Rating of the best epoxy resin for pouring in 2022

Resin is a substance adapted to harden under certain environmental conditions. Resins exist both artificial (man-synthesized) and natural (wood). "Epoxy" (commonly referred to as epoxy resin) refers to polymer resins, that is, it contains oligomers in its composition - molecules that have a small limited mass.

The main characteristics of the resin, as a substance, include:

- Moisture resistance, the ability to withstand open ultraviolet rays;

- The presence of an extremely weak susceptibility to destruction by alkalis and halogens, as well as acids;

- Ability to dissolve in acetone and esters;

- In the hardened state, there are no emissions of (harmful) volatile substances.

Epoxy (transparent) resin contains two components, respectively, two chemical processes are required to obtain the final product.In the first mixing step, a linear substance with a reduced molecular weight is produced, which, moreover, has thermoplasticity. In the second stage (solidification), an insoluble and refractory solid is formed.

The most valuable feature of epoxy resin is its ability to rapidly change from a liquid to a solid state. At the same time, as a result of such a transition, some surfaces with a sufficient degree of strength can be glued together. Hence the demand for the mixture for both creative works and household ones.

Content

Types and chemical compositions of the resin used for pouring

Epoxy has long and often been used by people in everyday life. For any household work that requires a reliable and solid connection - it has become an indispensable assistant.

According to the composition, several types of resin are distinguished at once:

- Epoxy-Dian, which are marked with the letters "ED" and have numbers 10,16,20 and 22. EP-SM-PRO resin also belongs to the same series.These substances are widely used in both household and industrial areas: the manufacture of complex materials (compounds) with the possibility of impregnation, the installation of self-leveling floors, the production of adhesive compositions, etc. This is not the whole list of applications for this type of resins;

- Epoxy-Dian, used in the preparation of varnishes and paints. They are marked "E" with numbers 40 and 40-P. Are irreplaceable in creation of paint and varnish coverings;

- Epoxy-modified - marking "EPOFOM" with numbers 1,2,3. Used for repair work;

- Epoxy special purpose. They may contain other substances, for example, resorcinol, chlorine, so their use is possible in special environmental conditions.

It is worth noting that any epoxy includes two elements - a hardener and the resin itself. And different fillers give it special properties.

Epoxy and its consumer qualities

The cost of this substance is quite high. Purchasing a small amount for household needs will not really hit your pocket, but buying large quantities will require a lot of money. However, the popularity of resin among the population does not fall. This fact can be explained by the excellent qualities of the polymer, which include the following:

- Bond strength. In some cases, with a high degree of compliance with the process technology, the hardened mixture may well compete even with certain types of concrete;

- Heat resistance. The resin is able to successfully withstand high temperatures (+200 degrees Celsius and even higher);

- Moisture resistance. When hardening, the resin absolutely does not pass and does not absorb moisture;

- adhesive properties.High level of adhesion, subsequent bonding strength, capable of gluing large surface areas;

- Practical resistance to most aggressive substances (eg acids);

- Light weight when frozen.

These properties are typical for all types of these substances. Properties can be reduced or enhanced by adding specific components used in the resin to the resin. In the process of acquiring epoxy resin, it is imperative to make sure of the intended purpose of the composition. This information can be obtained from the information written on the label or by consulting with a sales consultant. Even a slight deviation from the composition required for certain jobs can directly distort their result.

Areas of use of epoxy

The scope of its application is quite wide. The substance is very popular in use for both domestic and industrial needs. In turn, the technologies used for the manufacture of epoxy are being improved on an ongoing basis, which expands the scope of its application. At the same time, the composition acquires updated qualities.

Most often in production, resin is used to solve the following problems:

- Surface bonding and fiberglass impregnation. This is necessary for the construction industry, electrical engineering and radio electronics, aircraft and mechanical engineering, in the production of fiberglass, in the repair of cars and ships;

- Formation of a layer of waterproofing. A similar symbiosis of epoxy with other materials is used to cover walls in rooms with high humidity, basements, pools, and other tanks in which liquids are stored;

- Creation of chemically resistant coatings for their interaction with internal / external environments, as well as protection of porous materials;

- Creation of transparent parts, objects, by pouring resin into molds. In the future, such parts can be subjected to cutting, grinding, other machining.

When bonding hard surfaces, epoxy is much better suited than any other resin epoxy. Of course, the sticking effect can be achieved, but the special composition (glue) will achieve much better results.

Primary properties of epoxy resin

Almost all types of epoxy are transparent in their original state. But some of them have a yellowish tint. However, after reacting with the hardener, the yellowness remains. This is worth remembering if you want to apply a completely transparent bonding layer.

Other types of the polymer in question may have an increased viscosity and, after solidification in their mass, form small air bubbles that reduce the transparency effect. It is possible to eliminate them by heating the epoxy mass, both after the pouring process and before it. For such an operation, a burner or a special heating system is used. The procedure itself is time-consuming and does not always lead to the desired result.

Crafts made from epoxy can lose their transparency over time due to exposure to oxygen or ultraviolet light. This can be avoided if a special chemical additive containing antioxidants or UV protectors is present in the composition.

Thus, when choosing an epoxy, the following must be considered (which will depend on the direction of the intended work):

- The desired shade of resin before introducing all kinds of chemical additives;

- The degree of its viscosity;

- Features of the chemical composition.

Transparent types of epoxy can be used both for making models of parts or jewelry (souvenirs, various decor), and for the production of large-scale works (filling countertops, walls and shelves, etc.). The technology of application will directly depend on the work performed.

To be completely sure that the resin is designed for the tasks (especially when processing extremely large areas), you should purchase a small sample container and see how the epoxy will behave when applied to non-conspicuous elements.

Industrial use of epoxy

The permanent appearance of new chemical compositions significantly expands the scope of epoxy. With its help, it has now become possible not only to glue large objects, but also to make a replacement for metal parts in various designs from it, which will significantly reduce both the cost and weight of the product.

The main areas of application include:

- Manufacturing of composite objects. In a similar way, fiberglass, carbon fiber are made by impregnating synthetic fabric with resin. After these materials can be actively used in object-oriented modeling, when creating cars, aircraft, ships, rockets.

- Furniture manufacture. These can be both ordinary options (for example, kitchen countertops) and real exclusive household decor (slab tables and countertops, artificial rivers and waterfalls, etc.)

- Production of waterproofing / electrically insulating materials. The resin acts as a dielectric, and is also moisture resistant.

- Jewelry making and jewelry making. Resin jewelry looks great and is cheap.

- Repair and installation work.Resin can be used to treat a cracked countertop, renew a floor, fix a small boat (a leak in a fishing wooden boat), patch up a car body, etc.

Resin is many times easier to work with than ceramic/metal.

Rules for preparing for pouring

The preparation of the resin composition must be carried out in strict accordance with the instructions, which are without fail attached to each factory container. The lack of instructions in the kit calls into question the quality of the resin itself.

A huge role is played by the proportions that must be observed when mixing. The usual ratio of resin to hardener is 10 to 1. In special formulations, the ratio can vary from 5 to 1 to 20 to 1. Methods for preparing small and large volumes also differ. A large volume should first be thoroughly heated in order to reduce the viscosity. At the same time, it is worth remembering that an increase in temperature for every 10 degrees Celsius accelerates the polymerization process by a couple of times.

When heating the mixture, you need to constantly monitor its temperature. If you bring the substance to a boil, it will begin to become cloudy and foamy. This composition will become unsuitable for work. By means of special thinners, the viscosity of the mass can be reduced. However, it should be remembered that even minimal doses of these additives (5-7%) can significantly reduce the adhesive qualities.

Particularly relevant is the problem of purification of the substance from visible impurities before its application. Therefore, it is wiser not to allow stains to appear at all. If this trouble happened, then it is better to carry out cleaning in a banal mechanical way. But it does not apply to all surfaces. The use of special solvents may also not ensure the safety of surfaces. You can also use both freezing and heating.But none of these methods gives a 100% guarantee of complete cleaning.

Rating of the best epoxies for pouring for 2022

10th place: QTP-1130

Essentially universal brand designed for processing countertops. A good choice for beginners. The mixture itself is transparent, does not suffer from a yellowish tint. Reduced viscosity self-levels the surface and carefully fills voids. Scope of application - small tables.

Specifications:

| Name | Index |

|---|---|

| Coating type | anti-slip, high-strength, pourable |

| Color | colorless |

| Consistency | liquid |

| Shelf life | half a year |

| Air humidity | 0.85 |

| Component ratio | 100:60 |

| Compound | Epoxy |

| PRICE, rub/kg. | 674 |

- Suitable for inexperienced craftsmen;

- Does not have side shades;

- Has a self-levelling effect.

- Limited shelf life.

9th place: Art-Eco

The recommended maximum thickness of the applied layer should not exceed 5-7 mm. The quality of the components of the substance is very high, but strict adherence to proportions is required when mixed with a hardener. A slightly noticeable yellowish tint is possible, so its compositions are often tinted.

Specifications:

| Name | Index |

|---|---|

| Density, g/cm3 | 1.05 |

| Dynamic viscosity, Pa.s | 0.75 |

| Breaking stress, MPa | 65 |

| Tensile strength, MPa | At least 35 |

| Adhesion of impregnation from concrete, MPa | 2 |

| Relative elongation, in 5 | 5 |

| PRICE, rub/kg. | 1300 |

- Excellent penetrating ability;

- Stability of chemical properties;

- No strong odor.

- Full load on the treatment site is possible only after 7 days.

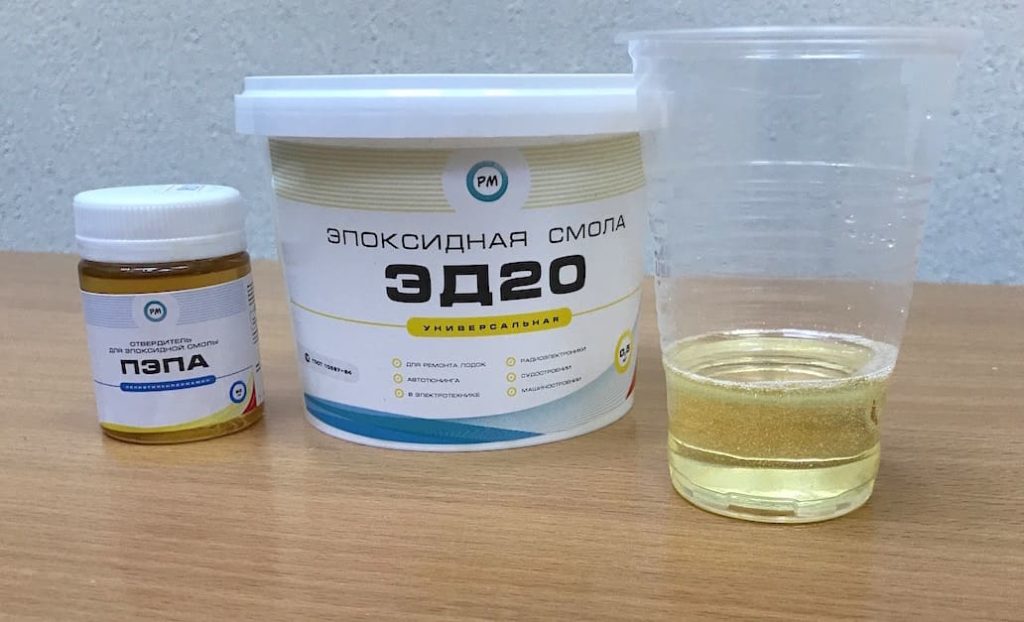

8th place: ED-20

Completely Russian development, made according to Russian GOSTs. It is characterized by high viscosity.Over time, transparency may decrease, a yellowish tint appears. However, this disadvantage is more than compensated by the increased density and the substance is perfectly used for pouring floors. The relatively low cost is also a big plus. Suitable for both experienced and novice craftsmen.

Specifications:

| Name | Index |

|---|---|

| Density, kg/m3 | 1.16 |

| Tensile strength, MPa | 40-90 |

| Polymerization temperature, degrees Celsius | 20 |

| Time of complete polymerization, hour. | 24 |

| Moisture absorption, in 24 hours in % | 0.001 |

| Impact strength, kJ/m | 5,25 |

| PRICE, rub/kg. | 505 |

- Good adhesion to glass, metal, ceramics;

- Resistance under the influence of aggressive environments;

- Full dielectric.

- An outdated formula, not always able to meet modern challenges.

7th place: CHS Epoxy 520

High-quality mixture of Czech production, supplied with a specially designed hardener. Perfect even for such delicate work as drawing up a herbarium. The main purpose is to work with small details and decor. Does not boil even when using large volumes

Specifications:

| Name | Index |

|---|---|

| Epoxy equivalent, g/mol | 182-192 |

| Color according to Hazen, no more | 100 |

| Dynamic viscosity, at 25 gr. Celsius (SPz) | 12000-14500 |

| Share of hydrolysable chlorine | 0.03 |

| Epoxy index | 5,2-5,5 |

| PRICE, rub/kg. | 1690 |

- High temperature of destruction of the hardened composition (from 90 degrees Celsius);

- No synthetic odor

- Practically not subject to the formation of yellow spots.

- Slightly increased elasticity.

6th place: Crystal Glass

This Russian product is distinguished by high fluidity, and it is excellent for pouring large surfaces.According to the instructions, after mixing with the hardener, which is sold in the kit, the mixture should be infused for a short time. This will result in better viscosity. Professionals prefer to work with this epoxy.

Specifications:

| Name | Index |

|---|---|

| Color | Transparent |

| Life time at 25 gr. Celsius, min. | 35-40 |

| Shrinkage | 0.02 |

| Tensile strength, MPa | 60-80 |

| Compressive strength, MPa | 80-110 |

| Mixture density, g/cm3 | 1,0-1,1 |

| PRICE, rub / 300 grams. | 570 |

- Easy to prepare;

- Suitable for jewelry production;

- Has extreme transparency.

- A high degree of thickening makes it impossible to make even small edits in the treated surface (the awl does not take, you have to use small drills).

5th place: PEO-610KE

Special elastic resin certified according to GOST. Elasticity is very suitable for processing countertops, because it allows you to evenly distribute the load on the bearing surface. Full curing - 2-3 days. In every sense it is a medium level substance.

Specifications:

| Name | Index |

|---|---|

| Mass viscosity at +25 gr. Celsius | 750 |

| Curing time, days | 02-03 |

| Hardness | 80 |

| Max. operating temperature (gr. Celsius) | 80 |

| Price, rub / 600 grams. | 1660 |

- Suitable for jewelry making;

- Does not turn yellow;

- Handles sanding well.

- Rather high price due to the specifics of the application.

4th place: EpoxAcast 690

Professional and expensive Russian-made compound. Used exclusively for jewelry. It is applicable for countertops, but the required layer should not exceed 5 cm. Despite its strength and lightness, it can shrink slightly in large volumes.

Specifications:

| Name | Index |

|---|---|

| Shrinkage, % | 0.25 |

| Tensile strength, MPa | 45 |

| Bending strength, MPa | 75 |

| Compressive strength, MPa | 66 |

| PRICE, rub/kg | 2010 |

- Great for both modeling and jewelry;

- Supports the use of paints to create color images;

- Long service life of the composition (300 hours).

- High price.

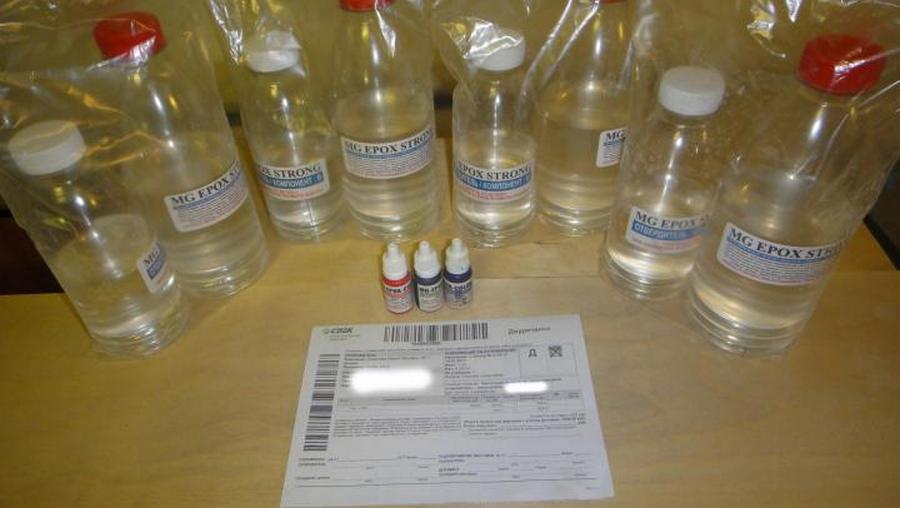

3rd place: MG-EPOX-STRONG

Epoxy from a German manufacturer. It has just an impeccable reputation due to its versatility. It is characterized as a heavy-duty and ultra-transparent composition. The final hardening time is a little less than 3 days.

Specifications:

| Name | Index |

|---|---|

| Component ratio | 100:40 |

| Life after mixing | 30 minutes. |

| Full hardening time | 72 hours |

| Transportation at negative temperature | Possible |

| PRICE, rub/kg. | 1100 |

- Unpretentious to the environment;

- Low probability of formation of brown spots;

- Relatively low price.

- Small filling thickness (up to 10 mm).

2nd place: Epoxy CR 100

Universal and maximally safe mixture with all the necessary modern properties. Differs in the increased wear resistance and antistatic character. Product for professionals

Specifications:

| Name | Index |

|---|---|

| Density, g/cm3 | 1,07-1,08 |

| Viscosity, MPa | 800-900 |

| Mixing ratio | 1:10 |

| Compressive strength, MPa | 52 |

| PRICE, rub/10 kg. | 18300 |

- Wide range of applications;

- Increased chemical resistance;

- The ability to self-level.

- Sensitive to use on contaminated surfaces (grease stains, dust).

1st place: Magic Crystal-3D

Wear-resistant and durable epoxy, not afraid of exposure to open sunlight. Often used for making jewelry and floors, with 3D imitation. Great for pouring even surfaces.

Specifications:

| Name | Index |

|---|---|

| Pour point, gr. Celsius | 25-50 |

| UV protection content | In stock |

| Component ratio | 100:50 |

| Complete liquefaction, gr. Celsius | 70 |

| PRICE, rub/set 160 gr. | 1050 |

- Ultra-transparent composition;

- Works great on glossy surfaces;

- Good fluidity, no bubbles.

- Extended hardening of even small items (up to 48 hours).

Instead of an epilogue

The fantasy of both a professional and a beginner in the use of resin is truly limitless. With the help of epoxy, you can carry out competent repairs and create beautiful jewelry. Fortunately, in its composition, this substance only becomes safer to use over time. And you can buy resin at any specialized hardware store at retail, or on online trading platforms, especially since you can find any necessary packaging option there.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131657 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127697 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124525 -

The best men's sneakers in 2022

Views: 124041 -

The Best Complex Vitamins in 2022

Views: 121945 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114984 -

The best paint for gray hair - top rating 2022

Views: 113400 -

Ranking of the best wood paints for interior work in 2022

Views: 110326 -

Rating of the best spinning reels in 2022

Views: 105334 -

Ranking of the best sex dolls for men for 2022

Views: 104373 -

Ranking of the best action cameras from China in 2022

Views: 102222 -

The most effective calcium preparations for adults and children in 2022

Views: 102016