Rating of the best fireclay bricks for 2022

When laying fireplaces and stoves, the question arises, which refractory material to choose for this? Most builders prefer fireclay bricks. This material is able to withstand temperatures up to 1300 degrees and is resistant to frost. In addition, refractories do not deform, chip or crack even during long-term operation.

Today we will talk about the features, types and application of such material, consider its characteristics and methods of installation. We will also give some recommendations on the choice of material and give a rating of the best refractory fireclay bricks, compiled taking into account the opinions of customers.

Content

Material Features

Refractory products are made from chamotte clay, which includes: alumina, corundum and zircon.

Fireclay material has a yellow-red color with a porous rough surface.

- Increased resistance to fire;

- High strength;

- Durability;

- Resistance to aggressive environmental influences;

- The material does not crumble and does not deform for many years;

- The smooth and even surface allows the stoves to be assembled without finishing.

- Not good for cutting

- Need a special solution for styling;

- For laying structures, it is desirable to involve a specialist;

- High price.

Laudatory reviews from both builders and buyers who already had experience with fireclay bricks make this material indispensable when laying various refractory structures.

Production

The composition of the fireclay product includes:

- Chamotte - finely crushed fired refractory clay;

- coal coke;

- Graphite;

- Aluminium oxide;

- Coarsely ground quartz.

The components are mixed and sent to a hot oven. The presence of aluminum oxide affects the porosity of the brick, its resistance to chemicals, environmental influences and resistance to fire.

Refractories are formed in various ways, such as:

- Melting;

- slip casting;

- Hot and thermoplastic pressing;

- plastic way;

- Semi-dry method.

Types and application

Refractories differ in shape, size, weight, degree of porosity and production technology.

The main types of fireclay:

- Classic;

- wedge-shaped;

- Trapezoidal;

- Arched.

Thanks to a large selection of shapes, you can build objects of any complexity. For example, the most popular models are rectangular bricks. And with the help of wedge-shaped products, arched structures are erected.

According to its composition, it is divided into 4 groups:

- Basic. It consists of 72% fireclay clay and about 30% fireclay and coke powder. It is used for the manufacture of Bessemer steel.

- Carbon. The main material for the construction of furnaces.

- Aluminous. During production, aluminum oxide is added to the composition. Most often, stoves, fireplace inserts are placed from it.

- Quartz. Silicon oxide is added to the composition. It is distinguished by increased fire resistance, but when interacting with alkali, it is destroyed.

Dimensions of fireclay bricks

Fireclay products are divided by markings and sizes:

- ShB-5 (23 × 4 6.5 cm);

- ShB-6 (23x4x4 cm);

- ShB-8 (25 × 12.4 × 6.5 cm);

- ShA-5 (23×11.4×6.5);

- ShA-6 (23×11.4×6);

- ShA-8 (30x15x6.5).

The most popular brands are ShB-5 and ShB-8.

In order to fold an arch or vault, wedge-shaped refractories are used:

- End. Sh-22 and Sh-23 with dimensions 23x11.4x6.5 cm and 23x11.4x6.5 cm.

- Rib. Sh-44 23x11.4x6.5 cm and Sh-45 - 23x11.4x6.5 cm.

Product weight

The weight of fireclay bricks varies from 2.4 to 6 kg, which contradicts the requirements of GOST (no more than 3.7 kg) and TU (up to 4.5 kg). This is due to the fact that such models are used when laying decorated structures with refractory properties.

Porosity and Density

These properties affect the weight of the refractory and its thermal conductivity.The higher the porosity, the lighter the product and the better it can conduct heat.

Marking

During production, each model is marked. So you can understand the characteristics and degree of its purpose. By application, refractory products are divided into the following groups:

- SHA, SHAQ and SHB - basic blocks that are used when laying house stoves and fireplaces;

- ShUS and ShV - More refractory. Most often used when laying walls in convective mines;

- ShL is a lightweight material for laying stoves that can withstand heat no more than 1300 degrees.

- ShTsU - used for the construction of rotary kilns.

The most popular are such brands as: SHA, SHB, SHL. There are actually many more grades and sizes of refractories. You can find them on specialized websites. We have considered only the most basic of them.

The best manufacturers of fireclay bricks

Bricks from fireclay in Russia are produced by many factories. Unfortunately, not all companies produce quality products. In the domestic market, you can find both products of excellent quality and frank garbage at a single price. High quality models have a high density, they are yellow-red in color with even sharp edges.

Professionals prefer to purchase models manufactured by Ogneupory OJSC. They are used not only when laying the entire furnace, stove-makers also line fireboxes and chimneys with them.

How to choose?

When buying, it is strongly recommended to ask the seller for the appropriate certificates. In addition, consult an experienced craftsman who can immediately determine the quality of the product, this will help to avoid mistakes when choosing.

If there is not a single qualified stove-maker in mind, then there are several ways to help separate high-quality materials from low-grade ones.

Selection Tips:

- Take a close look outside. It should not have chips, cracks and sagging: right angles, even and sharp edges. The classic red-yellow color should be evenly applied on all sides.

- Check for sound. The product, manufactured according to all necessary standards, has a homogeneous structure without any cracks. Lightly hit the brick with a hammer and if it quickly bounces, while making a clear sound, you can safely take it. If a dull vibration is heard instead, this means that the product is of poor quality.

- Examine the split. The outer side is painted brighter than the inside. The color must be uniform. If spots are present, then this indicates an incorrect annealing technology, and when heated, the refractory will simply collapse. Please note that the material should not crumble at the split point.

Dimensions according to GOST should not deviate by more than 2 mm.

Fireclay brick laying

In order to successfully lay the refractory, it is recommended to follow a few guidelines.

When building different structures, the product is placed in a certain way. For example, when erecting walls, it is laid on a plate, if the walls are rounded, then with an edge, and on the bream and hearths - with an end face.

The composition of the mortar must be prepared from the same raw materials as the bricks. It is bred from a mixture of refractory clay and fireclay powder.

There are 4 types of laying along the width of the seam:

- no more than 1 mm;

- 2 mm;

- 3 mm;

- more than 3 mm.

For masonry, the following tools are needed:

- Building level. Better even two. One large one is 2 meters and a small one is 50 cm.

- Trowel or trowel. You will need to dilute and apply the solution.

- Cord and plumb line. With their help, you can keep the vertical in level.

- Bushhammer. Thanks to him, you can chip off unnecessary pieces of brick.

- Corner grinder with a diamond blade. It will help to cut the stone evenly and without chips.

- Roulette.

Laying should be done very carefully, periodically checking the level. Properly and competently folded oven can serve you for many years. And inattention and mistakes will lead to repeated repairs and serious financial expenses.

Rating of the best fireclay bricks

Fireclay bricks are used in laying and lining furnaces both in everyday life and in industrial enterprises. In any case, a refractory with certain properties is selected. Domestic enterprises produce many types of refractory products, among which it is easy to get lost. Below we have compiled a rating of popular models, which included ordinary classic products, wedge-shaped and radius models, as well as fireclay slabs.

Classical

Brick black standard ROKA SHA-6

Roka black chamotte bricks have a standard rectangular shape with a smooth surface. It is used for the construction of furnace structures and fireplaces. Its weight is 2.19 kg, due to which there is not a strong load on the foundation. Fire resistance - 1100 degrees. Complies with all GOST standards. Dimensions 230x114x40.

The average price is 395 rubles.

- For a long time it is able to maintain its original appearance;

- Does not fade in direct sunlight;

- Moisture resistant;

- Looks expensive and aesthetically pleasing;

- Not afraid of frost;

- Resistance to mechanical damage and environmental influences;

- Withstands high loads.

- Not detected.

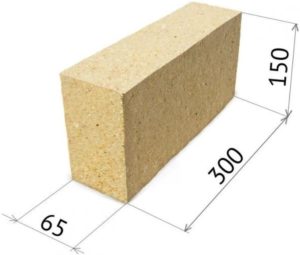

Chamotte brick SHA-9 "Borovichi"

The product is used when laying domestic and industrial stoves, fuel chambers, fireplaces.It can withstand temperatures not lower than 1690 degrees and is able to protect the structure from direct exposure to fire. The model has good thermal conductivity, so the room heats up quickly. The refractory has a granular, rough structure of sandy, yellow or light brown color. Dimensions - 300x150x65, Weight - 6 kg. Emptiness - full-bodied.

The average price is 190 rubles.

- Increased resistance to fire, withstands heating up to 1700 degrees;

- Good thermal conductivity;

- When heated, does not emit toxic substances;

- Price.

- The weight.

Bogdanovich brick from fireclay

Refractory is used for lining fireplaces, furnace structures, chimneys and chimneys. It is used to protect the masonry of furnaces from direct fire. The product is highly resistant to sudden changes in temperature, withstands heating of at least 1650 degrees. The surface of the refractory is smooth, straw-coloured. Dimensions - 230x114x65. Weight - 3.4 kg. Full bodied.

The average price is 61 rubles.

- Heat-resistant, with prolonged heating can withstand heat up to 1000 degrees;

- High strength;

- Resistant to direct fire;

- Retains heat for a long time;

- Increased resistance to environmental influences;

- Made from environmentally friendly components;

- No additional finishing required.

- Not detected.

Wedge and radius

Wedge ShA-44

The material is used for laying stoves, fireplaces, barbecues, barbecues, chimneys and pipes. Refractory is able to withstand temperatures of at least 1650 degrees. When laying, it is recommended to use solutions such as "mortar" or "chamotte clay".The structure of the refractory is smooth, sand-yellow in color. Dimensions - 230x114x65 / 55. Weight - 3.4 kg. Full bodied.

The average price is 94 rubles.

- Resistance to open fire;

- Increased strength;

- Resistant to mechanical damage;

- Withstands high loads;

- Can be used for both indoor and outdoor masonry.

- Not detected.

Wedge brick SHA-47 "Borovichi"

ShA-47 refractory is used for interior decoration of various types of furnaces, namely in those places where the material directly interacts with fire or is exposed to high temperatures. The wedge-shaped shape contributes to the lining of semicircular arches and vaults with any curvature. The material withstands both temperatures - 1400 -1800 degrees, and sharp fluctuations, so it can also be used in the construction of chimneys. The surface of the product is rough sand color. Dimensions - 250x124x65x55. Weight - 3.9. Full bodied.

The average price is 120 rubles.

- High strength;

- Durability (service life of at least 50 years);

- Withstands sudden changes in temperature;

- Resistant to harmful chemicals;

- Good thermal conductivity. Heats up the room quickly

- Frost-resistant.

- Not detected.

Refractory radius R60 SHA-8

R60 SHA-8 is used for laying out the inside of the furnace chamber, fireplace, chimney, used for lining and pillars. In addition, various furnace components are made from it: thresholds, under, vaults. Service life more than 20 years. Able to withstand temperatures up to 1650 degrees. The structure of the refractory is granular sand-yellow. Dimensions - 250x124x65. Weight - 4.9 kg. Full bodied.

The average price is 150 rubles.

- Can retain heat for 24 hours;

- Complies with all GOST standards;

- Able to withstand very high temperatures;

- Differs in the increased durability;

- Long service life.

- Not detected.

fireclay plate

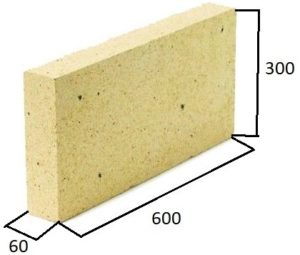

Fireclay refractory board SHA-188

The plate is designed for lining furnaces, fireplaces, fuel chambers and chimneys. Withstands temperatures up to 1650 degrees. The material protects stove elements from the harmful effects of direct fire, retains heat for a long time, which is important when heating a house or a bath. The structure of the slab is granular, light sand in color. Dimensions - 600x300x60 mm. Weight - 14 kg. Full bodied. Producer - Borovichi.

The average price is 1742 rubles.

- It conducts heat well and quickly warms up the room;

- Heating temperature - up to 1650 degrees;

- Increased strength;

- Frost-resistant.

- Price;

- The weight.

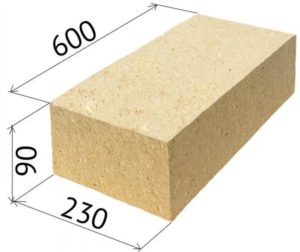

Fireclay SHA-96

The material is intended for lining home and bath stoves, fireplaces, barbecues, as well as boilers, open-hearth and glass furnaces in industrial enterprises. The refractory board is able to withstand direct exposure to open fire up to 1690 degrees. Possesses the increased resistance to chemicals, acids. Rough structure of sand-yellow color. Size - 600x230x90. Weight - 26.1. Full bodied.

The average price is 1329 rubles.

- High strength;

- It conducts heat well, quickly warming up the room;

- Resistant to high humidity;

- Withstands direct contact with fire from 1400 to 1800 degrees;

- Differs in high resistance to chemical influence of various type of fuel.

- The weight.

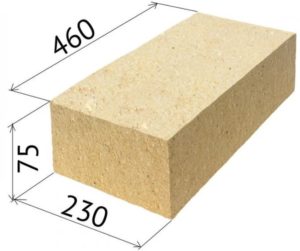

Fireclay plate SHA-94

Plate SHA-94 is characterized by high fire resistance, therefore it is in great demand in industrial and food enterprises. It is used for lining melting, blast furnace, open-hearth, coke ovens, fuel chambers and thermal units.

In everyday life, it is used as a fire-resistant surface for stoves where there is open contact with fire, fireplaces, kitchen hearths, barbecue areas. It is great for building a chimney, because. possesses the increased resistance to aggressive influence of chemicals. The plate withstands temperatures from 1350 to 1690 degrees. The plate has a rough yellow surface. Dimensions - 460x230x75. Weight - 17.2 kg.

The average price is 744 rubles.

- High fire resistance;

- Resistant to the harmful effects of chemicals;

- Withstands sudden changes in temperature;

- Possesses the increased durability;

- Manufactured according to all GOST standards;

- Temperature resistant up to 1400 degrees.

- Not detected.

How to make fireclay bricks with your own hands?

For manufacturing you need:

- The most plastic and refractory clay. Add kaolin if possible.

- To avoid the appearance of cracks during drying, you can add finely ground fireclay bricks.

- Sawdust. They can be taken at sawmills or furniture factories.

- For bonding, use wallpaper paste.

- Liquid soap will help to avoid the appearance of bacteria during molding.

Step-by-step instruction

- Using a mixer, dilute 5 kg. dry clay;

- Add 1 kg. fireclay, wallpaper glue and 50 gr. liquid soap;

- 4 kg. sawdust is slowly added to the resulting mixture, while not ceasing to interfere;

- The resulting solution must be kept for two days.

The finished mixture should be such that the mold can be adjusted to any size. In this case, it should be borne in mind that the size of the resulting product will decrease by about 15%. Next, dry it thoroughly on the board, then fire it at a temperature of 1200 for 7 hours, and then wait another 3 hours until the shutter speed has passed.

Conclusion

Chamotte clay products are materials that are unique in their functions. Durability and tolerance to high temperatures have become the main advantages for the construction of stoves, barbecues and fireplaces.

When choosing a fireclay brick, do not chase the most budgetary materials. Otherwise, you will get poor quality products. Such products are designed for laying the most important areas of refractory structures. Therefore, in no case should you take defective products.

For laying, use only the mortar, which includes the same components as in the brick. Otherwise, the structure will simply collapse after a while.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131649 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127688 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124517 -

The best men's sneakers in 2022

Views: 124031 -

The Best Complex Vitamins in 2022

Views: 121938 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114978 -

The best paint for gray hair - top rating 2022

Views: 113393 -

Ranking of the best wood paints for interior work in 2022

Views: 110318 -

Rating of the best spinning reels in 2022

Views: 105327 -

Ranking of the best sex dolls for men for 2022

Views: 104363 -

Ranking of the best action cameras from China in 2022

Views: 102214 -

The most effective calcium preparations for adults and children in 2022

Views: 102010