The best wood brushes for 2022

Everything in life comes back to normal. Having been saturated with modern designs of stone houses and interiors, many people began to return to their roots, more often using wooden products and furniture in their homes. The paraphernalia of aged wood is of indispensable interest to the public. Naturally, this process takes a long time, but modern innovations have made it possible to speed up this procedure by brushing. Artificial aging of wood reduces the final cost of such products in the consumer market and increase their distribution.

Content

Purpose of brushing process

By the presence of rings on the cut of a tree, its age is determined. Dark outlines indicate an early period of life, and light outlines indicate a late one. The texture of these surfaces is also different. The rings formed recently have a loose, soft substance. In contrast, the dark "relatives" are solid and monolithic.

To artificially age a tree, with the help of special brushes, they clean the soft structure of the fibers. Old and dense areas protrude to the surface, which creates a beautiful and clear relief. For greater depth of its outline, masters use surface painting with paints that correspond to the predominant color, but differ in tone. A dark shade is used to fill the recesses, and a light shade is used for protruding areas.

After numerous experiments with such staining, many woodworkers came to the conclusion that in order to obtain an “old” product as close as possible to the natural process, it is better to use gray paint to fill recessed areas. This method is equivalent to the 10-year aging of a tree in nature.

Advantages and disadvantages of the method

The benefits of brushing are:

- giving strength to a wooden structure during artificial processing in the absence of such quality in a natural process;

- exclusion of damage to raw materials by harmful insects and microorganisms, as well as the occurrence of the process of decay;

- an expanded range of manufacturing options for numerous design and interior elements;

- turning inexpensive raw materials into expensive exclusive items.

The disadvantage of the method is that certain tree species are required for its use, namely those that have a large fibrous structure and a distinct layering. This list includes:

- larch;

- oak;

- ash;

- pine;

- wenge;

- nut.

Due to the absence of the listed properties in birch, beech, alder, maple, cherry and teak, such a wood processing mechanism will be ineffective.

Processing methods

Looking at the beauty of wooden products that have undergone artificial structuring, it seems that only an experienced craftsman can do such work. But this opinion is wrong. According to experts, even a beginner is able to carry out such a procedure. To do this, you only need to have the appropriate tool and a great desire to create. For beginners to work with wood in this technique, it is recommended that you first try your hand at using hand tools. Further, if this activity turns into a hobby or business, you can switch to mechanized processing.

So, the manual tools needed for brushing include:

- Bulgarian,

- brushes,

- chisel,

- sanding paper.

The grinder provides for the use of various brush heads with a specific bristle for successive stages of brushing wooden surfaces. For the first stage, it is recommended to use brush heads with metal bristles, and for the final stage - with sisal or copper bristles. Most modern craftsmen process wood using a polymer brush with an abrasive.It allows you to extract soft wood pulp without touching its dense areas. But, when working with the use of high speed grinders, it is necessary to pay careful attention to ensure that the area being treated does not burn. To avoid this, the masters recommend installing a speed controller on the equipment.

Brushes are the main tools for wood processing at the initial stage. They come in soft or hard textures. These properties depend on the size of the pile. The larger the size of the bristles on the tool, the softer its action. For maximum effect, experienced craftsmen advise using hard-bristled brush heads. If the rigidity of the tool is not enough, then it can be increased by means of a grinder by cutting off a certain distance of the pile on the entire surface of the tool. The removal of the soft structure of wood with a brush should be carried out strictly in the same direction as its fibers. Thus, their solid sections will retain their integrity and create a clear, beautiful relief.

The chisel in this process plays the role of a "former" of deep convolutions and cracks, showing a complete analogy to natural aging. Skillfully using this tool, you can radically change the natural pattern of the tree bark and give it the desired configuration.

Coarse grit sandpaper can replace brush attachments when working with wood. It should also move in the direction of the structural fibers. In addition to the primary processing of raw materials with its help, furrows are formed on the surface area, additionally giving it a natural look. The degree of distinctness of scratches will also depend on the grain size of the paper.

Experts warn that during the first stage of processing a wooden surface, you can not use a gas burner for firing. This will not lead to the desired result. And its kerosene counterpart in this situation will be most effective.

The advantages of using this tool are:

- drying the outer layer of the tree;

- elimination of the remaining small threads;

- improvement of the relief structure of wood.

Brushing raw materials on a large scale requires the use of automated equipment. Among the most popular setups for home use are brush cutters and grinders. Some of them are Festool Rustofix RAS 180, Felisatti AGF 110/1010E and Makita 974.

Ranking of the best brushes for woodworking for 2022

Since tree brushing is carried out in 3 stages, each of them uses a certain type of brush. According to their composition, they are divided into:

- metal,

- synthetic,

- sisal.

Both domestic and foreign manufacturers are engaged in their release and delivery to consumer markets. The following is a list of the most popular product models in this category.

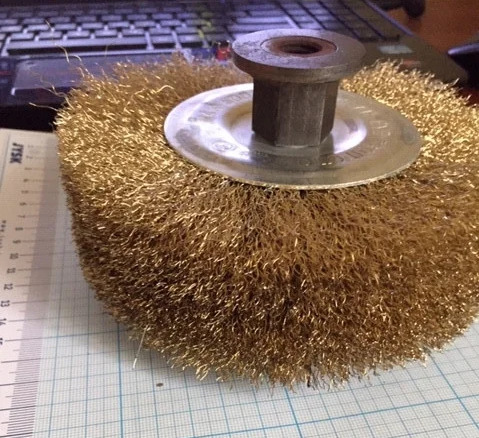

metal

This type of brush is used for primary, rough processing of wood. According to experts, tools with steel pile will be most effective for hardwoods. Brass brushes are suitable for a softer wood structure. But it is not recommended to use polymer products for the initial stage, since the desired effect cannot be achieved.

Disc brush D80 * 35 with tail D8, bristle - brass-plated steel 0.25 (code 1-083)

This model of the German company Osborn is designed to be used as a nozzle for a drill.Its function includes the initial processing of wood, that is, peeling off the rough surface layers of fibers of hardwoods. The bristles are made of brass-plated steel, the wire thickness of which is 0.25 mm. The shape of the pile is a untwisted pigtail. In addition to wood, this tool can process stone, concrete, metal. This model is designed for use at a maximum speed of 4000 rpm. For wood processing, the recommended speed is 2500 rpm.

- high performance;

- designed to work in hard-to-reach areas;

- great quality;

- versatility of use.

- not identified.

Brass brush head for brushing wood

The device declared by the Polish manufacturers of Proline has a diameter of 15 cm, which allows processing large surfaces. The pile, which is a brass wire with a diameter of 0.3 mm, provides deep cleaning of wood from soft fibers. Thick, dense bristles are a guarantee of high quality work. This model is used as a nozzle for a drill, grinder or grinder. Due to the high speed of rotation, during operation it is necessary to use a speed controller, as well as personal protective equipment to avoid injury.

- high performance;

- good quality;

- strength and reliability;

- high processing speed.

- not detected.

Polyamide

Models belonging to this group are intended for the intermediate stage of brushing, which consists in grinding surfaces and preparing them for final polishing. Brushes in this category use polyamide (synthetic) fiber with abrasive bristles. Products can be presented both in the form of separate hand tools and as attachments for angle grinders, drills and angle grinders.

Flat brushes 4-row stuffed with polyamide grain

This model is presented on the consumer market by the German company Lessmann. It has shown its effectiveness in the processing of soft, resinous wood. The maximum speed of the device, the nozzle of which is this brush, should be no more than 2500 rpm. The high quality of the product provides a long service life, and also has an excellent abrasive effect when brushing.

- high efficiency;

- great quality;

- long service life;

- reliability and durability of the tool.

- not detected.

Cylindrical 7-row brushes with polyamide grain

Also representative of the manufacturer Lessmann is a 7-row stuffed cylindrical brush with abrasive grain. It is used for intermediate grinding, and sometimes for primary polishing of wooden products after the initial stage of processing. Being a nozzle for a drill or a grinder, it works at a maximum speed of 2500 rpm. For the convenience of choice, customers are offered options with different parameters of abrasive grain.

- high quality goods;

- excellent efficiency;

- the possibility of choosing the required size of the abrasive grain;

- ease of use.

- not found.

Disc brush head D75*10 with tail D6 (code 1-064)

This model is presented by the German manufacturing company Osborn. Its purpose is to sand and lightly texturize the wood surface during the brushing process. It is also intended for shallow penetration and small surfaces. It is used as a nozzle for a drill or grinder. The permissible speed of this device is 4500 rpm. The bristles of the tool are made of red polymeric abrasive nylon. The diameter of the wavy pile is 1.2 mm. The abrasive is corundum (aluminum oxide) with a grain size of 80. Experts warn that strong pressure is unacceptable for this model.

- wonderful result;

- great quality;

- ease of use;

- high speed.

- pressing strongly reduces the effect of processing.

Cup brush head D110*M14 (code 6-003)

The Chinese-made model from PLM is a bowl-shaped nozzle for drills, angle grinders and angle grinders, and carries out grinding, surface structuring of wood. The abrasive, corrugated 60 grit nylon that makes up the pile also allows stone surfaces to be treated. This model is ideal for sanding and texturing vertical wooden objects such as timber, planken, log walls, clapboard, etc.

- good performance;

- great quality;

- convenience for processing vertical surfaces;

- versatility.

- not identified.

Disc brush head for brushing

The abrasive brush nozzle for intermediate processing of wooden surfaces by polishing is the representative of production of Spain. It carries out work with the help of any grinders, drills or grinders. A qualitative result is obtained when using the optimal speed of 2500 rpm. The bristles of the device are made of polymer nylon filled with an abrasive, the grit of which is 60. The diameter of the nozzle is 15 cm, which is well suited for use on large surfaces.

- wonderful quality;

- high performance;

- optimal speed;

- worthy result.

- not found.

Sisal

The difference between these types of brushes from other representatives is in the composition. The main raw materials for their production are natural materials. Such devices are designed to perform the final stage of wood processing, that is, the final grinding and polishing.

Sisal disc 150 mm

American manufacturers supply consumer markets with an excellent model of polishing device for finishing wood products. Her job is to softly, gently polish wood surfaces, giving them a smooth and shiny finish. The nozzle is used for conventional and angle grinders, as well as drills and angle grinders. Thanks to the low maximum speed of 2500 rpm, objects are handled gently and efficiently.

- great quality;

- natural composition;

- convenience and ease of use;

- wonderful result.

- short service life of a natural fiber part.

Every creative person is looking for an outlet for his desire and inspiration. The brushing of wood for further production of exclusive interior accessories and furniture is no exception. But these factors alone are not enough to implement the planned projects. A preliminary study of the methods of this process, the tools used and the use of the most popular brushes among the masters of their craft, presented in this article, will make it much easier to make your dream a reality.

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131658 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127698 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124525 -

The best men's sneakers in 2022

Views: 124041 -

The Best Complex Vitamins in 2022

Views: 121945 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114984 -

The best paint for gray hair - top rating 2022

Views: 113400 -

Ranking of the best wood paints for interior work in 2022

Views: 110326 -

Rating of the best spinning reels in 2022

Views: 105334 -

Ranking of the best sex dolls for men for 2022

Views: 104373 -

Ranking of the best action cameras from China in 2022

Views: 102222 -

The most effective calcium preparations for adults and children in 2022

Views: 102016