Rating of the best liquid plastic for 2025

Liquid plastic is a polymer-based adhesive mixture that is commonly used for bonding plastic and other objects. For example, to ensure a snug fit of frames in windows and doors to jambs, you can not use bulky sealants (which will lose their operational properties over time, requiring replacement), but close the existing gaps with “liquid plastic” that can provide a long and reliable working effect. Also, on its basis, you can make various molding objects (for example, small sculptures) and use it as a creative material.

Content [Hide]

- 1 General information and technical parameters

- 2 Scope and limitations

- 3 Specifics of application in certain conditions (or for certain materials)

- 4 Advantages and disadvantages of liquid plastic

- 5 Application technology

- 6 Rating of the best liquid plastic for 2025

- 7 Conclusion

General information and technical parameters

As a rule, liquid plastic is a transparent polymer based on one component (creative variations are always two) and has a reduced viscosity. It has the performance qualities of diffuse welding and can connect the objects of processing in a fraction of a second, while forming a monolithic seam layer, which is practically invisible visually. As a result, the hardened mass acquires the following properties:

- Resistance to temperature extremes;

- Reduced thermal conductivity;

- Good resistance to negative weather manifestations;

- Resistant to sunlight;

- Increased strength;

- Safety and environmental friendliness;

- Long-term preservation of the original color.

After application, the mass hardens within 2-4 minutes, and complete solidification to obtain the effect of maximum strength occurs in 24 hours.

Scope and limitations

The considered plastic-based polymer can successfully replace most of the modern adhesive materials. This mix is great for:

- PVC;

- plastics;

- Polycarbonate;

- Plexiglas;

- Reinforced PVC structures with aluminum profile;

- Polyethylene terephthalate glycol;

- Polystyrene.

The most modern varieties of liquid plastic can perfectly glue rubber and metal, ceramics and glass, as well as leather (natural and artificial).

However, it is still premature to talk about the complete universality of this mixture, because it has some limitations. For example, the composition is undesirable to use for:

- Objects that will be in permanent contact with moisture - the reason lies in the fact that the chemical formula of the substance was not developed for regular interaction with water.

- Porous objects, such as foam boards - its structure (or the structure of similar materials) does not allow effective diffuse welding to be fully carried out. Nevertheless, if gluing porous bases is essential, and there are no alternatives to liquid plastic at hand, then the treated bases must be carefully cleaned before gluing.

- Parts that have a different thermal expansion - if the processed material expands at lower positive temperatures than liquid plastic, then the superimposed layer will simply begin to peel off over time.

- Polypropylene - this material has a reduced chemical inertness, which does not imply high-quality diffusion, respectively, during operation, the applied seam will lose its strength;

- Metal - this material is suitable for processing only if its outer surface has a plastic layer, otherwise the seam will peel off.

Specifics of application in certain conditions (or for certain materials)

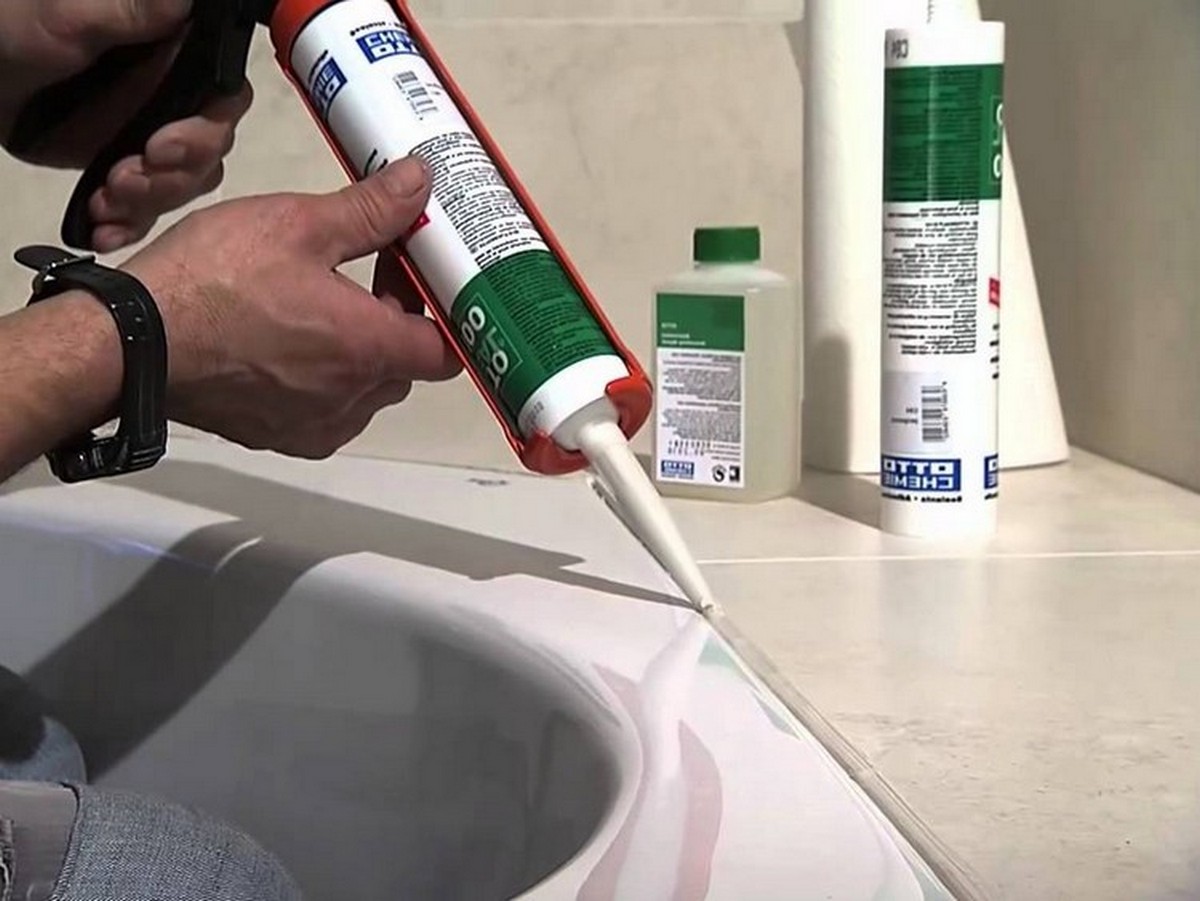

In bathroom

For this room, liquid plastic is most often used to seal the joints between the room itself and the walls, including the tiled floor and various vertical surfaces. Also, with the help of the composition in question, it is allowed to renew the coating of the bathroom bowl or shower tray. If we talk about restoration work regarding the bath / shower bowl, then they can be carried out using several methods using various mixtures:

- Restoration is carried out by means of acrylic mixtures;

- The surface is restored using a special adhesive enamel, similar in composition to liquid plastic, also made on the basis of polymers.

Using the above compositions, the restoration is carried out according to the pouring method, i.e. the sprayed material spreads over the inner surface of the bowl, forming a strong and even film over its entire area. As a result, the bathroom acquires an almost new, untouched appearance. At the same time, resistance to mechanical damage increases, the water poured into the bowl retains its positive temperature longer, and the surface becomes more resistant to the development of fungus / mold.

For bathroom work, liquid plastic is probably the most economical solution. Using it, you can postpone the need to purchase any bathroom accessory for a long time - from the bowl, tray to the door, and carrying out mandatory repairs after installation / dismantling also becomes optional.You can use the restored object after 36 hours. If the liquid plastic was specifically designed to perform exactly the above functions, then the manufacturer will usually establish a guarantee for the applied coating or seam, which averages about 20 years (subject to proper operation).

for windows

Quite recently, in the process of installing double-glazed windows made of plastic, only silicone sealant was used to seal gaps and openings, but today it has already been replaced by more effective liquid plastic. It can be used to seal voids that are formed during the installation of plastic windows and during the installation of window slopes, as well as when making window sills and other plastic elements included in the window set. Especially for these works, the substance is performed in a strictly white or transparent color, while simultaneously providing the mixture with a thick consistency. As it dries, the material forms an elastic film layer, which firmly connects the individual elements in a manner characteristic of diffuse welding. As a result, a monolithic seam is created that does not have even the smallest cracks or gaps. For these works, professionals recommend using liquid plastic of the Cosmofen brand. Unlike silicone sealants, it is characterized by stability in maintaining the original color, which is not lost even after a long time. At the same time, its shrinkage level is extremely low. The best representatives of this brand are samples:

- "Cosmofen HV+";

- Cosmofen 345.

For the latter option, the working mass is used to close the seams in the joints of window profiles made of PVC.Such layers receive increased resistance to sunlight, acquire proper reliability and strength, and in the future show a long service life. The first sample is more often used for fast gluing of rigid and elastic window-block parts, such as drains, flashings or other fittings.

For wood

In order to protect the wood surface from the negative impact of weather manifestations, from which putrefactive processes develop and the structure is destroyed, it is allowed to use liquid plastic, using it as ordinary paint (applies only to compositions made on a water-acrylic base). Thus, it is possible to completely paint wooden structures subject to special protection, which can be located both outside and inside the premises. The processing material itself is absolutely safe, which is achieved due to the presence of a water base, does not have unpleasant odors and hardens relatively quickly.

Also, using liquid plastic, you can perfectly cover the ends on the crowns of wooden log cabins, which will clearly increase the life of the future structure. The coating will create an elastic and durable film on the tree, which will prevent pests and water from reaching the base. It will also help to endure temperature fluctuations, will not dissolve when cleaning with aggressive detergents and will show resistance to mechanical stress of moderate severity.

If you choose liquid plastic as the basis for protecting wood objects, then the composition itself is often made by the manufacturer in such a way that it can be tinted to any color. The coating will not fade under the sun, because the applied mixture contains special additives that prevent the destruction of the formed film.It is desirable to work on wood only with specialized liquid plastic, especially for structures that are constantly in the open air. These include:

- Floors on verandas and terraces;

- Stairs;

- fences;

- Pavilions and other small architectural forms.

For mold casting (sculptural and artistic applications)

To carry out such work, the material under consideration has some differences in composition from its, so to speak, “applied counterparts”. It is produced in the form of a composition of two components and is focused on the manufacture of various parts, models, small sculptures and other items. Such liquid plastic has all the characteristics of a creative material and is a fluid substance that is poured into a special mold, and after filling it very quickly hardens to the strength of glass. Such a solution can reproduce the smallest elements that the form used has, and it is also characterized by the following properties:

- Increased mechanical strength and hardness;

- The possibility of tinting the poured mass;

- The hardened result is amenable to grinding and machining;

- Does not break down under UV rays.

Advantages and disadvantages of liquid plastic

The undoubted advantages of this product include:

- High environmental friendliness;

- No fading effect when exposed to external factors;

- Reliable filling of joints / cracks;

- Excellent strength due to the imitation of the work of diffuse welding (creating monolithic seams);

- Alignment of gaps on the surface;

- Good resistance to UV rays;

- Possibility of cleaning the newly formed plastic surface with aggressive cleaning chemicals;

- Reliable protection against mold and fungus.

Of the shortcomings, only three obvious ones can be distinguished, but they also have their justification:

- Accelerated polymerization - the working mass must be distributed within 60 seconds and have time to connect the selected objects. If the delay exceeds the specified time period, then the substance transforms into an elastic film and loses its adhesive properties.

- The presence of toxic emissions when the mass is in working condition - during operation, the substance may emit unpleasant odors, while after solidification, the polymer stops emitting them. Therefore, when working, it is recommended to use respiratory protection to prevent the occurrence of headaches and problems with the breathing apparatus.

- The impossibility of permanent contact with water - the seam can withstand a long downpour, but it is not safe for it to be constantly under water.

Application technology

Experts recommend not to use the working mass immediately after opening the container with it, but how to prepare the objects to be processed:

- Remove all contaminants from their surface;

- Subject them to proper drying;

- Carry out degreasing;

- Wipe with a simple rag.

For degreasing, it is better to use specialized products of the same brand as liquid plastic - fortunately, they are usually produced in tandem in a set. In extreme cases, this operation can be carried out with acetone. If you use a traditional solvent, then it is worth remembering that it is not suitable for all materials - some may collapse under its influence.

If we talk about the work of sealing joints in double-glazed windows, then this process is simple and intuitive: a thin strip of the working substance is squeezed out of the tube and applied along the entire length of the processed gap. In this case, smearing of the material is not allowed.At the end of the operation, it is worth waiting 15 minutes for complete hardening. Finishing slopes will require more complex manipulations, since it will require gluing objects together. Accordingly, after applying the working substance, one element should be attached to the other and, with a little pressure, hold. Then again wait for polymerization for 15 minutes.

Precautionary measures

It should always be remembered that the composition often has a toxic cyanoacrylate in its structure. This substance loses its activity only after polymerization. Therefore, when working, it is preferable to strictly observe some safety measures:

- Bonding must be carried out in special clothing (glasses, respirator, gloves);

- The work area must be adequately ventilated;

- Do not allow hot surfaces or sources of open flame near the place of work.

Recommendations of masters-specialists

Many consider handling liquid plastic a simple process, but a person without at least a little experience can make some mistakes that can affect the final result. In order to avoid problematic situations, you should adhere to the following simple rules:

- Attentiveness and speed of work - the place of application of the composition must be outlined in advance, and after squeezing the desired piece of substance out of the tube, apply it quickly and accurately;

- Do not work on foamed bases - although their processing is possible, after the foam falls off, the frozen plastic layer will inevitably deform;

- Do not start immediate operation of the object - it is always worth giving time for the layer to form and harden (from 15 to 20 minutes), which will mean only the initial hardening.The end of the polymerization process occurs at least after 24 hours (it is better to wait 36).

Difficulties in removing the layer of liquid plastic

There are situations when liquid plastic was applied to the wrong place. Such circumstances are especially typical for the installation of double-glazed windows, when a plastic substance gets on the glass. In this case, it can be removed (only after the initial solidification) with a sharp blade or solvent (better for a special purpose). If the polymerization process is just at the very initial stage, then individual drops of liquid plastic are removed with a corny wet rag. The greatest difficulty is removal from metal bases - although for most brands (except for Cosmofen) adhesion with metal is weak, it is better to remove the applied layer exclusively with special means.

Rating of the best liquid plastic for 2025

Budget segment

3rd place: "Cosmofen SL-660.210 200 ml 0.2 kg, transparent"

votes 0

The sample is intended for fast gluing of plastic parts. Acts by dissolving bonded plastics, can smooth out voids at joints. Ideal for quick bonding of PVC, plastic elements such as flashings, additional profiles and strips, elements, gutters or pipes. The recommended cost for retail chains is 407 rubles.

- Dries quickly, does not spread;

- Binds well, does not drip when working;

- Resistant to UV radiation.

- Not detected.

2nd place: "Cosmofen SL-660.220, white"

votes 1

The sample is used to fill window joints, cracks to protect against wind and moisture.It can be used to repair the internal walls of the refrigerator, repair the tray in the shower. It is characterized by fast and reliable bonding of PVC elements. Perfectly suited for gluing additional profiles such as flashings, flashings and roller shutter slats, gluing overhead caps and roller shutter inlet funnels to PVC profiles. Installation of advertising structures is possible. The recommended cost for retail chains is 420 rubles.

- Withstands significant temperature loads;

- moisture resistant;

- The result is a semi-solid adhesive line.

- Not detected.

1st place: "Real-Cast M4 (Russia) 0.8 kg, filling"

votes 0

This two-component casting composition is used for castings of monolithic products with a thickness of more than 5 mm. It has good fluidity and is odorless. Used in filled and unfilled form. The cured polymer is characterized by average strength indicators. The result is souvenirs, decor, models and other products of high detail. The recommended cost for retail chains is 1010 rubles.

- Very good fluidity;

- Let's apply with a large amount of a filler;

- Good adhesion to most materials;

- High surface finish;

- Good machinability;

- No strong odor.

- Precipitation is possible.

Middle price segment

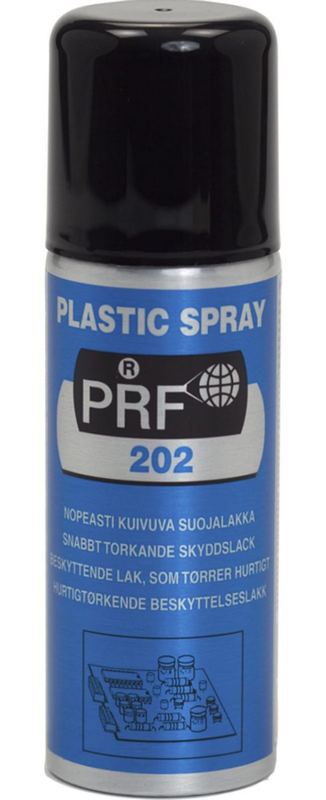

3rd place: "Taerosol 202 Plastic spray, spray 220 ml taePE20222"

votes 0

It is a quick-drying, transparent acrylic-based product used to protect electronic devices with outstanding dielectric properties.Protects moisture-sensitive electronic equipment placed in adverse atmospheric conditions from environmental factors. The innovative agent hermetically covers printed circuit boards, protecting conductive elements and parts from short circuits, induced and stray currents. The substance creates a transparent, but very durable plastic film that protects against dirt, dust, high humidity and prevents mold. It has unparalleled adhesion to plastic, wood, metal, glass, etc., it maintains excellent insulating and spark-extinguishing properties for a long time, and prevents leakage currents. Effective when applied to household appliances. The recommended cost for retail chains is 1140 rubles.

- Strong connection with most popular materials used in engineering and industry - plastic, wood, metal and glass;

- Guarantee against accidental leaks, but at the same time the possibility of reliable soldering of varnished circuit elements;

- Complete protection against corrosion.

- Not detected.

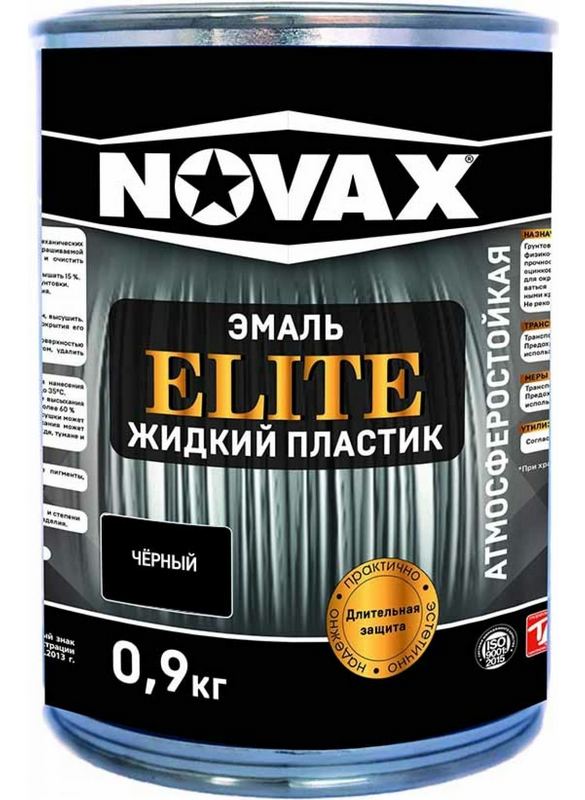

2nd place: "Goodhim NOVAX ELITE, black, 0.9 kg"

votes 0

The sample is used for gluing/painting/protecting various indoor and outdoor surfaces. Suitable for application on plastic substrates. It has protective and decorative properties, prevents corrosion on metal surfaces. The tool has good adhesion to building materials, due to which it is evenly distributed and does not smudge. The dried coating is resistant to adverse weather conditions and aggressive detergents.The recommended cost for retail chains is 1211 rubles.

- Simple use;

- Easy application;

- Has elasticity;

- Dries quickly even in cold climates;

- The resulting coating is wear- and moisture-resistant, impact-resistant.

- Not detected.

1st place: "PolyPlast (0.99 kg)"

votes 0

This is a two-component, non-foaming composition designed to obtain a quick-curing monolithic polyurethane. The system is designed specifically for the manufacture of decorative elements of furniture, architectural products, advertising and souvenir products by casting in open and closed molds. It is processed manually or with the help of special mixing and dosing equipment. Finished products based on this system have high strength characteristics, lightness, perfectly reproduce natural wood in terms of tactile sensations, are resistant to temperature fluctuations, do not crack or deform over time, are easy to paint and machine (turning, drilling, milling, cut). The recommended cost for retail chains is 1450 rubles.

- Primary polymerization - 2-3 minutes;

- Rare ivory;

- Excellent fluidity.

- Work only in a well ventilated area.

Premium class

3rd place: "Kremen Cast Simple (1 kg)"

votes 0

This durable substance ideally copies the relief and texture of the form into which it is poured. Ideal for molding decor, miniatures, figurines and imitation materials. The kit consists of two components that are mixed in a certain proportion: hard plastic requires mixing 60% of component A and 40% of component B.For soft rubbery plastic, mixing 80% A and 20% B. After curing, the plastic faithfully copies the shape into which it is poured. The recommended cost for retail chains is 1460 rubles.

- Ideally combined with dyes and fillers by weight;

- Possesses low viscosity;

- The time to start curing is 2 to 3 minutes.

- Not detected.

2nd place: "ACAST 70 (set 2 kg)"

votes 0

This two-component, fast curing beige potting substance is based on polyurethane. It is perfect for making furniture decor, wood imitation, sculptural products, modeling, etc. The hardness is 70 Shore D. It does not have a strong odor. Colored in mass, easy to mix and pour. The recommended cost for retail chains is 2040 rubles.

- Easy mixing;

- Good fluidity;

- fast polymerization.

- Not detected.

1st place: "Smooth-Cast 305 (USA) 0.86 kg, cast"

votes 0

This liquid polyurethane compound is snow white, has a pot life of 7 minutes, has a very low viscosity (no need for vacuum degassing), is easy to color in bulk and surface, mixes in a ratio of 1A:1B by volume. The casting has increased strength, wear resistance, and is easy to machine. It is used to make small and medium sculptures, prototype models for various industries, decorative ornaments, etc. The material is easy and pleasant to work with, bubbles do not appear during its processing, which makes the resulting products high-quality and durable. The recommended cost for retail chains is 3448 rubles.

- High strength;

- Possibility of industrial use;

- No need for degassing.

- Too high price.

Conclusion

Liquid plastic is a concept that includes a variety of all materials produced on the basis of polymers that have a fluid consistency that turns into a solid form during chemical processes or when exposed to air at a certain temperature. Their purpose can also be different - from purely adhesive to repair and creative. Modern manufacturers produce several types of such material, differing in their functionality, composition, scope and appearance. From this it is clear that it will not be difficult to choose the right brand today, the main thing is that it meets the challenges of the future.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131656 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127696 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124523 -

The best men's sneakers in 2025

Views: 124040 -

The Best Complex Vitamins in 2025

Views: 121944 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114982 -

The best paint for gray hair - top rating 2025

Views: 113399 -

Ranking of the best wood paints for interior work in 2025

Views: 110324 -

Rating of the best spinning reels in 2025

Views: 105333 -

Ranking of the best sex dolls for men for 2025

Views: 104371 -

Ranking of the best action cameras from China in 2025

Views: 102221 -

The most effective calcium preparations for adults and children in 2025

Views: 102015