Rating of the best acoustic foam rubber for 2025

Acoustic foam rubber is one of the best soundproofing materials that can reliably protect a car or a room from the penetration of extraneous sounds and damping internal ones. This type of polyurethane foam has a special softness that can fluctuate when exposed to acoustic waves and absorb their energy. Thus, the “flying echo” effect is suppressed, and the tonality of reproduced sounds, musical instruments and voices becomes more sonorous and clear.

Content [Hide]

- 1 The principle of operation of acoustic foam rubber

- 2 Types of premises protected by acoustic foam rubber

- 3 Existing sizes and shapes

- 4 Modern types of acoustic foam rubber

- 5 Features of the production of installation work for acoustic foam rubber

- 6 Rating of the best acoustic foam rubber for 2025

- 7 Instead of an epilogue

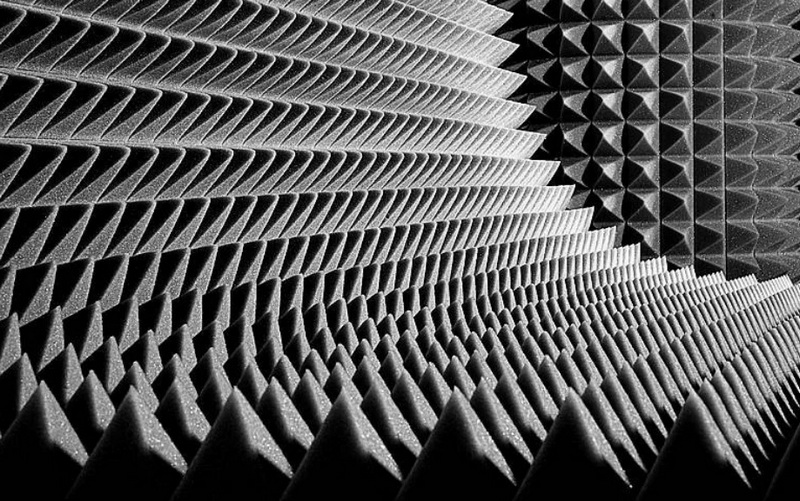

The principle of operation of acoustic foam rubber

Sound waves upon reaching physical objects are either absorbed by the latter or reflected from them. For example, if you enter a living space and scream loudly, then acoustic vibrations, reflected from the flat surface of the wall and bypassing possible obstacles, will create an echo. Carpets and upholstered furniture will only partially absorb the energy of sound vibrations, and objects with a smooth surface will distort it. To eliminate such shortcomings, soundproof foam rubber was created.

The foam rubber itself consists of a large number of polyurethane honeycombs that are filled with air. Through these honeycombs, the material is able to instantly absorb liquid and fill with air. And when a wave of sound passes through it, it is reflected from numerous cells of matter and is completely deprived of energy for further movement.

IMPORTANT! The lower the density of acoustic foam rubber and the larger the size of its honeycombs, the worse it delays various noises.

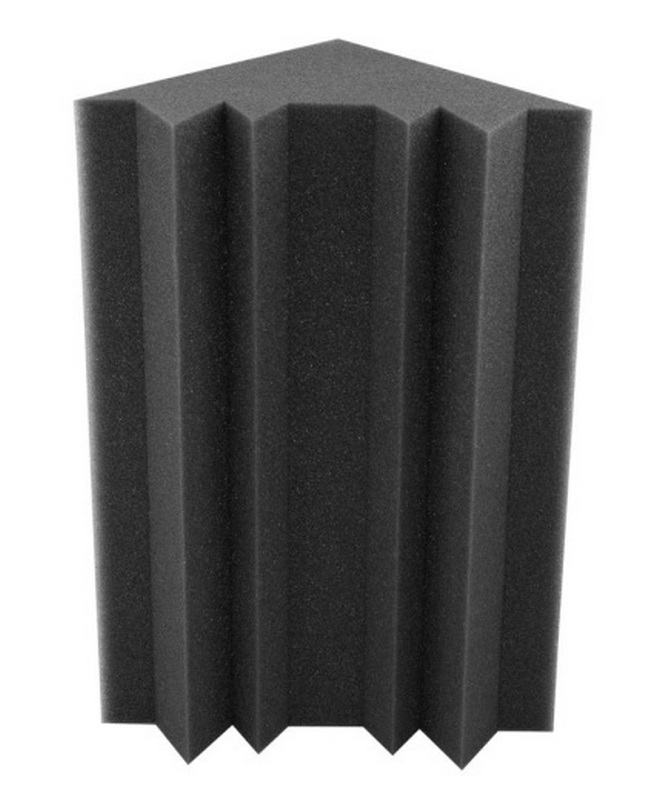

To eliminate noise at low frequencies, thickened polyurethane foam plates are used. They are called bass cubes or traps. However, it would be a mistake to assume that the material in question is capable of completely attenuating low frequencies. He can only "cut" their "ends" in space and remove the reflections of noise signals. In the corners of any room, low sound frequencies are concentrated, which is why they reach the human ear with a delay, and bass traps are designed to eliminate such low-energy accumulations. At the same time, the texture of the foam itself is not important for the bass trap - the dimensions of the material panels will depend on the parameters of the premises and the result obtained at the end.

The main technical properties of acoustic polyurethane are:

- No unpleasant odor;

- Variety of colors;

- Increased sound absorption;

- The variability of the execution of the relief surface;

- Easy installation;

- Small mass of panels;

- Possibility of use at various facilities (from car interiors to recording studios);

- Extended service life;

- Moisture resistance of the top layer;

- Environmental Safety.

Advantages and disadvantages of acoustic foam rubber

The considered soundproofing polymer has the following advantages:

- The panel can be placed on almost any surface and in any way - from gluing to physical fasteners;

- It has excellent qualities in terms of sound insulation, so it has practically no competitors in this environment;

- The whole installation process is quite easy and foam panels can easily be finished even with large rooms;

- He is not afraid of mechanical influences and after blows instantly restores his shape;

- Due to the possibility of giving it any color, it can successfully fit into any interior.

Its main disadvantages include the following qualities:

- Due to the high hygroscopicity (the ability to absorb and retain moisture for a long time), it is necessary to constantly monitor the degree of humidity in the room finished with it;

- Often overpriced;

- The material is very fragile and easily torn;

- The material is flammable and prone to rapid ignition.

Types of premises protected by acoustic foam rubber

Most suitable for the use of the material under consideration are houses with one or several floors, as well as: theaters and recording studios, objects of worship (churches, temples, synagogues, mosques, i.e. all objects where religious chanting is supposed), schools and lecture halls, offices and industrial warehouses. The material is suitable for rooms with any dimensions. Foamed polyurethane can be masked under any coatings of various types, or it can simply be laid over bare walls. Large panels look very organic in recording studios, which gives their interior not only the necessary functionality, but also a certain amount of sophistication and aesthetic appearance. To improve the efficiency of the coating, a small air gap should remain between them and the wall. Such a design will be able to better absorb sound waves falling on it.

Household soundproofing with foam rubber

Specialized foam rubber will be an excellent barrier to the penetration of extraneous noise into the apartment. The main source of sound entering the living space is the windows. Naturally, they can also be hung with thick curtains, which will muffle the noise to some extent, but the air chambers of the acoustic foam rubber honeycombs will cope with this much better. Honeycomb structures, having from 1 to 3 cells per square millimeter, can almost completely absorb sounds coming from outside. It is preferable to fix such foam rubber panels on the walls or ceiling - this way you can reduce extraneous noise that comes from neighbors on the side or above. This type of installation provides for the installation of each panel as a separate piece of the layer.

Office (industrial, commercial) soundproofing with foam rubber

To create a soundproof field in large office buildings and other public places, i.e. in places with a massive stay of a large number of people, the same panels are used that are intended for domestic use. But the process of laying them is slightly different, because for large rooms it is desirable to leave an air gap between the foam rubber and the bare wall. Walls and ceilings finished in this way will significantly reduce the noise load inside the facility. Foamed polyurethane will dampen not only the sounds of steps and people's voices, but also significantly reduce the hum produced by operating office equipment, muffle the knock of doors and drawers. Practice, as well as statistics show that the efficiency of workers working in soundproof rooms increases many times over.Regarding industrial facilities, where noisy production devices work extremely loudly, it can be noted that sound insulation is required for them even according to the norms of the current Russian legislation.

Existing sizes and shapes

The classic type of acoustic foam rubber is rectangular or square sheets, on which there is a certain type of bulge. They may be in the form:

- squares;

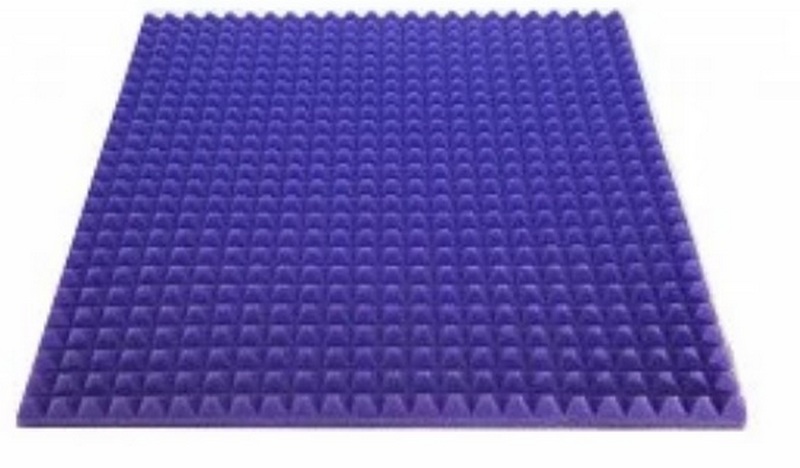

- Correct pyramids;

- truncated pyramids;

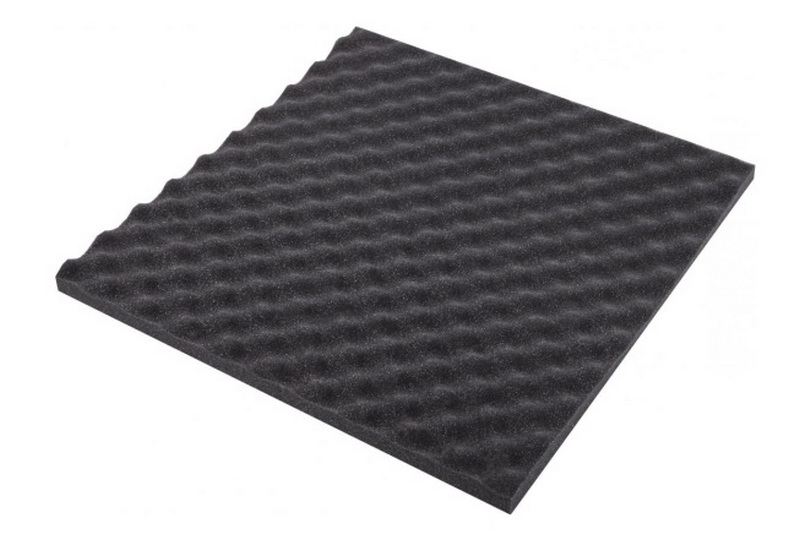

- waves;

- Puzzles (irregular geometric shapes).

The height of such bulges can be from 7 centimeters and above. The color of the panels itself is not important - they can be multi-colored, but their traditional colors are gray and black. There are also even (without bulges) slabs for sound insulation, which fill the voids and gaps between the bare wall and the cladding, which can be played by third-party material (from lining to drywall). Separately, it is worth mentioning models with bulges of irregular geometric shapes - most often they are produced in multi-colored and are used to decorate rooms where children are constantly present.

Modern types of acoustic foam rubber

The current market can present a potential buyer with many types of acoustic foam rubber, which will differ in purpose, color and relief.

Classic models

They are designed to dampen extraneous noise in the protected room and fully regulate the acoustic conditions. Such plates perfectly absorb unwanted sounds, suppress acoustic waves, and eliminate directed amplified noise flows. As a rule, their relief is made in the form of waves or pyramids (regular or truncated).

Foam rubber slabs, devoid of relief, can be called universal to some extent, because they can be used both as an independent element of sound protection and as a layer for finishing material. However, they struggle with the penetration of sound worse, in comparison with the relief "brothers", therefore, they are often used only for soundproofing partitions and thin walls.

IMPORTANT! Foam rubber for acoustic purposes is strongly not recommended to be crushed - from being constantly in a deformed position, it loses its soundproofing characteristics.

Honeycomb acoustic panels

They are also called "spongy foams" and are labeled in a foreign manner with the letters SPG (from the English - "sponge" - "sponge"). They can have large or small porosity. Such a material with small pores is perfect for domestic use - they can even wash dishes. But most often, it is used to make stands for acoustic speakers, so that the vibration of sounds propagates around the room properly. In turn, material with large pores is used for bass traps installed in the corners. Bass traps are used both in everyday life and in professional recording studios. Honeycomb panels are characterized by their own shade - gray or black-anthracite.

Resonant absorber panels

In most cases, they are used for home music studios or home theaters. Their production is based on a special type of foam rubber called Mappilsi. It is characterized by a standard graphite color, although its relief and thickness may be different. It is very easy to install, it is easy to impose on the walls. Standard parameters of this type of panels:

- Width - from one meter;

- Thickness - from 30 to 70 millimeters;

- The length of the plate is from 1 to 2 meters.

Car bass traps

They are produced in the form of pieces of acoustic foam rubber and often have an irregular shape, and in the vast majority of situations they are made to order in order to comply with the shape of the corner of the specific car body where they will be installed. Such devices work on the principle of capturing low-frequency sound waves in a limited space (car interior), namely at its corners. If you do not equip the interior of the car with such traps and at the same time use a powerful audio system in it, then a person can simply go deaf. By using such car bass traps, it is possible to obtain the proper effect of reducing unwanted vibration, and the basses themselves will receive greater strike clarity and speed, which means quality control of low-frequency energy.

Features of the production of installation work for acoustic foam rubber

For better implementation of the installation of soundproof foam rubber boards, it is preferable to use adhesive mixtures (rather than fixing directly with monolithic fasteners, such as nails, staples or self-tapping screws), without organic solvent impurities. Perfectly for these purposes, water-dispersion substances based on polyurethane, neoprene or polychloropropylene are suitable. In our country, a special brand for such material is popular, which has the name "Foam rubber" and its analogues. The process of slab finishing includes several stages:

- The surface to be finished must be clean and free of all kinds of contaminants. Laminated or metal areas must be cleaned of any dirt.And concrete-based surfaces must be cleaned with sandpaper, and subsequently primed.

- Next, markings corresponding to the dimensions of the plates are applied to the surface.

- Then, on the underside of the panel, a thin layer of adhesive should be evenly applied, which can be done with a spray gun. It is worth noting that if the adhesive substance is applied manually with a brush / roller, without using a sprayer, then in the future it will be necessary to face the effect of the plates sliding down the surface under the force of gravity.

- The main rule is that the material should be pressed tightly against the base (ceiling or wall) and held in this position for at least 30 seconds. This period of time is enough to securely fix the foam sheet on the wall or ceiling.

Separately, it is worth mentioning the issue of fixing the plates directly on the surface, which is made on the basis of metal profiles. Professionals recommend that you first finish a similar base with gypsum boards, and then stick acoustic foam rubber on them.

It is always worth remembering the unshakable rule - the higher the sound waves are supposed to be in the room, the thicker the foam sheets should be. Offices and residential premises, which are located in densely populated parts of megacities, should, at best, be finished with several layers of acoustic foam rubber at once, the thickness of which must be kept within the limits of 5 to 7 centimeters. At the same time, the density of the overall layer is also important - for the conditions described, it is preferable to use several thin slabs in several layers.

IMPORTANT! After securely fixing the foam rubber on the wall / ceiling, it should be thoroughly cleaned of construction debris.Even a household vacuum cleaner is perfect for these purposes, however, they need to work with great care, using not all of its power.

As a result, the use of acoustic foam rubber plates is an excellent option to create acceptable acoustic conditions in any room. Their material will reliably absorb extraneous noise, streamline the process of work or daily life, making it comfortable, and in addition, save people from annoying sounds.

Mounting Variations

Depending on the purpose of the room to be equipped and its ability to withstand unwanted noise effects, soundproofing foam rubber is fastened in various ways. Such methods can be both temporary and permanent:

- Permanent (permanent) - it is suitable for rooms in which on an ongoing basis there is a need to cut off excess noise - in this case, fastening is done on "liquid" nails or other powerful adhesive substance;

- Temporal (temporary) - it is suitable for one-time acoustic foam upholstery of a room and involves its removal after a short (relatively) use. This is typical for small recording rooms, summer radio cabins in children's camps, etc. In this case, the sheets can even be attached to ordinary pushpins or double-sided adhesive tape.

Rating of the best acoustic foam rubber for 2025

Budget segment

3rd place: "Aura"

votes 0

This type of foam panels is designed to perform a decorative function more than directly provide sound insulation. However, this material is quite comparable in its acoustic properties with foam rubber, made according to the pyramidal model.Due to the fact that the plates are relatively small in size (30x30 centimeters), it is possible to make interesting combinations of them that are suitable for a designer interior. Sticking them is quite convenient and simple, again due to their small size. The recommended cost for retail chains is 130 rubles per plate.

- Easy installation;

- Analogue to pyramidal acoustic panels;

- Possibility of design.

- Semi-decorative purpose.

2nd place: "Decor (Quadra)"

votes 0

Although these panels are decorative, they fully fulfill their soundproofing function, while they have a laconic design. The interior based on them always looks stylish and is ideal for finishing home theaters. The sound dampening efficiency is equal to the Pyramid 40 type acoustic foam rubber and is approximately equal in thickness to it. Structurally, the slab has three layers: the first (consisting of small squares) meets the sound wave and takes the main blow, the second is an air gap, and the third is a solid base of the slab, which finally dampens the sound. The established store price is 520 rubles for a slab measuring 100x100 centimeters.

- Acceptable price;

- Three-layer execution;

- Color variability.

- Not detected.

1st place: "Wave"

votes 0

This acoustic foam option is a one-stop solution for properly soundproofing music performance spaces. It is quite possible for them to decorate a small private studio, a home theater, a music class, and the like. The main thing is to correctly choose the size of the plate.The relief in the form of a wave is accessible and simply dampens the sound resonance, perfectly fights the echo, and also adds purity to the reproduced sound. The cost of one panel in the retail network is 660 rubles for a slab measuring 100x100 centimeters.

- Wave structure of the relief;

- Easy installation;

- Adequate price.

- There is no size variation.

Middle price segment

3rd place: "PRF Bass Trap"

votes 0

This trap panel is placed in the corners of the room, usually in their upper part (but it is also possible to place it in the middle). The connection of three walls (planes of two walls and a ceiling) will always be a cluster of sound reflections at low frequencies. Traps must be installed indoors, it is supposed to play percussion instruments. The recommended retail price is 720 rubles.

- Excellent damping of low frequencies;

- Placement variability;

- Execution quality.

- Not detected.

2nd place: "Pyramid"

votes 0

This variant of the acoustic panel is the most effective and popular and is rightfully considered a universal solution for music rooms. They can decorate a home theater, a large recording studio and a large music class. The main task is to correctly mark and install the pyramidal panel in order to reliably provide sound protection for the entire room. The pyramidal relief is designed to qualitatively dampen sound resonance and effectively eliminate echo, while a significant degree of purity is added to the reproduced sound. The recommended cost for a retail network is 850 rubles per sheet of 2 square meters.

- Many color solutions;

- The maximum degree of sound damping;

- Efficient echo cancellation.

- Small variation in plate sizes.

1st place: "AP15 Bass Trap ATEX"

votes 0

This low-frequency sound absorber is perfect for both domestic and professional music playing. Sound waves at low frequencies, causing increased resonance, are qualitatively delayed due to the presence of more ribs. The device can significantly reduce the period of natural reverberation in the room by cutting off the unnecessary sound "tail". Moreover, this effect will be observed even if there is no other type of sound-absorbing surfaces in the room. A clearer sound will also be respected. The recommended retail price is 2000 rubles.

- Increased size and number of ribs;

- Works great with low frequency noise.

- Increases the clarity of the main sound.

- Somewhat overpriced.

Premium class

3rd place: "AP WAVE 0.62"

votes 0

This material is used as an additional soundproof layer during finishing and construction and installation works. It is able to provide sound insulation not only in specialized rooms, but also in other structures. Great for listening and vocal practice rooms, announcer's offices in television companies, theaters and restaurants of the corresponding profile, industrial premises, city apartments. A good relief of the wave type with a thickness of 0.62 cm was used as an absorbing element. The established cost for store chains is 2100 rubles.

- The maximum size of the relief of the wave type;

- Reasonable price;

- Easy installation;

- Various purposes.

- Not detected.

2nd place: "AP PYRAMID 0.7"

votes 0

An excellent material for soundproofing completely different rooms. Perfectly extinguishes and cleans the reproduced sound. The "pyramid" type, which is considered the best for acoustic isolation, was used as a relief for damping. The thickness of the extinguishing element is 0.7 mm. It is possible to finish any room with this material - from a home theater to a professional recording studio and a vocal class. The established cost for retail chains is 2,500 rubles for a 100x100 cm slab.

- The best pyramidal relief;

- Large sheets of execution;

- Versatility of application.

- Not detected.

1st place: "AP23S purple ATEX"

votes 0

This material has a relief format in the form of a truncated pyramid, which is one of the best absorbent formats. The material used in the construction is acoustic polyurethane. Perfect for wall upholstery in recording studios, various music and rehearsal rooms. It copes well with capturing high and medium sound frequencies. Can be used for rooms of various sizes. The recommended cost for a retail network is 3,100 rubles for a panel measuring 1.5x1.5 meters.

- Large sheets of execution;

- Color variability;

- Versatility of application.

- Not detected.

Instead of an epilogue

The analysis of the market of the materials under consideration found that almost all of the presented samples are of Russian origin.Despite the fact that the quality of these samples is in no way inferior to foreign ones, and their price is far from high and quite adequate. At the same time, it is better to purchase acoustic foam rubber in specialized retail stores in order to be able to personally check its quality.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131651 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127691 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124519 -

The best men's sneakers in 2025

Views: 124033 -

The Best Complex Vitamins in 2025

Views: 121940 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114980 -

The best paint for gray hair - top rating 2025

Views: 113395 -

Ranking of the best wood paints for interior work in 2025

Views: 110319 -

Rating of the best spinning reels in 2025

Views: 105329 -

Ranking of the best sex dolls for men for 2025

Views: 104366 -

Ranking of the best action cameras from China in 2025

Views: 102216 -

The most effective calcium preparations for adults and children in 2025

Views: 102011