Rating of the best wooden mosaic for 2025

Today, wood mosaic based on various shades is one of the most popular options for interior design, although it has been used for a very long time. The resulting panels and ornaments look very impressive and original. Among other things, this material from natural wood is distinguished by a high degree of environmental friendliness and has hypoallergenic properties. In this regard, wood is in a better position than the highly common ceramic or glass variations (not to mention plastic ones), which makes them an excellent example of non-standard finishes.

Content [Hide]

Scope of application

In the production of this type of material, raw materials of different tree species are used - from the simplest to valuable ones (for example, mahogany). The use of natural components implies an increased degree of environmental safety of the final product, and this allows for the finishing of premises where small children or people with increased allergic sensitivity are constantly present. In addition, no toxic substances are used during the manufacturing process and during installation, and all elements are fixed on a chip-wood substrate by means of an adhesive substance. The final picture will look extremely attractive, giving the interior additional originality.

Most often, wooden mosaics are used to decorate interior spaces for various purposes - from residential to official. Of course, the external elements of structures can also be finished with a similar mosaic shape, but much less often. The reason for this is the extreme exposure of the tree to water - it is the substrate that will suffer the most, because it has a non-monolithic structure.Also, for flooring, this mosaic material is also not recommended, due to its rapid wear, first of all, this is a loss of external attractiveness due to surface abrasion.

The most common options for interior styles in which wooden mosaics are used can be:

- Minimalism;

- Modern;

- Retro;

- Country.

If we talk about the intended purpose of the finished premises, then this material can be used in:

- kitchens;

- living rooms;

- Bedrooms;

- hallways;

- Workrooms.

Do not assume that wooden mosaics are used only for finishing dry rooms, this material can also be laid in rooms with high humidity and temperature. It is allowed to decorate them with bathrooms, baths and saunas. However, in this case, all elements of the mosaic must have a special moisture-resistant and fire-resistant impregnation, and the best species for this can be coconut, cedar, ash or oak.

Self-production technology

Unlike most mosaics made from other materials, wooden ones can even be made independently and at home. However, for this the master will need special equipment and some skills. The simplest options to make will not be difficult, and the entire course of work will consist of the following steps:

- To begin with, the final total area of \u200b\u200bthe ornament or panel is determined;

- Determine the dimensions and dimensions of each individual chip-plate;

- By means of a milling machine, individual parts are cut from wooden blanks;

- Chips-plates are treated with special impregnations (to extend the service life or if the art object will be placed in rooms with extreme conditions);

- The final stage will be the grinding of each plate, the creation of a perfectly flat surface and its coating with a colored or colorless varnish.

Wood mosaic techniques

In our time, there are several types of laying out wooden mosaics, differing from each other in the structure of execution. The most popular include:

- Traditional (classic)

Such a mosaic type is a composition composed of plates of the same type of wood species (less often it may include a combination with other materials - metal, stone or glass). This technique is considered very ancient and was used even before our era when facing the houses of wealthy citizens of the Roman Empire, and earlier - Hellas (Greece). The most striking examples that have survived to this day are the decoration of the halls of the Winter Palace - the coating there perfectly preserved the ornament of concentric circles, including specific patterns of leaves and rosettes.

- Blockwise

This technique consists in the fact that, first of all, according to the drawn sketch, a monolithic block is created from glued wooden bars, which is then cut into separate plates with a pattern, from which the ornament is subsequently assembled. It is very convenient to embed such elements in background recesses or stick them on the surface to be finished. As a rule, parts with a length of up to 20 centimeters, with a cross section of 2x2 centimeters, are inserted into the block. Block technique is used more for valuable tree species in order to prevent unnecessary overspending of expensive material. As a result, the pattern is created on the basis of the end coloring of the bars included in the block.Upon completion of the creation and gluing of a separate block, it is cut into thin plates (with the same pattern), which can be inserted into the prepared groove or glued to any surface. The final step will be sanding each thin plate and coating it with a clear varnish.

IMPORTANT! When using this technique, the artist must develop a sketch of the whole panel in advance. Accordingly, for decoration, he must prepare several monolithic block mosaics with different patterns, which in the future can be assembled into a full-fledged image.

- Inlay

This finishing process involves decorating various objects with wooden mosaics (in most cases, massive pieces of furniture), during which individual patterns, artistic composite images, prefabricated ornaments are inserted / cut into the object. At the same time, each plate is attached in such a way that it does not protrude even a millimeter above the surface, in order to emphasize the inseparability of the monolithic structure of the object.

- intarsia

This technique is somewhat similar to inlay, but the object of decoration and the mosaic itself must be made of the same material, i.e. wood (ideally, even the tree species should match). All the difference can only be in the color and texture of the inserted ornament. Installation is carried out in specially cut recesses in the finished object, where each plate is fixed with mastic or glue. The front side of the intarsion mosaic is made of durable, beautiful and valuable wood species (boxwood, yew, cypress, etc.). The final stage of finishing always involves polishing and varnishing.

Advantages and disadvantages of wood mosaics

The considered mosaic type has a number of advantages over its "brothers", which include:

- A high degree of environmental friendliness and the absence of harmful substances in its structure - even with an increase in ambient temperature, the tree will not release harmful toxins into the air;

- A sufficient level of durability (especially if the surface has a protective coating, and the installation technology was strictly observed);

- Low thermal conductivity - the tree perfectly retains heat in the room;

- Increased vapor permeability - does not allow the manifestation of unnecessary factors that contribute to the formation of mold and fungi on its surface, while improving the microclimate in the room;

- Excellent compatibility with other materials - wood can be in perfect harmony with stone and brick, tile and simple plaster, and even with wallpaper;

- Ease of dismantling - it is very easy to replace individual worn / damaged elements of the mosaic, and it does not require its complete disassembly;

- Flexibility and the ability to create a camouflage effect - a wooden mosaic hides the defects of the treated surface very well;

- Soundproofing - wood is one of the best mosaic materials to absorb sound waves.

The disadvantages of wood material are not so many, but they are significant. The main one is poor resistance to interaction with moisture. From this it is clear that in a humid room a wood panel without special impregnation will not last long - it will simply dry out. In any case, even if you provide proper care and cover the base with wooden varnish, then this coating will have to be periodically updated.

Varieties of production material

For mosaics made of wood, the raw material can be either whole wood of almost any species (not excluding exotic ones), or waste from the furniture or woodworking industry, namely, simple shavings that are kneaded in cement mortar. The use of cement mortar allows you to give the sawdust sufficient density, shape and thickness. This type of raw material is the cheapest in this segment, but in terms of quality, appearance, and safety properties, it is only slightly inferior to expensive solid wood.

IMPORTANT! The color palette of chip-cement mosaic elements varies from gray to yellow. This range allows successful and harmonious folding of gradient patterns and, moreover, perfectly adheres to any surface (even with ordinary glue). The overall picture of the panel will look unusual and vividly express the properties of natural naturalness.

The most commonly used rocks as raw materials include:

- Pine - has a not very high price, but has a pronounced woody pattern of the structure;

- Lipu - only saw cuts of young trees up to 10 years old are used (older samples are prone to rapid drying);

- Aspen - lends itself perfectly to the processing procedure, because it has a very soft structure with an unusual yellow tint;

- Walnut is one of the most expensive woods, with colors ranging from very light to very dark. It fits perfectly into any interior, especially since the material can be both very hard and very soft. Finishing with an antiseptic is required to protect against the formation of mold and fungus.

For each specific type of rock, one should take into account not only its decorative and artistic properties, but also mechanical parameters.The most important parameter is the tendency of the rock to dry out quickly, or vice versa - to quickly swell with an increase in humidity in the room. Also, it is worth paying attention to the complexity of the processing process, whose result will directly affect the durability of the resulting products. Most experts prefer to use several types of wood in one panel at once, so that different indicators of hardness, density, etc. could compensate for each other, as well as the compatibility of their colors.

It is worth noting that in the production process it is often necessary to change the color of the wood species, using the firing procedure for this. Using this method, it is possible to obtain a decorative mosaic material with an unusual pattern, which will significantly increase the final value of the future image.

Experts also refer to the most popular exotic breeds:

- Lemon - the surface has characteristic golden tones;

- Amaranth - a pronounced woody texture with a purple-purple color;

- Anatolian walnut - distinguished by a catchy striped pattern;

- Rosewood - has purple and tan subtones;

- Ebony - casts a black palette;

- Holly - has a reddish surface.

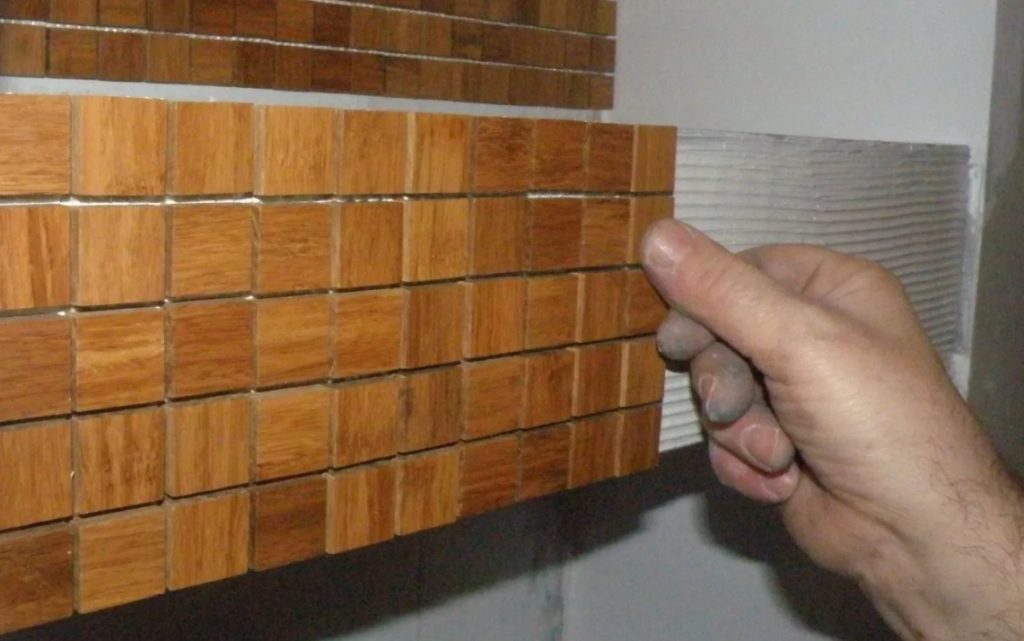

Features of the installation of wooden mosaics

During the installation of the described type of mosaic, special attention should be paid to its substrate. It should be as even as possible, otherwise it will repeat all the irregularities of the tiled base. Accordingly, the best substrates for processing will be either gypsum boards or well-plastered and leveled concrete flat objects. At the same time, it is worth remembering about the primer.In order for the mosaic elements to adhere properly, the surface must be well primed, which will increase its adhesive properties. Also, it is desirable to remove other flaws from the surface - we are talking about the need to seal even the smallest cracks using finishing putty.

When laying the mosaic directly on the base, it is necessary to clearly monitor the levels horizontally and vertically. It is preferable to carry out all laying on the type of glue recommended by the manufacturer of the mosaic product. If the adhesive contains PVA, then this property will be the key to better adhesion.

Special attention should be paid to the seams between the chips-plates - they should not be overwritten with ordinary tile grout. The reason lies in the fact that the tree must "breathe", and such a seam seal will soon crack and lose its attractive appearance. In any hardware store, you can purchase special grout options for wood materials (they will be able to narrow / expand, preventing cracking). In extreme cases, instead of a special grout, you can use a standard silicone-based sealant that fits the color palette.

Difficulties of choice

Before buying a wooden mosaic set, you need to pay attention to a number of essential points:

- Strength level - it can be recognized by color (the strongest is marked in red, the weakest in blue);

- The surface is rough or flat, which will depend on the purpose (for example, in the first case - for flooring, in the second case - for wall decoration);

- General dimensions and dimensions - depends on the area of the future image;

- The need for anti-slip coating - will be required for flooring in rooms with high humidity;

- The need for a decorative pattern - it is necessary to create large-scale ornaments;

- The type of wood - will depend on the place of installation (for dry rooms, you can also choose a very soft variation);

- Color palette - the importance of harmony with the overall interior;

- The shape of individual chips-plates is chosen solely on the basis of the preferences of the buyer himself.

Rating of the best wooden mosaic for 2025

Budget segment

3rd place: "Quadro3d100k-1 - Geometrica Flat"

votes 0

A good sample, which has a standard design and is recommended for finishing various surfaces, both vertical and horizontal. Laying is possible indoors, however, due to the specifics of the surface, it is not recommended to use this model as a floor covering. The pattern is uniform and has good visibility. The recommended cost for retail chains is 690 rubles.

- original design;

- Adequate cost;

- Easy layout;

- Large chips-plates.

- Not suitable for flooring.

2nd place: "3D Mozaique - hexo3k60-1 - 360*312mm"

votes 0

This model is made in a full three-dimensional design and is recommended for finishing vertical surfaces. The product has an appropriate impregnation to counteract the formation of fungus and mold, so these plates can be placed in rooms with an extreme environment. Chips-plates are characterized by a large size, they can be used both individually and in blocks. The recommended cost for retail chains is 700 rubles.

- Full 3D plate design;

- The presence of impregnation;

- Large size of individual elements.

- Not suitable for flooring.

1st place: "Hexo3k60-8 - Geometrica 3D"

votes 0

Another product with a fully 3D structure. It imitates the type of wood of the red series, which, however, does not indicate the softness of its structure. The entire set of protective impregnations is present in the product. Laying is recommended on vertical surfaces. Can be used with stone and glass. The option of a full-size panel can also be considered. The recommended cost for retail chains is 720 rubles.

- Imitation of expensive wood species;

- Full set of protective impregnations;

- Possibility of combination with glass and stone.

- Not detected.

Middle price segment

3rd place: "Line3d150s-7 - Geometrica Parkett"

votes 0

This sample is focused on floor covering, as evidenced by its name and the characteristic rectangular shape of chips-plates. The manufacturer notes that almost any adhesive base will allow this product to provide reliable adhesion to the base. By production the pine breed differing in the increased hardness is used. The recommended cost for retail chains is 725 rubles.

- Special orientation of the goods;

- Characteristic and convenient forms of plates;

- Possibility of additives on almost any adhesive base.

- Not detected.

2nd place: "Line3d120k-6 - Geometrica"

votes 0

Pretty standard product with all the necessary qualities.It is proposed to be used as a wall decoration in classic interiors. Unpretentious to operating conditions, because it has antibacterial impregnation. However, application in conditions of sudden temperature changes is undesirable. The installation process will not be difficult, but due to the need for uneven installation, finishing grouting should only be done with special compounds. The recommended retail price is 810 rubles.

- Quality manufacturing;

- Lock type clutch of individual plates;

- Classic wood grain.

- Not detected.

1st place: "Hexo2s60-24 - Geometrica Octo"

votes 0

A very original product with a non-standard shape of the plates. It is noteworthy that the plate can be divided into two trapezoidal elements, light and dark, respectively. Thus, it is possible to create original patterned panels on large areas. The model is suitable for both wall decoration and flooring. The recommended cost for retail chains is 870 rubles.

- The possibility of dividing the working plate into two parts;

- Original color design;

- Possibility of creating irregular ornaments.

- Not detected.

Premium class

3rd place: Sanded beveled oak, Triangle series

votes 0

This product is intended for block laying only. The manufacturer positions it as a model for wall decoration in residential premises. The surface of the product is well polished, the production material (oak) has sufficient strength, which indicates the possibility of using the product even on the outer parts of structures.A set of protective impregnations is present. The recommended cost for retail chains is 980 rubles.

- Non-standard form of chips;

- Block layout orientation;

- Quick completion of work.

- Not detected.

2nd place: "Sanded beveled thermoash, Quadro series"

votes 0

This sample is specially designed for finishing the premises of saunas, baths and bathrooms. The basis of the product is ash, subjected to high-quality heat treatment, so it is not afraid of fires, as well as high humidity. Installation is possible only on special glue, liquid sealant is prohibited. The entire surface is properly sanded, and the connection between the blocks is carried out by a seamless method, which will not require subsequent grouting. The recommended cost for retail chains is 1100 rubles.

- Seamless connection;

- Heat treatment of the wood base - ash;

- Adequate price.

- Not detected.

1st place: "3D chipped oak mosaic, mocha tinting"

votes 0

This product is intended exclusively for decoration of residential premises and is made on the basis of fully voluminous chips-plates. The manufacturer oriented his product for wall decoration, because due to the nature of the surface, it is not suitable for flooring. The recommended cost for retail chains is 1700 rubles.

- Easy installation;

- Unusual design style;

- Fully sized plates.

- Too high price.

Conclusion

Since ancient times, wooden mosaics have been used to decorate various kinds of premises and through it the interior acquires a special zest that artificial materials, such as ceramics or glass with plastic, cannot give. It will perfectly decorate both horizontal and vertical bases, and is also suitable for finishing individual furniture fittings. And do not think that the mosaic tree is the exclusive prerogative of classical styles - today such a finish can also fit well into the high-tech style.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131653 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127693 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124520 -

The best men's sneakers in 2025

Views: 124036 -

The Best Complex Vitamins in 2025

Views: 121941 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114981 -

The best paint for gray hair - top rating 2025

Views: 113397 -

Ranking of the best wood paints for interior work in 2025

Views: 110320 -

Rating of the best spinning reels in 2025

Views: 105331 -

Ranking of the best sex dolls for men for 2025

Views: 104369 -

Ranking of the best action cameras from China in 2025

Views: 102218 -

The most effective calcium preparations for adults and children in 2025

Views: 102013