and, for example, be directly responsible for the wear resistance of a particular top layer. As a result, the type of product under consideration consists of:

- Primary top layer, which is a protective coating designed to provide tensile strength to the surface of the module itself (i.e. resist abrasion);

- The second layer performs a decorative role and is responsible for the appearance of the tile;

- The third glass fiber layer provides shape and size constancy, counteracting excessive expansion / contraction of polymers when exposed to high temperatures;

- The fourth base layer consists entirely of PVC and is responsible for the overall strength.

Modern production produces the consumables in question in three main forms - a mosaic, squares and rectangles. The last two types are standard, but with the help of mosaic modules it is easy to implement very original design solutions when decorating the floor.

Applications

The type of consumable material under consideration is in demand for use in various fields:

- They can finish the floors in the bathroom and kitchen, which implies an excellent ability to withstand conditions of high humidity;

- It is possible to finish the floors of living rooms and corridors, which indicates a classic version of the application;

- Finishing children's rooms - this is allowed due to the sufficient environmental friendliness of the material;

- Finishing offices and public buildings, up to small garages.This possibility is due to the ability of the material to withstand increased operational load.

Classification according to the degree of load

The PVC modules under consideration are most often classified according to the level of load that they can withstand. In total, three main classes can be distinguished:

- Highest (43rd class) - the material has increased resistance to abrasion and is able to retain its original appearance even if medium-sized vehicles periodically pass through it. It is an excellent solution for a warehouse or other industrial premises;

- Medium (grades 32-42) - the model is suitable for intensive use and the thickness of such a module is from 2 to 2.5 millimeters. On such a plate, you can easily move large-sized furniture, which is provided by a protective top layer of 0.3 millimeters. The best choice for arranging home floors;

- Lower (grades 23-31) - this coating is suitable for arranging rooms with low traffic. The modules themselves of this class are cheap, their protective properties are low, and the total thickness of the tile barely reaches 2 millimeters.

Advantages and disadvantages

The undoubted advantages of the considered consumables include:

- For the production of standard square modules, the principle of size variability is strictly observed - these can be products 33 * 33 cm, 50 * 50 cm and 61 * 61 cm;

- The tile is characterized by increased strength, hygroscopicity, a variety of shades, regular geometry, good sound and heat insulating properties, and successful resistance to putrefactive processes;

- Models are quite easy to mount, can be cut with standard cutting tools, which allows you to independently create inserts with the desired shape;

- The modules are presented with different textures - their surface can be either completely glossy or with a high level of roughness, and this already indicates an expansion of the scope of use (from dance halls to showrooms);

- The possibility of providing a self-adhesive base, which greatly simplifies the installation process.

Significant disadvantages include:

- The complete artificiality of the material, which suggests the possibility of allergic reactions in some categories of people;

- Some difficulty in cleaning samples with a very rough top layer - it accumulates dust and dirt very well;

- For modules of small thickness, during installation, special preparation of the floor surface is required, namely, it must be made as even as possible;

- The use of polymers in the composition may involve the use of some particularly caustic elements to give the final product special protective properties.

Mounting Features

This process is not characterized by particular laboriousness and differs little from the similar one when installing other types of similar coatings. Nevertheless, before laying it is desirable to make the floor as even as possible in order to lay out at least the initial rows in a very neat way.

Tools used

It is not characterized by any special requirements for its composition and the whole process can be carried out with standard fixtures. This fact, in principle, can be attributed to another advantage of PVC tiles. As a result, for installation you will need:

- One and a half meter level (in extreme cases, one meter), a rule or a ruler. They are useful for creating an emphasis in the cutting process. If a metal tool is chosen, then it is better to stick double-sided tape on one side of it in order to prevent slipping.

- Construction / stationery knife and replaceable blades for it.

- Square and tape measure.

- Hammer with a rubber chipper - necessary for laying modules according to the end connection method.

- Lapping, which is an ordinary small wooden beam, upholstered in several layers of felt. It is used for self-adhesive tiles and is applied to properly level them.

- Spatula with teeth - used when laying models on a separate adhesive layer (preferably a triangular shape of teeth with a size of 1 * 2 mm).

- Building hair dryer - they can heat up individual modules in order to put them on a convex surface (for example, when you want to “bypass” a column or pipe).

Foundation preparation

PVC tiles can be laid on sand-cement screed, moisture-resistant plywood, fiberboard and similar sheet materials. Before installation, they must be treated with soil (which is especially important for screeds) in order to achieve the desired level of water absorption. In some cases, installation is even allowed on top of the old tile, but only on condition that all seam spaces in such a base are carefully sealed. For the type of PVC modules under consideration, the best base is considered to be a subfloor with moisture-resistant plywood, the thickness of which is from 15 to 18 mm. The modules themselves should be laid with an offset seam line, between which a gap of 2 millimeters should be left (this will compensate for possible thermal expansion).

Laying process

Installation methods can be as follows:

- On glue - a special adhesive composition is applied to the bottom of the module using a spatula with teeth. Next, a layer of glue must be evenly distributed over the entire contact area of \u200b\u200bthe tile.Depending on the type of adhesive used, the processed module is either immediately pressed against the base, or it takes 2-5 minutes to thicken the solution. After laying out, the tile is tapped with a rubber mallet, rolled with lapping. All these manipulations allow you to remove air from under the glued surface.

- On a self-adhesive base - all actions are, by and large, similar to the previous method, with the exception of self-application of an adhesive substance on the bottom. To start work, the protective film is simply removed from this part of the tile and the module is simply applied to the floor.

- On the lock connection - the entire installation process in this way should start from the wall of the room being processed. If necessary, the modules are cut along one of the sides to ensure that the geometry of the sides matches between the tiles or the wall. In any case, a proactive indent of 2-3 millimeters should be made from the wall. The tiles themselves are interconnected by inserting the protruding part of one module into the desired groove of the next, and so on until the row or line is laid out. To confirm the best adhesion, the junction is lightly tapped with a rubber mallet for each fragment.

Difficulties of choice

When buying the type of consumables in question, you need to pay attention to the following product parameters:

- Country of origin - in the current Russian market, products from South Korea are more popular, which are characterized by a high level of quality;

- The degree of repeatability of the pattern - if it is small and often repeated within the boundaries of one module, then this can visually cause discomfort in the form of "ripples in the eyes";

- The total density and thickness of the top layer - the higher these parameters, the longer the future coating will last;

- Production material - it is quartz-vinyl that is suitable for samples that require a separate application of an adhesive layer; for modules on a locking joint, it is better to prefer a combined quartz-vinyl (crushed fiberglass and quartz sand); the cheapest and most impractical option is pure PVC or hard plastic;

- The variability of the installation method - the lock is considered simpler, but less reliable than the adhesive, especially since the latter will additionally create a waterproofing layer, which is an important protective quality;

- The size of the lock bar - when determining the number of lock-type modular elements needed in terms of area, the resulting volume should be increased by 3%, as this is the size of the lock, which is not included in the concept of usable covering area.

Rating of the best PVC tiles for 2022

Budget segment

3rd place: "Ekopol" ECO-STYLE (modular)"

The surface texture of these modules resembles ordered drops or grains protruding above a flat plane. This design ensures good adhesion of shoes or car wheels to the floor. The texture does not allow the accumulation of dirt and dust: cleaning the flooring does not require much effort. Areas of application: in public institutions (thousands of people can pass a day for many years without causing any harm to the floor), in shopping centers and small shops. The ECO-STYLE coating can be easily and quickly washed with conventional means. It does not deteriorate from falling heavy objects and transporting goods. Complies with hygiene standards.Strength and durability guaranteed. The recommended cost for retail chains is 700 rubles.

- Large thickness;

- Excellent material resistance;

- Extended temperature limits of use.

- Not detected.

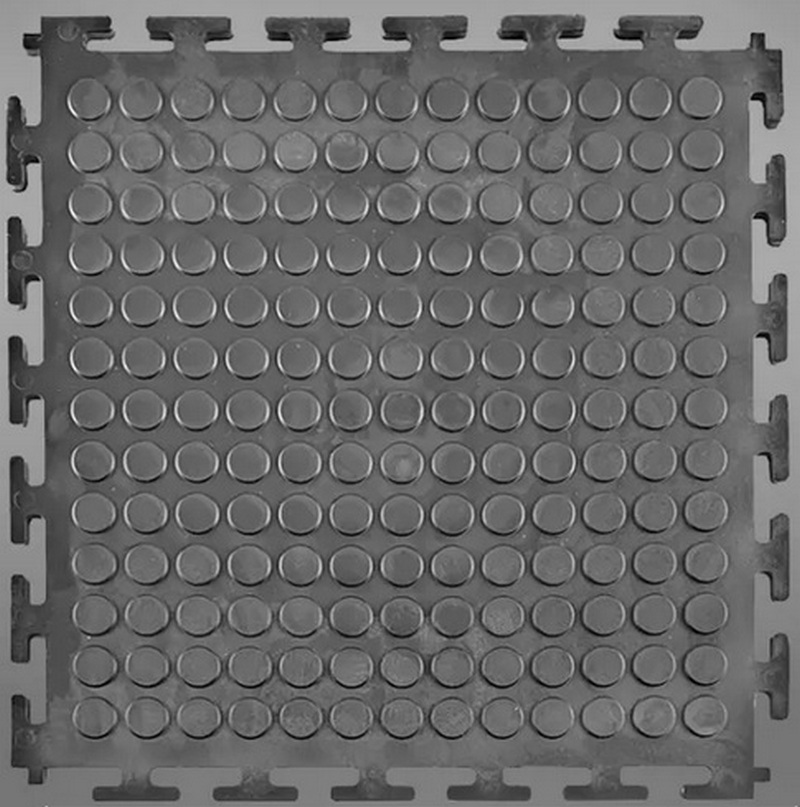

2nd place: "VIRST" black modular, 250 x 250, 16 pieces"

This universal floor covering is suitable for retail, sports, industrial premises, garages, hangars, boxes and warehouses. Easy installation and cost-effective repairs in outdoor and indoor areas will allow the anti-slip coating to serve for many years. The product has an texture in the form of coins, the texture gives anti-slip properties and does not interfere with the movement of equipment, carts and other vehicles. It is assembled according to the “puzzle” principle, which also facilitates repair work. If necessary, simply replace one of the tiles. And the great variability of styling and ways of combining color schemes can transform the look of any room. The recommended cost for retail chains is 1415 rubles.

- Laying is possible both without glue and with glue (for better adhesion to the floor surface when driving on the floor covering);

- Easy and economical repair by replacing damaged areas of the flooring;

- Possibility of dismantling and transfer to a new location;

- Easy cleaning and maintenance (it is not recommended to clean with abrasive substances, such as powder).

- Too much burr on the locks.

1st place: "Refloor Home Tile DTE 8903 Safari Oak"

This quartz-vinyl tile has the highest (42-32) wear resistance class, which implies operation in private premises with increased load and in public ones with low load. These are such premises as: any living quarters, rooms in hotels, separate offices, conference rooms, etc. The recommended cost for retail chains is 2510 rubles.

- Wide scope of application;

- Easy installation;

- Decent value for money.

- Not detected.

Middle price segment

3rd place: "Refloor Home Tile DTE 8901 Silver Oak"

This product fully meets modern requirements in design. The surface embossing and the unique graphic design create a natural effect and do not require special selection. The convenient shape of the tile and ultra-precise dimensions create a perfect fit. The top layer is made of 100% PVC and provides protection against abrasion and stains, while the patented embossing resists scratches. The unique structure and thickness of 0.45mm or 0.8mm makes it suitable for high traffic areas. The recommended cost for retail chains is 2600 rubles.

- Excellent embossing and texture;

- Easy installation;

- Reliable protection.

- The collection will soon be discontinued.

2nd place: "Tarkett Art Vinyl Lounge 43 class, 3 mm, Buddha"

The product fully complies with the requirements of fire safety (KM2), all the necessary certificates are available (including the international eco-label certificate "Leaf of Life").The product is characterized by high density and wear resistance (class 34-43), which significantly expands the area of application of this material. The chamfer on 4 sides not only visually increases the space, but creates a complete feeling of natural flooring. Educational institutions, offices, boutiques, restaurants, shops will emphasize their individuality thanks to modularity and a wide range of colors and textures. The collection was created specifically for those who love comfortable and modern solutions, who appreciate beauty, comfort and the possibility of creating a unique design. The line is represented by a wide palette of shades that allow you to zone the space, combining coatings of various types, and create original interiors. The recommended cost for retail chains is 3330 rubles.

- Adequate price;

- Quality invoice;

- Easily create a single floor contour.

- Not detected.

1st place: "Tarkett Art Vinyl Lounge Digi Edition 43 class, 3mm, Sander"

The creation of this product is inspired by natural stone motifs. The resulting appearance allows a person to relax as much as possible. When creating the collection, digital printing technology was used, which allows you to create unique designs. The LOUNGE DIGI EDITION collection is represented by 4 sets: abstraction, textiles, natural materials and exotic. Each set is designed to fill the space with individuality and unique style. The recommended cost for retail chains is 3340 rubles.

- Fast installation;

- Durability;

- Excellent elasticity.

- Not detected.

Premium class

3rd place: "Oak Santana" 91.4x15.2 cm 16 pcs, self-adhesive panels"

These laminate flooring panels provide a quick update to your floor while maintaining aesthetics and ease of use. Easy installation without the involvement of specialists - only scissors are needed. Foil base, which creates additional thermal insulation and the feeling of warm floors, and also makes it possible to re-glue the panels if necessary without damage. The flexibility of the material does not require a perfectly flat surface. Easy replacement of damaged elements. The recommended cost for retail chains is 3450 rubles.

- moisture resistance;

- Wear-resistant coating;

- Texture under the tree;

- Beautiful floor and wall finishes.

- Not detected.

2nd Place: "Tarkett Rockstars Grade 43, 3mm, Kurt"

The product has a protective layer of 0.7 mm, which provides the coating with high wear resistance. The design of the collection is selected taking into account the classic and modern trends in interior design. The fire hazard class KM2 makes it possible to recommend the product for both domestic and public premises with high traffic. The recommended cost for retail chains is 3900 rubles.

- High quality;

- Good thermal insulation properties;

- Velvet roughness.

- Not detected.

1st place: "Domingo" White Oak 8537, 152*915*2mm (1pack-5.0m2)"

This rather flexible and plastic material is made of vinyl and resin with the addition of stabilizers and other fillers. Such a tile has several layers: two main PVC layers, a layer with a pattern and a protective layer with a relief. The minimum service life is 25 years.The recommended cost for retail chains is 4030 rubles.

- Ease of installation;

- Durability;

- High relief.

- Not detected.

Conclusion

If you need to create a high-quality floor covering that is not afraid of moisture, then PVC floor tiles will really be the best choice. This modern and high-quality material has a number of undeniable advantages, and the laying technology will allow you to mount a floor covering based on it quickly and independently.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131649 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127687 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124515 -

The best men's sneakers in 2022

Views: 124030 -

The Best Complex Vitamins in 2022

Views: 121937 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114978 -

The best paint for gray hair - top rating 2022

Views: 113393 -

Ranking of the best wood paints for interior work in 2022

Views: 110317 -

Rating of the best spinning reels in 2022

Views: 105326 -

Ranking of the best sex dolls for men for 2022

Views: 104362 -

Ranking of the best action cameras from China in 2022

Views: 102214 -

The most effective calcium preparations for adults and children in 2022

Views: 102009