Rating of the best ceramic mosaic for 2025

Usually, ceramic tile mosaics are used exclusively as decoration. However, it also has many applications. So, the mosaic may well become a full-fledged replacement for ceramic tiles, if you need to lay out any complex artistic image. Using mosaic ceramics, it is very easy to decorate classic wall patterns, full-fledged panels, and even create landscape photos. There is an opinion that ceramic finishing should not be used in rooms with high humidity, and even more so when finishing street facades with it. This myth is based on the fact that ceramic glaze with frequent contact with moisture will lose its original luster and, in the end, simply wear out.It is very easy to debunk such a misconception - today's technologies have advanced so far that mosaic ceramics not only calmly withstands high humidity, but has even acquired a certain degree of fire resistance and can be placed in rooms with relatively high temperature loads.

Content [Hide]

Ceramic mosaic: general information

It is a type-setting image, where small ceramic tiles (or its fragments) act as components.The features of this mosaic type are not in the way the image is created or the method of laying, but in the special properties of the composite material. And at the forefront here is the indicator of the variety of various technical properties, which include:

- Water resistance - it is determined on the basis of the water absorption coefficient. For ceramics, these limits range from 0.5 to 20 percent, depending on the production material. The type of mosaic in question is made from different ceramics (even from porcelain stoneware, in some cases), therefore, for the design of the room, a type is selected that would correspond to the purpose of the room. For example, to place a ceramic panel in the living room, it is possible to use a rather porous ceramic material - majolica, but if the task is to facing the pool bowl, then the mosaic water resistance index should be high (white glazed ceramics with a water absorption of at least 3% would be the best solution).

- Abrasion resistance - like any mosaic, ceramic has its own wear resistance class. This indicator will also need to be taken into account when finishing certain surfaces. For example, for flooring, you should use a material that is thick enough, with an abrasion class of 2 to 5. For dry walls, in principle, any sample is suitable.

- Frost resistance - this parameter will play a crucial role when facing external (street) structures, which include a facade, platform or porch. For interiors, frost resistance will not play a big role.

- Slipperiness properties - for wall cladding, ceiling, they, of course, will not be particularly important, therefore, for these surfaces, it is allowed to use mosaics coated with a brilliant gloss.But for the flooring, matte or satin samples will be required. On the other hand, due to the fact that the elements in the mosaic floor, even on the panel, are quite small, the role of an anti-slip material can be played by an ordinary grout, which is poured into the connecting seams. Accordingly, even for flooring it is possible to use glossy ceramics;

- Originality of design - for the considered type of mosaic design, both one-color elements and those with various inclusions and fillings, up to the smallest images, can be used. Most often, professionals still use a simple pattern or imitation of any natural material - from wood to stone. The surface can also be any - and embossed, and structured, and simple smooth;

- Installation feature - unlike large ceramic tiles, mosaic tiles can be laid both on a flat and on a convex surface.

Manufacturing technology

The production of ceramic mosaic material does not differ much from the production of similar tiles, differing only in the size of the mold. The production itself goes through the following stages:

- Raw material preparation - at this stage, the components are crushed, mixed and dosed. The quantity and quality of ingredients will depend on the type of ceramics produced: for example, clinker and majolica are made from clay with different additives. After kneading, the raw materials are dried a little, because the grinding is carried out with water.

- Molding - molds are filled with raw material - they can have a different shape, and the pressing itself is carried out under pressure, which is necessary for the desired ceramic type.

- Drying - small chips are fired in an industrial oven at the proper temperature. If double-fired ceramics are required, they are first dried at a relatively low temperature, then glazed, then dried again.

For porcelain stoneware mosaics, the production method has some differences. The raw material is first produced in the form of a large sheet, and then cut into its component parts, always of the correct shape. Due to the fact that this raw material is hard, special industrial equipment is used for cutting.

"Broken" ceramics also has its own manufacturing characteristics. There is no doubt that a set of small components that are completely inconsistent with each other in form will become a considerable problem in work. To imitate curvilinearity, a special tool is used - a spiker, with the help of which the original large ceramic tile is split into seemingly different mosaic fragments. In fact, in a “broken” ceramic mosaic, you can always find components that combine with each other.

The leaders in the production of ceramic mosaics are companies in Spain and Italy, which is due to the historical development of this industry in these countries. However, today Chinese samples may well compete with them.

Technical specifications

Dimensions and dimensions

Ceramic mosaics are characterized by elements having an average level of thickness and an area of 10 to 100 millimeters squared. The smaller the plate, the more accurate the drawing can be assembled on their basis, respectively, smaller elements are more valuable. But for plain patterns, mixes, simple and even irregular samples with dimensions of 5x5 or 7x7 millimeters are suitable.

Ready modules

Ceramic mosaic modules are a set of tiles that form a pattern, image or ornamental element, which are fixed on a polymer mesh. The plates themselves are fixed from the wrong side; for installation, such a module is simply laid in the right place, glued and simply overwritten. Modules can also be formed on a paper base, but in this case, chips-plates are attached to paper from the front side. Laying with a paper module is extremely convenient for facing uneven, convex surfaces. The qualitative advantage of the "paper" method is also the fact that the seams on it do not diverge over time. The dimensions of the block module are usually 30 x 30 centimeters, however, there are also larger samples designed specifically for creating large-scale panels. It is worth noting that in such modules it is allowed to combine mosaic materials - they may contain elements made of glass, plastic or metal.

Mosaic forms

Standard forms can be as follows:

- Rectangular (square) - a classic type of mix, gradient, two-color panel. It is allowed to use for laying out drawings.

- Triangular - usually used to decorate wall panels in living rooms. On such forms, wide seams are obtained, and grouting along them better tolerates steam and moisture.

- Hexagonal - this original shape is used for interior decoration in the style of "hi-tech" and "techno".

- Oval (round) - in this case, the seams also turn out to be quite wide, and due to the unusual shape, it is customary for her to decorate children's rooms.

- "Broken" ceramics - at first glance, is a set of small elements of various shapes, from which the first mosaics were formed in the old days.However, if this type of mold is made in modern factory conditions, then it only creates the appearance of heterogeneity, but in fact the set contains chips-plates that coincide with each other in outline.

IMPORTANT! It should be noted that the outer surface of the chips-plate can also have its own shape and be convex, embossed, structural and imitate various natural objects - from river pebbles to ribbed slate.

Type and design of chips-plates

These parameters of the mosaic elements will depend on the nature of the material - porcelain stoneware, majolica, clinker, cotto or a simple design. The color palette for these samples is simply limitless: you can get any color by adding a certain pigment at the production stage. However, there are some design limitations:

- One-color - monocolor, i.e. the chip is painted uniformly in one color over the entire area, classically has a glazed surface.

- With gradients and additives - this is typical for unglazed ceramic elements, on the surface of which a transition between several shades is clearly visible.

- With imitation of wood or stone - a similar design is more inherent in porcelain stoneware. Its cost in this design is very high, production is laborious, therefore, this type is not very popular with the average buyer;

- Patterned - the smallest chips plate contains a simple image. It is customary to combine them with monocolor options in order to create the impression of a special variegation.

Installation and styling features

Foundation preparation

Mosaic material is quite demanding on the condition of the surface to be coated, because it must be tightly attached to it by means of glue, and proper preparation of the base increases adhesion properties:

- The walls, floor, ceiling or bottom of the pool bowl should be as even as possible, i.e. unforeseen height differences, cracks and chips are unacceptable.

- The surface should not be completely smooth either - it needs a slight roughness, which would best provide grip. Usually, a simple passage of a grinder through it will not be enough - it is preferable to use a sandblaster.

- The floor and walls are degreased without fail, because the presence of greasy stains will significantly reduce adhesion. At the same time, the surface should be freed from rust, cement "milk", excessive smudges, etc.

- The final step can be a primer with the proper composition.

Laying

This process is slightly different from conventional tiling, because the size of each cladding element is different, and there are also special requirements for the adhesive composition. Preliminary marking of the floor / wall will be required even if ready-made modules are used for installation. The main thing - when laying out the picture, the latter must be carefully transferred to the surface to be treated. The whole process takes place in several stages:

- First, the adhesive substance is prepared, according to the instructions for it. The application takes place in separate portions so that the glue quickly adheres to the mosaic chip and the surface without having time to dry.

- With modular laying, glue is applied to no more than 9 sheets at once (regular 3 x 3 square). For manual laying, each element is processed separately.For this operation, it is preferable to use a smooth trowel, then leveling the layer with a notched tool.

- The chips or module are pressed against the designated area and smoothed out with a rubber spatula so that the glue under the base is evenly distributed. The block on the mesh base should be placed on the adhesive mixture in such a way that the mesh sinks into the mixture. A block on a paper base is glued with the paper out.

- The width of the seams between the blocks should not be greater than the width of the seams between individual chips, otherwise the final surface will not visually cause a feeling of solidity, but will consist, as it were, of fragments. When manually laid, the seams can vary in size, which is natural, this will especially manifest itself if the mosaic is assembled from “broken” ceramics.

- After assembling a mosaic panel, it will take at least three days for full adhesion to the base. Of course, depending on the glue used, this period can be reduced, but 72 hours is considered the optimal period among professionals.

- After the glue has dried, you can start grouting. The fugue is applied with a rubber spatula, and any excess is immediately removed with a soft and damp cloth. The same rag can be used to polish the entire mosaic dry when finished.

Rating of the best ceramic mosaic for 2025

Budget segment

3rd place: "Mosaic ceramic 24.6 cm x 28.6 cm, chip size: non-standard mm"

votes 0

The original budget option, which is perfect for decorating a balcony, a billiard room, a living room, a nursery, a corridor, a kitchen, an office, a bedroom. The material works great with any kind of glue. Qualitatively adheres to different types of surfaces.There are fairly wide seams between the individual chips, which will simplify the finishing grout. The recommended cost for retail chains is 302 rubles.

- Profitable price;

- Convenient masonry;

- Classic grey.

- Not detected.

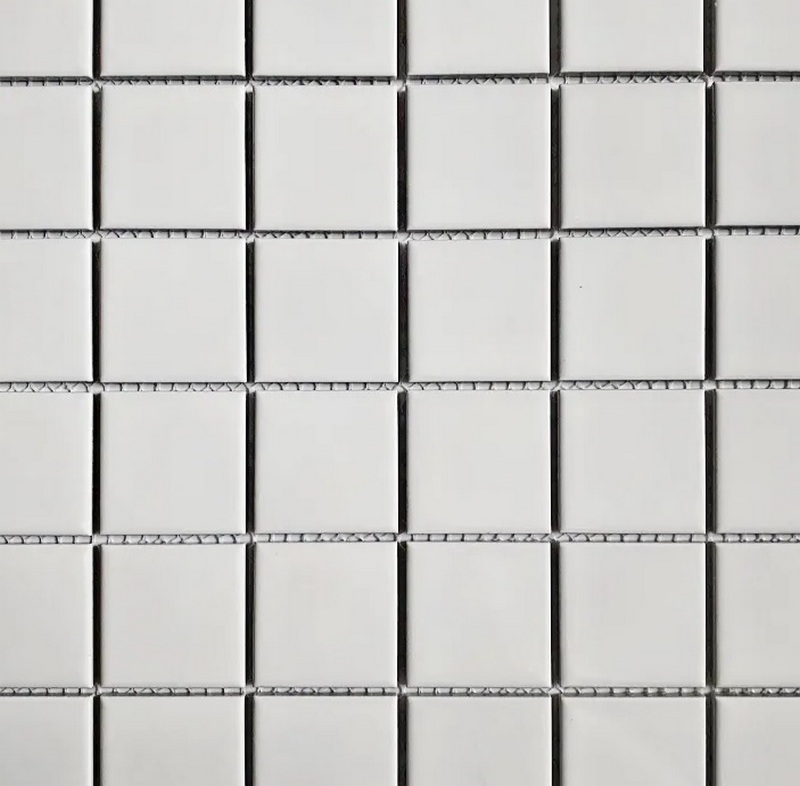

2nd place: "Mosaic ceramic 30.6 cm x 30.6 cm, chip size: 48×48 mm"

votes 0

Classic version with standard square chips. Perfectly will be suitable both for facing of internal rooms, and for finishing of external facades. Resistant to high humidity conditions. However, for installation, you will need to use a special mosaic glue. It is supplied both individually and in the form of block structures. The recommended cost for retail chains is 320 rubles.

- Variation of shades of gray;

- Placement of blocks on a polymer grid;

- Water resistance.

- The need to use special glue for installation.

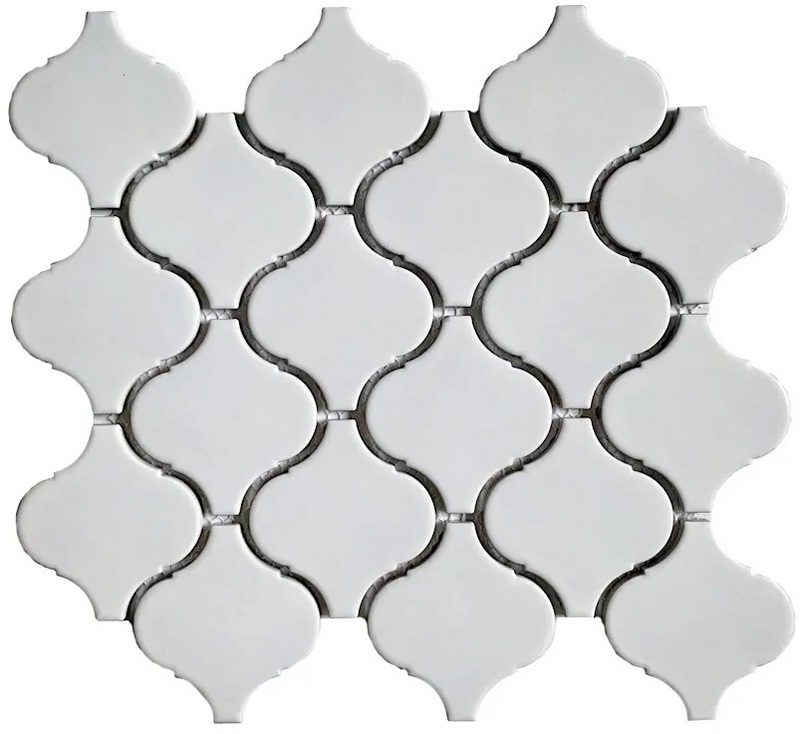

1st place: "Mosaic ceramic 32.5 cm x 28.1 cm, chip size: rhomboid mm"

votes 0

Another traditional version on a ceramic basis. With its help it is convenient to decorate the premises of the kitchen, bathrooms and bathrooms. The surface is specially provided with a pattern in the form of dark veins, which makes it easier to visually recognize the bottom under water when lining the pool bowl. There is a possibility of combinations with other materials when used as a floor covering. Installation does not cause problems. The recommended cost for retail chains is 395 rubles.

- Versatility;

- Traditional design;

- Convenient form of chips.

- Not detected.

Middle price segment

3rd place: "3D Hexagon White Glossy Mosaic"

votes 0

It is a classic example of design work and is designed to decorate walls and other vertical surfaces. Due to the fact that the surface of each chip has a rather convex pyramidal corrugation and a glazed coating, this mosaic cannot be used as a floor covering - it is very difficult to maintain balance on it, and the sharp corrugated edges do not facilitate comfortable walking. The recommended cost for retail chains is 458 rubles.

- original design;

- Classic gray shade;

- Corrugated surface.

- Placement on the floor is not allowed.

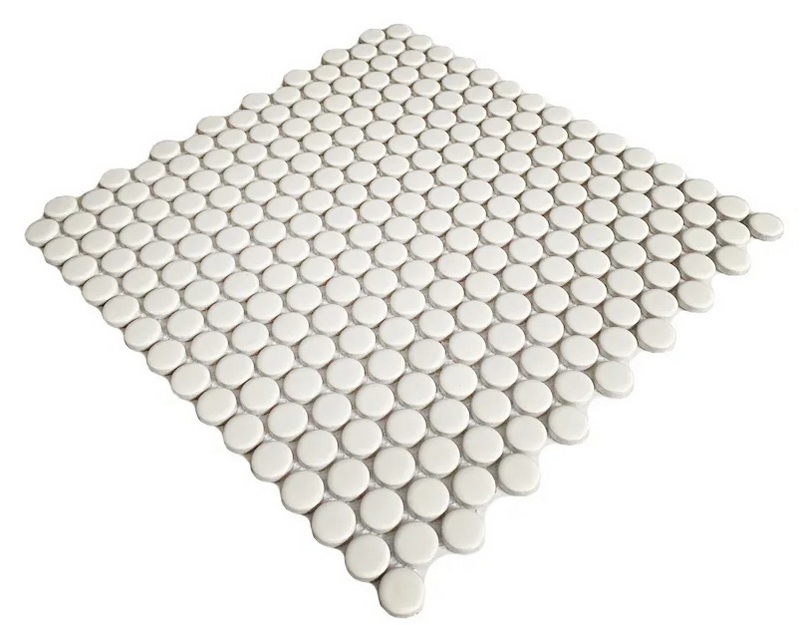

2nd place: "Mosaic ceramic 30.9 cm x 31.5 cm, chip size: round mm"

votes 0

Such a sample is characterized by the presence of large round chips, has an anti-slip surface, and is delivered immediately in “paper” blocks, which greatly facilitates its installation. Due to its inconspicuous design, as well as the presence of large seams, most consumers prefer to use this model as a floor covering in rooms with high humidity: baths, saunas, toilets, swimming pools and bathrooms. The recommended cost for retail chains is 530 rubles.

- Round chips against the background of large seams;

- Block "paper" equipment;

- Facilitated installation process.

- Narrow scope.

1st place: Mosaic GAUDI Hexa 28.3 cm x 24.5 cm

votes 0

This variant is glazed with a typical handmade texture.Its distinctive feature lies in the variety of rich colors and the presence of an organic, unique pattern of each chip. The original selection of colors visually enhances the visibility of the three-dimensional mosaic in space. Can be used for both exterior and interior decoration. The recommended cost for retail chains is 1390 rubles.

- original design;

- Versatility of application;

- Rare colors.

- Somewhat overpriced.

Premium class

3rd place: "Ceramic mosaic for the bathroom / kitchen backsplash / white / tile / 32.7 cm x 32.7 cm"

votes 0

It has a white color, size 327x327x4 mm - this is a decorative material used for finishing countertops, walls in the bathroom and other rooms. It is assembled from squares on a mesh base, therefore it is convenient to use and very reliable. The white surface of the sample has a pleasant glossy sheen, the product will make any room lighter and more spacious. The advantages include: high strength, resistance to moisture and corrosion, resistance to temperature extremes. The recommended cost for retail chains is 1500 rubles.

- Versatility of application;

- Classic colors;

- Selling 5 sheets per set.

- Not detected.

2nd place: “Ceramic porcelain mosaic gray 27.9 × 33.8 ceramic for walls”

votes 0

This product on a ceramic base imitates "porcelain" and is perfect as a facing material for the kitchen, where it will look spectacular in any interior.The original matte finish with a mysterious light play of shades will become one of the decorations of any room. Mosaic is not suitable for use in a swimming pool, but is able to withstand the directional impact of water and can be used as wall cladding in the shower. The material is intended for finishing vertical surfaces - walls, partitions, columns made of concrete, stone, brick, drywall, wood, metal and plastic. The size of the tile is 27.9 x 33.8 cm, the shape of the segments is hexagon. Average tile consumption per 1 sq.m. - about 11 pieces. The product does not emit toxic substances into the air, which corresponds to a high environmental friendliness class according to the VOC classification. Contaminants from the surface of the product are easily removed with neutral detergents. However, you will have to abandon the use of abrasive sponges and aggressive household chemicals. Do-it-yourself styling is possible. Fastening type - standard glue. The tile will serve for a long time without losing its decorative properties. The recommended cost for retail chains is 2030 rubles.

- Imitation of "porcelain";

- High class of environmental friendliness;

- Economical consumption of tiles when finishing.

- Cannot be used in a pool.

1st place: "Skalini 280 28.5 cm x 28.5 cm"

votes 0

This product is of exceptional quality. It is convenient to use it when finishing bar counters, for decorating a house, a room, ceilings, bedrooms, for walls and decorating columns, ceilings in the living room, walls in the bathroom, walls in the living room, walls in the kitchen, kitchen aprons, hamams, showers, pools and baths . It is also possible facing fireplaces and general decoration of the premises. The recommended cost for retail chains is 2400 rubles.

- Wide scope of application;

- Unusual variant of chips;

- Water resistance.

- Overpriced.

Conclusion

Among the huge variety of materials for decoration, ceramic mosaic is one of the most practical coatings for rooms of various types. Today it is already ordinary and familiar material. For those who need special originality and exclusivity, it is best to cover the surface with non-standard mosaic chips (oval or “broken”), which, as a result, will make up an original ornament or a solid artistic canvas.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131650 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127689 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124517 -

The best men's sneakers in 2025

Views: 124031 -

The Best Complex Vitamins in 2025

Views: 121938 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114978 -

The best paint for gray hair - top rating 2025

Views: 113393 -

Ranking of the best wood paints for interior work in 2025

Views: 110318 -

Rating of the best spinning reels in 2025

Views: 105327 -

Ranking of the best sex dolls for men for 2025

Views: 104363 -

Ranking of the best action cameras from China in 2025

Views: 102215 -

The most effective calcium preparations for adults and children in 2025

Views: 102010