Rating of the best clinker bricks for 2025

Exterior decoration of the house facade always requires the use of high-quality material. Clinker brick is best suited for such work today, because it is strong enough and weakly susceptible to mechanical damage, and is also affordable for the general population at a price. In addition, it will adequately protect the walls of the house from negative atmospheric influences and at the same time give the facade an attractive appearance, speaking with all its beauty of the quality factor and reliability of the building.

Content [Hide]

- 1 Clinker brick - general information

- 2 Types of clinker bricks

- 3 Technical specifications

- 4 Styling features

- 5 Difficulties of choice

- 6 Rating of the best clinker bricks for 2025

- 6.1 Building

- 6.2 facade

- 6.2.1 4th place: "MUHR 01 Niederlausitzer Gelb Wasserstrich, 1/2 DF 240x52x52"

- 6.2.2 3rd place: "MUHR 01 EG Niederlausitzer Gelb Edelglanz rustic, NF 240x115x71"

- 6.2.3 2nd place: "Feldhaus klinker K745RF75 vascu geo venito"

- 6.2.4 1st place: ABC Klinkergruppe Wittenburg-Kohlebrand mit Sinterschmolz wasserstrich, art. 1875"

- 7 Conclusion

Clinker brick - general information

State Standard No. 530 of 2012 describes this product as "very durable and with low moisture absorption, which together gives it excellent strength characteristics and decorative qualities." This material is allowed to be used in aggressive external environments when finishing and cladding the external walls of buildings and structures.

The consumable itself has a geometrically correct shape of a parallelepiped with dimensions specified by GOST. Its outer surface is slightly rough, the color can vary from dark brown to light yellow. The modern assortment range of such a product from almost any manufacturer exceeds a good hundred samples with different shades, which has become possible to achieve thanks to a simple tinting technology during manufacture, by introducing the necessary additives into the raw materials.

Differences between clinker brick and traditional ceramic brick

Outwardly, their differences for a non-professional will hardly be noticeable.Moreover, the type under consideration is quite easy to confuse with engobed samples, which have a thin ceramic layer on the surface. However, there are differences between these two species and they are quite significant. Such nuances lie in special technical parameters that have a powerful impact on operational properties. As a result, clinker samples easily surpass ceramic ones in the following indicators:

- Water absorption - it lies in the fact that the less the product is able to absorb moisture, the longer its service life. The same property indicates the possibility of using such a building material in the northern cold latitudes. Accordingly, ceramic samples take 9-12% moisture, and for clinker it is much less and amounts to 2-6%.

- Frost resistance - clinker can withstand almost absolute zero Celsius, while ceramics can withstand temperatures up to 60 degrees.

- Strength - for clinker it does not happen below M250, and models with M1000 are already being produced today! The limit for ceramics ends at M200.

- Density - for ceramic models, it does not exceed 1100 kg / m3, and for clinker models it only starts from 1450 kg / m3.

IMPORTANT! In fairness, it should be noted that ceramic samples are much cheaper than their clinker counterparts. The “expansion” in prices between them can be from 3 to 10 times!

Types of clinker bricks

Professional builders traditionally classify the type of consumables under consideration according to their intended purpose.

- For construction.

Such standard and single samples are used for laying out supporting structures, which are supposed to be subjected to increased loads.These include the following power parts: pillars, plinths, foundations, stair steps and columns. Such structures are simply required to have increased mechanical strength and be extremely resistant to external influences, while not losing in terms of durability.

- For facing.

This type is intended specifically for facades and is distinguished by excellent decorative qualities and a variety of possible shades. Its outer surface is glazed in a special way, which allows you to get the most stable protection against negative weather manifestations and exposure to ultraviolet rays. Their shape may not necessarily be only rectangular - options with irregular geometry are quite acceptable, which will give the facade additional originality.

- For laying out sidewalks.

It is customary to pave garden, pedestrian and bridge paths with such bricks, as well as to decorate the walkway in park alleys with it. This type is characterized by a high level of abrasion, it can successfully withstand various mechanical stresses. Thus, the resulting element of landscape design will retain its performance properties and good appearance for a long time.

Technical specifications

Forms

The consumables under consideration are divided into two main types according to their form:

- Figured - are products with a variety of geometries and are used for the design and layout of figured balconies, columns, cornices and other original facade elements. Market share - no more than 15%, due to the high price due to the complexity of the production process;

- Standard - they look like a geometrically regular parallelepiped. They are the most common material and are used, as a rule, for the construction of load-bearing walls.Market share - at least 85%.

Dimensions

Clinker-brick can be produced in the following modification dimensions:

- One and a half - 120 * 25 * 88 millimeters (grade 1.4 NF);

- Double - 120 * 250 * 140 millimeters (grade 2.1 NF);

- Half - 60 * 250 * 65 millimeters (0.5 NF brand);

- Euro standard - 85 * 250 * 65 millimeters (grade 0.7 NF);

- Modular single - 138 * 288 * 65 millimeters (grade 1.3 NF).

IMPORTANT! On the market, you can also find samples of non-traditional sizes, for example, 90 * 240 * 52 or 115 * 240 * 174 mm. Such models are produced by manufacturers more often by special order, and sometimes their batch may not be fully demanded by the customer. And then they get on sale for a wide range of consumers.

It should be noted that rather high production standards are applied for clinker products, which are enshrined in the State Standard No. 32311 of 2012. So, the deviation in length for them is not allowed more than 4 millimeters, in thickness - no more than 2 millimeters, and in width - no more than 3 millimeters. In addition, the correct geometry of the parallelepiped must be observed, which makes it impossible for the faces to diverge more than 3 millimeters.

If we talk about curly models, then most often they have the shape of a trapezoid, a triangle or even a wedge and may have rounded edges, have various protrusions. From this it is clear that in most cases it is impossible for them to comply with certain dimensions due to the peculiarities of their purpose.

Filling

Like traditional bricks, clinker bricks can be produced both hollow and completely monolithic. Its scope will depend on this design feature:

- Full-bodied - the product is a completely monolithic structure. It is distinguished by a large mass, which adds strength to it, and this, in turn, makes it the optimal material for the construction of load-bearing walls of various structures, furnaces and chimneys for them.

- Hollow - this is a lightweight version that has some recesses in its design (holes and recesses can be round or rectangular). According to standards, voids can be up to 40% of the total brick structure. These voids are needed to facilitate this construction consumable, which will reduce the load on the foundation. At the same time, one should not assume that the strength qualities of such products are much lower than those of monolithic ones.

IMPORTANT! The only drawback of hollow models is that they are not recommended for laying load-bearing walls. But for facing work, such material is optimal.

Texture

Classic clinker brick has a smooth matte surface, it is smooth and pleasant to the touch. However, today manufacturers have begun to produce products with different types of surface in order to satisfy a wide variety of customer needs. On modern equipment, it is easy to give such a consumable the desired degree of relief. Such technologies include the following:

- The application is standard - it provides for the usual way of forming the desired texture, in which a certain pattern is applied to the surface of the finished product that has been fired. Then, the product is again sent to the oven, where the applied image is fixed under the influence of high temperature, while obtaining the necessary relief.It should be noted that such double firing does not impair the strength qualities of the consumable.

- Engobing - this technology involves applying a thin layer of ceramic, called engobe, to a dried / fired object. It is a combination of metal oxides with clay, which, bonding to the surface of a brick under the influence of high temperatures, give it a special shade. The final overall color of the object also depends on the engobe. Using the same technology, the product is given an artificially aged look.

- Shotcrete is another popular method of surface texturing. Unlike previous technologies, in this one, before the start of primary firing, mineral chips are already applied to the surface. As a result, a product with melted crumbs on its outer sides is obtained, which gives the original texture and attractive appearance.

- Glazing - with the help of this technology, the surface is given a glossy and sliding quality, making it very pleasant to the touch. The process itself strongly resembles engobing, but instead of ceramics, a special building glaze is used here.

IMPORTANT! It should be understood that glazing is not just a way of decorative design. By applying the glaze, the water absorption rate will be significantly reduced and the possibility of a simple and easy cleaning of the surface will increase.

Styling features

The main nuance that must be carefully monitored when laying clinker bricks is strict adherence to the thickness of the seams, which should not exceed 10 millimeters.If it is required to make an air void in the wall for ventilation, which is important for internal wooden structures, then it will be necessary to leave an unfilled vertical seam for every 4 rows, which will later be covered with thermal insulation material. During laying, it is also necessary to ensure that the bonding solution does not get into the voids between the cladding and the wall. For this purpose, it is only necessary to press it more tightly with a trowel against the clinker from the side of the empty gap.

Due to the fact that clinker consumables have low water absorption rates, it is recommended to wet each brick in water for better adhesion. Each new layer should lie at the level of the mooring cord, with which the average height for the row was previously set. The standard dressing of the seams must be taken as a quarter of the length of the brick. Equip expansion joints should be at the closest distance to the corners of the future structure and the distance for them should vary within 10-13 millimeters.

It is recommended to lay no more than 5-6 rows in one sitting. To level the overall masonry, the base of each element must not be knocked out, but filed. Excess solution must be removed immediately, otherwise such an operation will require the use of a stiff brush or a pointed spatula and a lot of effort will have to be made.

For the most effective adhesion of the cladding layer to the supporting structure, it will be necessary to use anchors made of alloy steel, which are implanted into the base of the walls at a certain angle to the facade. This is necessary to prevent moisture from entering the insulation when condensation forms over the anchor.

Difficulties of choice

Before buying, you must obtain complete information about the selected product. It is for clinker bricks that you should pay attention to the following characteristics:

- Filling - on whether the material is selected monolithic or with voids, its soundproofing and heat-insulating properties will depend. More voids - sound insulation will be worse. Complete solidity means a good level of heat retention, so these models are perfect for laying out stoves and chimneys for them.

- Strength grade - reflects the properties of the goods in compression. For the construction of low-rise structures (or for facade decoration), values starting from M250 are suitable. For large buildings, it is better to choose samples with a tensile strength starting from M500.

- Frost resistance - it is determined in the number of winter-summer cycles that a brick is able to transfer without collapsing. Varies from F100 (meaning 100 years of service) and up.

- Shape and dimensions - in Russia, the standard shape of a parallelepiped with dimensions of 240 * 115 * 71 millimeters is more often used. In general, the shape and dimensions must be selected based on the upcoming construction task.

- Forming type - it can be automatic or manual. The first assumes the severity of forms, and the second, as a rule, has a figured irregular geometry. It is used for decorative and finishing facade works.

Rating of the best clinker bricks for 2025

Building

4th place: "Construction red "London" birch bark, LSR"

votes 0

This model is used to implement the most daring design decisions in the construction of buildings. Also, it can be used for laying out the walls of rooms that need special sound insulation. At the same time, they are allowed to paving sidewalks, garden paths.It is characterized by increased strength (M300) and in its manufacture refractory grades of clay are used, which are fired at a temperature of 1300 degrees Celsius. The recommended cost for retail chains is 27.37 rubles.

- The use of refractory grades of clay;

- Excellent level of sound insulation;

- Good decorative quality.

- Not detected.

3rd place: Pavement 0.51NF, red Flash Nottingham, LSR

votes 0

This full-bodied specimen is oriented towards finishing garden paths in landscaping, but can also be used for laying out stoves. It has a wide shape and the correct geometry. The weight of each brick is only 2.4 kilograms. The percentage of water intake does not exceed 2.5%. The final building will easily withstand 300 winter-summer cycles. The recommended cost for retail chains is 35 rubles.

- Very smooth texture;

- Dual purpose item;

- Guaranteed 300 years of service.

- Not detected.

2nd place: "Building 0.71NF M-300, red flash "Nottingham" birch bark, LSR"

votes 0

This sample has a not quite standard rough texture and is intended for use in unusual types of masonry. It is characterized by sufficient frost resistance - it can withstand up to 100 freezing cycles. It does not form efflorescence on the surface of the masonry, which is achieved due to the high temperatures during production, where the salts and sulfates present in the clay are completely sintered. It has low thermal conductivity (6%), and its hollowness provides a reduced load on the foundation. The recommended cost for retail chains is 37 rubles.

- Special texture;

- Good heat retention;

- Does not form efflorescence.

- Not detected.

1st place: "Universal "Wittmunder Klinker Sortierung 219 DF Bunt"

votes 0

This brick is universal - it can be used both for construction and for facade cladding. It is made from shale clay of natural origin. The entire composition is completely natural (produced in Germany). It is used for façade cladding/construction of public buildings, country houses, cottages, as well as for interior design (cladding of walls, partitions, fireplaces, etc.). Possesses the increased density, wear resistance and durability. The recommended cost for retail chains is 41 rubles.

- Color fastness;

- Long service life;

- Manual sorting.

- Not detected.

facade

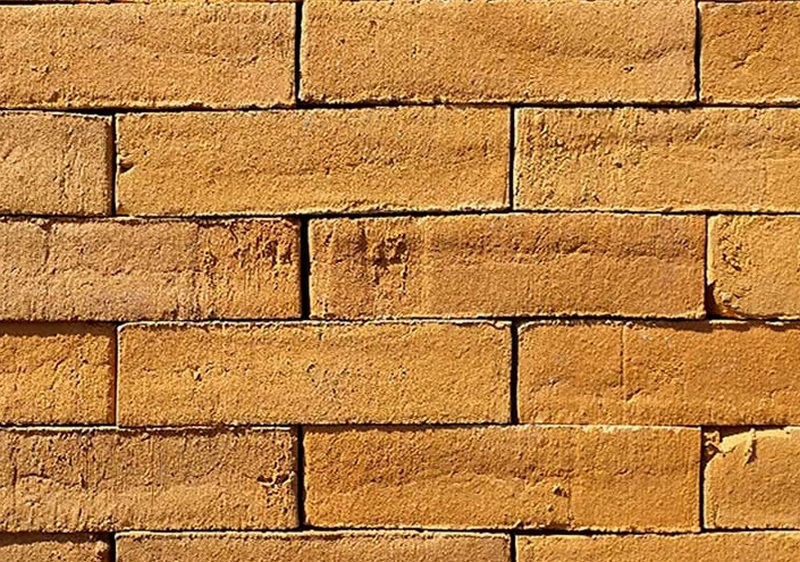

4th place: "MUHR 01 Niederlausitzer Gelb Wasserstrich, 1/2 DF 240x52x52"

votes 0

This product has a colorful original color and is perfect for finishing the front parts of low-rise buildings. The innovative material for making bricks will reliably protect external walls from negative weather manifestations and will be able to last for a long time (at least 100 winter-summer cycles). Laying the material is quite simple, when using a high-quality mortar, the maximum level of adhesion with the supporting base will be achieved. The recommended cost for retail chains is 80 rubles.

- Innovative manufacturing material;

- Original color shade;

- Sufficient service life.

- Not detected.

3rd place: "MUHR 01 EG Niederlausitzer Gelb Edelglanz rustic, NF 240x115x71"

votes 0

Such a sample is perfect for finishing a residential building with any number of storeys, since it is able to lie down perfectly in high rows. Its rough surface will not allow dirt to accumulate in large volumes on the wall and the adhering layers will fall off themselves. Does not require special cleaning procedures. Excellent resistance to ultraviolet radiation. It has a special frost resistance and will withstand about 300 winter-summer cycles. The recommended cost for retail chains is 110 rubles.

- Quality German clay;

- Unpretentious care;

- Frost resistance for 300 cycles.

- Not detected.

2nd place: "Feldhaus klinker K745RF75 vascu geo venito"

votes 0

This hollow brick has a variegated dark brown color and is hand molded. It has a standard rectangular shape and is made of high quality German clay. During production, it was double-fired, which indicates its increased strength. Easily lends itself to additional external finishing with any materials, ranging from decorative to protective. Provides the base base with a reliable cover from negative atmospheric phenomena. The recommended cost for retail chains is 158 rubles.

- Orientation to the decoration of cottages and country houses ("feldhouse");

- Sufficient protective qualities by default;

- Designer color.

- Somewhat overpriced.

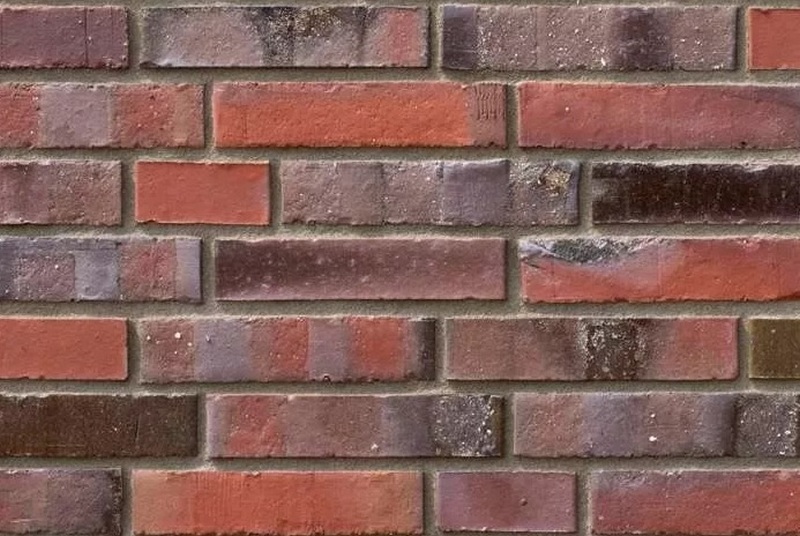

1st place: ABC Klinkergruppe Wittenburg-Kohlebrand mit Sinterschmolz wasserstrich, art. 1875"

votes 0

Such glazed brick is an excellent finishing material for decorating the external walls of various buildings. It has a classic red-brown brick shade. Easily laid out on the surface, can work with solutions of varying degrees of viscosity. It has the lowest degree of water absorption. The recommended cost for retail chains is 185 rubles.

- Maximum low water absorption;

- Classic color;

- Ability to work with various adhesive solutions.

- Somewhat overpriced.

Conclusion

Clinker brick is one of the most durable and reliable materials. Due to its unique physical and chemical properties, it is far superior to traditional ceramic bricks. High technical, mechanical, operational and aesthetic performance make this material an ideal solution for the construction of a presentable and durable building.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131653 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127693 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124520 -

The best men's sneakers in 2025

Views: 124035 -

The Best Complex Vitamins in 2025

Views: 121941 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114981 -

The best paint for gray hair - top rating 2025

Views: 113397 -

Ranking of the best wood paints for interior work in 2025

Views: 110320 -

Rating of the best spinning reels in 2025

Views: 105331 -

Ranking of the best sex dolls for men for 2025

Views: 104369 -

Ranking of the best action cameras from China in 2025

Views: 102217 -

The most effective calcium preparations for adults and children in 2025

Views: 102012