Rating of the best lifting equipment for 2022

It is no secret that any construction activity involves lifting / moving weights. This is also true in relation not only to assembly / disassembly work, but also to the functioning of warehouses, to various production operations, and in general to the performance of many other tasks. Naturally, it is not always possible to get by with the muscular strength of a person alone, because he is clearly unable to work with massive and large-sized objects. To invest in human labor, special devices and mechanisms have been developed that simplify the process of moving goods.

Due to the fact that the area of use of lifting equipment is quite extensive, many devices have been developed that differ from each other in their design parameters and features.To solve a specific problem related to the movement of a certain type of objects, it is necessary to select a special mechanism that is most suitable for this.

Content [Hide]

Modern types of lifting equipment, their characteristics, advantages and disadvantages

Tali

The main purpose of this suspension equipment is the lifting and transportation of goods. There are two types of hoists: electrical and mechanical. The latter work by means of manual control and are divided into lever and gear. Gear devices are hung on a hook to a support and the operator controls them from the ground, being in close proximity to the object being moved.Lever samples are also suspended on a support, but the object is lifted by a lever mounted on the hoist body, i.e. the operator must be directly at the machine and near the support.

For electric models, lifting is carried out due to the operation of the electric motor. Usually, electric hoists are mobile (in rare cases, their stationary installation is used, because then it does not allow using the entire production capacity of the device). Electric hoists are mounted on an overhead track made of rails, along which goods are transported not only horizontally, but also vertically.

The main advantages of mechanical hoists include:

- Light weight;

- autonomy;

- Wide scope of use;

- Small cost;

- Ease of maintenance.

The main advantages of electric hoists are:

- Greater speed of work;

- Ability to move in the direction of the laid rails;

- Increased lifting height (up to 36 meters);

- The presence of a remote control.

The disadvantages of mechanical models can be identified:

- Low working speed;

- The need to purchase spare parts only from the manufacturer (universal parts practically do not exist);

- Lifting height limited.

Electric hoists are also not without certain disadvantages:

- The need for power supply from the mains;

- Massiveness and considerable weight;

- High price;

- The need to monitor the likelihood of overheating;

- Need only professional service.

Mounting and traction mechanisms

They are designed to move large objects on horizontal and inclined planes. These devices are mechanical with exclusively manual control.To transport goods in a horizontal direction, the mechanism is fixed on a vertically mounted support and the load is moved by means of a handle on the body. The carrying capacity of such a device ranges from 0.8 to 5.4 tons, with the entire rope length of 20 meters.

The undoubted advantages of the mounting-traction mechanism include:

- autonomy;

- Wide range of uses;

- Small cost;

- Simple maintenance.

Its negative qualities can be called:

- The need to apply sufficient muscular effort on the part of the operator;

- Low speed.

Winches

These devices are used for vertical lifting of loads. Structurally, they are divided into mechanical and electrical. The former work from the muscular efforts of the operator, their carrying capacity can be from 0.25 to 3 tons, with a working rope length of 10 to 60 meters.

IMPORTANT! By installing additional blocks in the overall working scheme of the mechanism, the load capacity can be increased.

In electric samples, objects are lifted by the operation of an electric motor. Their carrying capacity starts from 200 kilograms, with a maximum working rope length of up to 250 meters.

The advantages of mechanical models include:

- Small weight and overall autonomy;

- Ability to use for various tasks;

- Easy maintenance;

- Adequate cost.

The advantages of electrical samples are:

- fast work;

- Increased rope length;

- Ability to integrate with cranes and hoists.

The disadvantages of mechanical winches are:

- Low working speed;

- The presence of restrictions on carrying capacity;

- Small capacity rope drum.

Electric models have their drawbacks:

- The need for power supply from the mains;

- Fair weight of the device;

- Overpriced;

- The need to monitor overheating conditions;

- Special requirements for the qualification of service personnel.

Jacks

These devices are designed exclusively for lifting objects. Their peculiarity lies in the fact that they are always located under the bottom of the load being lifted, and not on top. Jacking devices are divided into bottle (they are also hydraulic) and rack and pinion. In bottle jacks, the object is lifted by extending the piston under oil pressure, which is pumped either by mechanical pumping of a special handle by the operator (for small masses), or through the operation of an electric oil module (for large masses). These devices are capable of lifting objects ranging from 1 to 200 tons. They are used, for the most part, in the field of construction, mechanical engineering, or as part of a hydraulic pipe bender.

Rack models are a rack with teeth, along which the support heel moves with the help of a gear, which is set in motion by rotation of the handle by the operator. The carrying capacity of these samples varies from 3 to 25 tons. The scope of use is very wide - installation / dismantling in construction, car service work, railway construction.

The positive qualities of bottle samples include:

- The small size of the device;

- Light weight;

- Greater reliability;

- Adequate price tag;

- Simple service.

For rack models, the advantages will be:

- Possibility of picking up cargo at low height;

- Extended rod stroke;

- Ease of maintenance;

- Unpretentiousness in storage.

The disadvantages of bottle jacks include:

- Mandatory storage only in an upright position;

- Small piston stroke;

- The need for a significant height to pick up the load.

For rack jacks, the minuses will be:

- A fair amount;

- Overpriced;

- Significant dimensions.

Cranes

Crane equipment is boom, hydraulic and so-called "window cranes". Hydraulic cranes are commonly referred to as "geese". The principle of their operation is that the boom, equipped with a hook, is raised / lowered by means of a hydraulic cylinder driven by the handle. Most often, such models are used at car service stations for the purpose of mounting / dismantling the engine from the engine compartment of the car.

Jib cranes consist of a support base with a wheeled chassis, a swivel boom, a winch equipped with a rope and a hook. The boom provides reach and the ability to move the load some distance from the main base of the crane. This condition is obligatory for unloading / loading on-board vehicles, lifting objects along the facade of various structures, if the crane is installed on the roof.

IMPORTANT! If you lengthen the reach of the boom, then the carrying capacity of the mechanism will decrease.

In order to facilitate the transportation of the crane itself, the boom has a collapsible design and can be decomposed into two separate parts. Thus, the jib crane can be transported by truck.

"Crane in the window" is designed to lift cargo to a given floor along the facade of the building. It is a small-sized design capable of working with objects of small mass. Can be used in construction and manufacturing.

The undoubted advantages of hydraulic models include:

- Small dimensions and overall compactness;

- Affordable cost;

- Increased reliability;

- Simple service.

The boom models are characterized by the following advantages:

- They have a large lifting height;

- They have a significant range in terms of carrying capacity;

- They have adjustable reach;

- Possibility of transportation by trucks;

- Unpretentious in service.

The faucet-to-window models have the following advantages:

- Small weight and compactness;

- Adequate price;

- Possibility of indoor use.

The disadvantages of the considered models of cranes include:

- Hydraulic - narrow specialization;

- Boom - have a lot of weight and low mobility;

- "Cranes in the window" - have a low carrying capacity and their installation is possible only on floors or on the roof.

Lifts

These devices are designed to lift people and goods. It is from the objects being lifted that the distinction among these devices will depend. Lifts can be mast and they are used to lift loads, but platforms are used to lift people (they are correctly called facade lifts or cradles). It is worth noting that the principle of operation for both devices is almost 90% similar.

Mast models are used in production, in construction, when performing repair work. The principle of their operation is to move the bearing base vertically along the support mast. The mast, in turn, is fixed on the facade of the building, its wall or a special support on the industrial site, which provides the entire structure with the appropriate degree of rigidity. Lifting height can be from 3 to 100 meters, with a total load capacity of 500 to 2000 kilograms.

IMPORTANT! Mast models can also be converted to transport people, but this will require their technical modification plus obtaining permits from the competent supervisory authorities.

Working platforms (cradles) are used in the decoration / repair of building facades. Consoles are mounted on the roof of the building and cables are lowered along which the cradle moves vertically. The working cradle is mainly designed to lift the working personnel, therefore it has protective railings. Based on work tasks, the platform can be 2, 4 or 6 meters long. The control panel is located directly in the cradle itself, which adds to the efficiency of control. The load capacity can be up to 630 kilograms, with a lifting height of up to 100 meters.

The main positive qualities of lifts can be called:

- Increased reliability;

- Possibility of work and at essential wind;

- Sufficient lifting height;

- General modular-collapsible system.

Platforms will benefit from:

- Small cost;

- Ease of assembly;

- Modular design;

- Simple control.

There are practically no cons of these models.

Regulatory and technical requirements for lifting equipment

From the regulatory and technical legislation in force in Russia, the production and operation of the devices in question is regulated by:

- Guiding Documents No. 36-62 of 2000, which describes the technical requirements;

- Industry Standard No. 36-62 of 1981, which governs operating conditions.

On the technical side, the following mandatory requirements are imposed on lifting devices:

- Materials - when producing the devices in question, it is necessary to use only those materials whose quality is confirmed by a special certificate.On request, the manufacturer can order special additional tests in order to check the quality of raw materials.

- Welding of structures - during this stage of production, all materials must be brought to a cleaned state. When welding, the steps of the technological process should be strictly followed. Deviation from the standards in the drawing documentation is unacceptable, therefore, control during welding is carried out permanently. All operations are performed only by specialists with the appropriate approval.

- Mechanical assembly - upon completion of the assembly, the object is checked for the presence of nicks, scuffs and other damage, which are unacceptable, because they will certainly lead to a decrease in the strength of the product. All structural forms must fully comply with the approved drawings. If a threaded element is present in the design, then it must be free from any distortion and damage.

- Electrical equipment - its installation must be carried out in such a way that moving parts cannot harm electronic systems. Also, the comfort factor for the operator when using electrical equipment should be taken into account.

- Protective coating - any mechanism must have a protective coating in order to prevent the formation of corrosive traces (the exception applies to those elements that operate in an oily environment).

- Testing - any lifting equipment, prior to delivery to the end user, must be tested for reliability.

- Accompanying documentation and marking - each lifting mechanism must be supplied with appropriate documentary information (certificates and accompanying documents).Also, this technique must be appropriately labeled.

Difficulties of choice

Lifting equipment should be properly selected, paying attention to the following main criteria:

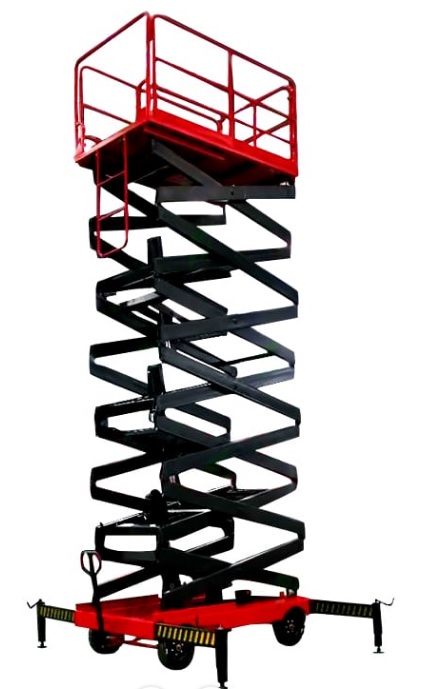

- Lifting mechanism - the scissor version is preferred, it is more comfortable to work with and more stable, and the telescopic version is considered easy to operate and quite inexpensive;

- The method of movement of equipment - it can be stationary and mobile. This quality is considered depending on the tasks.

- Carrying capacity - it is better to select this indicator according to the maximum level, if the issue of the financial side is not very acute.

- The minimum lifting height - it is desirable to count it from the 16-meter level.

- Nutrition - its choice should depend on the availability of an appropriate source at the work site.

- Security systems - it is desirable that the device has stoppers, light / sound warning signals, retractable supports, emergency valves, the possibility of an urgent stop.

Rating of the best lifting equipment for 2022

Tali

3rd place: "Manual gear hoist TOR TRSH (C) 1TX12M 1011121"

votes 0

This manually operated chain hoist does not need to be connected to a power source, which makes it possible to use it completely autonomously. The load capacity of the unit is 1000 kilograms, therefore it is suitable for use in both household and construction and industrial sectors. The sample is equipped with a locking system, which makes it possible to stop the load during descent / ascent during emergency situations. The recommended cost for retail chains is 8960 rubles.

- Adequate cost;

- chain length;

- Sufficient load capacity.

- Not detected.

2nd place: "Manual gear hoist TOR TRSH (C) 3TX3M 101331"

votes 0

This hand hoist is made of very durable materials, which allows you to lift objects with a total weight of up to 3000 kilograms. The device is powered by the muscular strength of the operator, the use of third-party power sources is not required. There is a special locking mechanism with which you can quickly and easily fix the load at the desired height. The recommended cost for retail chains is 9300 rubles.

- Unpretentiousness at work;

- Decent traction;

- The presence of anti-corrosion protection.

- Not detected.

1st place: "Electric hoist TOR PA-500/1000 20/10 m 1101001"

votes 0

A similar electric hoist sample is supplied without a trolley, however, it is a convenient tool for lifting objects weighing up to 1000 kilograms. A special ballast guarantees a full vertical position of the hook for quick pickup of the transported load. The motor has a power of 1600 W, which allows you to lift the load at a speed of up to 10 meters per minute. As the weight being transported increases, the lifting speed will decrease. The recommended cost for retail chains is 19,800 rubles.

- Smooth running;

- Sufficient drum size;

- Excellent build.

- Outlet block missing.

Winches

3rd place: Traction winch JET JG-150A 1.5 t 286515

votes 0

This winch is an easy-to-operate device capable of both vertical and horizontal transportation of goods.The body of the device is made of high-strength aluminum, which effectively protects the working mechanism from damage. It has small dimensions, has a small weight, which guarantees ease of movement and storage. This device is used during installation, repair and construction work. The recommended cost for retail chains is 20,700 rubles.

- Requires minimum effort;

- There is a security system;

- Comfortable work.

- The kit does not include a cable.

2nd place: Electric portable winch TOR SQ-03 250 kg 8.0 m 220 V 1140255

votes 0

This electric version of the winch is used for moving/lifting objects weighing up to 250 kilograms. The handle at the grip point has a special coating, which makes it easy to carry. The hook suspension is equipped with a special carabiner, which makes it possible to attach the load with particular reliability. The rope winding speed is 0.08 meters per second. The steel cable is particularly reliable, which eliminates the need for additional extensions. The recommended cost for retail chains is 20,900 rubles.

- Lifting speed adjustment;

- Steel rope;

- High speed rope winding.

- The remote control is not included in the kit, the control is carried out by the keys on the case.

1st place: "Electric winch T-Max ATW PRO 4500 W0370"

votes 0

This electric winch has a specific application purpose and is designed to pull heavy-duty vehicles (ATVs, swamps, all-terrain vehicles) from bogs and swamps.This model will be an excellent choice, because it has all the properties of durability and reliability. The device is characterized by easy operation, does not require very complex maintenance. There is a possibility of work from the battery – 650ССА. The recommended cost for retail chains is 21,500 rubles.

- Reducer with an electric motor of asynchronous type;

- Sealed control box;

- Low power consumption.

- Not detected.

Lifts

3rd place: "Scissor lift 6 m, 380 B PROLIFT PF 0805AC"

votes 0

This scissor lift is capable of lifting 2 people up to a height of 6 meters along with a working tool (and other accessories). The total lifting weight is 500 kilograms. The lifting mechanism is based on a hydraulic system. The model is of high build quality, and all elements are made of reinforced metal. The control is carried out by means of a remote control, which is very convenient when working at height. The recommended cost for retail chains is 363,000 rubles.

- Silent operation of the hydraulic system;

- Sufficient load capacity;

- Limit switches for safe work;

- Base of working platform PROLIFT PF 0805AC made of corrugated steel sheet;

- Solid wheels with bearings;

- Great ground clearance.

- High price.

2nd place: Telescopic lift 220 V PROLIFT GTWY8-200 AC

votes 0

This telescopic lift can accommodate up to two people and lift them to a height of up to 8 meters along with working accessories.The work is carried out by means of a hydraulic drive, and the two-mast design made it possible to increase the load capacity to 700 kilograms. There is an emergency descent and shutdown function, which provides for safe operation. The wheels have a black molded rubber tread, and they allow you to withstand heavy loads while ensuring safe movement of the platform. The recommended cost for retail chains is 383,000 rubles.

- Convenient control panel PROLIFT GTWY8-200 AC;

- High railings for added security;

- Lightweight aluminum mast;

- Limit switches for safe operation;

- Retractable supports protect against capsizing;

- The base of the working platform made of corrugated steel sheet provides strength and long service life.

- Overcharge.

1st place: "Self-propelled scissor lift GROST Tower 0.5-7 211420"

votes 0

This self-propelled scissor lift will be very convenient in the implementation of repair, finishing and construction work. The lifting system is very simple and based on hydraulics. The design is reliable, the presence of a large platform, and allows you to work at height without any problems. It is possible to move independently when folded, which qualitatively simplifies work on large areas. It has strong sides and outriggers for stability. The recommended cost for retail chains is 860,000 rubles.

- Easy to move when folded;

- Long service life;

- Powerful engine;

- Reliable lifting system.

- Extremely high price.

Instead of an epilogue

The analysis of the market of the devices under consideration found that the price of devices, even from the budget segment, is extremely expensive. Therefore, most professionals recommend purchasing this equipment only in trusted stores, while simultaneously requiring a certificate from the seller for the goods. This condition is necessary because lifts are classified by Russian legislation as objects of increased danger.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131649 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127687 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124516 -

The best men's sneakers in 2022

Views: 124030 -

The Best Complex Vitamins in 2022

Views: 121937 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114978 -

The best paint for gray hair - top rating 2022

Views: 113393 -

Ranking of the best wood paints for interior work in 2022

Views: 110317 -

Rating of the best spinning reels in 2022

Views: 105326 -

Ranking of the best sex dolls for men for 2022

Views: 104363 -

Ranking of the best action cameras from China in 2022

Views: 102214 -

The most effective calcium preparations for adults and children in 2022

Views: 102010