Ranking of the best mini small business equipment for 2022

Small business in Russia, despite its youth, has firmly established itself in many industries.

A small business is easy to establish and eventually turn into a profitable enterprise.

Content [Hide]

- 1 Advantages of mini equipment

- 2 Criteria for the right choice of mini-equipment

- 3 The best mini equipment for small businesses

- 4 Conclusion

Advantages of mini equipment

- compact dimensions allow you to place production facilities in a convenient area - an apartment, a garage, a house, a box;

- there is no need for a large staff of workers;

- low costs for technical support, preventive maintenance, power supply;

- minimum terms of creation and organization of the manufacturing process.

Equipment from China is very popular among Russian small businesses.

In the modern "World Factory" you can find:

- industrial installations;

- semi-finished products;

- general goods.

Chinese equipment is of good quality, reasonable cost and quick payback, durability.

Disadvantages of equipment from China:

- the language barrier;

- long delivery;

- territorial distance;

- customs clearance;

- lack of accompanying documents, instructions, diagrams in Russian;

- lack of service.

Criteria for the right choice of mini-equipment

To successfully run your own business, you must adhere to certain rules and take them into account in a business plan.

- performance indicator

The correct calculation of the products obtained at the output, subject to its successful implementation, provides a profitable part and payback periods. For this, the main indicator is used - the volume of finished products per unit of time taken.

- Reasonable price

At the initial stage of production, the equipment should not cost too much. Having paid back the investment in a short period of time and having gained the necessary experience, it will be possible to consider the issue of expanding and increasing capacities.

- Dimensions and noise level

By cutting costs, a novice businessman is forced to save on rent and storage space. Many entrepreneurs use the sites of garages adjacent to a private house territories.Some innovators have mini-equipment at home. With such a dislocation, it is important to know not only the dimensions of the unit, but the maximum decibels of noise that can interfere with neighbors. It is important to consider air emissions and waste volumes.

- Assembly

High-quality assembly will not only save the owner from downtime from breakdowns, but also will not require additional costs for the purchase of spare parts and parts, the work of craftsmen, adjusters.

- Service

A number of machines and machine tools require regular maintenance, so a competent approach implies the presence of this expense item in the project.

- Purchase method

The cost of equipment when buying online and at the official point of sale is not particularly different. Delivery time is key.

Errors when choosing

It is important to consider the entire production cycle step by step, paying attention to details.

- Raw materials

The supply and purchase of cheap source material affects the smooth operation and the embedded estimated part of the cost per unit of output.

- Staff

With good sales volumes, shift work is possible, which will require several specialists. Staff training and their salaries should be provided for.

- Loading

With high costs for the unit and its insufficient load, it is impossible to ensure stability and the required level of income. The sales market needs to be researched in advance and options for alternatives considered.

- Risks

Each area of the business environment has its own risks. Focusing on recent world events, one can point to blockdowns, disruption of supplies from abroad, changes in contractual terms.

The best mini equipment for small businesses

Popular models of equipment include food and manufacturing industries, waste processing, metal and wood machines, units for the manufacture of building materials and daily consumption goods in moderate volumes.

Budget options are represented by cars:

- for the automatic production of dumplings, the cost on AliExpress is from 37,000 rubles;

- PVC window welding machine, price on Alibaba from 30,000 rubles;

- for the production of school chalk, the cost is 38,000 rubles.

Smoking equipment

Izhitsa 1200-M2

votes 1

The principle of operation of the domestic production unit is based on the direction of the smoke mixture obtained from the conversion of the electronic wind to the product.

- full smoking cycle - 90 minutes;

- without product weight loss;

- preservation of juiciness;

- high efficiency;

- with exhaust into the atmosphere no more than 3% of smoke;

- connection is made to a three-phase power supply at 380 V;

- resistance of equipment manufacturing materials to aggressive environment;

- the unit is not afraid of weather and temperature changes;

- smokes any products;

- the bottom supply of a smoke excludes hit of condensate on a product;

- with reliable thermal insulation;

- the presence of pallets for excess moisture ensures easy maintenance and cleanliness;

- with measurement of smoke density and humidity, air flow velocity;

- the output is a high quality product;

- available raw materials - slats, wood chips;

- cost - from 143 1000 rubles.

- there is no refrigeration compressor.

Making a chain-link mesh

The material is in demand for fencing not only in garden and industrial areas, but also for areas where livestock and poultry are kept.

Additionally, you can use a fine-weave mesh for reinforcing layers.

Machine SAS 2.220

votes 1

The unit from a domestic manufacturer with an improved design is designed for high performance at low energy costs.

- automatic and semi-automatic adjustment;

- mesh weaving speed varies;

- with double bend;

- winding without a pipe for easy removal of the finished roll;

- easy transportation due to small dimensions;

- high reliability;

- available material.

- works from a network of 220 V.

wood splitters

Lightning 300

votes 1

A Russian-made hydraulic machine processes 5-6 m³ per hour, which is typical for a high productivity of a small enterprise.

- with internal combustion engine or electric drive;

- design reliability;

- with a splitting force of 20 tons;

- easy operation;

- splitting is available for 12, 8, 6, 4, 2 parts;

- wide range of temperatures available for operating mode -30С° ÷ +40С°;

- splits large chocks, twisted butts;

- high performance.

- equipment greatly affects the cost.

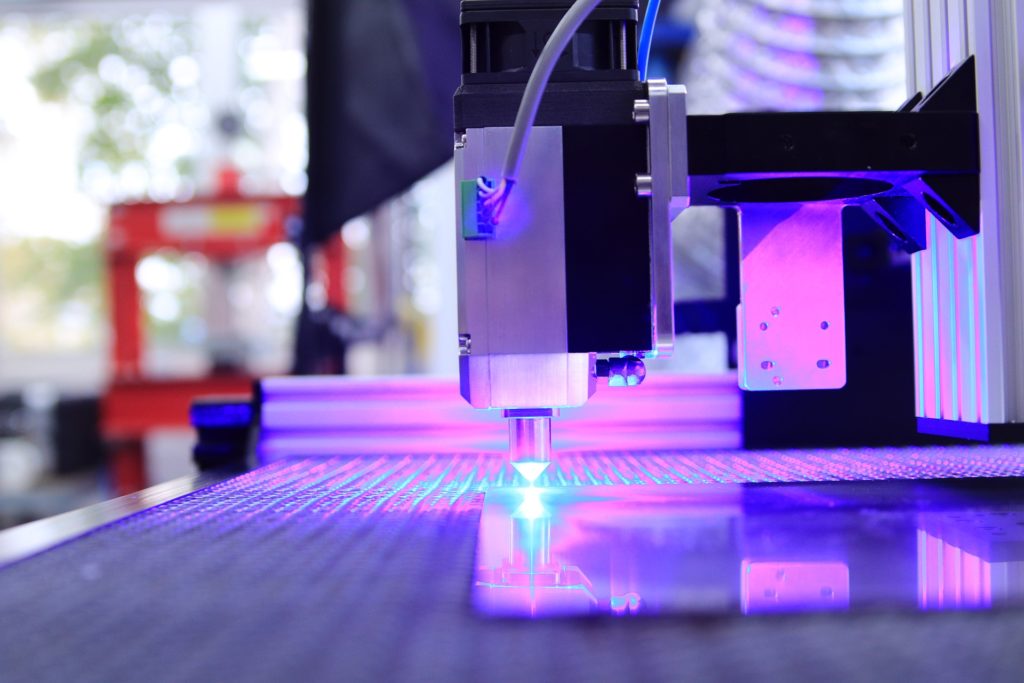

Laser machines

Engraving is carried out on sports trophies and jewelry, as well as on crystal and glass surfaces.

Cutting and engraving work can be carried out with similar equipment on the following materials:

- ceramic products;

- stone

- metal;

- glass;

- plywood;

- tree;

- rubber;

- fabrics;

- fur;

- acrylic;

- MFD;

- Chipboard;

- cardboard and paper.

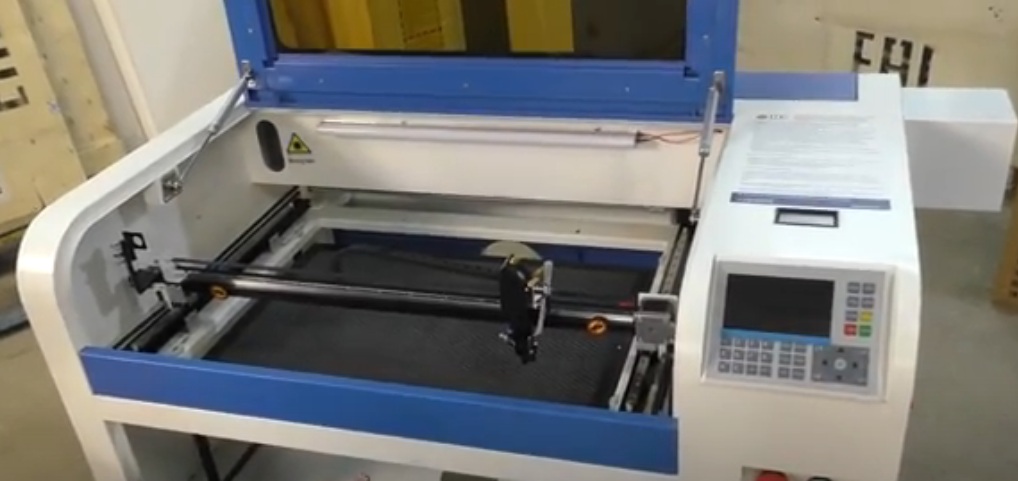

Kimian 6040

votes 1

Installation of domestic production includes:

- exhaust and water pump plus installation systems;

- laser target designator;

- laser tube;

- table on the electric drive lifting;

- honeycomb and lamella desktops;

- piston compressor with blowing of the cutting zone.

The unit has a working field of 600 * 400 mm in size and one working laser with a power of 80 watts.

- supports all graphics formats;

- runs on three versions of PC operating systems;

- support for vector editors;

- with water cooling;

- with a collapsible body;

- the minimum applied character is 1×1 mm in size;

- thickness of non-metals for cutting 10 mm.

- The laser tube lasts up to 8000 hours.

Machines for printing on T-shirts and mugs

Transferring images to a fabric and ceramic, glass surface can be done in 3 ways:

- number;

- sublimation;

- silkscreen.

All processes are different and require separate equipment.

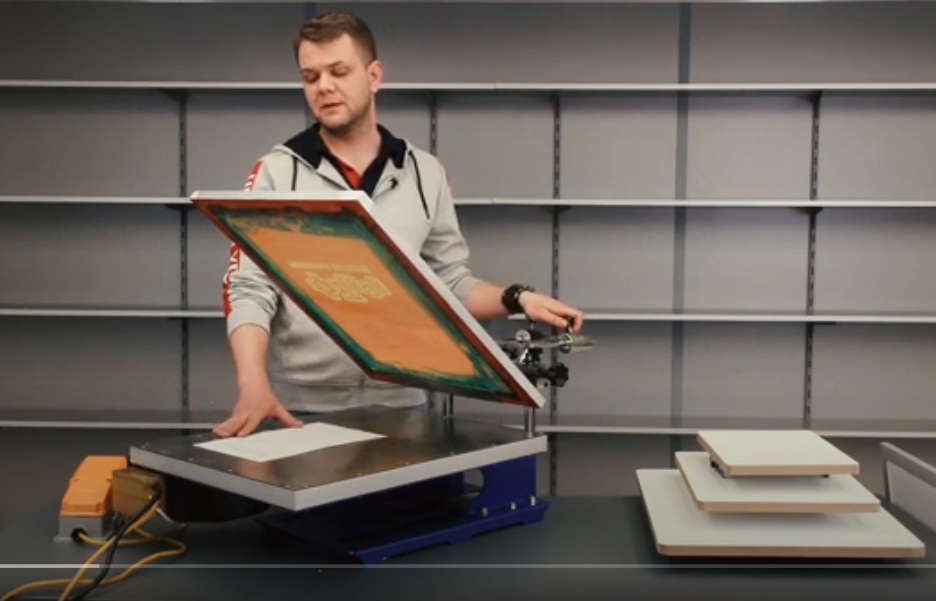

Screen printing or silkscreen

The technology of transferring images from virtual media to any surface requires special equipment.

The process requires:

- semi-automatic or manual screen printing machines;

- printing flat equipment semi-automatic;

- carousel aggregates for circular printing;

- exposure systems;

- chemical constituents.

The first stage is the competent preparation of the image on a PC with special software. Next, the sketch is transferred to the film, resulting in a photoform that will be needed to obtain a stencil. Photoforms are printed on high-resolution printers designed for photo output.

Making a stencil mold requires:

- exposure camera;

- grid;

- net tensioner;

- frame;

- a number of chemical constituents.

The light-sensitive layer of the emulsion transfers the pattern or image onto the printing plate with the help of an exposure camera.

At the final stage, the image is directly printed through a stencil and paint is applied to the mesh by pressing. For small runs, manual machines are used, for large batches, automated, semi-automated units.

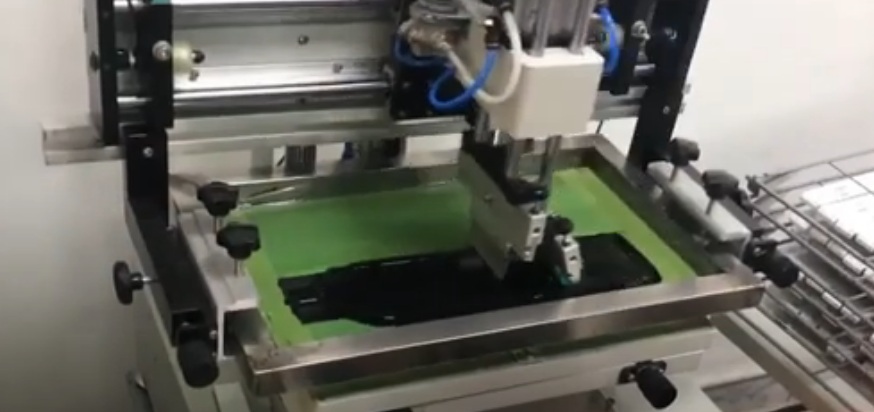

Silk screen machine

votes 1

A semi-automatic machine from a Chinese manufacturer is designed for desktop placement and has a vacuum table.

- pneumatic-cylindrical carriage travel and vertical movement of printing plates;

- vacuum table 25×40 cm;

- with a height of products up to 6 cm;

- frame lift 12.5 cm;

- prevents dripping of paint;

- convenient print format;

- light centering.

- format restriction.

CHAMELEON DUO DECK

votes 1

The manual carousel is designed for printing on textiles and has a US patent for a multi-tiered pyramid. The rotor with tables is located on the first level, the printing units have a stackable scheme and occupy the 2nd and 3rd levels. Thanks to a similar principle, 4.6 ink units can be expanded up to 10 ink units.

- light and rigid trapezoidal shape of the supporting frame is made of steel profile;

- hardened steel shaft with ø76.2 mm;

- precise fixation of the rotors in Timken bearings;

- aluminum tables are covered with a layer of rubber of high resistance to temperature and wear;

- the functionality of the fastening mechanisms ensures fast positioning and safe fixation;

- the combination of paints occurs according to a patented system on micrometric mechanisms;

- the presence of double regulation of technological gaps;

- printing forms move in 8 directions;

- with adjustable lifting and lowering force;

- the v-shaped catcher has steel centering eccentric bearings.

- a number of additional equipment may be needed, which will require investments.

sublimation printing

Full-color indirect printing on ceramic, porcelain, faience, glass, metal, plastic objects is called sublimation. A special polymer coating is first applied to the surface. Sublimation can be done on fabric synthetics that do not require coatings.

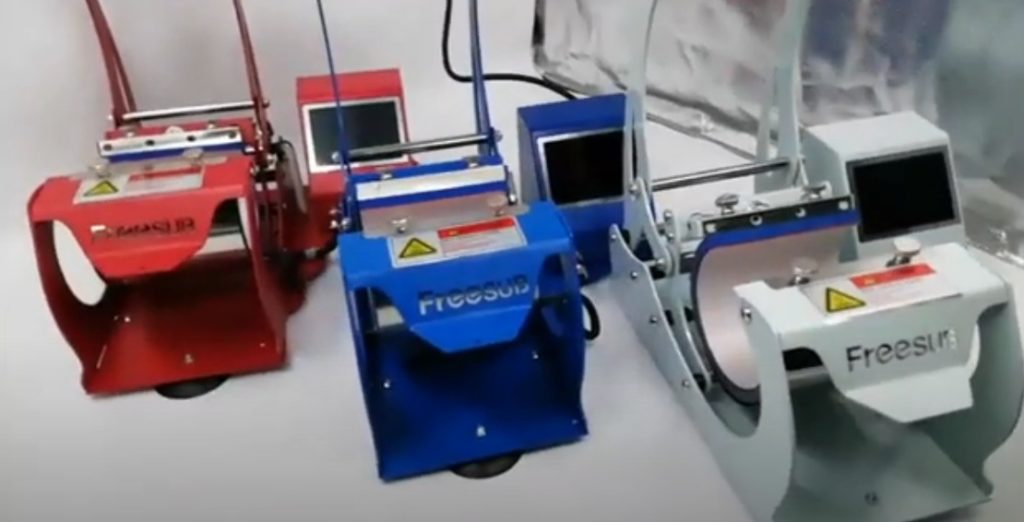

FreeSab ST-1520 3D

votes 1

Vacuum sublimation heat press is used to print images on the surface of mugs, shot glasses, bottles, jars and plates.

- multifunctionality;

- compact dimensions;

- temperature control in the range 0°С÷200°С;

- works from the mains 220 V;

- the presence of a digital timer;

- with electronic temperature controller;

- with intelligent control system;

- the heater has a high resource of 100,000 hours;

- modern design.

- not always in stock.

Vacuum forming machines

The machine produces products according to the principle of hot forming from sheet blanks with thermoplastic properties. Mannequins and packaging, signboards and auto parts, molds for casting building blocks are made using a similar method. The cost of units starts from 75,000 rubles.

VFM 1000.600.180 SF

votes 2

Automatic equipment belongs to the economy class.

The unit is used for the production of a wide range of products, such as:

- posters for advertising;

- molds for artificial stones;

- cake packaging;

- blister packs;

- decorative wall panels.

The machine is equipped with devices for unwinding the raw material and maintaining the level of blanks, air filming and a cooling fan.

- affordable price;

- a wide range of possible assortment;

- automatic process mode;

- high quality parts;

- simple handling;

- good payback;

- low technical costs.

- not suitable for the production of large products.

Machine tools with numerical control - CNC

The units work according to templates created using special computer programs. High precision and versatility distinguishes engraving, milling, drilling operations performed on CNC machines. Machine tools are used for the production of toys, including those made of wood.

TRACE MAGIC ТМ 04 0605

votes 1

The machine can be used for souvenir and promotional items, molds, furniture accessories, as well as for high precision engraving.

- processes wood, plastic, metal;

- high accuracy;

- air cooling;

- centralized lubrication system;

- the presence of a rotary control rack.

- requires training of specialists to work on the machine.

| The best models of mini-equipment | ||||||

|---|---|---|---|---|---|---|

| 1. | Smoking equipment | |||||

| Equipment | Installation weight, kg | Power consumption, maximum, kWh | Process time, hour | Cost, rubles | Volume | |

| Izhitsa 1200-M2 | 120 | 0.6 | 1.5 | 136000 | 100 kg | |

| Izhitsa GK | 270 | 9 | 4.5 | 196000 | 115 | |

| 2. | Making a chain-link mesh | |||||

| CAC 2.220 | 250 | 1.5 | - | 230000 | - | |

| 3. | wood splitters | |||||

| Lightning 300 | 250 | 380 | 1 | 100000 | 6m³ | |

| 4. | Laser machines | |||||

| Kimian 6040 | 110 | 1.8 | 600 mm/s | 136000 | - | |

| 5. | Machines for printing on fabrics and mugs | |||||

| Silk screen machine | 77 | 3.5 | 1 | 295000 | 1000 impressions | |

| FreeSab ST-1520 3D | 14.9 | 6 | 1 | 20000 | 100 | |

| CHAMELEON DUO DECK | 272÷476 | - | 1 | 750000 | 50 | |

| 6. | Vacuum forming machines | |||||

| VFM 1000.600.180 SF | 450 | 24 | 1 | 190000 | 800 | |

| 6. | CNC machines | |||||

| TRACE MAGIC ТМ 04 0605 | 400 | 60 | 1 | 200000 | 1000 |

Conclusion

Time is rapidly changing the conditions for the development of small businesses. Despite the difficult conditions, entrepreneurs continue to develop their production activities, gaining new experience and solving the tasks set. The market for mini-equipment is growing, improving quality and driving down prices. The word "deficit" is going out of use, due to the maximum satisfaction of needs in the proposed assortment of goods.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131656 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127697 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124524 -

The best men's sneakers in 2022

Views: 124041 -

The Best Complex Vitamins in 2022

Views: 121945 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114983 -

The best paint for gray hair - top rating 2022

Views: 113400 -

Ranking of the best wood paints for interior work in 2022

Views: 110325 -

Rating of the best spinning reels in 2022

Views: 105333 -

Ranking of the best sex dolls for men for 2022

Views: 104372 -

Ranking of the best action cameras from China in 2022

Views: 102221 -

The most effective calcium preparations for adults and children in 2022

Views: 102015