Best 3D printers in 2025

The modern world of technology is diverse and exciting. Progress is constantly striding forward, each year presenting surprises. To date, the opportunity has already become available to independently create real things. This does not mean painstaking manual labor, but machine work that does not require any physical effort from the user. We are talking about 3D printers.

Once upon a time, these devices were available exclusively in factories. These were clumsy and heavy machines that could not be placed in an ordinary city apartment, but over time the devices improved and now every consumer can take home or purchase a 3D printer for a small business.These devices help to expand one's horizons, showing that even seemingly complex things can be created at home, and not only at huge factory enterprises.

Content [Hide]

What is a 3D printer for?

Previously, one could only imagine that the item was not bought, but created at home. Does the child want a plastic teddy bear? No problem! We start the car and the toy is ready. Broken towel hook in the bathroom and too lazy to go to the hardware store for a new one? So that's great! So there is no need to go anywhere, just set the machine the task of creating a hook.

A 3D printer is a kind of "magic wand" that fulfills wishes at the household and production levels.The device can be used by students when creating demonstrative materials, by architects making models of buildings, and also by electronics engineers. The range of application of such devices is quite wide. Products created with a 3D printer are suitable for personal use, entertainment, work, and are also suitable for business use.

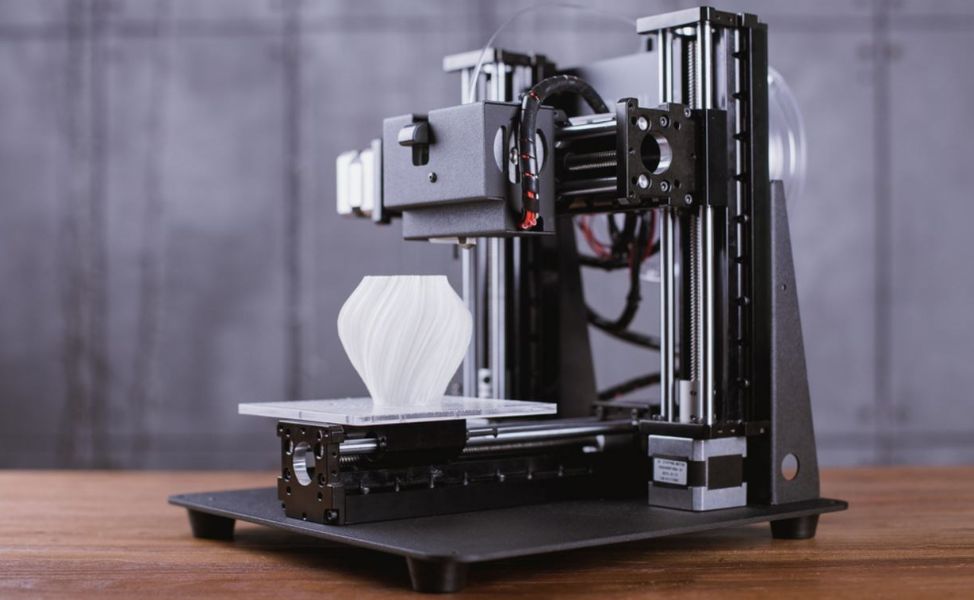

Principle of operation

A 3d printer creates any thing thanks to layers that are sequentially superimposed on each other. In simple words, at first the personal computer gives information on the object to the printer, and the printer already displays a three-dimensional model. The smallest layers of the consumable are stacked on top of each other, layer by layer, until a specific planned item is obtained. Layered printing technology is fast and has the advantage of no human error. This means that the device works smoothly and eliminates all sorts of errors.

Materials needed for work

To produce high-quality products on a printer, you need to know the production technology. Do not think that as soon as you buy a machine, it will print itself.

A lot depends on the source material. The following six types of consumables are very popular.

ABS plastic

This is the most common material. It has a special impact-resistant structure, which allows it to withstand strong mechanical stress. This consumable surpasses many materials in terms of strength and rigidity. It can be used for precision casting, welding or vacuum plating.

Dimensional stability is up to the mark. When you print objects made of ABS plastic, they have a shiny surface.

PLA plastic

This type of consumable can be safely attributed to the most ecological material.It is perfect for 3D printing. Objects that are printed out of PLA plastic have excellent glide, which means that things like plain bearings can be created from it. This material is also ideal for making toys for children. Why? Because it does not contain toxic substances.

PVA plastic

This cryptic word is polyvinyl acetate. Simply put, this is PVA glue. This type of consumable has such a quality as solubility in water, which means that long-lasting products cannot be created from PVA plastic, but it can be used as a reference material.

Photopolymers

This consumable can change its shape under certain exposure to sunlight. The consumable may be in liquid or solid form. Objects that are created from photopolymers are distinguished by enviable strength, as well as resistance to water and the sun.

metal powder

Such a consumable is often used to print various items. Its role will not necessarily be played by the metal itself. You can take copper, aluminum, gold or alloys. It is also used in the manufacture of jewelry or jewelry.

Nylon

The material is very similar to ABS plastic, but against its background, it absorbs moisture much better and has a high resistance at high temperatures. Among the shortcomings, long solidification and toxicity should be highlighted. There are other materials, but the above consumables are among the most popular.

The best 3D printers for the home

Professionals who have already dealt with 3D printing probably know which 3D printer is better to buy for use at home. Basically, these are budget devices of an open design.They are produced partially disassembled, but provide extensive opportunities for customization and experimentation: in such devices, you can change gears, extruder nozzles, desktops and controller firmware.

Creality3D Ender-3

votes 0

This device is a sensation in the 3D printing industry. Shenzhen Creality 3D entered the low-end 3D printer segment with the introduction of the CR-10, but the device we are reviewing has taken the market by storm. The average number of samples that were released within 12 months reached 300,000, which is about 25,000 devices per month.

This 3D printer is an intuitive and high-quality device that, as of 2025, in addition to being one of the best solutions for beginners, is also ideal for experienced users. Ease of use for beginners lies in intuitive and quick assembly, as well as easy setup and stable operation out of the box.

The device does not need any modifications, and experienced users have found in it a high-quality, but at the same time affordable device that can be used both as an additional tool for professional equipment and as the main unit.

The average price is 17,000 rubles.

- availability;

- ease of assembly;

- small dimensions;

- prints great out of the box;

- intuitive to use.

- not detected.

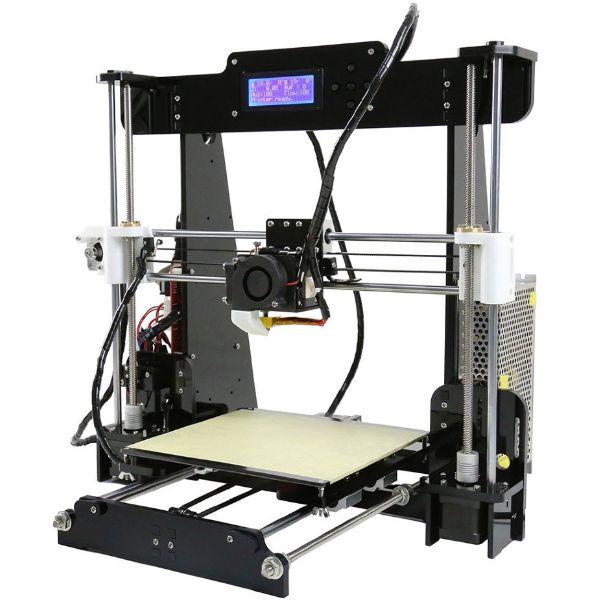

Anet A8

votes 0

This model is an improved modification of its predecessors, which has become even more famous when compared with previous generation devices.

In this version, the developers have improved the base, completed the calibration along the guides and improved the mobile platform. The device has an automatic calibration sensor and 1 extruder, which is 100% made of metal. This feature increases the mechanical reliability of the device and makes it possible to interact with the printer in difficult conditions without loss in terms of performance.

The guide moves along the X-axis by means of an inductive sensor, which makes it possible to accurately process the edges and bumps of the printed sample. To get started, you need to assemble the device. It's easy to install, and it's been tested at the factory before, so you shouldn't have any problems with your first print.

This model is widely used in various fields.

The average price is 18,000 rubles.

- adequate price;

- heated table;

- good extruder;

- can be printed with soft plastic SDS;

- easy to remove and wash the glass.

- long time to collect.

Anycubic 4Max Pro

votes 1

This 3D printer is equipped with a touch-screen display, filament end sensor, print resume (in case of power failure), nozzle cleaning brush for sticky plastic, air purification system, passive thermal camera and auto-off option when printing is finished.

Compared to the previous model, this one is sold assembled. All that the user needs to do for the initial start-up is to unpack the printer, remove the transport ties and supports, fix the filament end sensor with 2 bolts on the back of the device, hang the plastic retainer here and fill the gadget with material.

On the left is a connector for connecting a USB cable, a tray for an SD drive and a carrying handle.On the right side there is a second handle for transportation, a power cord port with an ON / OFF button and a ventilation hole for cooling the PSU.

On the front of the printer there is a plastic door fixed with 2 magnets, a diagonal touch screen, and a device start button. There is a hole at the top that is closed with a special transparent plastic cover, which makes it possible to easily print with shrinkable plastic that needs a thermal chamber.

The average price is 35,500 rubles.

- compact;

- closed;

- quiet;

- pretty fast;

- able to print a decent range of plastics: PLA, PETG, ABS, Nylon.

- not very successful blowing of the print area.

- The warm air exhaust is fed directly to the control board.

The best 3D printers for medicine

3D printing has been used in medicine since 2000, when the technology was first used to create dental implants.

Since that time, the use of 3D printing for medical purposes has increased significantly - experts from all over the planet tell how to apply this technology to create ears, skeletal parts, respiratory organs, jawbone, eye parts, cells, etc.

Wanhao Duplicator i3 Mini

votes 1

This is a small device that prints in a layered directionality. As consumables, you can use PLA plastic and other materials that do not need platform heating.

The printer does not take up much useful space on the desktop, and the lack of heating has a positive effect on electricity consumption.Among other things, this minimizes the risk of burns, so that minor calibration can be done directly during the printing process. Due to Wanhao's adequate pricing policy, both medical institutions and beginners in the field of 3D printing can purchase this device.

The printer is suitable for use in schools.

The average price is 15,500 rubles.

- the principle of work - "got it, turned it on, print";

- easily connects to the seven;

- glue stick included;

- securely holds the sample;

- good print quality.

- not detected.

Hard Light Sirius

votes 0

This is a completely new photopolymer model from a Russian manufacturer with a large number of innovations and improvements. The new version of the printer has an improved twin 2K matrix, a completely updated appearance, increased speed and accuracy of printing along the XY guides, rigid four-point calibration, a 72-watt laser, a 3.5-inch color screen and, of course, Russian software.

Supports all base and biocompatible types of polymeric materials.

The average price is 55,000 rubles.

- has 2K LCD display and 405nm PARALED matrix;

- calibrated shaft mechanics, made of hardened type steel, makes it possible to obtain a smooth finish and no vibration along the Z-axis;

- quality localization;

- thoughtful interface;

- simple control.

- not detected.

The best entry-level 3D printers

The printing process of such devices is based on FDM modeling. The plastic filament is melted and then sprayed in thin layers to form a sample.Devices from the inexpensive segment have 1 nozzle for displacing the thread.

Recently, SLA DLP models have begun to appear, which after some time will be equal in price to FDM.

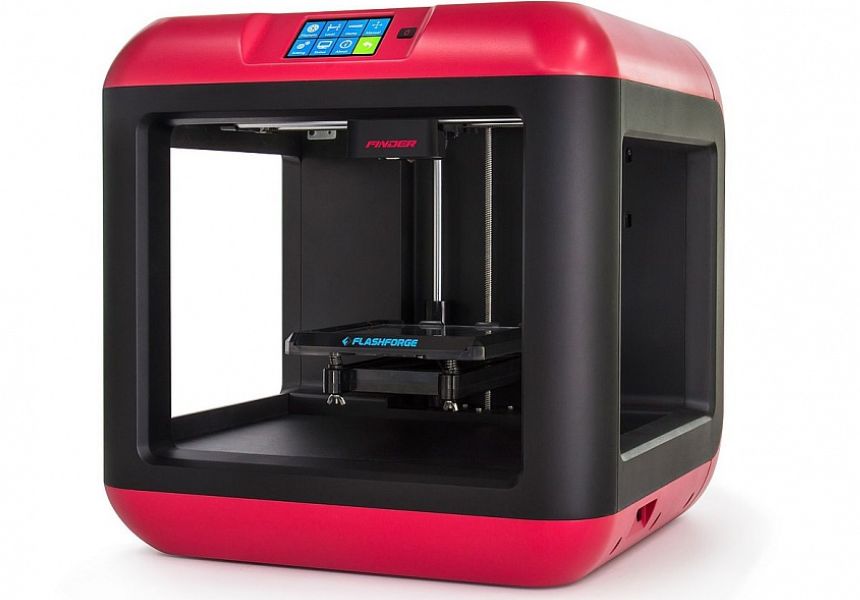

Flash Forge Finder

votes 0

The model is produced in the assembly, so it is ready to use "out of the box". This device will be an excellent choice for home, school, university, as well as beginners in the field of 3D printing. The heating components of the device are protected from contact, and non-toxic and ECO-friendly PLA is used as a consumable, which makes the device in question safe for both adults and children.

Due to the "smart" calibration system, preparing and setting up the gadget for work does not take a lot of time.

The average price is 31,500 rubles.

- practical 3.5" touchscreen display with required control components as well as real-time 3D model preview and print status;

- consumable supply completion sensor during printing;

- the ability to work via USB;

- wireless control with second generation Wi-Fi;

- ten gigabytes of integrated memory.

- not detected.

Creality3D Ender 3 Pro

votes 0

This is an improved modification of the company's previous 3D printer with FDM technology. The model also provides an overall area with heating, so the user is given the opportunity to interact with various consumables from PLA and ABS to TPU. The dimensions of the site are 235x235x250 mm, which allows you to accommodate almost any project.

The average price is 20,500 rubles.

- the MK-10 extruder has passed numerous tests, which reduces the likelihood of contamination or incorrect material supply;

- high smoothness of the carriage was achieved thanks to the installation of modern durable rollers;

- all grooves on the Y-axis are machined, thereby minimizing possible gaps;

- a large nut, practically located under the platform, is responsible for calibrating the table;

- the device has integrated memory, which makes it possible to interact with the printer even in the event of power outages.

- incomprehensible menu.

The best educational 3D printers

3D printing technology, in addition to being widely used both in small and large companies and in additive manufacturing, is also becoming one of the most fashionable trends in the field of education. Even with the basic configuration model, it is now possible to make a real physiological object of high quality, which is important when training technical and creative specialists.

An increasing number of managers decide to install devices from this segment in educational institutions. What matters is not only improving the equipment of computer science classes, but also facilitating the training of teachers to teach children how to work with non-standard materials.

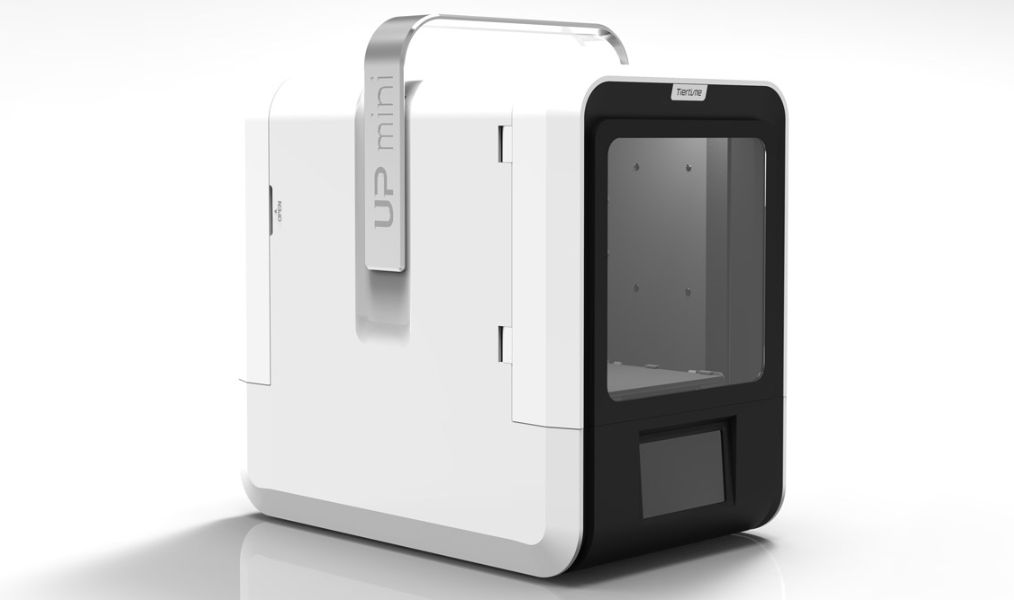

Tiertime UP mini 2 ES

votes 0

This is an updated and improved model of the popular Up mini 2 3D printer with improved technical parameters and software. The device adopted from the previous version an elegant miniature body, a container with compartments for consumables and auxiliary tools, as well as a HEPA filter with activated carbon.

The filter effectively reduces the content of toxic elements in the air, which are released during printing with ABS plastic.

The average price is 50,000 rubles.

- task sequencing;

- touch screen control;

- improved communication functionality - there is Wi-Fi, Ethernet and an additional USB connector;

- you can replace consumables during printing;

- files are stored in the cloud.

- not detected.

Wanhao Duplicator D9/500 Mark II

votes 0

This is one of the most common versions used in the global industry. To ensure high stability of the device, the developers made a metal case, which also reduces vibrations. All this allows you to produce the most accurate models on this printer and minimizes operational errors.

The average price is 66,900 rubles.

- a bearing system was taken for the guides;

- the software is represented by an intuitive code that is easy to understand even for beginners;

- the device does not overheat during operation, since the developers have installed an auxiliary overall fan;

- the device is equipped with a monolithic extruder of the MK10 modification, made of sheet metal, which makes it possible to interact with the device in a wide range of melting temperatures (the maximum melting temperature is 500 0FROM);

- compatible with many types of consumables;

- The gadget is suitable not only for professionals, but also for beginners.

- the motor drivers on the board are not removed, and therefore, in the event of a breakdown, it will not be possible to change them without completely removing the board and soldering.

The best industrial 3D printers

These are high-end units that stand out from the background of others with increased stability of operation, excellent performance, as well as a large area, speed and clarity of 3D printing of elements up to several microns in size. On such printers, it is possible to create both single projects and models of various shapes and dimensions.

Exclusively this type of 3D device allows you to print with metal consumables - metal powders. With the help of such metal powder devices, it is possible to reproduce the most complex shapes and textures that cannot be achieved by casting and other classical methods.

Kongten MBrush

votes 0

This industrial style model stands out from the competition with a modern look that makes it portable and ergonomic. This printer is highly configurable and can also sync with the user's mobile device so all printing activities can be controlled with a single button.

The average price is 13,000 rubles.

- suitable for printing on paper;

- makes high-quality prints on cardboard;

- able to apply color drawings on wooden surfaces;

- prints excellently on plastic;

- syncs with mobile devices.

- not detected.

3D Systems sPro 60 HD-HS

votes 0

A distinctive feature of the devices of this line is their block architecture, which allows increasing the functionality of the device by integrating special systems and packages.The last two include, for example, the ProScan GX digital scanning system, the TruTemp temperature system and other technologies, the use of which makes it possible to improve the performance parameters of the standard version of the device by more than 2 times, as well as to minimize the technical differences between the created models.

This industrial 3D printer allows you to create reliable and highly accurate plastic models from an extensive list of compatible consumables. The system of this device allows you to upgrade the sPro to an ultra-fast production system to maximize productivity parameters.

Like the rest of the latest generation of 3D printers in this series, this system offers high-speed formation of elements, the availability of consumables, as well as best-in-class design clarity.

Based on 3D Systems patented highly reliable and tested SLS printing technology, the sPro series of modern industrial devices produces durable and reliable plastic models that can be up to 457mm long.

Average price - not specified by the manufacturer.

- multifunctionality;

- high quality output samples;

- fast and easy change of materials;

- an extensive range of different consumables compatible with SLS printing technology;

- The integrated ProScan system guarantees the high quality of mirror-surface models.

- lack of price information.

TRONXY X5SA 330 PRO DIY

votes 0

This printer is an upgraded version of the X5SA-330.The main difference between the models is only in the presence of an automatic level sensor, which facilitates the calibration process of the device before printing. Among other differences, it is worth highlighting that the ordinary screen was replaced with a touch screen - more understandable and practical.

In the version we are considering, we changed the guides and the PSU with wiring to better ones. The body of the device is made of aluminum profile, which gives it better stability. In addition, during operation, this favorably affects the final quality of the model, in particular, in the process of high-speed printing. The diameter of the nozzle that comes with the device is 0.4 mm. The nozzle can be changed. The device also has a heated print pad, which makes it possible to interact with all key consumables.

This instrument is based on Filament Melting Modeling (FDM) technology.

The average price is 35,000 rubles.

- touchscreen;

- alignment is carried out automatically;

- heating sensor;

- robust housing made of aluminum profile;

- the possibility of replacing the nozzle.

- not detected.

The best professional 3D printers

This category includes additive devices that are designed for special use in factories.

Due to the extensive range and exclusive characteristics of consumables (such models work with plastic, photopolymer resins, gypsum, wax, etc.), professional-type devices are suitable for the aviation, automotive, engineering industry, as well as medical, jewelry, scientific and design industries.

Anycubic Photon S

votes 1

Instead of a metal case, this model got a plastic one. This did not affect the technical parameters, except perhaps that the developers managed to reduce the weight of the device. In addition, thanks to this decision, the manufacturer managed to improve the rest of the components of the device without raising the price tag.

The most important modification concerns the vertical guides. Now there are 2 of them, which reduced the risk of wobbles (the formation of "waves" on the vertical sides of the model). The UV illuminator now includes 28 LED elements, up from 4 on its predecessor. Thus, it was possible to increase the total power of the LEDs from 40 to 50 watts.

This allows users to work with a minimum exposure interval of each layer, and therefore the printing process can be done faster. The printed pad is not made with an anodized mirror surface, but matte. It seems to be nonsense, but it greatly reduces the risk of tearing off the model.

The average price is 32,900 rubles.

- the ability to work offline;

- quick preparation of the printer for work;

- advanced ultraviolet block;

- dual guides for the Z axis;

- 2K LCD backlight display.

- not detected.

Wanhao Duplicator 8

votes 1

This is Wanhao's most desired photopolymer model, which stands out from the competition with the most favorable price-quality ratio. The principle of operation of the printer is based on LCD technology with an LCD display that is responsible for backlighting.

If we talk about the technical parameters, then this device is similar to the D7, but there are a number of significant differences.First of all, the difference between the devices lies in the working area, which in the model we are considering is much larger and is 192x120x180 mm.

The ease of installation of the print bath makes cleaning or changing the film quick and easy. All you have to do is position the bath above the display and fix it with locking nuts.

There is also a large touchscreen display for real-time adjustment of print characteristics. Reproducible information includes print times, temperature status, number of layers, part preview, resin level, calibration sensor, USB and Wi-Fi indication.

The model does not have a camera.

The average price is 91,900 rubles.

- ease of installation of the printing bath;

- large touch screen;

- high calibration speed;

- a small translucent window with a measuring scale is provided on the printing platform, which is located on the side and makes it possible to monitor the amount of resin.

- not detected.

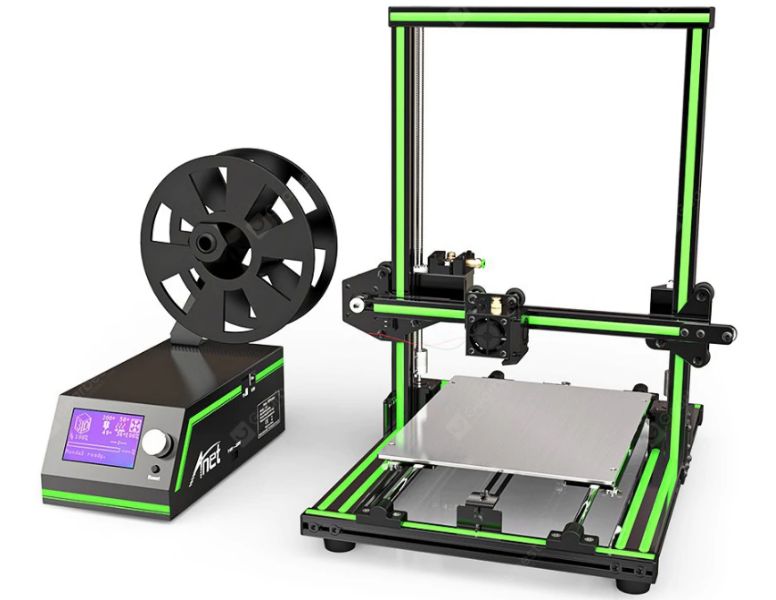

Anet E10

votes 1

This is one of the first models to have a large print space. Due to the fact that the device does not have an extruder made of solid sheet metal, the operating temperature level does not rise above 240 degrees Celsius. The upper layers are cooled by blowing. The bar is fed according to the scheme with separate fastening of the pulling mechanism and the head.

The model is available in 2 colors:

- Black and green.

- Black and orange.

A laconic metal frame combined with bright colors will appeal to many users. Electronic components are placed in a separate system module, which reduced the load on the frame of the device.

This model is sold as a kit, which must be assembled by hand.

The average price is 24,900 rubles.

- excellent print options;

- clear control by means of the touch LCD screen;

- the ability to connect to a personal computer via a USB-B port;

- micro SD flash drive included;

- compatible with all basic varieties of plastic consumables, as well as HIPS.

- not detected.

Conclusion

What to look for when buying a 3D printer? First of all, of course, you need to ask yourself the question: for what needs this technique is required. If for the home, then inexpensive models are suitable, and if for business, then you should pay attention to professional or semi-professional equipment. Over time, the cost of buying will definitely justify itself. In any case, the fantastic 3D printing technology can saturate your life with new vivid emotions.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131653 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127693 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124520 -

The best men's sneakers in 2025

Views: 124036 -

The Best Complex Vitamins in 2025

Views: 121941 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114981 -

The best paint for gray hair - top rating 2025

Views: 113397 -

Ranking of the best wood paints for interior work in 2025

Views: 110320 -

Rating of the best spinning reels in 2025

Views: 105331 -

Ranking of the best sex dolls for men for 2025

Views: 104369 -

Ranking of the best action cameras from China in 2025

Views: 102217 -

The most effective calcium preparations for adults and children in 2025

Views: 102012